Professional Documents

Culture Documents

Lifting Lug Material and Stress Check

Uploaded by

veeru2906Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lifting Lug Material and Stress Check

Uploaded by

veeru2906Copyright:

Available Formats

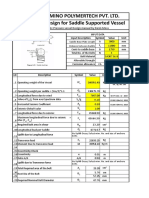

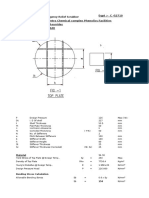

Lifting Lug Check

Lifting lug material Repad material Head material Allowable stress @ room temperature S Yield stress @ room temperature Sy Allowable tensile stress @ room temperature STa =0.5Sy Allowable shear stress @ room temperature Ssa = 0.4Sy Allowable stress of weld @ room temperature Swa Head thickness Repad thickness D S L R LTP HTP Combined lifting coefficient k Lifting weight per lug W Vertical lifting force Fv = kW Lateral lifting force Fh = Fv tg 30 Lifting force F = Fv / cos 30 Bending moment M = FhL Stress in the Lug Tensile stress at the hole plane: ST = F / [(2R-D)S] = 32697.3 / [(2*60 -50) * 16] = 29.19 MPa < 131.0 MPa SA 516 Gr.70 SA 516 Gr.70 SA 516 Gr.70 138.0 MPa 262 MPa 131.0 MPa 104.80 MPa 93 MPa 16 mm 16 mm 50 mm 16 mm 140 mm 60 mm 220 mm 140 mm 1.65 17161.6 28316.7 16348.7 32697.3 2288811.8 N N N N N

Under the most pessimistic situation , shear stress will be equal to the tensile stress, Ss = ST = = 29.19 MPa < 104.80 MPa = 0.501 < 1 ST/STa + Ss/Ssa 29.19/131 + 29.19/104.8

Lug's thickness is sufficient. Stress in the Lug's weld : The Area of weld : tw A Swt Sws Swb = = 9 mm = = = = =

0.5

= 2 (L*tan10 + R) tw Fv / A = Fh / A = 6M / [tw*(2(L*tan10 + R))]

2 (140 * tan10 + 60 ) * 9 18.58 MPa 10.73 MPa 6 *2288811.8/[9*(2*(140*tan10 + 60))] 72.57 MPa

1524 mm

53.19 MPa

(( Swt + Swb ) + Sws )

Weld thickness is sufficient

You might also like

- Standard Pad Eye 10T SWL-modifDocument8 pagesStandard Pad Eye 10T SWL-modifrustamriyadiNo ratings yet

- Lifting LugDocument7 pagesLifting LugSajal KulshresthaNo ratings yet

- JASMINO POLYMERTECH PVT. LTD. Anchor Bolt DesignDocument6 pagesJASMINO POLYMERTECH PVT. LTD. Anchor Bolt DesignPankajDhobleNo ratings yet

- Lifting LugDocument24 pagesLifting LugMas Arman Tewo100% (6)

- Boiler and Pressure Vessel Engineering - Lifting Trunnion Common Practices PDFDocument4 pagesBoiler and Pressure Vessel Engineering - Lifting Trunnion Common Practices PDFAlexandru AsmarandeiNo ratings yet

- Lifting Lug - Skid - 2018.07.16Document4 pagesLifting Lug - Skid - 2018.07.16RaghNo ratings yet

- Lifting Lug Calculation RefDocument2 pagesLifting Lug Calculation Refmarc_albertoNo ratings yet

- Wind Calculation SheetDocument32 pagesWind Calculation SheetaauppalNo ratings yet

- Vessel lifting lug design data and stress analysisDocument3 pagesVessel lifting lug design data and stress analysismiteshpatel191100% (1)

- Trunnion AnalysisDocument45 pagesTrunnion AnalysisChiragJansariNo ratings yet

- Design of lifting lug for 8MT load capacityDocument2 pagesDesign of lifting lug for 8MT load capacityKeyurNo ratings yet

- Base Ring Fillet Size CalculationDocument4 pagesBase Ring Fillet Size Calculationmiteshpatel191No ratings yet

- Lifting Lug CalculationDocument7 pagesLifting Lug CalculationErin JohnsonNo ratings yet

- Lifting Lug Calculation 4april2018Document2 pagesLifting Lug Calculation 4april2018Diosdado Mingi Jr.No ratings yet

- LIFTING LUG DESIGN CALCULATIONDocument12 pagesLIFTING LUG DESIGN CALCULATIONsurefooted1No ratings yet

- Lifting Lug CalculationDocument2 pagesLifting Lug CalculationDaison Paul63% (8)

- Platform Cleat CalculationDocument1 pagePlatform Cleat Calculationmiteshpatel191No ratings yet

- Longitudinal Bending Stress: M1 Allowable Limit RemarkDocument16 pagesLongitudinal Bending Stress: M1 Allowable Limit RemarkSandal JepitNo ratings yet

- Design of Flat Head For HydrotestDocument12 pagesDesign of Flat Head For HydrotestSAGARNo ratings yet

- Lifting Lug CalculationsDocument1 pageLifting Lug CalculationsshazanNo ratings yet

- Lifting Lug Design CalculationsDocument17 pagesLifting Lug Design CalculationsSiva baalan100% (1)

- Saddle design calculationsDocument9 pagesSaddle design calculationsduf fuNo ratings yet

- Sample Section Modulas CalculationDocument18 pagesSample Section Modulas CalculationShamik ChowdhuryNo ratings yet

- Bolt Sizing CalculationDocument64 pagesBolt Sizing Calculationpilar gilangNo ratings yet

- Lifting Lug SampleDocument1 pageLifting Lug Sampleabdul marpaung0% (1)

- Saddle CalcDocument26 pagesSaddle CalcVamsi S100% (2)

- Spreader Beam (Planning)Document28 pagesSpreader Beam (Planning)AKSHAY BHATKARNo ratings yet

- Heat Exchanger Strength Calculation: Shell Side Design Data Tube Side Design DataDocument2 pagesHeat Exchanger Strength Calculation: Shell Side Design Data Tube Side Design DataSteve MoonNo ratings yet

- Lifting Lug Calculation For Small Horizontal VesselDocument2 pagesLifting Lug Calculation For Small Horizontal VesselshaishavNo ratings yet

- Lifting Lug Calculations KodDocument2 pagesLifting Lug Calculations Kodanu radhaNo ratings yet

- Pipe Cap Thickness Calculation for ASME Section VIIIDocument9 pagesPipe Cap Thickness Calculation for ASME Section VIIILcm TnlNo ratings yet

- Design of Flanges - Loose Hub Type 2010Document58 pagesDesign of Flanges - Loose Hub Type 2010bakellyNo ratings yet

- Lifting Lug Design and Stress AnalysisDocument2 pagesLifting Lug Design and Stress AnalysisDarkvader0% (1)

- Lifting Lug Calculation On Dish EndDocument156 pagesLifting Lug Calculation On Dish EndTejas Shah33% (3)

- Calculation of Lifting ForcesDocument9 pagesCalculation of Lifting ForcesprantikduarahNo ratings yet

- Documents - Tips - Pressure Vessel Design Calc Asme VIII Div 1Document35 pagesDocuments - Tips - Pressure Vessel Design Calc Asme VIII Div 1bainNo ratings yet

- Skid Lifitng Lug CalculationsDocument5 pagesSkid Lifitng Lug CalculationsinnovativekarthiNo ratings yet

- Pressure Vessel Lifting Lug CalculationDocument2 pagesPressure Vessel Lifting Lug Calculationtekstep767% (3)

- Saddle Road Transportation Analysis 1Document2 pagesSaddle Road Transportation Analysis 1vpjagannaathNo ratings yet

- 28 Roark Flat PlatesDocument4 pages28 Roark Flat PlatesJorge Silva100% (1)

- The Clamp BoltsDocument2 pagesThe Clamp BoltsНемања Караклајић100% (1)

- Lifting LugDocument39 pagesLifting LugSasikumar JothiNo ratings yet

- Studding Outlet Calculation - PV Elite 2016Document8 pagesStudding Outlet Calculation - PV Elite 2016Liu YangtzeNo ratings yet

- Ccsviiid1 2260Document2 pagesCcsviiid1 2260DieguitoOmarMoralesNo ratings yet

- (B) Schematic Diagram of 2 Nos Lugs With No Tailing Lug: .0 Lifting Lug Design CalculationDocument7 pages(B) Schematic Diagram of 2 Nos Lugs With No Tailing Lug: .0 Lifting Lug Design CalculationArt G. Enzi100% (1)

- Simply Support Beam. Centre LoadDocument7 pagesSimply Support Beam. Centre LoadjhsompuraNo ratings yet

- Rectangular Tubesheet Design Guideline by HEIDocument6 pagesRectangular Tubesheet Design Guideline by HEIm5416No ratings yet

- Braced Legs ClaculationsDocument2 pagesBraced Legs Claculationssumit_waghmareNo ratings yet

- Lifting Lug Calc - VerticalDocument7 pagesLifting Lug Calc - Verticaljahiranazri100% (1)

- Flat Plate - Roark & YoungDocument15 pagesFlat Plate - Roark & YoungPrasad Pingle0% (1)

- LIFTING LUG CALCULATIONDocument2 pagesLIFTING LUG CALCULATIONhuangjlNo ratings yet

- Bolt TorqueDocument3 pagesBolt TorqueHeri KurniawanNo ratings yet

- Asme Viii Calculation Xls PDF FreeDocument28 pagesAsme Viii Calculation Xls PDF FreeMisbachul ChoirNo ratings yet

- Lifting Lug Calculation For Small Horizontal VesselDocument2 pagesLifting Lug Calculation For Small Horizontal VesselshaishavNo ratings yet

- Lifting LugDocument8 pagesLifting LugAzwan ShahNo ratings yet

- 吊耳计算Document4 pages吊耳计算huangjlNo ratings yet

- Skid Lifting Lug DesignDocument3 pagesSkid Lifting Lug Designmahhor82_635643838No ratings yet

- Displacement Control STN 10iDocument2 pagesDisplacement Control STN 10itungNo ratings yet

- Lifting - Lug (Modification)Document11 pagesLifting - Lug (Modification)Sam LowNo ratings yet

- Design Stress and FatigueDocument30 pagesDesign Stress and FatigueAshok DargarNo ratings yet

- Transparent Proxy With Linux and Squid mini-HOWTODocument10 pagesTransparent Proxy With Linux and Squid mini-HOWTONursalim S komNo ratings yet

- Boyles Law and Charles LawDocument23 pagesBoyles Law and Charles LawSharmaine C. TABADANo ratings yet

- Design Codes and StandardsDocument22 pagesDesign Codes and StandardsFederico.IoriNo ratings yet

- I. Organics (Bod, Cod, Toc, O&G) : Understanding Laboratory Wastewater TestsDocument8 pagesI. Organics (Bod, Cod, Toc, O&G) : Understanding Laboratory Wastewater Testsurie666No ratings yet

- PracticeProblems 4315 SolutionsDocument9 pagesPracticeProblems 4315 SolutionsKashifRizwanNo ratings yet

- DP27, DP27E, DP27R and DP27Y Pilot Operated Pressure Reducing ValvesDocument36 pagesDP27, DP27E, DP27R and DP27Y Pilot Operated Pressure Reducing ValvesAntonio FedatoNo ratings yet

- Vector Group Testing at Site - MonographDocument13 pagesVector Group Testing at Site - Monographsamiron roy100% (1)

- WorksheetDocument4 pagesWorksheetMarrin MarquesNo ratings yet

- Metal Casting Full Lecture NotesDocument51 pagesMetal Casting Full Lecture Notesumarnasar_1987105074% (19)

- Coupler REG-K Mounting The Coupler: Areas 1 and 2 With Lines 1.1 and 2.1Document1 pageCoupler REG-K Mounting The Coupler: Areas 1 and 2 With Lines 1.1 and 2.1Carlos HerreraNo ratings yet

- Describe The Structure of Starch and State Which Structural Feature Is Key To The Colour Change in The Iodine Test For StarchDocument9 pagesDescribe The Structure of Starch and State Which Structural Feature Is Key To The Colour Change in The Iodine Test For StarchFelix AlfonsoNo ratings yet

- TURBO-Buick V6 Turbo Intro 780413Document21 pagesTURBO-Buick V6 Turbo Intro 780413T Smi100% (1)

- Electrical & Electronics Engineering Syllabus-Sem III To Sem VIIIDocument64 pagesElectrical & Electronics Engineering Syllabus-Sem III To Sem VIIISaroj Kumar RajakNo ratings yet

- Standards For Pipe LineDocument57 pagesStandards For Pipe Linegopaltry33% (3)

- Lecture Exercise No. 3 Cell Structures and Their Functions Name:Luis Miguel W. Bautista Section:7 Date SubmittedDocument3 pagesLecture Exercise No. 3 Cell Structures and Their Functions Name:Luis Miguel W. Bautista Section:7 Date Submittedessketit ruruNo ratings yet

- Rtts PackerDocument2 pagesRtts Packersaeed65100% (2)

- Chemistry Webquest Introduction to AtomsDocument3 pagesChemistry Webquest Introduction to AtomsMarx GomesNo ratings yet

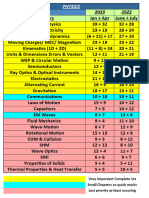

- Priority List JEEDocument3 pagesPriority List JEE6r5x5znb8bNo ratings yet

- IPR100QuickGuide V022 enDocument15 pagesIPR100QuickGuide V022 enKheme VitoumetaNo ratings yet

- FTP Imp RCDocument48 pagesFTP Imp RCKarthik KeyanNo ratings yet

- Simulation of Continuous Physical Refiners For Edible Oil DeacidificationDocument11 pagesSimulation of Continuous Physical Refiners For Edible Oil DeacidificationTeekay CarterNo ratings yet

- CVA DVA Werkstuk Bekele - tcm39 91310Document40 pagesCVA DVA Werkstuk Bekele - tcm39 91310s_75No ratings yet

- Generation of High Voltages & CurrentsDocument79 pagesGeneration of High Voltages & CurrentshamzaNo ratings yet

- Cisco Virtual Update Cisco Sdwan ViptelaDocument55 pagesCisco Virtual Update Cisco Sdwan ViptelaSanjeev MoghaNo ratings yet

- Detecting deception through languageDocument15 pagesDetecting deception through languageSara EldalyNo ratings yet

- Fujitsu LMCE - Technical ManualDocument56 pagesFujitsu LMCE - Technical ManualKornelije KovacNo ratings yet

- AB 14 para Tranzystorow DarlingtonaDocument23 pagesAB 14 para Tranzystorow DarlingtonavengalamahenderNo ratings yet

- 5 Optimising The Speed Potential of Curves - Increase in Permissible Cant Deficiency - FeasibilityDocument12 pages5 Optimising The Speed Potential of Curves - Increase in Permissible Cant Deficiency - FeasibilitydevidattairsmeNo ratings yet

- Electric Towing Tractors: NTT/NTF SeriesDocument5 pagesElectric Towing Tractors: NTT/NTF SeriesВася100% (1)

- BS en Iso 945 Part 3Document52 pagesBS en Iso 945 Part 3vkkt2016No ratings yet

- You Can't Joke About That: Why Everything Is Funny, Nothing Is Sacred, and We're All in This TogetherFrom EverandYou Can't Joke About That: Why Everything Is Funny, Nothing Is Sacred, and We're All in This TogetherNo ratings yet

- Welcome to the United States of Anxiety: Observations from a Reforming NeuroticFrom EverandWelcome to the United States of Anxiety: Observations from a Reforming NeuroticRating: 3.5 out of 5 stars3.5/5 (10)

- Other People's Dirt: A Housecleaner's Curious AdventuresFrom EverandOther People's Dirt: A Housecleaner's Curious AdventuresRating: 3.5 out of 5 stars3.5/5 (104)

- The Asshole Survival Guide: How to Deal with People Who Treat You Like DirtFrom EverandThe Asshole Survival Guide: How to Deal with People Who Treat You Like DirtRating: 4 out of 5 stars4/5 (60)

- The House at Pooh Corner - Winnie-the-Pooh Book #4 - UnabridgedFrom EverandThe House at Pooh Corner - Winnie-the-Pooh Book #4 - UnabridgedRating: 4.5 out of 5 stars4.5/5 (5)

- The Inimitable Jeeves [Classic Tales Edition]From EverandThe Inimitable Jeeves [Classic Tales Edition]Rating: 5 out of 5 stars5/5 (3)

- The Importance of Being Earnest: Classic Tales EditionFrom EverandThe Importance of Being Earnest: Classic Tales EditionRating: 4.5 out of 5 stars4.5/5 (43)

- The Best Joke Book (Period): Hundreds of the Funniest, Silliest, Most Ridiculous Jokes EverFrom EverandThe Best Joke Book (Period): Hundreds of the Funniest, Silliest, Most Ridiculous Jokes EverRating: 3.5 out of 5 stars3.5/5 (4)

- Humorous American Short Stories: Selections from Mark Twain, O. Henry, James Thurber, Kurt Vonnegut, Jr. and moreFrom EverandHumorous American Short Stories: Selections from Mark Twain, O. Henry, James Thurber, Kurt Vonnegut, Jr. and moreNo ratings yet

- Tidy the F*ck Up: The American Art of Organizing Your Sh*tFrom EverandTidy the F*ck Up: The American Art of Organizing Your Sh*tRating: 4.5 out of 5 stars4.5/5 (99)

- Sexual Bloopers: An Outrageous, Uncensored Collection of People's Most Embarrassing X-Rated FumblesFrom EverandSexual Bloopers: An Outrageous, Uncensored Collection of People's Most Embarrassing X-Rated FumblesRating: 3.5 out of 5 stars3.5/5 (7)

- Lessons from Tara: Life Advice from the World's Most Brilliant DogFrom EverandLessons from Tara: Life Advice from the World's Most Brilliant DogRating: 4.5 out of 5 stars4.5/5 (42)

- The Comedians in Cars Getting Coffee BookFrom EverandThe Comedians in Cars Getting Coffee BookRating: 4.5 out of 5 stars4.5/5 (8)

![The Inimitable Jeeves [Classic Tales Edition]](https://imgv2-2-f.scribdassets.com/img/audiobook_square_badge/711420909/198x198/ba98be6b93/1712018618?v=1)