Professional Documents

Culture Documents

Meter Ail

Meter Ail

Uploaded by

pomar026Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Meter Ail

Meter Ail

Uploaded by

pomar026Copyright:

Available Formats

Properties of Materials

Properties and Strength of Materials

1-1 Introduction:

Those notes are devoted to shed some lights on the mechanical properties of the main

two elements composing reinforced concrete: Steel and Concrete.

.

:

-1 .

-2

.

-3 .

-4

.

-5 .

-6

.

-7

.

1-2 Definitions

1-2-1 Strain

is a dimensionless value, it is the ratio between the change of length to the original

L

L0

length:

=

Where:

L = Change in length,

L0 = Original length.

1-2-2 Stress

Is the intensity of internal forces = Force / Area

Stress units = Force unites / Area Units = Kg./Cm2, lb./in2, T/m2.

1 Kg. = 2.205 lb. and 1 in. = 2.54 cm

Prepared by Amr A. El-Sayed, Civil Eng. Dept., El-Minia Univ., Eg.

Properties of Materials

then 1 Kg./Cm2 = 14.223 lb / in2 , and 1 Kg./Cm2 = 10.0 T/m2.

1-2-3 Normal Stress

is the stress normal to the section, and could be tension or compression stress:

P

Tension

Compression

P

A

Where:

P

A

Normal stress

Applied load

Cross sectional area

1-2-4 Shear stress

Is the tangential stress.

Q

A

Q

Where:

Q

A

Shear stress

Shearing (tangential) force

Cross-sectional area

1-2-5 Poissons Ratio

Is the ratio between lateral strain to the longitudinal strain.

Lateral Strain

Longitudinal Strain

The value of for all materials varies over a range of 0.0 0.50 .

1-2-6 Youngs Modulus

Is the ratio between stress and strain in the elastic stage.

Prepared by Amr A. El-Sayed, Civil Eng. Dept., El-Minia Univ., Eg.

Properties of Materials

Stress

= , the Youngs modulus is also called (Modulus of Elasticity), and its units are

Strain

as the same stress units, (because the strain is dimensionless).

E=

1-2-7 Complementary Shear

Shear stresses in vertical planes are always accompanied by shear stresses in

horizontal planes perpendicular to the applied shearing force. Such stress is called

complementary shear.

For equilibrium:

M = M1

dy

Moment = area . stress . distance

(t.dx) . . dy = (t.dy) . . dx

then:

=

dx

1-2-8 Shear strain

Is the ratio between the change in length in lateral direction to the original length.

Shear Strain =

Deformation

Couple arm

= tan

x

L

then =

Where is the shear strain defined by the

angular displacement in radians as is very

small.

1-2-9 Shear Modulus

The shear modulus is the ratio between shear stress to shear strain

Shear Modulus (G ) =

Shear Stress ( )

Shear Strain ( )

in stress units

Prepared by Amr A. El-Sayed, Civil Eng. Dept., El-Minia Univ., Eg.

Properties of Materials

** Relation between E & G:

E

) 2(1 +

=G

For steel, E = 2100 T/cm2 = 2100*104 T/m2

For concrete, E = 210 T/cm2 = 210*104 T/m2.

1-3 Types of loading

1-3-1 Static loading

The load is applied slowly and increases gradually till its maximum value without

developing any impact or vibrations.

) (Test Specimen

.

)) (Continues Loading (

. :

a- Short time static loading: the time between the application of load and the load reaches its

maximum value (at the specimen failure) is few minutes.

.

b- Long time static loading: The load is applied gradually till its maximum value, and remains

constant for sufficient time to enable its probable final effect to be predicted.

)

( .

1-3-2 Dynamic loading

The load is applied to the specimen in a form of vibrations or shocks. The dynamic

loading may also be caused by impact.

.

.

) . (Equivalent Static Load

).(Load Factor

Equivalent Static Load

= Load Factor

Dynamic Load

Prepared by Amr A. El-Sayed, Civil Eng. Dept., El-Minia Univ., Eg.

Properties of Materials

1-3-3 Repeated loading

The load is applied in small quantities for several times.

.

.

6

0.8

0.5

4

Stress

Stress

0.4

Stress

0.6

0.2

-1

0

0

-0.5

6

Time

Time

Time

12

10

)(1

)(2

)(3

:

-1 .

-2 .

-3 .

1-4 Mechanical properties of materials

1-4-1 Elasticity

Is the ability of the material to return to its original dimensions when the external

applied load is removed.

.

.

) (Elastic Limit Stress

.

1-4-2 Plasticity

Is the property which permits materials to undergo permanent change in shape without

fracture, i.e the material does not return to its original dimensions.

.

Prepared by Amr A. El-Sayed, Civil Eng. Dept., El-Minia Univ., Eg.

Properties of Materials

1-4-3 Ductility

Is the ability of the material to stand large plastic deformation in tension, i.e the

property of the material which enables it to be drawn out to a considerable extent before

failure.

:

-1 =

-2 =

-3 =

L L0

.100

L0

= % Elongation

A A

% Reduction of area = 0

.100

A0

A A

Elongation factor = 0

.100

A

1-4-4 Malleability

Is the property which represents the capacity of the material to withstand plastic

deformation in compression without failure.

.

Prepared by Amr A. El-Sayed, Civil Eng. Dept., El-Minia Univ., Eg.

Properties of Materials

1-4-5 Brittleness

Is the property of the material which makes it fractured before much or no

deformation is noticeable.

.

1-4-6 Strength

Is the resistance of the material to any applied forces, and is measured in the known

stress units.

This resistance is usually known as the tensile strength if the applied load is tension or

compressive strength if the applied force is compression. The ultimate strength is the

maximum stress which the material is capable to withstand, developed under a slowly axial

applied load.

) (

( Bending) ) (

.

.

1-4-7 Stiffness

Stress

Stress

Is the property of the material to resist any sort of deformation. A stiff material is that

material which withstand high unit stress with relatively small unit deformation. In uni-axial

tension and compression tests, the stiffness is quantitatively measured by the modulus of

elasticity within the elastic limit.

Strain

Strain

Modulus of Elasticity .

Modulus of Elasticity .

.(- )

Prepared by Amr A. El-Sayed, Civil Eng. Dept., El-Minia Univ., Eg.

Properties of Materials

E=

Stress

= = tan

Strain

E1 = tan 1, and E2 = tan 2

but 1 > 2.

then, E1 > E2, the material no. (1) is stiffer than no. (2)

1-4-8 Toughness

It is the ability of the material to withstand or absorb mechanical energy. Tough

material is that material which can withstand great deformation together with high stress.

Pf

Py

Pu

Load

Toughness is measured by means of the modulus of toughness which represents the

amount of energy absorbed per unit volume from the time of load application till failure.

Lf

Elongation

.-

Toughness =

Py + Pu

.L f

Modulus of Toughness =

1-4-9 Resilience

Toughness y + u

=

. f

Volume

2

It is the capacity of the material to store mechanical energy; given in energy units

(kg.m, or lb.in i.e. force.distance). Resilience is measured by the Modulus of Resilience,

which is the maximum amount of mechanical energy that may be stored in a unit volume and

be completely recovered upon the removal of load.

Prepared by Amr A. El-Sayed, Civil Eng. Dept., El-Minia Univ., Eg.

Properties of Materials

.

.

- .

Stress

Load

Resilience

Modulus of Resilience

Strain

Elongation

1-4-10 Hardness

Is the ability of the material to resist scratching, abrasion, cutting, or indentation. The

hardness of non-metallic materials such as stones, gravel, and rock is usually measured by its

resistance to abrasion by friction.

.

-1 Indentation Hardness

-2 Rebound Hardness

-3 Scratch Hardness

-4 Wear Hardness

-5 Mechineability Hardness

-

1-4-11 Endurance

Is the ability of the material to withstand repeated application of load. The endurance

limit is the highest repeated stress that can be applied infinite number of times causing failure

to the material.

.

1-4-12 Durability

Is the ability of the material to resist the internal or external destructive conditions

over long period of time.

Prepared by Amr A. El-Sayed, Civil Eng. Dept., El-Minia Univ., Eg.

Properties of Materials

1-5 Axial deformations:

1-5-1 Due to external force:

L

P

,=

and

A

L0

P

A = P.L0

E= =

L

A.L

L0

L =

P.L

E. A

. (1-1)

1-5-2 Due to self weight

a- the cross section is constant:

Specific weight (density)

Cross-sectional area

t/m3:

cm2:

. x dx

W

A

: x

Px = W.x.A

ton

x (at any sec tion x) =

(W .x. A).dx = W .x.dx

E

W

W x2

L (Total Extension) = .x.dx =

E

E0 2

0

L

L =

W .L2

2.E

W.x.A

dx

E. A

W.L.A

Px .Lx

E. A

. (1-2)

Prepared by Amr A. El-Sayed, Civil Eng. Dept., El-Minia Univ., Eg.

10

Properties of Materials

1-5-3 Due to external variable load

The load various linearly from 0.0 to w. The load equation is from first degree, so, the

normal force diagrams degree will be 2.0 (2nd degree parabola).

w.L/2

w=0

L/2

w.L/2

L/2

w t/m

dx

Wx

w

The load at any section x:

WX W

=

X

L

WX = W .

X

L

Normal force at any section x:

X

X

0 W . L .dx

at x = 0.0, the normal force =

N=

W .L W . X 2

2

2.L

1

N .dx

E. A 0

W .L2

3.E. A

W X2

Lo 2

X

W

. X .dx

L 0

W .L

, then

2

c=

W .X 2

+c

2.L

W .L

2

. (1-3)

L

1 W .L W . X 2

E. A 0 2

2 .L

.dx

W X3

1 W .L

.X

.

E. A 0 2

2 .L 3

L

. (1-4)

Prepared by Amr A. El-Sayed, Civil Eng. Dept., El-Minia Univ., Eg.

11

Properties of Materials

Example: Find the total extension of the bar shown in figure. A = 12.50 cm2, E = 2100

t/cm2.

5.0 t

5.0 t

20.0

5.0

15.0 t

10.0

5.0 t

10.0

10.0 t

10.0 t

q = 0.125 t/m

2.50 t

2.5

7.50 t

7.5

10.0 t

5.0 t

10.0

20.0

20.0

10.0 t

5.0 t

5.0

5.0 t

L1 =

P.L1

5.0 * 20.0

=

= 0.004 Cm.

E. A 2100 *12.50

L 2 =

P.L2

10.0 * 10.0

=

= +0.004 Cm

E. A 2100 * 12.50

L31 =

L3 2

10.0 * 20.0

= +0.0076 Cm (due to concentrated load)

2100 *12.50

0.125 * 20.0 2

W .L2

=

=

= 0.001 Cm (due to uniform load)

3.E. A 3 * 2100 *12.50

L41 =

2.50 * 20.0

= 0.0019 Cm (due to concentrated load)

2100 * 12.50

L4 2 =

W .L2

0.125 * 20.0 2

=

= 0.0019 Cm (due to uniform load)

2.E. A 2 * 2100 *12.50

L5 =

5.0 * 10.0

P.L

=

= 0.0019 Cm

E. A 2100 *12.50

Total change in length = 0.0009 cm

Prepared by Amr A. El-Sayed, Civil Eng. Dept., El-Minia Univ., Eg.

12

Properties of Materials

b- the cress section is variable:

Elongation due to external force P

d` = d0 2.ab,

ab

x

=

ac L0

and

ab

x

=

d 0 d1 L0

then

ab =

d 0 d1

.x

2.L0

d0

d 0 d1

.x

L0

= d0 k.x

d` (diameter at any section x) = d 0

d 0 d1

L0

A (cross-sectional area at x) = .d`2 / 4 =

(stress at any section x) =

(strain at section x) =

(d 0 k .x )2

P

4 .P

=

Ax .(d 0 k .x )2

dx

k=

where

cb a

L0

then

e

d

4 .P

1

.

E. (d 0 k .x )2

d`

P

4 .P

dx

x = .dx =

.

E. (d 0 k .x )2

L

4 .P 0

2

. (d 0 k .x ) .dx

L =

E. 0

L0

L =

4.P (d 0 k .x )

.

E.

1 * k

0

L0

4 .P

1

,

.

L =

E. .k (d 0 k .x )

replacing (k) with

d 0 d1

L0

Prepared by Amr A. El-Sayed, Civil Eng. Dept., El-Minia Univ., Eg.

13

Properties of Materials

L

4.P

1

1

0

L =

.

.

E. d 0 d1

d0 0

d 0 d1

d 0 L .L0

L =

L0 1

4 .P

1

.

.

E. d 0 d1 d1 d 0

L =

L =

4.P.L0

E. .(d 0 d1 )

L0 d 0 d1

4 .P

.

.

E. d 0 d1 d 0 .d 1

. (1-5)

1-6 Stress in compound sections

:( as one unit)

1- S = C

2- Pt = PS + PC

Suppose we have a bar made of two materials steel, and copper.

S =

then

S

ES

S

ES

C =

, and

C

EC

EC

P

and S = S

AS

C =

PC

AC

Steel

Copper

PS

PC

=

E S . AS E C . AC

PS = PC .

E S . AS

,

E C . AC

E .A

P = PC 1 + S S

E C . AC

but

P = PS + PC

Prepared by Amr A. El-Sayed, Civil Eng. Dept., El-Minia Univ., Eg.

14

Properties of Materials

or,

PC = P.

EC . AC

E C . AC + E S . AS

. (1-6)

PS = P.

E S . AS

EC . AC + E S . AS

. (1-7)

1-6-1 Reinforced Concrete Columns

P

PS

PC

S

C

S = C ,

Total load carried by the column

load carried by steel bars

load carried by concrete

stress in steel

stress in concrete

then

ES

C

EC

S = C.

ES

EC

ES

= n = (mod ular ratio)

EC

S = n. C

P = PS + PC

Concrete

= S.AS + C.AC

Steel

P = n. C.AS + C.AC

A

P = C . AC 1 + n. S

AC

P = C .AC (1+ n.)

AS

=

AC

. (1-8)

Prepared by Amr A. El-Sayed, Civil Eng. Dept., El-Minia Univ., Eg.

15

Properties of Materials

1-7 Simple statically indeterminate problems:

.(Compatibility Equations)

Examples:

1- Find the normal stresses, and reactions, E = 2000.0 t/cm2.

.CB = AC

AC = CB

RA

A

R A .L AC R B .LCB

=

E. A

E. A

30.0

2

R A = .RB

3

3.RA = 2.RB

but,

RB

RA

RA + RB = 10.0 t

10.0 t

2

.R B + R B = 10.0

3

RB = 6.0 t, and

20.0

LAC = 30.0, and LCB = 20.0

RB

RA = 4.0 t

Prepared by Amr A. El-Sayed, Civil Eng. Dept., El-Minia Univ., Eg.

16

Properties of Materials

1-7 Thermal stresses

:

-1 ) (

L (due to temperature t) = .L.t

where:

L

t

Coefficient of thermal expansion

Original length of the bar

)Temperature change = (t1 t0

-2 :

P.L

= L

= .L.t

E. A

P=.t.E.A

And the thermal stress = P / A

t = . t . E

) ( .

:

. t . L -

= .t

.t.L

L

t = .E

t = .t .E

L

17

Prepared by Amr A. El-Sayed, Civil Eng. Dept., El-Minia Univ., Eg.

Properties of Materials

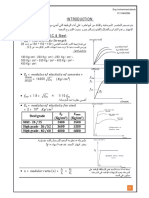

2- Mechanical properties of metals in static tension test

.

b c

f

d

1- Elastic Stage (0 to a)

2- Yield Stage (b d)

3- Elastic-Plastic Stage (Ductile

Stage).

1 2

4- Plastic Stage (Necking Stage)

2-1 Elastic Strength

The elastic strength can be determined from:

2-1-1- Proportional limit

Is the maximum value of the applied stress in the elastic zone.

(a) ( ) ( )

.

2-1-2 Elastic limit

Is the maximum stress that the material can withstand, and if that stress is removed,

there will be no permanent deformations.

) (

(Elastic ( Proportional Limit)

( b) .

. Limit)

.(Johanson) ( Elastic Limit)

Prepared by Amr A. El-Sayed, Civil Eng. Dept., El-Minia Univ., Eg.

18

Properties of Materials

Johansons appearant Elastic limit:

) (Johanson ) (-

% 50 ).(Elastic Limit

and,

Tangent inclination = mt,

Straight line inclination = ml

El. L

mt = ml 0.50 mt.

1.50 mt = ml.

mt = (2/3) ml

ml = Y/cd

then,

Y

3 .cd

2

= mt

) (cd de = 0.5 cd : .ce = 1.50 cd : ) (oe

) (oe ).(Elastic Limit

2-2 Proof Stress

) (Elastic stress ). (Plastic stress

example:

P Tons

L mm

(0.10 % proof stress) means the stress which

causes 0.10 % of permanent elongation.

) ( ): (P -

0.10

=

.L0

100

X

) (Proof load .

Pr oof Load

A0

19

Prepared by Amr A. El-Sayed, Civil Eng. Dept., El-Minia Univ., Eg.

= Pr oof Stress

Properties of Materials

2-3 Stiffness

Stress

Stiffness is measured by the modulus

of elasticity.

E = tan ()

in the elastic stage.

E=

Strain

2-4 Resilience

Modulus of Resilience = Resilience / Volume

P

.d ,

Load

( P-)

.()

Stress

.

LP

1

R = P.d = .PP * LP

2

0

Resilience

Modulus of Resilience

and = E.

Elongation

M. of Resiliense =

E. .d

Strain

= 0.5 E. 2P

2-5 Plastic strength

:

PMax.

A0

P

2- Fracture Strength f = Frc.

A0

1- Ultimate Strength u =

kg/cm2

kg/cm2

Where:

PMax.

the maximum force on the curve

PFrac.

The load at fracture.

Prepared by Amr A. El-Sayed, Civil Eng. Dept., El-Minia Univ., Eg.

20

Properties of Materials

2-6 Ductility

:

.100

A0 A

.100

A0

L L0

= % Elongation

1-

= % Reduction of area

2-

= Elongation factor

3-

L0

A0 A

.100

A

2-7 Toughness

Load

Pu

)Toughness = Total area under the (P-

LF

P + PU

.LF

diagram = P.d Y

2

0

Pf

Py

Modulus of Toughness = Toughness / Volume

F

+ U

= .d Y

. F

2

0

Toughness Index Number:

= u . f

Lf

Elongation

3- Elongation Equation

:

-1 L0

-2 .A0

:

-1

.

L1 = constant * L0

-2 :A0

L1 L0,

then

L1 = b . L0

A0

L2 = c .

L = L1 + L2

21

Prepared by Amr A. El-Sayed, Civil Eng. Dept., El-Minia Univ., Eg.

Properties of Materials

). (3-1

L = b.L0 + c. A0

L Y L0 .X b,c

.

L

C. A0

L0

) (L , L0 Y c. A0

A

L

= % Elongation = b + c. 0

L0

L0

A0

L0

A0

L0

For Egyptian specifications:

22

for long specimens

L0 = 11.30 * A0

for short specimens

L0 = 5.65 * A0

Prepared by Amr A. El-Sayed, Civil Eng. Dept., El-Minia Univ., Eg.

Properties of Materials

3-1 True stress-True strain diagram

a- True Stress : equals the applied force at any moment divided by the cross-sectional area at

the same moment.

`=

Pi

Ai

b- True strain:

d1

d2

di

L1

L0

Li

L1

L0

d0

L

L0 L1 L2

True strain (`) =

+

+

+ ........... + i =

L0

L1

L2

Li

` =

Li

dl

Li

L0

L

L

= log e L = log e ( Li ) log e ( L0 )

L0

` = log e

Li

L0

. (3-2)

but

Li = L0 + Lt

` = log e

L0 + Lt

L0

` = log e 1 +

Lt

L0

= log e (1 + )

. (3-3)

Prepared by Amr A. El-Sayed, Civil Eng. Dept., El-Minia Univ., Eg.

23

Properties of Materials

True strain = loge (1 + ordinary strain)

The volume of specimen is constant, i.e,

A0 * L0 = Ai * Li

Li

A

= 0

L0

Ai

A0

Ai

` = log e

. (3-4)

A0 d 0

=

Ai d i

and for circular specimens

d

= log e 0

di

`

d

= 2. log e 0

di

. (3-5)

from equations (3-3) and (3-4)

1+ =

Ai =

` =

A0

Ai

A0

1+

Pi

,

Ai

` =

. (3-6)

Substituting from equation (3-6)

Pi

.(1 + ) ,

A0

but

Pi

is the normal stress ()

A0

` = .(1 + )

. (3-7)

Equation (3-7) represents the relationship between the true stress (`), and the

ordinary stress ().

(` - `) ( mild steel)

:

1- Part I: Elastic Stage

from

` = 0

` = a . `

to

` = `P

(3-8)

Prepared by Amr A. El-Sayed, Civil Eng. Dept., El-Minia Univ., Eg.

24

Properties of Materials

where:

a

)is a constant ( a = E Modulus of Elasticity

2- Part II: Elastic-Plastic stage:

)` (` -

:

` = b . `c

where:

)b, and c are constants (related to each material

b is called Strength coefficient, and c Strain hardening component

3- Part III : Plastic stage

)` (` -

:

`` = k + m.

). (3-9

` = `f

` = `u

to

from

Where:

k, and m are constants

m

strain hardening coefficient

:

)

(

. ) (

:

dP = 0

). (3-10

Pi = ` . Ai

A0

Ai

) ). ( Equation (3-4

A0

` e

= Ai

or,

` = loge

A0

`= e

Ai

But,

Then,

Ai )(3-10

A0

). (3-11

` e

) (3-11 ) (Pmax.

.

Pi = `.

25

Prepared by Amr A. El-Sayed, Civil Eng. Dept., El-Minia Univ., Eg.

Properties of Materials

dP = A0 `.e `(1).d `+e `.d ` = 0

`.e `.d `= e `.d `

`=

d `

d `

. (3-12)

( `-`) ( 3-12)

.( `)

( `-`)

.`

For part II of the (`-`) curve:

` = b . `c

d `

= b.c. `c1

d `

c 1

c. ` = `

= ` = b . `c

`c

c = c 1 = `cc +1

`

c = `

. (3.(`max.) ( 3-00) `

`max . = b.c c

. (3-

4- Factors affecting the tensile properties of metals:

1- Carbon Content

(u)

. (y)

2- Rate of loading

3- Temperature

4- Over straining

5- Cold working

6- Size and shape of test specimen

7- Effect of eccentric loads

8- Alloying elements

9- Heat treatment

Prepared by Amr A. El-Sayed, Civil Eng. Dept., El-Minia Univ., Eg.

26

Properties of Materials

5- Failure of metals under compression

P

A

The compressive force

Cross-sectional area

For the inclined plane (),

A

A`=

cos

Pn = P. cos and

n =

Pn P.(cos )2

=

A`

A

Where

Pn

the normal force to the inclined plane ().

n

the normal stress

Pt = P. sin

q=

Pt P

= . sin . cos

A` A

where:

the tangential (shear) force to the inclined plane ().

the shearing stress

Pt

q

= tan

Where:

Angle of the internal friction.

Friction reaction (f) = . n.

. =

Stress causing failure = ( q f )

F=

P

P

. sin . cos tan . . cos 2

A

A

F is maximum when

dF

= 0, and note that is constant.

d

dF P

= [sin .( sin ) + cos .(cos ) + 2 tan . cos . sin ]

d A

Prepared by Amr A. El-Sayed, Civil Eng. Dept., El-Minia Univ., Eg.

27

Properties of Materials

dF P

= cos 2 sin 2 + 2 tan . cos . sin

d A

but,

cos (2) = cos2 - sin2

sin (2) = 2.sin . cos

dF P

1

= cos(2 ) + 2 tan . . sin(2 ) = 0.0

d A

2

-cos (2) = tan . sin (2)

tan =

but,

cos(2 )

= cot(2 )

sin( 2 )

cot = tan (90-),

tan = - tan (90-2)

then,

tan = tan (2-90)

= 2 - 90

90 +

= 45 +

2

2

Prepared by Amr A. El-Sayed, Civil Eng. Dept., El-Minia Univ., Eg.

28

Properties of Materials

Section II

Properties and Strength of Concrete Aggregate

2-1 Introduction

.

2-2 Definitions

1- Volume Weight (`):

) (

W

Vt

= ` = U W

vV

Aggregate

sV

tV

Voids

2- Specific Gravity ():

) (

W

Vs

Where

the volume of solids only

29

Vs

Prepared by Amr A. El-Sayed, Civil Eng. Dept., El-Minia Univ., Eg.

Properties of Materials

.

3- Absolute Specific Gravity:

. )(

.

4- Appearent Specific Gravity:

) ( ) 20

( .

or

1000 Kg/m3.

lb/Ft3.

Unit weight of water = 1.0 gr/cm3,

in English system

w = 62.40

and

s g = 2.65 t/m3.

5- Voids Ratio:

.

.

)Total volume of aggregate (including voids

Volume of voids

)Volume of solids (absolute volume of aggregate particles

Vt

Vv

Vs

)a- Voids ratio with respect to total volume (Porosity n

Vs

Vt

Vv Vt Vs

=

Vt

Vt

n =1

=n

).(Volume Weight Wa

Wa Wa

/

Vt Vs

Wa Vs

.

Wa Vt

n =1

n =1

but,

Wa

=

Vs

and

Wa

`=

Vt

` Specific Gravity Volume Weight

=n

=

Specific Gravity

n =1

). (2-1

30

Prepared by Amr A. El-Sayed, Civil Eng. Dept., El-Minia Univ., Eg.

then,

Properties of Materials

=

b- Voids ratio with respect to solid volume (e)

e=

Vv Vt Vs Vt

W W

=

= 1= a / a 1

Vs

Vs

Vs

Vs Vt

e=

1

`

e=

` Specific Gravity Volume Weight

=

`

Volume Weight

. (2-2)

( Volume Weight)

.

6- Relation Between (e, and n)

n=

Vv

Vv

=

Vt Vs + Vv

1 Vs + Vv Vs

=

= +1

n

Vv

Vv

n=

e

e +1

1 1

e +1

= +1=

n e

e

. (2-3)

Prepared by Amr A. El-Sayed, Civil Eng. Dept., El-Minia Univ., Eg.

31

Properties of Materials

2-3 Grading and Sieve Analysis:

.

) ( ) (

.

Sand

100

52

25

Gravel

2

14

3

"

16

2.5 1.25 0.625 0.321 0.156

3

3

"

"

8 16

10

3

"

4

1

" 1

2

20.0

mm

40.0

mm

Specification

British

Egyptian

:

:

Sedimentation by Hydrometer

Clay

Test

Sieve analysis by sieves

Sand

Silt

Fine

Gravel

Coarse Medium

Soil

Type

Fine

No. 200

No. 60

No. 100

No. 40

No. 20

No. 10

No. 4

1/2

3/8

3/4

Sieve

100

80

70

60

50

40

30

20

10

0.005

0.075

0.15

0.25

0.42

0.84

4.75

19.0

12.7

9.52

0.0001

0.001

0.01

0.1

1.0

10

Diameter of soil grain in mm

32

Prepared by Amr A. El-Sayed, Civil Eng. Dept., El-Minia Univ., Eg.

100

Percentage of passing by weight %

90

Properties of Materials

) (Logarithmic Base :

and

) log(a ) = b. log(a

) log(a.b ) = log(a ) + log(b

b

) (2 )) (log(2

.

: )) (log(2

:

1- It is required to draw the grading curves for both sand and gravel

100

52

25

14

3

"

16

3

"

8

3

"

4

1

" 1

2

Sieve Size

6

0

24

0

45

0

60

0

81

0

96

3

100

36

100

75

100

96

% passing Sand

% passing Gravel

90

nd

a

S

80

70

Gr

av

el

60

50

40

30

20

10

" 1.50

"3/4

"3/8

" 3 / 16

No. 7

No. 14

No. 25

No. 52

Sieve Size

33

Prepared by Amr A. El-Sayed, Civil Eng. Dept., El-Minia Univ., Eg.

No. 100

Percentage of passing by weight %

100

Properties of Materials

2- The sieve analysis test was carried out on two samples of aggregates, the total weight of

gravel sample was (10000 gm), and the total weight of sand sample was (1000 gm).

The weight on each sieve for both sand and gravel is displayed in the following table. It is

required to draw the grading curves for both sand and gravel.

Sieve Size

1

1 "

2

3

"

4

3

"

8

3

"

16

14

25

52

100

Pan

weight of sand

weight of gravel

480

5050

3000

20

1250

130

220

100

-

260

-

370

-

110

-

10

-

Solution

Sieve Size

3

"

4

3

"

8

3

"

16

14

25

52

100

Pan

20

150

250

510

880

990

100

480

5530

8530

15

25

51

88

99

100

4.8

55.3

85.3

97.80

100

100

100

100

100

100

100

100

100

98

85

75

49

12

95.2

44.7

14.7

2.20

9780 10000 10000 10000 10000 10000 10000

100

90

80

Sa

nd

70

60

50

Gr

av

el

40

30

20

10

1.50 "

3/4"

3/8"

3 / 16 "

No. 7

No. 14

No. 25

No. 52

No. 100

Percentage of passing by weight %

Total weight of

sand

Total weight of

gravel

% retained

sand

%retained

gravel

% passing

sand

% passing

gravel

1

1 "

2

Sieve Size

Prepared by Amr A. El-Sayed, Civil Eng. Dept., El-Minia Univ., Eg.

34

Properties of Materials

2-4 Finesse Modulus

).(100

= Finesse Modulus for Sand

2 to 3.75

= Gravel

5 to 8

2-5 Maximum nominal size

) (%95

:

0.25 -1 0.20 .

3/2 -2 4/3 .

Note: Sieve number (25) determines the size of sand according to the percentage passing

through it as follows:

Percentage Passing

Type of Sand

< 34

35 59

60 79

80 - 100

Coarse

Medium

Fine

Very fine

2-6 Limits of Grading

35

Prepared by Amr A. El-Sayed, Civil Eng. Dept., El-Minia Univ., Eg.

Properties of Materials

Problems on Grading of combined aggregate (1)

( ) ( ) -1

.( n : m )

Sand : Gravel

(in combined aggregate)

n : m

1- Mathematical Method

S n

=

G m

Where:

S

G

A

refers to Sand

refers to Gravel

refers to combined Aggregate

A=

n

m

.S +

.G

n+m

n+m

A=

n.S + m.G

n+m

Where:

(n+m)

S

G

A

. (2-

For example, if the mix proportion of Sand to Gravel was 2 : 3, and for sieve size (3 / 8 ) the

percentage passing of sand was 100, and the percentage passing of gravel was 36, then the

percentage passing of the combined aggregate will be:

A=

n.S + m.G

n+m

2 * 100 + 3 * 36

= 61.60 %

2+3

Prepared by Amr A. El-Sayed, Civil Eng. Dept., El-Minia Univ., Eg.

36

Properties of Materials

2- Graphical Method

100

100

"3/4

90

70

60

50

40

3/

"

57.3 %

/1

80

3

.7

no

.1

4

25

no

no.

10

0.0

60

50

40

30

30

20

70

no. 52

n. 100

% Passing Sand

% Passing Gravel

80

"8

90

20

10

0.0

100 90 80 70 60 50 40 30 20 10 0.0 % Sand / Aggregate

% Gravel / Aggregate 0.0 10 20 30 40 50 60 70 80 90 100

-1 ) ( ) (

).(0.0 to 100

-2 (Sand /

) Aggregate ).(Gravel / Aggregate

-3 ) (

)" (3/8

) ( .

) (100% ) (36% ) (100 )(36

.

-4 ) (1 : 2 ) (1:3 = 0.333

) (2:3 = 0.666 ) (0.33

) (3/8 ) (57.33

) (57.33% .

37

Prepared by Amr A. El-Sayed, Civil Eng. Dept., El-Minia Univ., Eg.

Properties of Materials

Example:

1- Given the grading of both fine and coarse aggregate. It is required to obtain the grading

of combined aggregate with the ratio (1 Sand : 2 Gravel).

Solution

-1 :

:

n.S + m.G

n+m

=A

Where:

m=2

100

52

25

14

3

"

16

3

"

8

3

"

4

1

" 1

2

6

0

24

0

45

0

60

0

81

0

96

3

100

36

100

75

100

96

15

20

27

34

57.33

83.33

97.33

n = 1, and

Sieve Size

% passing Sand

% passing Gravel

% passing Aggregate

S + 2*G

3

-2 .

)Problems on grading of aggregate (2

-2 .

.

: :

3

(5.0 mm or

16

) inch

n.S + m.G

n+m

3

(5.0 mm or

16

=A

).inch

G = 0.0

38

For combined aggregate,

% Passing Gravel = 0.0,

Prepared by Amr A. El-Sayed, Civil Eng. Dept., El-Minia Univ., Eg.

Properties of Materials

A=

n.S

n+m

A

n

=

S n+m

S n+m

m

=

=1+

A

n

n

m S

SA

= 1=

n A

A

n

A

( Mix proportion ) =

m

SA

. (

) (G = 0.0)

.(G 0.0) ((5 mm)

A=

n.S + m.G

n+m

A.n + A.m = n.S + m.G

n( A S ) = m(G A)

n (A G)

=

m (S A)

S, G, and A are the values of percentage passing of Sand, Gravel, and

Aggregate from sieve size (5 mm).

: :

1.5 "

100

90

% Passing Sand

80

70

60

50

40

90

no

.7

no

.

80

/1

"

14

no.

3/

70

4"

25

3/

8"

20

0.0

60

50

30

10

100

40

30

% Passing Gravel

Where,

. (

20

no. 52

10

n. 100

0.0

65.6

34.40

100 90 80 70 60 50 40 30 20 10 0.0 % Sand / Aggregate

% Gravel / Aggregate 0.0 10 20 30 40 50 60 70 80 90 100

Prepared by Amr A. El-Sayed, Civil Eng. Dept., El-Minia Univ., Eg.

39

Properties of Materials

3

-1 (5.0 mm or

16

) inch

.

-2 (5.0 mm or

3

16

) inch .

Example:

Given the grading of a desired combined aggregate, and the grading of both sand and

gravel. It is required to find the ratio of (Sand : Gravel) to satisfy the grading of the desired

combined aggregate.

100

52

25

14

3

"

16

3

"

8

3

"

4

1

" 1

2

Sieve Size

2

0

1

12

0

5

50

0

18

72

0

25

83

0

30

96

3

35

100

22

49

100

55

70

100

100

100

% passing Sand

% passing Gravel

% passing Aggregate

-1 :

n ( A G ) 35 3 32

= 0.525

=

=

=

m (S A) 96 35 61

:

n.S + m.G

n+m

=A

for example, Sieve (3 / 4 ):

32 * 100 + 61 * 55

= 70.484 %

32 + 61

=A

-2 :

) (35%

3

(5.0 mm or

16

) inch ).(65.6) (34.4

n 34.4

=

= 0.524

m 65.6

40

Prepared by Amr A. El-Sayed, Civil Eng. Dept., El-Minia Univ., Eg.

Properties of Materials

Problems on grading of aggregate (3)

. -3

inch)

3

(5.0 mm or

16

.

Example:

1- The grading of a combined aggregate is shown in the following table. It is required to

find the mix proportion of (sand : gravel), and the grading of both of them.

Sieve Size (mm)

% passing Aggregate

60

98

40

92

20

56

10

31

5

20

2.5

17

1.25

15

0.63

9

0.31

3

0.16

1

Solution

( 20 %) ( 5 mm)

.(20 %)

S

n

%=

A

n+m

n

20

=

100 n + m

100 * n = 20 * n + 20 * m

80 * n = 20 * m

n 20 1

=

=

m 80 4

n:m=1:4

A=

n.S + m.G

n+m

1- For sieves (60 mm to 5 mm),

G=

S = 100 %

A(n + m ) n.S

%

m

Prepared by Amr A. El-Sayed, Civil Eng. Dept., El-Minia Univ., Eg.

41

Properties of Materials

n = 1, m = 4, S = 100

)(A

) .(60 mm to 5 mm

G = 0.0 %

2- For sieves (5 mm to 0.16 mm),

) A(n + m

n

)(A

(5 mm to 0.16 mm

).

42

=S

Prepared by Amr A. El-Sayed, Civil Eng. Dept., El-Minia Univ., Eg.

Properties of Materials

Surface area of aggregate

.

.

Effect of surface area on the properties of concrete

:

-1 ) 5-2\2(.

-2 .

:

-1 ) 100-60 \2 (

.

-2

.

) +( :

-1

-2 .

-3 .

) 30-25\2(.

300

200

25 - 30 cm2/gm

50

40

30

100

0.0

20

10

Specific Surface Area cm2 / gm

400

0.0

Specific Surface Area Cm2/gm

43

Prepared by Amr A. El-Sayed, Civil Eng. Dept., El-Minia Univ., Eg.

Properties of Materials

Calculating the surface area of aggregate:

.

:

1- Assuming that the particles have spherical shape:

..

) (Wt . (W1,

).W2, W3,.

:

-1 = = N

-2 = d

-3 ) = (Specific Weight

=

3

4 d

. . .N .

3 2

.d 3 .N .

= `W

6

` 6.W

=N

.d 3 .

=

2

d

.N

2

` 6.W

d .

` 6.W

.d 3 .

= 4. .

.d 2 .

=

Where:

Weight of aggregate passing through a specific opening d1, and retained on the

sieve opening d2

Average size of aggregate particles:

d, can be represented by:

`W

d

d1 + d 2

)(Arithmetic mean

2

)d = d1 .d 2 (Geometric mean

) log(d1 ) + log(d 2

= )log (d

2

=d

)(Logarithmic mean

44

Prepared by Amr A. El-Sayed, Civil Eng. Dept., El-Minia Univ., Eg.

Properties of Materials

Specific weight of aggregate material

:

` 6.W1 ` 6.W2 ` 6.W3

+

+

+ ..............

d 2 .

d 3 .

d1.

=

Where:

: d1 )(1

) : d2 ) + (1 )( (2

) : d3 ) + (2 ) ( (3

=

Wt

` 6.W1 ` 6.W2 ` 6.W3

+

+

+ ..............

d 2 .

d 3 .

d1.

If (P1, P2, P3, .) are the percentage passing from sieves (1, 2, 3, ..) respectively,

= then the specific surface area

100

) 6.( P1 P2 ) 6.( P2 P3 ) 6.( P3 P4

+

+

+ ..............

d 2 .

d 3 .

d1.

2- Assuming that the particles have different shapes:

).(Angularity, or form Factors

=

Wt

` 6.W1

` 6.W3

` 6.W2

S1

+ S2

+ S3

+ ..............

d 2 .

d 3 .

d1 .

S1, S2, S3, :

=S

)S = 1 (in case of spherical particles

45

Prepared by Amr A. El-Sayed, Civil Eng. Dept., El-Minia Univ., Eg.

Properties of Materials

Example:

1- It is required to determine the specific surface area for the Sand, and Gravel samples

given their grading in the following table. Assume that specific gravity () for both sand

and gravel = 2.65 t/m3, and the form factor = 1.40.

Sieve Size mm

% passing Sand

% passing Gravel

40

100

95

20

100

44.8

10

100

13.4

5

97.5

0.6

2.5

85

-

1.25

75

-

0.625

48

-

0.31

12

-

0.16

1

-

Solution

1- Specific surface area of Sand:

Sieve size

mm

Logarithmic

Mean (d)cm

% passing

P

40

20

10

5

2.5

1.25

0.625

0.31

0.16

2.8284

1.4142

0.7071

0.3536

0.17678

0.0884

0.0442

0.0221

100

100

100

97.5

85

75

48

12

1

P1 P2

6.( P1 P2 )

d .

2.5

12.5

10

27

36

11

8.0051

80.04

128.077

691.5393

1844.348

1127.1

S.

6.( P1 P2 )

d .

11.207

112.056

179.3078

968.155

2582.0872

1577.94

5430.75

Specific surface area of sand = 5430.75 / 100 = 54.3 cm2 / gr.

2- Specific area of Gravel

Sieve size

mm

40

20

10

5

Logarithmic

Mean (d)cm

% passing

P

2.8284

1.4142

0.7071

95

44.8

13.4

0.60

P1 P2

6.( P1 P2 )

d .

50.20

31.40

12.80

40.185

50.27

40.98

S.

6.( P1 P2 )

d .

56.259

70.378

57.372

184.016

Specific surface area of Gravel = 184.016 / 100 = 1.84 cm2/gr.

Prepared by Amr A. El-Sayed, Civil Eng. Dept., El-Minia Univ., Eg.

46

Properties of Materials

- : :

:

-1 ) (

-2 ) (

-3 .

:

: .

-1 :

n. As + m. Ag

n+m

= Aa

Where:

Specific surface area of combined aggregate

Specific surface area of sand

Specific surface area of gravel

Mix proportion of sand : gravel

) m.( Aa Ag ) = n.( As Aa

Aa

As

Ag

n,m

n. Aa + m. Aa = n. As + m. Ag

( .

) n (Aa Ag

=

) m ( As Aa

-2 :

-1 ) ( ) (

.

-2 (Sand /

) Aggregate ).(Gravel / Aggregate

-3 ) ( )

(.

n

-4 %

n+m

m

.

%

n+m

-5 ) (4 ) (3

.

47

Prepared by Amr A. El-Sayed, Civil Eng. Dept., El-Minia Univ., Eg.

50

50

40

40

30

30

22.8

20

20

10

10

0.0

0.0

Surface area of Gravel cm2/gm

Surface Area of Sand cm2/gm

Properties of Materials

100 90 80 70 60 50 40 30 20 10 0.0 % Sand / Aggregate

% Gravel / Aggregate 0.0 10 20 30 40 50 60 70 80 90 100

:

30-25)

( ) (/2

./2 25

Examples:

1- In the previous example, if the percentage of sand and gravel in the mixed aggregate was

40.0 %, and 60.0 % respectively, find the specific surface area of the resulted aggregate.

Solution

1- Mathematical method:

n : m = 40 : 60 = 2 : 3

Aa =

n. As + m. Ag

n+m

2 * 54.3 + 3 * 1.84

= 22.82 cm2/gr.

2+3

2- Graphical method:

Sand : Aggregate = 2 : 5 = 40 %,

The solution is given in the previous chart.

Prepared by Amr A. El-Sayed, Civil Eng. Dept., El-Minia Univ., Eg.

48

Properties of Materials

2- two samples of sand, the first is coarse, and its specific surface area equals to 50 cm2/gm,

and the second is fine with specific surface area of 80 cm2/gm. There is also a sample of

gravel with 5.0 cm2/gm specific surface area.

Determine the mix proportion of both the two samples of sand with the sample of gravel to

obtain a sample of aggregate with 25.0 cm2/gm specific surface area in each case. It is also

required to find the resulted specific surface area of the aggregate if each type of sand is

mixed with gravel by (1:1), and (1 : 4). Use both mathematical and graphical methods.

Solution

1- Mathematical method:

a- for sand with 50.0 cm2/gm specific surface area:

n Aa Ag

=

m As Aa

n:m=4:5

n 25 5

20 4

=

=

=

m 50 25 25 5

= 1 : 1.25

b- for sand with 80.0 cm2/gm specific surface area:

n Aa Ag

=

m As Aa

n 25 5

20 4

=

=

=

m 80 25 55 11

n : m = 4 : 11 = 1 : 2.75

90

90

80

80

70

70

60

60

50

50

40

40

30

30

20

20

10

10

0.0

44.4

26.7

0.0

Surface area of Gravel cm2/gm

Surface Area of Sand cm2/gm

2- Graphical method:

100 90 80 70 60 50 40 30 20 10 0.0 % Sand / Aggregate

% Gravel / Aggregate 0.0 10 20 30 40 50 60 70 80 90 100

Prepared by Amr A. El-Sayed, Civil Eng. Dept., El-Minia Univ., Eg.

49

Properties of Materials

to find the surface area of aggregate:

Aa =

n. As + m. Ag

n+m

1- Coarse sand with gravel ( 1 : 1)

Aa =

1 * 50 + 1 * 5

= 27.50 cm2/gm

2

2- Coarse sand with gravel ( 1 : 4)

Aa =

1 * 50 + 4 * 5

= 14.0 cm2/gm

5

3- Fine sand with gravel ( 1 : 1)

Aa =

1 * 80 + 1 * 5

= 42.50 cm2/gm

2

4- Fine sand with gravel ( 1 : 4)

90

90

80

80

70

70

60

60

50

50

40

42.5

40

30 27.5

20 20.0

14.0

30

0.0

0.0

20

10

Surface area of Gravel cm2/gm

1 * 80 + 4 * 5

= 20.0 cm2/gm

5

Surface Area of Sand cm2/gm

Aa =

100 90 80 70 60 50 40 30 20 10 0.0 % Sand / Aggregate

% Gravel / Aggregate 0.0 10 20 30 40 50 60 70 80 90 100

Prepared by Amr A. El-Sayed, Civil Eng. Dept., El-Minia Univ., Eg.

50

Properties of Materials

Section III

Cement

3-1 Introduction

Soundness of Cement

.

) (Soundness

) (Strength and Durability

.

:

1- Free Lime

) "" (

) (:

) ( + +.

2 Ca O + 2 H2 O 2 Ca (OH)2 + Heat

(Free

) lime

.

) (.

2- The presence of too high Magnesia

% 5

3- The presence of excess of Sulphate

) (S O3 .% 2

) (Cement Unsoundness :

-1 ) (

) (Clay .

51

Prepared by Amr A. El-Sayed, Civil Eng. Dept., El-Minia Univ., Eg.

Properties of Materials

-2

.

:

)

(.

52

Prepared by Amr A. El-Sayed, Civil Eng. Dept., El-Minia Univ., Eg.

Properties of Materials

Section IV

Tests applied on aggregate and Cement

1- Volume weight

:

.

:

) 3( ) 15 (

50 16 .

:

-1 .W1

-2 25

25 25

.

-3 ) ( .W2

W2 W1

-4 =

Volume of cylinder

2- Specific weight

:

.

:

100 1000 .

:

:

-1 110-100

.W

-2 V1

.

-3 ) +( .V2

-4 = ).(V2 V1

53

Prepared by Amr A. El-Sayed, Civil Eng. Dept., El-Minia Univ., Eg.

Properties of Materials

W

-5 =

V2 V1

:

.

3- Voids ratio

:

.

:

.

:

-1 123 .

-2

.

-3 .V

V

-4 =

Volume of cylinder

:

=

)4- Angularity Factor (S

) (S ` W

) (V ) (WL

3 ) 25 (

) (WC ).(

=

=

54

WL

WC

Prepared by Amr A. El-Sayed, Civil Eng. Dept., El-Minia Univ., Eg.

Properties of Materials

S (Angularity Factor) =

WL

WC

5- Strength of aggregate

6- Crushing value of aggregate

7- Hardness of aggregate

8- Toughness of aggregate

9- Harmful impurities in aggregate

Prepared by Amr A. El-Sayed, Civil Eng. Dept., El-Minia Univ., Eg.

55

Properties of Materials

10- Soundness of cement

11- Strength of cement

Prepared by Amr A. El-Sayed, Civil Eng. Dept., El-Minia Univ., Eg.

56

Properties of Materials

Section V

Solved Problems

1- In a tension steel member of 2.0 m long the elongation was found to be 2.0 mm

corresponding to a force of 4000 Kg. Calculate the area of the member cross section, and

the applied normal stress if the modulus of elasticity of this type of material is 2100 t/cm2.

Solution

Data:

L0 = 200.0 cm

L = 2.0 mm = 0.20 cm

P = 4000.0 kg. = 4.0 tons

E = 2100.0 t/cm2.

Required:

A (cross-sectional area), (Normal stress)

L =

P.L0

E. A

Then, A =

P.L0

4 .0 * 2 .0

=

= 0.02 cm2.

E.L 2100.0 * 0.2

P 4.0

=

= 210.0 t/cm2.

A 0.02

2- A load of 2.0 t is hanged down from a vertical round steel rod of 2.1*106 kg/cm2 modulus

of elasticity. If the stress in the rod was 1500.0 kg/cm2, find:

a- Diameter of the rod.

b- Length of rod corresponding to an elongation of 0.3 mm.

c- The change in the rod diameter if the Poissons ratio equals to 0.30

Solution

a- =

P

A

then, 1500.0 =

2000.0

.d 2

4

d = 1.30294 cm.

Prepared by Amr A. El-Sayed, Civil Eng. Dept., El-Minia Univ., Eg.

57

Properties of Materials

b- L =

2000.0 * L0

0.30

=

10

2.1 * 10 6 * 1.333

P.L0

E. A

L0 = 42.0 cm

c- =

Lateral Strain

Longitudinal Strain

A

0.30 =

A0

1.333 A1

=

0.03

L0

1.3333

42.0

A1 = 1.333047 cm2 = . d2/4

d = 1.3028 cm

change in diameter = 1.3029 1.3028 = 0.0001 cm

3- For the beam shown, calculate the magnitude of the normal stresses in the different

parts as well as the value of the resulted deformation at the free end. The beam cross

sectional area is 10.0 cm2, and its modulus of elasticity equals to 2.0*106 kg/cm2.

(neglect the own weight of the beam).

Solution

1- for part no. (1)

L =

P.L0

E. A

P = 6.0 t (tension) = 6000.0 kg., A = 10.0 cm2., and L0 = 200.0 cm

P 6000

= 600.0 kg/cm2 (tensile)

=

A

10

L =

6000.0 * 200.0

= +0.060 cm

2 *10 6 * 10.0

2- for part (2)

P = 3.0 t (compression) = 3000.0 kg., A = 10.0 cm2., and L0 = 200.0 cm

P 3000

= 300.0 kg/cm2 (compressive)

=

A

10

Prepared by Amr A. El-Sayed, Civil Eng. Dept., El-Minia Univ., Eg.

58

Properties of Materials

L =

3000.0 * 200.0

= -0.03 cm

2 *10 6 *10.0

total elongation at the free end = 0.06 0.03 = 0.03 cm

4- Calculate the value of the tension force P which causes total elongation of 0.55 mm in

the shown combined rod. The upper part is cast iron of 7.50 cm diameter, and the lower

part is of mild steel and 5.0 cm diameter.

Modulus of elasticity of cast iron and mild steel is 1.2*106 kg/cm2, and 2.10*106 kg/cm2

respectively.

Solution

L =

P.Li

P.Ls

+

E i . Ai E s . As

Li (length of cast iron rod) = 30.0 cm

Ai (cross-sectional area of cast iron rod) = .d2/4 = * 7.502 / 4 = 44.18 cm2.

Ls (length of mild steel rod) = 30.0 cm

As (cross-sectional area of mild steel rod) = .d2/4 = * 5.02 / 4 = 19.635 cm2.

30.0

30.0

L = P

+

= 0.055

6

6

1.20 *10 * 44.18 2.10 * 10 *19.635

P = 75.6 tons

5- A steel rod, circular in section, tapers from 3.0 cm diameter to 1.50 cm diameter in a

length of 60.0 cm. Find how much this length will increase under a pull of 2.0 tons if E =

2.10*106 kg/cm2.

Solution

L =

4.P.L0

E. .(d 0 d1 )

P = 2.0 t

d0 = 3.0 cm

L =

L0 = 60.0 cm

d1 = 1.50 cm

E = 2.10*106 kg/cm2

4 * 2000.0 * 60

= 0.0485 cm

2.10 *10 6. .(3.0 1.50)

Prepared by Amr A. El-Sayed, Civil Eng. Dept., El-Minia Univ., Eg.

59

Properties of Materials

Problems:

1- A tension test was carried out on a high tensile steel specimen of 2.20 Cms diameter and

11.0 Cms gauge length. The load (P) in tons and the extension (L) in mms were recorded as

follows:

0.0

0.0

P (Tons)

L (mm)

2.0

6.0

12.0 14.0

0.032 0.096 0.192 0.225

16.0

0.38

17.0

1.20

18.0

2.50

19.0

7.30

19.2

11.50

Solution

20

P Tons

15

10

0

0

10

12

L mm

1- The bar AB is considered to be absolutely rigid, and a load of 18000 kg is applied as shown

in figure (1). The connection at A is a pin, and AB is supported by the steel rod EB and the

copper rod CD. The cross sectional area of CD is 5.0 cm2, and that of EB is 3.0 cm2.

Determine the stress in each bar.

Es = 2.10 * 106 kg/cm2

Ec = 1.0 * 105 kg/cm2

2- The sieve analysis test was carried out on samples of aggregates, the percentage passing

from each sieve was as follows:

Sieve Size

Sand

Gravel

Aggregate

40

0.0

77

85.2

20

0.0

30

51.0

10

0.0

7

39.5

5

98

0.0

29.4

2.5

77

0.0

26.9

1.25

64

0.0

25.4

0.63

47

0.0

16.4

0.31

9

0.0

5.7

0.16

3

0.0

1.20

It is required to determine the optimum ratio of combination of sand and gravel to

obtain all-in aggregate with the grading stated above, and then find:

a- The fineness modulus of the combined aggregate.

b- The type of sand according to its grading, and

c- The specific surface area for the given gravel.

Prepared by Amr A. El-Sayed, Civil Eng. Dept., El-Minia Univ., Eg.

60

You might also like

- Module 1 Fundamentals of Deformable Bodies StressDocument15 pagesModule 1 Fundamentals of Deformable Bodies StressArlie Laica BascoNo ratings yet

- Mechanical Properties of Polymers PDFDocument45 pagesMechanical Properties of Polymers PDFMONIRUZZAMAN MONIRNo ratings yet

- Shear Modulus at Room Temperature: Standard Test Method ForDocument5 pagesShear Modulus at Room Temperature: Standard Test Method ForROHITNo ratings yet

- حقيبة الرسم الفني لتقنية اللحام PDFDocument63 pagesحقيبة الرسم الفني لتقنية اللحام PDFmahmoud aliNo ratings yet

- كتاب إنشاء المباني لزهير ساكو وارتين ليفون باللغة العربيةDocument148 pagesكتاب إنشاء المباني لزهير ساكو وارتين ليفون باللغة العربيةyousif awad100% (8)

- Tenses English For UniDocument14 pagesTenses English For UniAhmedMahirNo ratings yet

- فن وأسرار اتخاذ القرارDocument114 pagesفن وأسرار اتخاذ القرارeman shamseldinNo ratings yet

- Arabic Autocad in 3DDocument231 pagesArabic Autocad in 3DHassan Sid AhmedNo ratings yet

- مقاومة مواد PDFDocument61 pagesمقاومة مواد PDFali aliNo ratings yet

- MetE230-Chap8-Mechanical PropertiesDocument44 pagesMetE230-Chap8-Mechanical PropertiesEric WilliamNo ratings yet

- 1-Tensile TestDocument8 pages1-Tensile Testحسين كاظم ياسينNo ratings yet

- Lab 4 Mechanical Testing Tensile and Torsional TestingDocument8 pagesLab 4 Mechanical Testing Tensile and Torsional TestingTommy MilesNo ratings yet

- Concepts of Stress and Strain: Group 1Document11 pagesConcepts of Stress and Strain: Group 1John Kris San LuisNo ratings yet

- 19-25 Mechanical Properties of MaterialsDocument7 pages19-25 Mechanical Properties of MaterialsChamalNo ratings yet

- ElasticityDocument8 pagesElasticityGuru GuroNo ratings yet

- Objective: Experiment 4: Mechanical Testing - Tensile and Torsional TestingDocument7 pagesObjective: Experiment 4: Mechanical Testing - Tensile and Torsional TestingTommy MilesNo ratings yet

- Lesson No. 2 in Machine Design 1Document19 pagesLesson No. 2 in Machine Design 1Carl JavierNo ratings yet

- lmcm2 Aula4Document26 pageslmcm2 Aula4Daryll Escusa100% (1)

- 2009 RAMS Warranty Prediction Random StressesDocument7 pages2009 RAMS Warranty Prediction Random StresseskasavisutanNo ratings yet

- Chapter 3 Mechanical PropertiesDocument41 pagesChapter 3 Mechanical PropertiesMai Huong Bui ThiNo ratings yet

- Full Report Solid MechDocument19 pagesFull Report Solid MechMUHAMMAD ARIFF DYAMIMNo ratings yet

- Module #1: States of Stress and StrainDocument62 pagesModule #1: States of Stress and Strainkamel touilebNo ratings yet

- Chap 3aDocument88 pagesChap 3ajingning2929No ratings yet

- Solid MechanicsDocument14 pagesSolid MechanicsArghya ModakNo ratings yet

- Lecture 3 - Mechanical, Electrical Thermal PropertiesDocument88 pagesLecture 3 - Mechanical, Electrical Thermal PropertiesHafizatul AqmarNo ratings yet

- Manufacturing Processes: Mechanical Properties of MaterialsDocument41 pagesManufacturing Processes: Mechanical Properties of MaterialsMohammed JehadNo ratings yet

- Billaudeau 2004Document10 pagesBillaudeau 2004Majed NesrineNo ratings yet

- L3 - Mechanical Properties of Structural Materials (Tension and Compression Tests)Document44 pagesL3 - Mechanical Properties of Structural Materials (Tension and Compression Tests)محمد المطيريNo ratings yet

- Tensile Test LabDocument4 pagesTensile Test LabputrosigarhidayatNo ratings yet

- Iso 377-1997Document5 pagesIso 377-1997Chan UeiNianNo ratings yet

- Material Engineering Lecture 2Document9 pagesMaterial Engineering Lecture 2Mohannad OrabiNo ratings yet

- Simple: StrainDocument41 pagesSimple: Strainstephaniejeancortez522No ratings yet

- Materials and Metallurgy (ME-209) Week 1 - Lecture 2 Mechanical Properties of MaterialsDocument28 pagesMaterials and Metallurgy (ME-209) Week 1 - Lecture 2 Mechanical Properties of MaterialsFahad afzalNo ratings yet

- CIVE.3110 LN01 TensileTest Fundamentals CompressedDocument45 pagesCIVE.3110 LN01 TensileTest Fundamentals CompressedMetal deptNo ratings yet

- Chapter6 MechanicalpropertiesDocument58 pagesChapter6 Mechanicalpropertiesrisaulfa622No ratings yet

- CHAPTER 7 - Mechanical Properties of Metals and AlloysDocument98 pagesCHAPTER 7 - Mechanical Properties of Metals and AlloysAlex HunterNo ratings yet

- 1.1 Direct or Normal StressDocument38 pages1.1 Direct or Normal StressMahmudul Hasan TanvirNo ratings yet

- Three Point Bending Test PDFDocument5 pagesThree Point Bending Test PDFAlif HaidarNo ratings yet

- Mechanical Properties of Materials PDFDocument126 pagesMechanical Properties of Materials PDFNazario Emil LintagNo ratings yet

- Module 1 PDFDocument39 pagesModule 1 PDFPrakhar TiwariNo ratings yet

- LESSON NO. 1 in Machine Design 1Document9 pagesLESSON NO. 1 in Machine Design 1Carl JavierNo ratings yet

- Stress Concentration and FatigueDocument22 pagesStress Concentration and FatiguelosoceNo ratings yet

- Design Guide For Floor VibrationsDocument56 pagesDesign Guide For Floor VibrationsText RangerNo ratings yet

- Unit 2Document138 pagesUnit 2Abhishek ChavanNo ratings yet

- Stress..strain in Thick PlatesDocument63 pagesStress..strain in Thick PlatesHitesh MudgilNo ratings yet

- L4 - Design Against Fluctucaing LoadsDocument26 pagesL4 - Design Against Fluctucaing LoadsDhyan PatelNo ratings yet

- Tensile Strength of Mild SteelDocument11 pagesTensile Strength of Mild SteelPavan Ps50% (2)

- 04-Đã G PDocument47 pages04-Đã G PNguyễn Nam AnhNo ratings yet

- Addis Ababa Institute of Technology: School of Mechanical and Industrial Engineering Materials Science and EngineeringDocument40 pagesAddis Ababa Institute of Technology: School of Mechanical and Industrial Engineering Materials Science and EngineeringColorgold BirlieNo ratings yet

- Manufacturing Processes Ch.3-ModifiedDocument41 pagesManufacturing Processes Ch.3-ModifiedHani BanatNo ratings yet

- Materials OneNotesDocument93 pagesMaterials OneNotes200130111057No ratings yet

- 0702metz PDFDocument3 pages0702metz PDFNguyen ThangNo ratings yet

- Chapter 17 - FatigueDocument26 pagesChapter 17 - FatigueSumit BabbarNo ratings yet

- Module 1 Stress and StrainDocument62 pagesModule 1 Stress and StrainDurgadevi ParamasivamNo ratings yet

- Experiment 4: Steel Tensile Test Theory: A. Stress-Strain RelationshipDocument3 pagesExperiment 4: Steel Tensile Test Theory: A. Stress-Strain RelationshipSabri SalihinNo ratings yet

- Lecture 2Document88 pagesLecture 2Hizb UllahNo ratings yet

- R.C. Design: Eng /mohammed Daloob 01114842584Document11 pagesR.C. Design: Eng /mohammed Daloob 01114842584Ehab MuhammedNo ratings yet

- Experiment No. - 1: Material Testing Lab (MOM Lab) 1of 4 PagesDocument4 pagesExperiment No. - 1: Material Testing Lab (MOM Lab) 1of 4 PagesKirtismita TalukdarNo ratings yet

- Short NotesDocument170 pagesShort NoteskiranNo ratings yet