Professional Documents

Culture Documents

Presentation Code: R1-TS33-PP04: Radiant Tube Partially Shielded

Presentation Code: R1-TS33-PP04: Radiant Tube Partially Shielded

Uploaded by

Caldare IoanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Presentation Code: R1-TS33-PP04: Radiant Tube Partially Shielded

Presentation Code: R1-TS33-PP04: Radiant Tube Partially Shielded

Uploaded by

Caldare IoanCopyright:

Available Formats

Presentation Code: R1-TS33-PP04

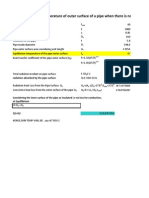

By studying the burning process and heat transfer inside an unshielded radiant tube it is observed that the wall temperature of the tube is not uniform, high at the burner side (707C) and much lower at the burned gases exhaust fan side (231C). The solution, presentRadiant tube ed as a novelty, is using a cover shield around the tube to uniform the wall temperature, obtaining thermal comfort in a radiant tube heated room.

Cover shield

Burner

St=1m2

qgt=(ac+ar)*(Tg-Tt)

Radiant tube Radiation shield

Shielded radiant part

Unshielded radiant part

Te qte=co*10-8 *(Tt4 -Te4) qe0=dt/de*co*10-8*(Te4-T04)

Envirorment

Radiant tube partially shielded

T0 Te

qe = dt/de * qt

Methods

To

qt = Q/(*dt*x) Tt Q = cpg*Dg*(Tgi-Tge) = (c+r)*(Tg-Tt)* /(*dt*x)

Tgi

A new calculus program, named TUBECR was conceived for the heat flux calculus, which calculates the temperatures along the radiant tube wall. The calculus is made both for an unshielded radiant tube and for the tube with 1, 2 and 3 meters long cover shield. Results Mounting the concentric cover on the initial part of the radiant tube creates a radiation shielding effect, diminishing the outside temperature of the radiant tube. The diagrams and the table (Figure 6) illustrate the temperature variation of the radiant tube wall from the burner (shielded part) to the burned gases exhaust fan. Conclusions Radiant tubes with cover shield are a novelty, with great chances of becoming very efficient solutions. The cover works like a thermal shield, reducing the radiant heat flux by half with an absolute temperature equal to the geometric ratio of the tube and environment temperature.

Author: EC.DR.ING . IOAN CALDARE

Tg

Tge

You might also like

- Design of Shell Tube Heat Exchanger by Kern Method 2 57 Excel TemplateDocument2 pagesDesign of Shell Tube Heat Exchanger by Kern Method 2 57 Excel TemplateAbhishek SinglaNo ratings yet

- Skin Temp of Pipe Exposed To SunDocument8 pagesSkin Temp of Pipe Exposed To SunDebasis PalNo ratings yet

- HMT Answer 2 & 16 Marks HMTDocument85 pagesHMT Answer 2 & 16 Marks HMTChandra Sekar100% (3)

- Design Heat Exchanger Shell and Tube TheDocument8 pagesDesign Heat Exchanger Shell and Tube ThezatamaqeelNo ratings yet

- Relief PDFDocument0 pagesRelief PDFscribpenumakaNo ratings yet

- MENG 412 Thermal Science Laboratory Expt. 6: Extended Surface Heat TransferDocument10 pagesMENG 412 Thermal Science Laboratory Expt. 6: Extended Surface Heat TransferFatima Khalid100% (1)

- Design of Heat ExchangerDocument13 pagesDesign of Heat ExchangerTilak AvNo ratings yet

- Heat Loss Optimisation of A Concentric Cylindrical Solar Collector Employing A Cobalt Oxide Selective AbsorberDocument17 pagesHeat Loss Optimisation of A Concentric Cylindrical Solar Collector Employing A Cobalt Oxide Selective AbsorberResearcherzNo ratings yet

- ME 2306 Thermal Engineering Lab - I Lab ManualDocument43 pagesME 2306 Thermal Engineering Lab - I Lab ManualShane HarrisNo ratings yet

- Performance Evaluation and Improvement oDocument10 pagesPerformance Evaluation and Improvement oSivasankar CNo ratings yet

- Assignment 1: Shell and Tube Heat Exchanger Overall Heat Exchanger Value, U ValueDocument27 pagesAssignment 1: Shell and Tube Heat Exchanger Overall Heat Exchanger Value, U ValueAravind NaiduNo ratings yet

- ME1324-Hmt Group 2Document14 pagesME1324-Hmt Group 2Arnab Dutta ChoudhuryNo ratings yet

- A 10 605 1Document9 pagesA 10 605 1matteo2009No ratings yet

- Thermal Lab ReportDocument43 pagesThermal Lab ReportMainakendra Nath MandalNo ratings yet

- Fired Heater DesignDocument35 pagesFired Heater Designzorro21072107100% (6)

- Experimental and Three Dimensional Finite Element Analysis of Thermal History of Oxy-Acetylene Line Heating ProcessDocument6 pagesExperimental and Three Dimensional Finite Element Analysis of Thermal History of Oxy-Acetylene Line Heating Processalvaromviegas_191514No ratings yet

- HJD Institute of Tech Edu & Research Mechanical Engg DeptDocument6 pagesHJD Institute of Tech Edu & Research Mechanical Engg DeptM Hamza NadeemNo ratings yet

- FlatPlate With Evacuated TubesDocument16 pagesFlatPlate With Evacuated TubesMohamed ElsewedyNo ratings yet

- TE Lab 2Document50 pagesTE Lab 2Gopi RaguNo ratings yet

- Design of Shell and Tube Heat ExchangerDocument42 pagesDesign of Shell and Tube Heat Exchanger3004 Divya Dharshini. MNo ratings yet

- Index: S.No Name of The Experiment RemarksDocument9 pagesIndex: S.No Name of The Experiment RemarksArnab Dutta ChoudhuryNo ratings yet

- MM321 Lab N# 4: Bypass Factor of A Heating CoilDocument7 pagesMM321 Lab N# 4: Bypass Factor of A Heating CoilSiddhant Vishal ChandNo ratings yet

- Thermal Simulation of Biogas Plants Using Mat LabDocument5 pagesThermal Simulation of Biogas Plants Using Mat LabShaheen M SainNo ratings yet

- HW 11Document7 pagesHW 11Devendraa MuniandyNo ratings yet

- Thermal Behavior of Polymers PDFDocument9 pagesThermal Behavior of Polymers PDFjraman24No ratings yet

- Design HeatexchangerDocument15 pagesDesign HeatexchangerMayurMahajan100% (1)

- Forced Convection ApparatusDocument3 pagesForced Convection ApparatusAshish VermaNo ratings yet

- Thermal Design of Heat ExchangerDocument9 pagesThermal Design of Heat ExchangerNaqqash SajidNo ratings yet

- Experiment No. 03 Aim: To Determine The Heat Transfer Coefficient in Natural ConvectionDocument6 pagesExperiment No. 03 Aim: To Determine The Heat Transfer Coefficient in Natural Convectionpriya3939No ratings yet

- Vertical Storage Tank Heat Loss Calcs - Rev.1 31.12.2010Document16 pagesVertical Storage Tank Heat Loss Calcs - Rev.1 31.12.2010jnmanivannanNo ratings yet

- Control Scheme Flow Chart: Simulation and TestingDocument1 pageControl Scheme Flow Chart: Simulation and TestingJames StocktonNo ratings yet

- Lab Report Content: ME-341, Heat and Mass Transfer: ExperimentsDocument12 pagesLab Report Content: ME-341, Heat and Mass Transfer: ExperimentsAnonymous R7wV0zbMNo ratings yet

- Natural Convection Heat Transfer From A Vertical CylinderDocument6 pagesNatural Convection Heat Transfer From A Vertical CylinderanbuvrpNo ratings yet

- Heat Transfer in Free Convectio1Document3 pagesHeat Transfer in Free Convectio1Vishnu SubramaniNo ratings yet

- (Paper) Simple Method To Predict Fire Resistance of Composite ColumnsDocument12 pages(Paper) Simple Method To Predict Fire Resistance of Composite ColumnsGregory SimmonNo ratings yet

- Experiment T2-4: Lagging EfficiencyDocument5 pagesExperiment T2-4: Lagging EfficiencyIzzat AzmanNo ratings yet

- Development of Simulation Model For Predicting The Performance of A Hybrid Photovoltaic/Thermal (PV/T) Air Heating System For Regenerating Silica Gel in The Air Conditioning RoomDocument6 pagesDevelopment of Simulation Model For Predicting The Performance of A Hybrid Photovoltaic/Thermal (PV/T) Air Heating System For Regenerating Silica Gel in The Air Conditioning RoomMario Lucio López MéndezNo ratings yet

- Heat Exchanger Part 1 PDFDocument22 pagesHeat Exchanger Part 1 PDFRyu RyloNo ratings yet

- 2marks & 16 Marks HMT PDFDocument85 pages2marks & 16 Marks HMT PDFSrini VasanNo ratings yet

- Forced ConvectionDocument5 pagesForced ConvectionRahul NairNo ratings yet

- Tutorial 3 ThermoDocument27 pagesTutorial 3 ThermoHaiqal AzizNo ratings yet

- Thermal Conductivity ApparatusDocument4 pagesThermal Conductivity ApparatusBalRam DhimanNo ratings yet

- TRIAL ON Vortex TubeDocument7 pagesTRIAL ON Vortex Tubevyankatesh visputeNo ratings yet

- Experimental Study On Multi-Layered Type of Gas-To-Gas Heat Exchanger Using Porous MediaDocument9 pagesExperimental Study On Multi-Layered Type of Gas-To-Gas Heat Exchanger Using Porous Media11751175No ratings yet

- ME3122 Tutorial 1 - Conduction-SolutionsDocument9 pagesME3122 Tutorial 1 - Conduction-SolutionsUnknown uploaderNo ratings yet

- Experiment No. O1Document61 pagesExperiment No. O1Singh Aman100% (1)

- MSC I Sem - BRP - Lect 8Document20 pagesMSC I Sem - BRP - Lect 8Nutan GautamNo ratings yet

- CEMENTDocument4 pagesCEMENTEyael ShimleasNo ratings yet

- Modeling and Simulation of Steam CrackersDocument6 pagesModeling and Simulation of Steam CrackersFathan FathullahNo ratings yet

- Reactor Sizing FinalDocument34 pagesReactor Sizing FinalJobb Six-steps MatheusNo ratings yet

- Cooling Tower ManualDocument4 pagesCooling Tower ManualXclusive StarNo ratings yet

- Measurement of The Thermal Conductivity of Solid Substances by DSCDocument4 pagesMeasurement of The Thermal Conductivity of Solid Substances by DSCSai Li100% (1)

- Furnace Heater DesignDocument7 pagesFurnace Heater DesignSamNo ratings yet

- Handbook of Chemical Engineering Calculations, Third Edition. Nicholas P. ChopeyDocument3 pagesHandbook of Chemical Engineering Calculations, Third Edition. Nicholas P. ChopeyRay RichalmyNo ratings yet

- Worked Problems in Heat, Thermodynamics and Kinetic Theory for Physics Students: The Commonwealth and International Library: Physics DivisionFrom EverandWorked Problems in Heat, Thermodynamics and Kinetic Theory for Physics Students: The Commonwealth and International Library: Physics DivisionRating: 4 out of 5 stars4/5 (3)

- Thermodynamic analysis of geothermal heat pumps for civil air-conditioningFrom EverandThermodynamic analysis of geothermal heat pumps for civil air-conditioningRating: 5 out of 5 stars5/5 (2)