Professional Documents

Culture Documents

Piping Per Process Areas Interconnecting Valves Each: Labor

Uploaded by

sivavalaiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Piping Per Process Areas Interconnecting Valves Each: Labor

Uploaded by

sivavalaiCopyright:

Available Formats

289

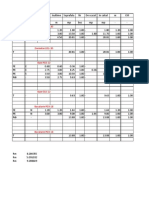

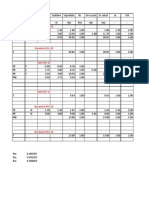

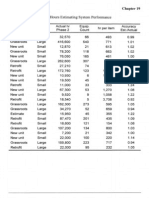

Semi-Detailed Estimating System

Table 19.10 Comprehensive Piping Estimating Units- 304 S S

~~

.-C

hr.i

or,

d

p)

r0

Labor,

E r n

Piping - per foot

Process

areas

Interconnecting

Valves

hr.

Labor,

Marl,$

Fab.

Erect.

Mat'l,

Up to 1

10

10

10

10

10

10

10

10

10

1 112

2

3

4

6

8

10

12

26.50

27.20

30.00

36.80

45.00

70.50

104.00

147.00

182.00

0.92

0.97

1.00

1.10

1.22

1.49

1.73

1.90

1.98

0.30

0.38

0.49

0.59

0.71

0.96

1.31

1.63

1.98

14.50

16.80

22.80

29.30

46.00

70.00

102.00

135.00

- each

Fab.

Erect.

0.14

0.16

0.19

0.22

0.28

0.36

0.43

0.51

Marl,$

0.36

0.47

0.53

0.66

0.89

1.10

1.32

1.57

Fab.

Erect.

97.00

2.0

99.00

2.3

110.00

3.2

152.00

4.1

198.00 5.0

364.00

7.2

640.00

9.4

1,035.00 11.9

1,518.00 15.0

1.5

1.8

2.4

3.1

3.8

4.8

6.8

9.4

11.0

Material:

304 SS Rating: 150 Ib.

Connections Up to 314 S.W. 1 in & over B.W. & L.J. flg.

Service

Process Corrosive hydrocarbons & inorg. solutions.

Labor

Unloading,storing,andbagging.

Layout andfitup.

Shop and field welds and joints.

Valve handling and installation.

Installation of vents, drains, and instrument connections (trims).

Installation of hangers and supports.

Hydrotesting.

Theunithourswerederivedfromthebasicunits

in Table 19.17, which

represents the pondered average of nine different sources, contractors as well

as

published data. They are based on direct hire (reimbursable) work. For work done

through a competitive lump sum contract, the figures must be reduced

by 15%.

You might also like

- British Commercial Computer Digest: Pergamon Computer Data SeriesFrom EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNo ratings yet

- Enhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsFrom EverandEnhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsRating: 5 out of 5 stars5/5 (1)

- 290 Table 19.11 Comprehensive Piping Estimating Units 3 16 SSDocument1 page290 Table 19.11 Comprehensive Piping Estimating Units 3 16 SSsivavalaiNo ratings yet

- Piping Per Foot Process Areas Interconnecting Valves EachDocument1 pagePiping Per Foot Process Areas Interconnecting Valves EachsivavalaiNo ratings yet

- Ujian SOPDocument136 pagesUjian SOPsugendengalNo ratings yet

- Semi-Detailed Estimating System: M LabDocument1 pageSemi-Detailed Estimating System: M LabsivavalaiNo ratings yet

- Comprehensive Piping Insulation Estimating Units: Cold ServiceDocument1 pageComprehensive Piping Insulation Estimating Units: Cold ServicesivavalaiNo ratings yet

- Volume CalculationDocument10 pagesVolume CalculationAdjei BaldanNo ratings yet

- Accumulator Sizing DataDocument6 pagesAccumulator Sizing DataSubham GhantaNo ratings yet

- Perbandingan Grafik Spektrum Dengan Variasi GDocument23 pagesPerbandingan Grafik Spektrum Dengan Variasi GRizki KresnaNo ratings yet

- Gas Absorption Lab ReportDocument12 pagesGas Absorption Lab ReportGracylla RoseNo ratings yet

- Espectro de Respuestas: Sistema AporticadoDocument9 pagesEspectro de Respuestas: Sistema AporticadoEnrique CvsNo ratings yet

- Table A9-4. Discharge of Constant-Head Orifice (CHO) Turnout in FTDocument1 pageTable A9-4. Discharge of Constant-Head Orifice (CHO) Turnout in FToctatheweelNo ratings yet

- Practica DomiciliariaDocument16 pagesPractica DomiciliariaJhon Brandhon Cutti TalaveranoNo ratings yet

- Step 1) Calculate The Pressure Derivative Functions of The Well-Test Data (Tabulated in Table 4.11)Document13 pagesStep 1) Calculate The Pressure Derivative Functions of The Well-Test Data (Tabulated in Table 4.11)jonathan_leal09No ratings yet

- PsychrometricChart (Q 1) NUSDocument1 pagePsychrometricChart (Q 1) NUSZaw Moe KhineNo ratings yet

- Technical Data 37 FlaredDocument13 pagesTechnical Data 37 FlaredhernychtNo ratings yet

- PNW gtr135cDocument64 pagesPNW gtr135cwerqwrq3rqrwNo ratings yet

- C-D Nozzle ExperimentDocument3 pagesC-D Nozzle ExperimentKarthick MurugesanNo ratings yet

- Sprinkler Irrigation Application Rates and DepthsDocument2 pagesSprinkler Irrigation Application Rates and DepthsKhurram SherazNo ratings yet

- Process Dynamics and Control SolutionsDocument15 pagesProcess Dynamics and Control Solutionsciotti620940% (5)

- Lab Pea 1Document4 pagesLab Pea 1HenriqueNo ratings yet

- Design of Drip Irrigation SystemDocument38 pagesDesign of Drip Irrigation SystemNiiteSajo0% (1)

- Design Presentation (Compatibility Mode)Document28 pagesDesign Presentation (Compatibility Mode)Wissam JarmakNo ratings yet

- NTE-030 Espectro de Diseño: 0.4 1 1.2 2.5 (TP/T) 8 980 cm/s2Document3 pagesNTE-030 Espectro de Diseño: 0.4 1 1.2 2.5 (TP/T) 8 980 cm/s2Jhonatan ArelaNo ratings yet

- EVAPOTRANSPIRASI BalqisDocument1 pageEVAPOTRANSPIRASI Balqislinda ritongaaNo ratings yet

- RJ45 Modular Jack With Magnetic Filter: Section 11Document20 pagesRJ45 Modular Jack With Magnetic Filter: Section 11hendpraz88No ratings yet

- The Complete Smith ChartDocument8 pagesThe Complete Smith ChartMohammed AbulmakaremNo ratings yet

- Hydrology Lab WriteupDocument15 pagesHydrology Lab WriteupJohn DunnuckNo ratings yet

- Table A8-10. Free-Flow Discharge Through 6-Inch Parshall MeasuringDocument1 pageTable A8-10. Free-Flow Discharge Through 6-Inch Parshall MeasuringoctatheweelNo ratings yet

- Rve 22Document9 pagesRve 22frevNo ratings yet

- Soil Mechanics Laboratory: (3) : Grain Size Analysis - (Sieve Method+ Hydrometer Method)Document6 pagesSoil Mechanics Laboratory: (3) : Grain Size Analysis - (Sieve Method+ Hydrometer Method)Rana Abdelbaset BostanjiNo ratings yet

- NPSH CalculationDocument14 pagesNPSH CalculationgrabettyNo ratings yet

- SmithDocument1 pageSmithHưng PhạmNo ratings yet

- Thermal Expansion CoeffDocument1 pageThermal Expansion CoeffJoel VinothNo ratings yet

- Smith Chart: E L E NDocument1 pageSmith Chart: E L E NDavid Antonio Millan Orduz100% (1)

- Pipe Schedule and WeightDocument1 pagePipe Schedule and WeightAffendiNo ratings yet

- Fundamentals Wagoner&Chenot ProblemSolutionsDocument169 pagesFundamentals Wagoner&Chenot ProblemSolutionsVishweshRaviShrimali100% (1)

- बोरिङ्ग जडान Proposal करजन्हा न पाDocument10 pagesबोरिङ्ग जडान Proposal करजन्हा न पाyginternationalhospitalNo ratings yet

- F - 155 - Esempio Di Calcolo IdraulicoDocument5 pagesF - 155 - Esempio Di Calcolo Idraulicokikohassan123No ratings yet

- Substrate ConcentrationDocument1 pageSubstrate Concentrationapi-301205420No ratings yet

- HC Calc SPK 1Document4 pagesHC Calc SPK 1Walter Yañez Jr.No ratings yet

- C/ P, C RW: TD 'Ed: Red KT TDDocument12 pagesC/ P, C RW: TD 'Ed: Red KT TDBrenda Rojas CardozoNo ratings yet

- Psychrometirc Chart3Document1 pagePsychrometirc Chart3Kartik DhandNo ratings yet

- PCB3013 HW#5 SolutionDocument5 pagesPCB3013 HW#5 SolutionChai CwsNo ratings yet

- Calibration of WeirDocument15 pagesCalibration of WeirWidi Yuniarto100% (1)

- Expt4 SCILAbDocument11 pagesExpt4 SCILAbRaj VaityNo ratings yet

- Minimum Base Shear Graphs-MaffeiDocument3 pagesMinimum Base Shear Graphs-MaffeiRico PadillaNo ratings yet

- Unit Hydrograph DerivationDocument7 pagesUnit Hydrograph DerivationSudharsananPRSNo ratings yet

- EKSPANSI GAS IDEAL Kelompok 3Document10 pagesEKSPANSI GAS IDEAL Kelompok 3Diyan MeiNo ratings yet

- Determinación Del Grado de MoliendabilidadDocument13 pagesDeterminación Del Grado de Moliendabilidadbone cabero laoNo ratings yet

- Electric Oscillations Lab 4Document14 pagesElectric Oscillations Lab 4Lukas KingmaNo ratings yet

- Assignment 2Document3 pagesAssignment 2tinsaeNo ratings yet

- Experiment 4: Sedimentation: Group No.: 6 Date: 6 September 2011Document13 pagesExperiment 4: Sedimentation: Group No.: 6 Date: 6 September 2011Ankur GargNo ratings yet

- Anchor and Base Plate CalculationDocument6 pagesAnchor and Base Plate Calculationselahattin_erturk06No ratings yet

- Dormitor P01-20: FE PE PDCDocument6 pagesDormitor P01-20: FE PE PDCRaluca RaduNo ratings yet

- Dormitor P01-20: FE PE PDCDocument8 pagesDormitor P01-20: FE PE PDCRaluca RaduNo ratings yet

- Prote SistemasDocument8 pagesProte Sistemasdhaclin Cabrera ValverdeNo ratings yet

- H (M) W U C X (M) : Fellenius MethodDocument2 pagesH (M) W U C X (M) : Fellenius MethodmdalgamouniNo ratings yet

- British Commercial Computer Digest: Pergamon Computer Data SeriesFrom EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNo ratings yet

- Hours: Table 19.25 Engineering Estimating System PerformanceDocument1 pageHours: Table 19.25 Engineering Estimating System PerformancesivavalaiNo ratings yet

- Cost Estimate Summary Case: Estimating 119Document1 pageCost Estimate Summary Case: Estimating 119sivavalaiNo ratings yet

- Project Control: Plant LayoutDocument1 pageProject Control: Plant LayoutsivavalaiNo ratings yet

- Phases The Startup: of An For ofDocument1 pagePhases The Startup: of An For ofsivavalaiNo ratings yet

- Communications 241: 17.2 Documentation ChecklistDocument1 pageCommunications 241: 17.2 Documentation ChecklistsivavalaiNo ratings yet

- 3 - Shakedown Areas.: Construction ManagementDocument1 page3 - Shakedown Areas.: Construction ManagementsivavalaiNo ratings yet

- Speclfic To Project: 2 - Depth and BreadthDocument1 pageSpeclfic To Project: 2 - Depth and BreadthsivavalaiNo ratings yet

- This Page Intentionally Left BlankDocument1 pageThis Page Intentionally Left BlanksivavalaiNo ratings yet

- Project Control Problem Correction: During ConstructionDocument1 pageProject Control Problem Correction: During ConstructionsivavalaiNo ratings yet

- 14.3 Construction Management ActivitiesDocument1 page14.3 Construction Management ActivitiessivavalaiNo ratings yet

- 15.5 Control During Construction: 80% of Bulk Materials Normally SuppliedDocument1 page15.5 Control During Construction: 80% of Bulk Materials Normally SuppliedsivavalaiNo ratings yet

- Agreement: ContractingDocument1 pageAgreement: ContractingsivavalaiNo ratings yet

- All Equipment Should Be Accessible by Either Crane or Lift TruckDocument1 pageAll Equipment Should Be Accessible by Either Crane or Lift TrucksivavalaiNo ratings yet

- Estimating Methods: Engineering EstimatesDocument1 pageEstimating Methods: Engineering EstimatessivavalaiNo ratings yet

- 2 - Drawings.: 3 - SpecificationsDocument1 page2 - Drawings.: 3 - SpecificationssivavalaiNo ratings yet

- Process Design Phaseolphasel: Phase 1 SpecificationsDocument1 pageProcess Design Phaseolphasel: Phase 1 SpecificationssivavalaiNo ratings yet