Professional Documents

Culture Documents

Report On Cylinder Compression Check

Uploaded by

afifezzatOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Report On Cylinder Compression Check

Uploaded by

afifezzatCopyright:

Available Formats

Cylinder Compression Check for Continental Engine

Aim To find out the pressure inside the engine by rotating the propeller

Objectives To make sure the engine is serviceable and ready to use To know how the pressure inside the engine affect the efficiency and performance

Engine Specifications Carbureted 6 cylinder, horizontally opposed, aircooled aircraft engines developed for flight a/c.

Tools used Spanner set Deep socket Braker bar Differential pressure gauge Air hose Spark plug rack General & philips screwdriver

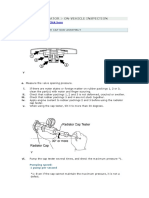

Procedures 1. Remove high tension cable from the spark plug. 2. Remove spark plug top and put it at the spark plug rack according to the cylinder number. 3. Close the spark plug hole by using thumb, and rotate the propeller, until the air inside the cylinder pushes the thumbs, indicating the piston is moving from BDC to TDC. 4. Adjust the propeller until the piston is at TDC, check by using general screwdriver. 5. Connect air hose to the compressed air. Connect the pressure gauge to the air hose. Make sure the restrictoris closed. 6. Connect the gauge to spark plug hole. 7. Allow compressed air to flow, and adjust it to 80 psi. 8. Hold the propeller tightly in place and open the restrictor. 9. Record readings on the pressure gauge.

Result Cylinder 1 2 3 4 5 6 Discussion Lower pressure indicates leaking in that specific cylinder Pressure, psi 66 50 62 50 72 48

Conclusion The pressure inside each cylinder is not reach standard requirement in the aircraft manual so that we can conclude the engine is not in high performance and cannot be used for flight

You might also like

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Operation 1Document9 pagesOperation 1Wbamlak AshebrNo ratings yet

- (D) Viewing Procedure of Piston Assembly: Cleaning BasketDocument7 pages(D) Viewing Procedure of Piston Assembly: Cleaning BasketesakkimuthuNo ratings yet

- ICE Lab ReportDocument34 pagesICE Lab ReportUmair Ali RajputNo ratings yet

- Engine DiagnosticDocument9 pagesEngine DiagnosticKuleba iddiNo ratings yet

- Air Driven Hydraulic Pumps P820Document14 pagesAir Driven Hydraulic Pumps P820e_qda100% (1)

- Ford CarbDocument27 pagesFord Carbsmcdonald2536100% (1)

- Testing of Engines - 0Document12 pagesTesting of Engines - 0S lenkaNo ratings yet

- GRP - Composite Air Operated Grease Pump5Document3 pagesGRP - Composite Air Operated Grease Pump5rquinchia1No ratings yet

- Cocu 3 (Lite) Intro g452 JB1Document21 pagesCocu 3 (Lite) Intro g452 JB1sreetharanNo ratings yet

- Engine Test EquipmentDocument63 pagesEngine Test Equipmentalipotjoshua2003No ratings yet

- Fridge Shop CERA (Workshop Practice Refrigeration& Air Condition)Document48 pagesFridge Shop CERA (Workshop Practice Refrigeration& Air Condition)Md ZakariaNo ratings yet

- Roots Blower Operating ManualDocument15 pagesRoots Blower Operating Manualanup_nairNo ratings yet

- Overhauling Air Compressor On ShipsDocument12 pagesOverhauling Air Compressor On ShipsTun Lin Naing100% (3)

- CAV Pintaux Injection Nozzle RebuildDocument6 pagesCAV Pintaux Injection Nozzle RebuildDanny DanNo ratings yet

- TM 5-3805-254-14P-2 Part 6 Ihc F-5070Document116 pagesTM 5-3805-254-14P-2 Part 6 Ihc F-5070AdvocateNo ratings yet

- Technical Note: 1.0 Maintenance ScheduleDocument6 pagesTechnical Note: 1.0 Maintenance ScheduleJhan Carlos RamosNo ratings yet

- Operating Instructions & Service Manual Blue Max Ii Hydrostatic Test PumpDocument10 pagesOperating Instructions & Service Manual Blue Max Ii Hydrostatic Test PumpdocrafiNo ratings yet

- Mep March 2023Document17 pagesMep March 2023Subham SamantarayNo ratings yet

- Maintenance and Repair of Fuel Suppply, Lubrication and Cooling System Fuel Pump TestingDocument12 pagesMaintenance and Repair of Fuel Suppply, Lubrication and Cooling System Fuel Pump TestingAdarsh AnilNo ratings yet

- Activity 5. Assuming That You Are About To Perform Leak Test in Your Car. Make Your Own Procedures inDocument2 pagesActivity 5. Assuming That You Are About To Perform Leak Test in Your Car. Make Your Own Procedures inkhathleneNo ratings yet

- Air Compressor and Starting Air SystemDocument15 pagesAir Compressor and Starting Air SystemAlimul Raji AshiqueNo ratings yet

- Gravely Convertible 76 Service Manual 1174Document30 pagesGravely Convertible 76 Service Manual 1174ducatiss900100% (1)

- 07 1963 CH-Engine Tune-UpDocument3 pages07 1963 CH-Engine Tune-UpJose LaproviteraNo ratings yet

- Aeaf Lab ManualDocument40 pagesAeaf Lab ManualvairamNo ratings yet

- Series 60 - Section 6.3 Intake ManifoldDocument7 pagesSeries 60 - Section 6.3 Intake ManifoldJuan RiveraNo ratings yet

- Diesel Engine Performance TestDocument69 pagesDiesel Engine Performance TestWarriorNo ratings yet

- EOOW - Orals Questions & AnswersDocument54 pagesEOOW - Orals Questions & Answersnkosithandile Vuke100% (1)

- R05323-M-079-X009-233 - Manual Blower D600-31Document12 pagesR05323-M-079-X009-233 - Manual Blower D600-31Walter Efrain Armas SeguraNo ratings yet

- 2009 Pontiac G6: 2009 ENGINE Engine Mechanical - 3.5L - G6Document30 pages2009 Pontiac G6: 2009 ENGINE Engine Mechanical - 3.5L - G6Mick Drake WSNo ratings yet

- FAN Presentation 06.04.11Document52 pagesFAN Presentation 06.04.11Senthil KumarNo ratings yet

- Unit Ii Inspection of Piston EngineDocument45 pagesUnit Ii Inspection of Piston Engineraj6062No ratings yet

- Small Engine Reassembly: A Visual GuideDocument40 pagesSmall Engine Reassembly: A Visual GuideArjun GuptaNo ratings yet

- Engine Systems InspectionDocument29 pagesEngine Systems InspectionGetachew Tikue100% (1)

- TACH DWELL Tester InstructionsDocument7 pagesTACH DWELL Tester InstructionsJohn Haycox75% (4)

- Basic Mechanical Engineering Lab ManualDocument71 pagesBasic Mechanical Engineering Lab ManualseenuNo ratings yet

- Engine Tune-Up: Ii. Tools and MaterialsDocument6 pagesEngine Tune-Up: Ii. Tools and MaterialsdrakuleeNo ratings yet

- Section 11 - Special EquipmentDocument11 pagesSection 11 - Special EquipmentRamonNo ratings yet

- Manual de Toyota 2nz..Document50 pagesManual de Toyota 2nz..francisco iman sosaNo ratings yet

- Basic Preventive Maintenance Check List For ReciprocatingDocument4 pagesBasic Preventive Maintenance Check List For Reciprocatingsubramanyanvenkat6185100% (1)

- Manufacturer'S Operating Instructions TEST PUMP MODEL DP-Series (3/4/6/8/56-250)Document2 pagesManufacturer'S Operating Instructions TEST PUMP MODEL DP-Series (3/4/6/8/56-250)babjihanumanthuNo ratings yet

- Tune-Up Guide For Geo Metro 1.0 Liter CarsDocument8 pagesTune-Up Guide For Geo Metro 1.0 Liter CarsDerek JewettNo ratings yet

- SC 2Document1 pageSC 2risirarocksNo ratings yet

- Fuel Pump Replacement ManualDocument7 pagesFuel Pump Replacement Manualapi-542121636No ratings yet

- FIND CARBURETOR REPAIR GUIDEDocument20 pagesFIND CARBURETOR REPAIR GUIDEIgree Y. BleaNo ratings yet

- Diesel Engine Maintenance ManualDocument108 pagesDiesel Engine Maintenance ManualSilas F Pimenta100% (10)

- Servicing Diesel Injector NozzlesDocument8 pagesServicing Diesel Injector NozzlesKifu Ye100% (1)

- Udor Maintenance Trouble ShootingDocument4 pagesUdor Maintenance Trouble ShootingMONA100% (1)

- Te Lab Manual Vgec FinalDocument63 pagesTe Lab Manual Vgec Finalarun panduNo ratings yet

- Training ManualDocument135 pagesTraining ManualVinithra Rajesh100% (1)

- Operating and Maintenance Instructions PDFDocument13 pagesOperating and Maintenance Instructions PDFshihabNo ratings yet

- CompressorDocument8 pagesCompressorLOKINo ratings yet

- Holley Carburettors High Performance TuningDocument10 pagesHolley Carburettors High Performance Tuningkoolchangescribd100% (1)

- Oh LolDocument5 pagesOh Lolrhomel hamoyNo ratings yet

- Nordson EFD 736HPA NV Installation Guide PDFDocument4 pagesNordson EFD 736HPA NV Installation Guide PDFFelipePerezNo ratings yet

- Carburetor Tuning: Understanding CarburetionDocument11 pagesCarburetor Tuning: Understanding CarburetionMuhammad Rashid Jaidon ⎝⏠⏝⏠⎠80% (5)

- Install piston governorDocument2 pagesInstall piston governorJose ChuctayaNo ratings yet

- Marvel Carbureter and Heat Control As Used on Series 691 Nash Sixes Booklet SFrom EverandMarvel Carbureter and Heat Control As Used on Series 691 Nash Sixes Booklet SNo ratings yet

- Reciprocating Compressors:: Operation and MaintenanceFrom EverandReciprocating Compressors:: Operation and MaintenanceRating: 4 out of 5 stars4/5 (7)

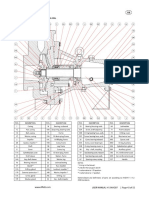

- Sectional DrawingDocument1 pageSectional DrawingafifezzatNo ratings yet

- Torsionally Flexible Couplings for Process Pumps and Industrial ApplicationsDocument4 pagesTorsionally Flexible Couplings for Process Pumps and Industrial ApplicationsafifezzatNo ratings yet

- Thrust Ball Bearings, Single Direction: DimensionsDocument4 pagesThrust Ball Bearings, Single Direction: DimensionsAditya Sangita Kisan SonawaneNo ratings yet

- History - REVISE Jan 2013Document89 pagesHistory - REVISE Jan 2013afifezzatNo ratings yet

- Discussion SkillsDocument12 pagesDiscussion SkillsafifezzatNo ratings yet

- Tutorials:: Stress & Strain - Axial LoadingDocument9 pagesTutorials:: Stress & Strain - Axial LoadingafifezzatNo ratings yet

- Ot CalcDocument2 pagesOt CalcafifezzatNo ratings yet

- Foreword: Installation, Operation & Maintenance InstructionsDocument4 pagesForeword: Installation, Operation & Maintenance InstructionsafifezzatNo ratings yet

- Ultrasonics PhysicsDocument14 pagesUltrasonics PhysicsafifezzatNo ratings yet

- The Essential Job Search ProcessDocument16 pagesThe Essential Job Search ProcessafifezzatNo ratings yet

- Assignment Student ListDocument1 pageAssignment Student ListafifezzatNo ratings yet

- Cara Membuat AltetakDocument3 pagesCara Membuat AltetaksalsanetNo ratings yet

- Assignment - Isometric (Jan 2013)Document5 pagesAssignment - Isometric (Jan 2013)afifezzatNo ratings yet

- Assignment # 1Document7 pagesAssignment # 1afifezzatNo ratings yet

- 727 Fuel SystemDocument2 pages727 Fuel SystemafifezzatNo ratings yet

- 727 Fuel SystemDocument2 pages727 Fuel SystemafifezzatNo ratings yet

- ICAO ScaleDocument1 pageICAO ScaleafifezzatNo ratings yet

- Jojo Lolo MomoDocument648 pagesJojo Lolo MomoafifezzatNo ratings yet

- Introduction-Worldwide Immigrants StatisticsDocument13 pagesIntroduction-Worldwide Immigrants StatisticsafifezzatNo ratings yet

- Easa TCDS E.052Document11 pagesEasa TCDS E.052afifezzatNo ratings yet

- Report On Cylinder Compression CheckDocument2 pagesReport On Cylinder Compression CheckafifezzatNo ratings yet

- GliderfdsfDocument9 pagesGliderfdsfafifezzatNo ratings yet

- The Effect of Illegal Immigrants in Malaysia FINAL DRAFTDocument4 pagesThe Effect of Illegal Immigrants in Malaysia FINAL DRAFTkenttenomNo ratings yet

- Model 250Document49 pagesModel 250robbertmd100% (8)

- How To Write A Letter of MotivationDocument2 pagesHow To Write A Letter of MotivationdianitadiniNo ratings yet

- Optics Optics: Malaysian Institute of Aviation TechnologyDocument39 pagesOptics Optics: Malaysian Institute of Aviation TechnologyafifezzatNo ratings yet

- Boyle's Law ExperimentDocument4 pagesBoyle's Law ExperimentafifezzatNo ratings yet

- How The Secondary Flight Control System Operates?: Wing FlapDocument5 pagesHow The Secondary Flight Control System Operates?: Wing FlapafifezzatNo ratings yet

- What is a Glider? An Introduction to Glider Design and FlightDocument13 pagesWhat is a Glider? An Introduction to Glider Design and FlightafifezzatNo ratings yet

- Module 13-Aircraft Aerodynamics, Structures and SystemsDocument1 pageModule 13-Aircraft Aerodynamics, Structures and SystemsafifezzatNo ratings yet