Professional Documents

Culture Documents

Nozzle

Nozzle

Uploaded by

haryfadlyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nozzle

Nozzle

Uploaded by

haryfadlyCopyright:

Available Formats

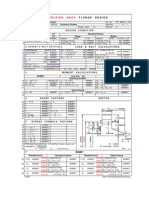

Prepared by: Baher EL Shaikh

Page ( 6 / 41 )

ASME Code VIII Div. I Edition 2004, Addenda 2005

Nozzle (N1)

Pressure Vessel Calculation

(8")

Sheet (1/2)

Head Data

SA-516 Gr 70 M

138000

1.00

mm

14

2.362

914.5

4.000

20,000

in

0.551

0.093

36.0

0.157

:- Shell material.

:- (Sv), Max. allowable stress -(Kpa, (psi))

:- (E1), efficiency of shell at nozzle.

:- (tv), wall thick, uncorroded

:- (tr), required wall thickness

:- (Rsi), inside radius of shell

:- (c), corrosion allowance

Nozzle Data:

SA-106 Gr. B M

1.00

1.00

12.5%

88.9

3.500

Kpa

psig

118000.00

118000

00

358.73

17,100

1 100

51.0

:- Nozzle material.

:- (E) Nozzle Efficiency.

:- (F) Correction factor.

:- (Utp), undertolerance of nozzle pipe.

:- (Do), Outside diameter - (mm, (in))

(S ) M

ll

bl stress

t

:- (Sn),

Max. allowable

: (P), (P=Pi+Ps) Internal Pressure

Nozzle Required Wall Thickness (trn) UG-27 (C)& Appendex 1-1

trn = P*(Do/2)/(Sn*E+0.4*P)

By adding corrosion all. (AC)= trn+2*c

By adding pipe tolerance = AC+UTP*trn

=51*(3.5/2)/(17100*1+0.4*51)=

=0.005+(2*0.157) =

=0.163+0.125*0.005 =

Use Nozzle 8" Sch120 B36.10M (tn)

Variables:

Under tolerance(UT) =

Nozzle corroded thickness (tc)

=

Nozzle Inside corroded Diameter (d) =

Nozzle corroded inside raduis (Ron) =

Nozzle uncorroded inside raduis (Rn) =

Vessle corroded thk.(t) =

tn*UTp = 0.719 * 0.125

tn-c-UT = 0.719-0.157-0.09

Do-2*tc

Do/2

d/2

tv-c

= 3.5 - 2*0.472

= 2.557/2

= 2.56/2

= 0.551 - 0.157

UT =

tc =

0.005

0.163

0.163

0.719

in

in

in

in

0.13

4.13

4.15

18.26

mm

mm

mm

mm

0.090

0.472

in

in

2.28

11.98

64.94

44.45

32.47

10.00

10.26

mm

mm

d = 2.557

Ron =

1.75

Rn = 1.28

t=

0.394

Nominal thk. of internal projection of nozzle wall (ti) =tn-2c

=0.719-(2*0.157) =

ti=

0.404

Extension of nozzle beyond the inside surface of the vessel wall (h) = min. of {(2.5*tv),(2.5*ti)

h = Min.{(2.5*0.551),(2.5*0.404)=

h=

1.010

fr1 = MIN(Sn/Sv,1)

= MIN(17100/20000, 1)

fr1 = 0.855

fr2 = MIN(Sn/Sv,1)

= MIN(17100/20000, 1)

fr2 = 0.855

MIN(Sn/Sv,Sp/Sv,1)

fr3 =

= MIN(17100/20000, 0/20000,1)

fr3 = 0.000

fr4 = MIN(Sp/Sv,1)

= MIN(0/20000,1)

fr4 = 0.000

in

in

in

in

in

in

mm

mm

mm

mm

mm

ASME Code VIII Div. I Edition 2004, Addenda 2005

Page ( 7 / 41 )

Pressure Vessel Calculation

Sheet (2/2)

Nozzle (N1) (8")

Nozzle Neck Thickness (UG-45):

Wall thickness per UG-45(a) tr1=trn+c

Wall thickness per UG-45(b) tr2=tr+c

Wall thickness per UG-16(b) tr3=0.0625+c

Wall thickness per UG-45(b)(4) tr4=(t std -Utp)+c

The greater of tr2 or tr3 tr5 =

The lesser of tr4 or tr5 tr6 =

Required per UG-45 largest of tr1 or tr6 tr7=

tr7 tn-Utp*tn

=0.005+0.157 =

=0.093+0.157 =

=0.0625+0.157 =

=0.189+0.157 =

=Max(0.25,0.22) =

=Min(0.346,0.25) =

=Max(0.163,0.25) =

=0.250.719-0.09

0.163

0.250

0.220

0.346

0.250

0.250

0.250

in

in

in

in

in

in

in

4.13

6.36

5.59

8.80

6.36

6.36

6.36

mm

mm

mm

mm

mm

mm

mm

0.750 in

19.05

mm

0.551 in

14.00

mm

Ok

Calulating Size of Fillet Weld (Leg41,Leg42) used UW-16&Fig. UW-16:

tmin1= from UW-16(b)

Between Nozzle and Shell

tmin= Min(tv,tn,tmin1) =MIN(0.551,0.719,0.75)

Calulation of (tc) UW

UW-16(b)

16(b)

tc1

=0.7*0.551 =

tc2= 0.7*tmin

=Mim.(0.25,0.386)

tc= Min.(tc1,tc2)

By considering equal fillet weld

=2^1/2*0.25

Leg of outward nozzle weld = 21/2*tc

use Leg41 = Leg43

0.250 in

0.386 in

0.250 in

6.35

9.80

6.35

mm

0.354 in

0.472 in

8.98

12.00

mm

Between Reinforcing and Shell

tmin= Min(tv,te,tmin1) =MIN(0.551,0,0.75)

=2^1/2*0/2

Leg of outward nozzle weld = 21/2*tmin/2

Use Leg42 =

0.000 in

0.000 in

0.000 in

0.00

0.00

0.00

mm

mm

mm

mm

mm

mm

MDMT for the nozzle :1- For W.N. flange B16.5

MDMT W/O impact test {UCS-66(C)}

2- For nozzle pipe SA-106 Gr. B, curve B

Min temp. at nominal thk. W/O impact test (UCS-66)

Nominal thk. of nozzle (tn)

Required thk. of nozzle wall (trn)

Ratno = trn * E / ( tn - c )

Reduction in MDMT = (1 - ratio)*100 OF (Fig. UCS-66.1)

MDMT at required thk. W/O impact test (UCS-66.1)

MDMT for the nozzle (assembly)

-20

O

13

F

0.719 in

0.005 in

0.01

<

-99.07 O F

-86.07 O F

-20

-29

O

C

-11

18.263 mm

0.13 mm

0.35

O

-72.74 C

O

-65.53 C

-29

You might also like

- UHX CalcsDocument5 pagesUHX CalcsJ.SIVIRA100% (2)

- WRC 297Document9 pagesWRC 297akisdassas100% (1)

- Flange CalculationsDocument3 pagesFlange CalculationssanjaysyNo ratings yet

- Pd5500 Flange CalculationDocument6 pagesPd5500 Flange CalculationMakrand SakpalNo ratings yet

- Body Flange Design-Appx-2Document4 pagesBody Flange Design-Appx-2Matthieu100% (1)

- Heat ExchangerDocument420 pagesHeat ExchangerRavindra S. Jivani75% (4)

- 26 Pressure Vessel.Document21 pages26 Pressure Vessel.mishtinil93% (14)

- Pressure Vessel Design Calc - ASME VIII Div 1Document22 pagesPressure Vessel Design Calc - ASME VIII Div 1aauppalNo ratings yet

- Sif B31.3Document10 pagesSif B31.3Rob Gillespie100% (1)

- Weldstrength Calc ProgDocument10 pagesWeldstrength Calc ProgSajal KulshresthaNo ratings yet

- Using The ASME VIII-1 Nozzle F Factor (UG-37)Document7 pagesUsing The ASME VIII-1 Nozzle F Factor (UG-37)Ricardo Paz SoldanNo ratings yet

- ISO and EIGA Standards For Cryogenic Vessels and AccessoriesDocument36 pagesISO and EIGA Standards For Cryogenic Vessels and AccessoriesBaher Elsheikh100% (1)

- Mbr300 Man Ing Rv04Document42 pagesMbr300 Man Ing Rv04Bhavin Doshi100% (1)

- Pathology Question PapersDocument26 pagesPathology Question PapersShane Rodriguez100% (2)

- Section VIII CalDocument21 pagesSection VIII CalRuben Samoel Barros RochaNo ratings yet

- Section VIII CalDocument19 pagesSection VIII CalPradeep Kothapalli100% (1)

- Asme Viii CalcsDocument20 pagesAsme Viii CalcsSriram VjNo ratings yet

- 302 - Nozzle Design Tool Ver E4.01Document2 pages302 - Nozzle Design Tool Ver E4.01Honey TiwariNo ratings yet

- Nozzle Neck CalculationDocument4 pagesNozzle Neck CalculationAkshat JainNo ratings yet

- Design of Flanges - Full-Face Gasket 2010Document29 pagesDesign of Flanges - Full-Face Gasket 2010bakelly100% (2)

- Heat Exchanger DesignDocument7 pagesHeat Exchanger Designsiva sankarNo ratings yet

- Expansion Loop Flexibility Analysis (Weaver)Document3 pagesExpansion Loop Flexibility Analysis (Weaver)bakelly100% (1)

- Storage Vessel DesignDocument4 pagesStorage Vessel DesignArpit ThumarNo ratings yet

- Leg CalculationDocument21 pagesLeg CalculationBahtiar Anak LaNangNo ratings yet

- Nozzle Reinf Calc (Rough)Document12 pagesNozzle Reinf Calc (Rough)Sajal Kulshrestha100% (1)

- Pressure Vessel Design CalculationsDocument2 pagesPressure Vessel Design CalculationsMohan VarkeyNo ratings yet

- Flange CalculationsDocument5 pagesFlange CalculationsswapnavattemNo ratings yet

- ASME B31.3 - 2008 PipeCalculationDocument6 pagesASME B31.3 - 2008 PipeCalculationArt G. Enzi100% (8)

- Flange From Plate - Asme 16.5Document1 pageFlange From Plate - Asme 16.5Rey Fiedacan100% (1)

- Design of Pressure Vessel (Int & Ext)Document394 pagesDesign of Pressure Vessel (Int & Ext)api-3824026100% (8)

- Pressure Vessel Design (Faiz Zelin)Document1 pagePressure Vessel Design (Faiz Zelin)moonstar_dme100% (3)

- Mechanical Design Calculations of Pressure Vessel - SampleDocument27 pagesMechanical Design Calculations of Pressure Vessel - SampleSakthi Vel100% (1)

- DummyDocument1 pageDummythopa_nath100% (2)

- New - Reinforcement of NozzleDocument31 pagesNew - Reinforcement of NozzleNithin ZsNo ratings yet

- Reinf S1Document2 pagesReinf S1tasingenieriaNo ratings yet

- Nozzle Load T1011 12Document12 pagesNozzle Load T1011 12koyahassanNo ratings yet

- Calcu Nozzle NeckDocument15 pagesCalcu Nozzle Necksachmaya0% (1)

- WRC CalculationsDocument20 pagesWRC Calculationsanu radha50% (2)

- Reinforcement Calculations For Nozzle (N1) : OD ID Thick NessDocument15 pagesReinforcement Calculations For Nozzle (N1) : OD ID Thick NessMuhammad Hassan MaqsoodNo ratings yet

- Sudyrah, Station Design Calculation of Existing Steel Tank Inlet Connection N-1 Doc. No.96-QC20-J-414Document7 pagesSudyrah, Station Design Calculation of Existing Steel Tank Inlet Connection N-1 Doc. No.96-QC20-J-414Hgagselim SelimNo ratings yet

- Design Calculation Sheet: H2So4 Neutralization TankDocument43 pagesDesign Calculation Sheet: H2So4 Neutralization TankEkki Petrus BubunNo ratings yet

- Reinforcement of Openings On Tori-Dish (Trial)Document23 pagesReinforcement of Openings On Tori-Dish (Trial)Sajal KulshresthaNo ratings yet

- Studding Outlet Calculation - PV Elite 2016Document8 pagesStudding Outlet Calculation - PV Elite 2016Liu YangtzeNo ratings yet

- 93 Qc20 J 414 Inlet NozzleDocument6 pages93 Qc20 J 414 Inlet NozzleHgagselim SelimNo ratings yet

- Pvelite PruebaDocument6 pagesPvelite PruebaLuis Cordova RamonNo ratings yet

- WRC 297Document9 pagesWRC 297akisdassasNo ratings yet

- 03 CalDocument56 pages03 Calnatarajan RavisankarNo ratings yet

- Nozzle and ReinforcementDocument23 pagesNozzle and ReinforcementAzharyanto Fadhli100% (1)

- Samb Expand End PlateDocument5 pagesSamb Expand End PlateArbiNo ratings yet

- Asme Viii Shell & Se HeadDocument5 pagesAsme Viii Shell & Se HeadSnr George RaczNo ratings yet

- Clean Water Tank - Id - 7200x10900 HDocument208 pagesClean Water Tank - Id - 7200x10900 HWilly SastraleksanaNo ratings yet

- Larsen & Toubro Limited: 1. Sectional PropertiesDocument8 pagesLarsen & Toubro Limited: 1. Sectional Propertiesprajjwal patidarNo ratings yet

- UG-37 F FactorDocument7 pagesUG-37 F FactorjamesNo ratings yet

- Asme Seccion Viii Div. 1 Ed 2015 Calculos MecanicoDocument72 pagesAsme Seccion Viii Div. 1 Ed 2015 Calculos MecanicoSivateja NallamothuNo ratings yet

- Shell Inputs: Use Asme Code Section-8 Division I (Ug-37)Document34 pagesShell Inputs: Use Asme Code Section-8 Division I (Ug-37)Bashu PoudelNo ratings yet

- New - Reinforcement of NozzleDocument31 pagesNew - Reinforcement of NozzleChagar HarshpalNo ratings yet

- Using The ASME VIII-1 Nozzle F Factor (UG-37)Document7 pagesUsing The ASME VIII-1 Nozzle F Factor (UG-37)stalin_83No ratings yet

- 05 CalDocument53 pages05 Calnatarajan RavisankarNo ratings yet

- SA 516M GR 485: If Actual Thickness of Head After Forming 9 MMDocument2 pagesSA 516M GR 485: If Actual Thickness of Head After Forming 9 MMMehta MehulNo ratings yet

- Buffer Tank DesignDocument1 pageBuffer Tank DesignSuresh Damu BhadNo ratings yet

- Shell CalculationsDocument3 pagesShell CalculationsBaher Elsheikh100% (7)

- Trunnion AnalysisDocument45 pagesTrunnion AnalysisChiragJansariNo ratings yet

- Beam To Column'S Flange Fixed Connection - Bcff-3: Design DataDocument6 pagesBeam To Column'S Flange Fixed Connection - Bcff-3: Design DataAchmad RifaiNo ratings yet

- Heat Exchangers Part 6 - Common Tube DefectsDocument13 pagesHeat Exchangers Part 6 - Common Tube DefectsBaher ElsheikhNo ratings yet

- Heat Exchangers Course Baher Part04Document32 pagesHeat Exchangers Course Baher Part04Baher ElsheikhNo ratings yet

- Heat Exchangers Course Baher Part03Document18 pagesHeat Exchangers Course Baher Part03Baher ElsheikhNo ratings yet

- Heat Exchangers Course Baher Part02Document21 pagesHeat Exchangers Course Baher Part02Baher ElsheikhNo ratings yet

- Heat Exchangers Course - Baher - Part 01Document24 pagesHeat Exchangers Course - Baher - Part 01Baher ElsheikhNo ratings yet

- Codes and Standards: Petroleum Engineering Technology (Pet) Department Polytechnic Abu Dhabi (Adpoly)Document37 pagesCodes and Standards: Petroleum Engineering Technology (Pet) Department Polytechnic Abu Dhabi (Adpoly)Baher Elsheikh100% (2)

- 5.david - .Spencer - Air Cooled HE TTSDocument6 pages5.david - .Spencer - Air Cooled HE TTSBaher ElsheikhNo ratings yet

- Utility Boiler Condition AssessmentDocument12 pagesUtility Boiler Condition AssessmentBaher ElsheikhNo ratings yet

- Static Equipment Awarness Session - 02Document156 pagesStatic Equipment Awarness Session - 02Baher Elsheikh100% (2)

- Repair of Tube-Tubesheet Weld Cracks in A Cracked Gas/Steam Heat ExchangerDocument7 pagesRepair of Tube-Tubesheet Weld Cracks in A Cracked Gas/Steam Heat ExchangerBaher ElsheikhNo ratings yet

- 5 Shell-And-tube Heat Exchanger - EckrichDocument22 pages5 Shell-And-tube Heat Exchanger - EckrichAshley JacksonNo ratings yet

- Static Equipment in Oil and Gas - BaherDocument95 pagesStatic Equipment in Oil and Gas - BaherBaher Elsheikh100% (9)

- Nureg 6007Document122 pagesNureg 6007Baher ElsheikhNo ratings yet

- 4688 Tube To Tube Sheet Weld Scanning ServiceDocument2 pages4688 Tube To Tube Sheet Weld Scanning ServiceBaher ElsheikhNo ratings yet

- Corrosion Behaviour of CIDocument1 pageCorrosion Behaviour of CIBaher ElsheikhNo ratings yet

- SSW - April 2020 - Lowres Pages 42 45 PDFDocument4 pagesSSW - April 2020 - Lowres Pages 42 45 PDFBaher ElsheikhNo ratings yet

- Atrix HD LGDocument28 pagesAtrix HD LGJachal VisionNo ratings yet

- Sampling For Pesticide Residue AnalysisDocument23 pagesSampling For Pesticide Residue AnalysisAle OosaNo ratings yet

- Internation Health AgenciesDocument39 pagesInternation Health AgenciesAnmah100% (1)

- FINAL MINI-PROJECT - (Group Coagulation Tank)Document25 pagesFINAL MINI-PROJECT - (Group Coagulation Tank)khenpin977No ratings yet

- Indictment For Steven Mathew WallenDocument3 pagesIndictment For Steven Mathew WallenAnonymous 6Exo2J1No ratings yet

- Background Report For The National Dialogue On PaintDocument82 pagesBackground Report For The National Dialogue On PaintMSCT TrainingNo ratings yet

- Palm Kernel ProcessingDocument17 pagesPalm Kernel ProcessingTunde Ajayi100% (2)

- Employee Retention Strategies HDFCDocument83 pagesEmployee Retention Strategies HDFCsuryakantshrotriya100% (2)

- Zhengli Company BrochureDocument15 pagesZhengli Company BrochureZoey ZengNo ratings yet

- Statistics For Analytical ChemistryDocument49 pagesStatistics For Analytical ChemistryDragana Srdic100% (2)

- EARTH SCIENCE Week 1 ActivitiesDocument3 pagesEARTH SCIENCE Week 1 ActivitiesKristian AaronNo ratings yet

- Presenter 6 - Puan Nor Hayati Abdul Rahim-PPT PKA 2Document38 pagesPresenter 6 - Puan Nor Hayati Abdul Rahim-PPT PKA 2Samantha SeeNo ratings yet

- Fault Indicator-TonyDocument53 pagesFault Indicator-TonyCesarNo ratings yet

- HSE QuestionnaireDocument5 pagesHSE Questionnairera sa75% (4)

- People v. EchegarayDocument9 pagesPeople v. EchegarayJohn Soap Reznov MacTavishNo ratings yet

- MG FCPS GuidelinesDocument23 pagesMG FCPS GuidelinesWajih FarhanNo ratings yet

- College Packing ListDocument5 pagesCollege Packing ListAdviana KirubalinNo ratings yet

- Faculty Information: ST THDocument2 pagesFaculty Information: ST THjamoonNo ratings yet

- Datasheet of ACS730Document25 pagesDatasheet of ACS730Nguyên NghĩaNo ratings yet

- Module 8Document28 pagesModule 8Rio TomasNo ratings yet

- Process Gases and Distribution Systems in Pharmaceutical ProductionDocument9 pagesProcess Gases and Distribution Systems in Pharmaceutical ProductionHenry BarriosNo ratings yet

- Mobilfluid 426Document2 pagesMobilfluid 426tribolasNo ratings yet

- Biography: Ruined by Her 35m Jackpot: Britain's Biggest Lottery WinnerDocument9 pagesBiography: Ruined by Her 35m Jackpot: Britain's Biggest Lottery WinnerBalbina Alicja PędziwiatrNo ratings yet

- Edi Ion PureDocument3 pagesEdi Ion PurecuongtdbsbNo ratings yet

- StiochiometryDocument36 pagesStiochiometryMUSIC channelNo ratings yet

- Portarlington Parish Newsletter May 16th 2021Document2 pagesPortarlington Parish Newsletter May 16th 2021John HayesNo ratings yet

- Breaking Bad NewsDocument1 pageBreaking Bad NewsUZNAPMNo ratings yet

- CBC 101 Chapter 6Document6 pagesCBC 101 Chapter 6N PARTHASARATHY100% (1)