Professional Documents

Culture Documents

12 - Page 108 PDF

Uploaded by

vik03223Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

12 - Page 108 PDF

Uploaded by

vik03223Copyright:

Available Formats

90

Mechanics of Materials

4 . 8 (A/B). A 120 x 180 x 15 mm uniform I-section steel girder is used as a cantilever beam carrying a uniformly distributed load o kN/m over a span of 2.4 m. Determine the maximum value of w which can be applied before yielding of the outer fibres of the beam cross-section commences. In order to strengthen the girder, steel plates are attached to the outer surfaces of the flanges to double their effective thickness. What width of plate should be added (to the nearest mm) in order to reduce the maximum stress by 30%? The yield stress for the girder material is 320 MN/m2. C3S.S kN/m, 67 mm] 4 . 9 (A/B). A 200 mm wide x 300 mm deep timber beam is reinforced by steel plates 200 mm wide x 12 m m deep on the top and bottom surfaces as shown in Fig. 4.27. If the maximum allowable stresses for the steel and timber are 120 MN/m2and 8 MN/m2 respectively, determine the maximum bending moment which the beam can safely carry. For steel E = 200 GN/mZ;for timber E = 10 GN/m2. CI.Mech.E.1 C103.3 kN m.]

Fig. 4.27.

4 . 1 0 (A/B). A composite beam is of the construction shown in Fig. 4.28. Calculate the allowable u.d.1. that the beam can carry over a simply supported span of 7 m if the stresses are limited to 120 MN/m2 in the steel and 7 MN/mZ in the timber. Modular ratio = 20. [1.13 kN/m.]

All dimensions i n mm

&A

Fig. 4.28.

4 . 1 1 (A/B). Two bars, one of steel, the other of aluminium alloy, are each of 75 mm width and are rigidly joined together to form a rectangular bar 75 mrn wide and of depth (t, + t A ) , where t , = thickness of steel bar and t A = thickness of alloy bar. Determine the ratio oft, to t,, in order that the neutral axis of the compound bar is coincident with the junction of the two bars. (E, = 210 GN/m2; E A = 70 GN/m2.) If such a beam is SO mm deep determine the maximum bending moment the beam can withstand if the maximum [0.577; 1.47 kNm.] stresses in the steel and alloy are limited to 135 MN/m2 and 37 MN/m respectively.

4 . 1 2 (A/B). A brass strip, 50 mm x 12 mm in section, is riveted to a steel strip, 65 mm x 10 mm in section, to form a compound beam of total depth 22 mm, the brass strip being on top and the beam section being symmetrical about

the vertical axis. The beam is simply supported on a span of 1.3 m and carries a load of 2 kN at mid-span.

You might also like

- 12 - Page 109 PDFDocument1 page12 - Page 109 PDFvik03223No ratings yet

- G For The Material Is 82 GN/m2. If The I-Section Is Replaced by A T-Section Made of TheDocument6 pagesG For The Material Is 82 GN/m2. If The I-Section Is Replaced by A T-Section Made of Theክበር ተመስጌንNo ratings yet

- Mechanical ScienceDocument12 pagesMechanical ScienceFernando EyzaguirreNo ratings yet

- StrengthDocument101 pagesStrengthSigue Ramel Hinayas0% (1)

- r09222502 Mechanics of SolidsDocument9 pagesr09222502 Mechanics of SolidsNida Bagoyboy NatichoNo ratings yet

- Strength WorksheetDocument9 pagesStrength WorksheetHabtamu GetaNo ratings yet

- Analysis of Prestress and Bending Stress: Force 170 KNJ.)Document5 pagesAnalysis of Prestress and Bending Stress: Force 170 KNJ.)Kim JunmyeonNo ratings yet

- Question Bank SOM-IIDocument6 pagesQuestion Bank SOM-IISurjit Kumar GandhiNo ratings yet

- HandoutsDocument3 pagesHandoutssheena Marjorie Cabidog100% (1)

- Handouts PDFDocument3 pagesHandouts PDFMayoune GalvezNo ratings yet

- 9A01401 Strength of Materials - IIDocument4 pages9A01401 Strength of Materials - IIsivabharathamurthyNo ratings yet

- Excersise CH 5Document6 pagesExcersise CH 5Ab AnNo ratings yet

- Engineering and The Circular Economy AY2020 - 2021 S3 BSC210 Class Test #1 Attempt All Questions Date: 06/07/21 DURATIONDocument1 pageEngineering and The Circular Economy AY2020 - 2021 S3 BSC210 Class Test #1 Attempt All Questions Date: 06/07/21 DURATIONVado PrinceNo ratings yet

- EMM7241-Advanced Machine Design Examination June 2016Document8 pagesEMM7241-Advanced Machine Design Examination June 2016Charles OndiekiNo ratings yet

- Assignment No 1 MD-1..Document3 pagesAssignment No 1 MD-1..Yadnyesh TaNo ratings yet

- Foundation of Solid Mechanics: C D 50 KNDocument12 pagesFoundation of Solid Mechanics: C D 50 KNLata SharmaNo ratings yet

- Assignment No 2 (SOM-201)Document2 pagesAssignment No 2 (SOM-201)Raushan JhaNo ratings yet

- UTHMDocument8 pagesUTHMJoena LindaNo ratings yet

- Problem Set 2 V2Document3 pagesProblem Set 2 V2RalphNo ratings yet

- DME Assignment 1Document2 pagesDME Assignment 1sumikannuNo ratings yet

- Statically Indeterminate MembersDocument7 pagesStatically Indeterminate MembersKhan ToothNo ratings yet

- Ce6306 16Document3 pagesCe6306 16Arul JONo ratings yet

- Strength of MaterialsDocument18 pagesStrength of MaterialsRuth Abegail de VeraNo ratings yet

- Assignment No. 2 Mechanics of Solids (NME-302)Document2 pagesAssignment No. 2 Mechanics of Solids (NME-302)nitin_johriNo ratings yet

- Instruction: Answer All Question: Assignment 1 Analysis of Prestress and Bending Stress BFS 40303Document4 pagesInstruction: Answer All Question: Assignment 1 Analysis of Prestress and Bending Stress BFS 40303tashadzureenNo ratings yet

- BotlsDocument32 pagesBotlsJohn Lancer FabonNo ratings yet

- TEST No. 1 - Strength of Materials: ReadDocument4 pagesTEST No. 1 - Strength of Materials: ReadJames CENo ratings yet

- Worked Solution To Various QuestionsDocument29 pagesWorked Solution To Various QuestionsJohn MutumaNo ratings yet

- Assignment 5Document3 pagesAssignment 5Rohit KumarNo ratings yet

- Problems in I UnitDocument6 pagesProblems in I UnitjeroldscdNo ratings yet

- Aat 1Document4 pagesAat 1HARNITH EVILLNo ratings yet

- 41346877859Document5 pages41346877859Lelouch BlacknightsNo ratings yet

- Student Stresses in BeamsDocument3 pagesStudent Stresses in Beamsparamarthasom1974No ratings yet

- 9A01302 Strength of Materials - IDocument8 pages9A01302 Strength of Materials - IsivabharathamurthyNo ratings yet

- SM Assignment 1Document1 pageSM Assignment 1vikram eedaNo ratings yet

- Mechanics of Solids PDFDocument8 pagesMechanics of Solids PDFprashanthreddy26No ratings yet

- Lecture 2 - Simple StressDocument21 pagesLecture 2 - Simple StressJhaztin EmmanuelNo ratings yet

- Design of Reinforced Concrete Ribbed Slabs (MAXSpan Slabs)Document2 pagesDesign of Reinforced Concrete Ribbed Slabs (MAXSpan Slabs)ISABIRYE BAKALINo ratings yet

- Model Question PaperDocument10 pagesModel Question PaperM.Saravana Kumar..M.E100% (1)

- Strength of Materials PDFDocument35 pagesStrength of Materials PDFromeo08100% (1)

- 1762009272317design - FRPDocument33 pages1762009272317design - FRPPreetham PjNo ratings yet

- Composite BeamsDocument5 pagesComposite BeamsbertinNo ratings yet

- QbankDocument8 pagesQbanknkchandruNo ratings yet

- CE6306 SOM Important QuestionsDocument4 pagesCE6306 SOM Important QuestionsUTHIRANo ratings yet

- ME-1203 Solid Mechanics-EEE (Solved Problem Slide)Document9 pagesME-1203 Solid Mechanics-EEE (Solved Problem Slide)sadfNo ratings yet

- MOM Assignment 1 1Document1 pageMOM Assignment 1 1tejaslilhore59No ratings yet

- Board Exam Problems-SteelDocument5 pagesBoard Exam Problems-SteelAngela Mae Francisco100% (1)

- Som Part B CDocument16 pagesSom Part B CSrini VasanNo ratings yet

- SOM3601 Assignment 2Document3 pagesSOM3601 Assignment 2Elendu Emmanuel ChigozieNo ratings yet

- Design Examples - Singly-Reinforced RCBDocument5 pagesDesign Examples - Singly-Reinforced RCBchandrasekarNo ratings yet

- Assigment 1Document2 pagesAssigment 1Chris Jay Diong-anNo ratings yet

- Bending Stress and Shearing Stress in Timber BeamDocument98 pagesBending Stress and Shearing Stress in Timber BeamCharizza Montarin CE100% (2)

- Machine Desig1Document1 pageMachine Desig1Francis John S. TanarteNo ratings yet

- Assignment No 1Document2 pagesAssignment No 1Abhishek BordoloiNo ratings yet

- SM Model Exam QuestionDocument5 pagesSM Model Exam QuestionAravind PhoenixNo ratings yet

- Simply Supported BeamDocument14 pagesSimply Supported BeamAslam SaifiNo ratings yet

- Answers To 1 Problem SetDocument7 pagesAnswers To 1 Problem SetJherod LoversonNo ratings yet

- DME AssignmentDocument2 pagesDME Assignmentchirag sanghaniNo ratings yet

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyFrom EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNo ratings yet

- Slope and Defection of Beams: KN 2 0 K N KNDocument1 pageSlope and Defection of Beams: KN 2 0 K N KNvik03223No ratings yet

- 12 - Page 136 PDFDocument1 page12 - Page 136 PDFvik03223No ratings yet

- D 2 y M - EX: Slope and Dejection of BeamsDocument1 pageD 2 y M - EX: Slope and Dejection of Beamsvik03223No ratings yet

- Slope and Dejection Of: X X X Dy DX X Dy DXDocument1 pageSlope and Dejection Of: X X X Dy DX X Dy DXvik03223No ratings yet

- D2y dx2 Dy: Mechanics of MaterialsDocument1 pageD2y dx2 Dy: Mechanics of Materialsvik03223No ratings yet

- 12 - Page 140 PDFDocument1 page12 - Page 140 PDFvik03223No ratings yet

- 116 Mechanics Materials g5.11Document1 page116 Mechanics Materials g5.11vik03223No ratings yet

- Mechanics: 5.8. Principle of SuperpositionDocument1 pageMechanics: 5.8. Principle of Superpositionvik03223No ratings yet

- Slope and Defection of Beams: Fig. 5.24. Maxwell's Theorem of Reciprocal DisplacementsDocument1 pageSlope and Defection of Beams: Fig. 5.24. Maxwell's Theorem of Reciprocal Displacementsvik03223No ratings yet

- 5.7 Slope and Deflection of Beams: (C) Simply Supported Beam With U.D.LDocument1 page5.7 Slope and Deflection of Beams: (C) Simply Supported Beam With U.D.Lvik03223No ratings yet

- 12 - Page 138 PDFDocument1 page12 - Page 138 PDFvik03223No ratings yet

- 12 - Page 137 PDFDocument1 page12 - Page 137 PDFvik03223No ratings yet

- 12 - Page 144Document1 page12 - Page 144vik03223No ratings yet

- Mechanics Materials Solution: X X X X XDocument1 pageMechanics Materials Solution: X X X X Xvik03223No ratings yet

- 12 - Page 119 PDFDocument1 page12 - Page 119 PDFvik03223No ratings yet

- Fig. 4.14. Eccentric Loading of Rectangular Sections-"Middle Third"Document1 pageFig. 4.14. Eccentric Loading of Rectangular Sections-"Middle Third"vik03223No ratings yet

- 12 - Page 123 PDFDocument1 page12 - Page 123 PDFvik03223No ratings yet

- Mechanics of Materials: ProblemsDocument1 pageMechanics of Materials: Problemsvik03223No ratings yet

- Slope Deflection of Beams: (A) Deflection Positive UpwardsDocument1 pageSlope Deflection of Beams: (A) Deflection Positive Upwardsvik03223No ratings yet

- 12 - Page 116 PDFDocument1 page12 - Page 116 PDFvik03223No ratings yet

- 12 - Page 122 PDFDocument1 page12 - Page 122 PDFvik03223No ratings yet

- 5.1 Continuous Beams-Clapeyron's "Three-Moment" Equation: Slope and Deflection BeamsDocument1 page5.1 Continuous Beams-Clapeyron's "Three-Moment" Equation: Slope and Deflection Beamsvik03223No ratings yet

- 12 - Page 96 PDFDocument1 page12 - Page 96 PDFvik03223No ratings yet

- Lo6 Io: Mechanics of MaterialsDocument1 pageLo6 Io: Mechanics of Materialsvik03223No ratings yet

- Slope Deflection of Beams: y (Or Dy DX D 2 y EI dx2 D 3 y EI-dx3 D4y EI - dx4Document1 pageSlope Deflection of Beams: y (Or Dy DX D 2 y EI dx2 D 3 y EI-dx3 D4y EI - dx4vik03223No ratings yet

- 12 - Page 125Document1 page12 - Page 125vik03223No ratings yet

- Mechanics of Materials: or orDocument1 pageMechanics of Materials: or orvik03223No ratings yet

- 5.7. Mohr's "Area-Moment" Method: B.M. DiagramDocument1 page5.7. Mohr's "Area-Moment" Method: B.M. Diagramvik03223No ratings yet

- Sbpe Ot: A Wirh Moment WithDocument1 pageSbpe Ot: A Wirh Moment Withvik03223No ratings yet

- Java RMIDocument11 pagesJava RMIDavid Raju GollapudiNo ratings yet

- The Hotel Accommodations: Lesson 4 Fundamentals of Lodging OperationsDocument40 pagesThe Hotel Accommodations: Lesson 4 Fundamentals of Lodging Operationsraul m partozaNo ratings yet

- Daily Report, Selasa 21 Januari 2020 PDFDocument2 pagesDaily Report, Selasa 21 Januari 2020 PDFAndika AndikaNo ratings yet

- When Can We Move inDocument177 pagesWhen Can We Move inSteven BalacdaoNo ratings yet

- Saroj Bluebells RERA Area StatementDocument10 pagesSaroj Bluebells RERA Area StatementVeena SNo ratings yet

- MPLS Over IP TunnelDocument36 pagesMPLS Over IP TunnelAkhmad Badaruddin SaktiNo ratings yet

- Basic Soil and Water RelationsDocument2 pagesBasic Soil and Water RelationsFelizardo GuiananNo ratings yet

- Nitoproof 120Document2 pagesNitoproof 120Balasubramanian AnanthNo ratings yet

- Accenture Smart Disaster Recovery With Amazon Web Services 092014Document16 pagesAccenture Smart Disaster Recovery With Amazon Web Services 092014Mangaras Yanu FlorestiyantoNo ratings yet

- Pathein Cinema ListDocument3 pagesPathein Cinema ListThi Ha SoeNo ratings yet

- EUROPA 2 - EuroconfortDocument4 pagesEUROPA 2 - EuroconfortPeradNo ratings yet

- PCI MNL-116-99 Structural QC Manual PDFDocument332 pagesPCI MNL-116-99 Structural QC Manual PDFJason Powell100% (1)

- NTRsupport Product OverviewDocument2 pagesNTRsupport Product OverviewNTRglobal-DocumentationNo ratings yet

- Micro Exit Bank Reviewer 1Document82 pagesMicro Exit Bank Reviewer 1JinLi ChenNo ratings yet

- 1 ARKitDocument14 pages1 ARKitclaudius567No ratings yet

- Thesis 3 PDFDocument40 pagesThesis 3 PDFMohamed Abrar SALAMNo ratings yet

- Design of Stair CaseDocument2 pagesDesign of Stair Casepathan is khanNo ratings yet

- 2014 PVI JOURNAL Cement Concrete Composites 2014 Modulus of Elasticity and Tensile Strength of Self Compacting ConcreteDocument9 pages2014 PVI JOURNAL Cement Concrete Composites 2014 Modulus of Elasticity and Tensile Strength of Self Compacting Concrete8790922772No ratings yet

- Prisma-Plus Switchboard BrochureDocument16 pagesPrisma-Plus Switchboard Brochurem.abdelsalam772570No ratings yet

- MM850262-1c MCal PM200Document66 pagesMM850262-1c MCal PM200ctmtectrolNo ratings yet

- Staad Example NewDocument58 pagesStaad Example Newsusarlasaicharan100% (1)

- Introduction To KliaDocument9 pagesIntroduction To Kliaanis100% (2)

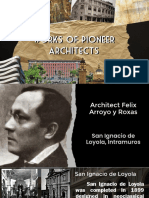

- Works of Pioneer Architects PDFDocument23 pagesWorks of Pioneer Architects PDFKimNo ratings yet

- Christiansee, K. Et Al. (Eds.) (2019), The Grand ProjetDocument326 pagesChristiansee, K. Et Al. (Eds.) (2019), The Grand ProjetAlexandra MeraNo ratings yet

- Album de Guitarra Facil PDFDocument4 pagesAlbum de Guitarra Facil PDFeldbrandakade0% (1)

- CC124Document1 pageCC124Hưng NguyễnNo ratings yet

- The Pink CityDocument7 pagesThe Pink CityKaur SimranNo ratings yet

- MOZZA TILE - Katalog JAN 2020Document28 pagesMOZZA TILE - Katalog JAN 2020Dunia AnakNo ratings yet

- Cholas DynastyDocument5 pagesCholas DynastyShambhav SinghNo ratings yet

- Greek and Roman Town PlanningDocument55 pagesGreek and Roman Town PlanningSanjeev BumbNo ratings yet