Professional Documents

Culture Documents

Design of A Parallel Tube Heat Exchanger

Design of A Parallel Tube Heat Exchanger

Uploaded by

Moiz SubhanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design of A Parallel Tube Heat Exchanger

Design of A Parallel Tube Heat Exchanger

Uploaded by

Moiz SubhanCopyright:

Available Formats

Lecture 20

ChE 333 1

Design of a Parallel Tube Heat Exchanger

The Exchanger

100F

Water: 70F

5 ft/s

Benzene

180 F

7500 lb/h

The Design Equation for a Heat Exchanger

Q

H

= UA

T

2

T

1

ln

T

2

T

1

= UAT

lm

Problem

Find the Required Length of a Heat Exchanger with Specified Flows:

Turbulent Flow in Both Streams

The design constraints are given in the schematic above. We show this as

a countercurrent configuration, but we will examine the cocurrent case as

well. The benzene flow is specified as a mass flow rate (in pound mass

units), and the water flow is given as a linear velocity. Heat transfer

coefficients are not provided; we will have to calculate them based on our

earlier discussions and the correlations presented in earlier lectures.

The inside tube is specified as "Schedule 401-14 inch steel."

Lecture 20

ChE 333 2

Pipe "schedules" are simply agreed-upon standards for pipe construction

that specify the wall thickness of the pipe. Perrys Handbook specifies the

following dimensions for

the inside pipe :

Schedule 40 1 1/4 pipe

D

o

= 1.66 in. = 0.138 ft. S

c

= D

2

/4 = 0.0104 ft

2

D

i

= 1.38 in = 0.115 ft. (cross-sectional area for flow)

the outside pipe :

Schedule 40 2 pipe

D

i

= 2.07 in = 0.115 ft.

To calculate the heat exchanger area, we must find A

o

= DL. We know

the diameter; what is the length ?

The Design Equation is

Q

h

= U

o

A

o

T

ln

The overall heat transfer coefficient, U

o

, is given by

U

o

=

1

r

o

1

r

o

h

o

+

ln r

o

/ r

i

k

+

1

r

ihi

1

We can write it as:

U

o

A

o

L

=

1

h

o

A

o / L

+

ln r

o

/ r

i

2k

+

1

h

i

A

i

/ L

1

= R

1

To evaluate the parameters of the problem, we need the physical and

thermal properties and conditions for flow in the system

T

b

= 140F

b

= 52.3 lb

m

/ft

3 C

p

= 0.45 BTU/lb-F

k

b

= 0.085 Btu / h ft F

Pr =

C

pb

k

b

= 5

b

= 0.39 cP =

0.39

1000

1

47.88

= 8.1 x 10

6

lb

f

s / ft

2

= 2.6 X 10

4

lb

m

/fts

Lecture 20

ChE 333 3

Internal Film Resistance

The Nusselt number on the inside of the inner pipe is given by the Dittus-

Boelter equation.

Nu =

h

i

D

i

k

b

= 0.023 Re

0.8

Pr

0.3

= 337

so that the film heat transfer coefficient

h

i

= 249 Btu/hft

2

F

The heat transfer area per unit length is

A

i

L

= (0.115) = 0.361 ft

2

/ft

so that the inner film resistance is :

h

i

A

i

L

1

= 249 (0.361)

1

= 0.011 h ft F / Btu

The other tube dimensions are

D

oi

= 0.138 ft and D

io

= 0.172 ft

Calculation of the Water Flow Rate

The hydraulic diameter is

D

eq

= 4

D

2

i,o

D

o,i

2

/ 4

D

i,o

+ D

o,i

= D

i,o

D

o,i

= 0.034 ft

Given the water velocity of 5 ft/s, we can solve for the water flow rate

W

water

= 9300 lb

m

/h

The Overall Energy balance

(wC

p

T)

benz

= (wC

p

T)

water

Solving for the outlet water temperature:

7500 (0.45) (100 180) = 9300 (1) (70 T

out

)

gives the exit temperature as:

T

out

= 99F

Lecture 20

ChE 333 4

External Film Resistance

The physical properties of the water must be estimated in order to

determine the film heat transfer coefficient in the annular shell. The

average water temperature T

b

is calculated as 84.7 F

= 0.8 cp k = 0.34 BTU/h-ft-F = 62.4 lb/ft

3

so that the Reynolds number can be calculated.

Re

VD

eq

=

62.4 lb

m

/ft

3

32.2 lb

m

f/lb

f

s

2

(5 ft / s) 0.034 ft

1.67 x 10

5

lb

f

s / ft

2

= 2 x 10

4

From the Dittus-Boelter equation, the Nusselt number is given as:

Nu = 0.023 Re

0.8

Pr

0.4

= 127

so that the external film coefficient, h

o

, is

h

o

= 1270 Btu/hft

2

F

The external area/length is

A

0

L

= (0.138) = 0.434 ft

2

/ ft

so that the external film resistance is

h

0

A

0

L

1

= 1270 (0.434)

1

= 0.00181hftF / Btu

Conduction Resistance

The last term in the equation for the overall heat transfer coefficient is

ln r

0

/ r

i

2k

= 0.00116 h ft F / Btu

Overall Heat Transfer Coefficient

The overall resistance is

(U)

1

= R = 0.011 + 0.00116 + 0.00181 + = 0.014

benzene wall water

Lecture 20

ChE 333 5

Log-Mean T

T

ln

=

(180 99) (100 70)

ln (81 / 30)

= 51F

Heat Load

Q

h

= wC

p

T

= 7500 (0.45) (180 - 100) = 2.7 x 10

5

Btu/h

Heating Rate/unit Length

Q

h

L

=

UA

L

T

ln

= (R)

1

T

ln

= 3640 Btu / h ft

Given the heat load, we can calculate the length of tubing so that

L =

Q

h

3640

=

2.7 x 10

5

3640

= 74 ft

The case we considered was countercurrent flow, but we noted in an

earlier example that in co-current flow we could be more fluid. Now is the

pipe longer or shorter ?

Lecture 20

ChE 333 6

A Co-current Flow Heat Exchanger

The Design Equation for a Heat Exchanger

Q

H

= UA

T

2

T

1

ln

T

2

T

1

= UAT

lm

The heat loads are identical, the Overall Resistances to heat transfer (UA)

-1

are no different since the film coefficients do not change, but the T

lm

are

different.

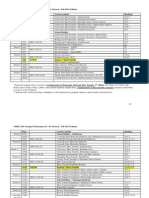

Counter current Co-current

T

1

(water) = 99 T

1

(water) = 70

T

1

(benzene) = 180 T

1

(benzene) = 180

T

2

(water) = 70 T

2

(water) = 99

T

2

(benzene) = 100 T

2

(benzene) = 100

T

1

= 81 T

1

= 110

T

2

= 30 T

2

= 1

T

ln

= 51 T

ln

= 23.2

L = 74 L = 163 ft

There are two observations to be made. First that the tube length required

for co-current flow is more than twice as long. Secondly that the approach

temperature for co-current flow becomes diminishingly small.

Lecture 20

ChE 333 7

Questions

Question 1.

To have a single concentric pipe heat exchanger 73 ft. long may be

impractical. Why ?

Question 2.

What are the alternatives and can you make a rapid evaluation of the their

requirements ?

Question 3.

What if we use more tubes, do I need more area ? How do I estimate the

number of tubes and the required area for a single pass heat exchanger.

Question 4.

If we use more tubes, should we specify the tubes to be smaller. Why?

How do we estimate the effect ?

Lecture 20

ChE 333 8

Question 1.

To have a single concentric pipe heat exchanger 73 ft. long may be

impractical. Why ?

Where do I put a 73 ft. piece of pipe ? Can I fold it up? Can I cut it into

shoter pieces and have them in parallel. ?

Question 2.

What are the alternatives and can you make a rapid evaluation of the their

requirements ?

One alternative is to cut the pipe into 12 equal length, place them in a

header and put a shell around the bundle of tubes.

Question 3.

If we use more tubes, do I need more area ? How do I estimate the number

of tubes and the required area for a single pass heat exchanger.

If we use N identical tubes, Re

new

= Re

old

/N since

Re =

UD

=

Q

4D

From the Dittus-Boelter equation we have

Nu = 0.023 Re

0.8

Pr

0.4

= 127

The internal film heat tarnsfer coefficient h

i

~ Q

If the new flow rate is Q/N then h

i

~ (1/ N

new

)

0.8

So that for 12 identical tubes h

inew

= 0.137 h

iold

The overall resistance is now

R = 0.011/(0.137) + 0.00181 + 0.00116 = 0.0833

The required length is L

new

/L

old

= R

new

/ R

old

/ = 0.0833/0.014 = 5.95

so that L

new

is 73(5.95) = 434.2 ft.

Lecture 20

ChE 333 9

Question 4.

If we use more tubes, should we specify the tubes to be smaller. Why?

How do we estimate the effect ?

When we introduced the use of multiple tubes, we decreased the Re to

significantly reduce the internal film resistance. We can then use similar

arguments in decreasing the tube diameter, but we have the following

consequences

1. we reduce the area/length for heat transfer.

2. we increase the Reynolds number and the heat transfer coefficient

3. we increase the pressure drop

4. we make it harder to clean

How do we do evaluate the trade-offs ?

You might also like

- Asme - Shell External Pressure REV ADocument1 pageAsme - Shell External Pressure REV APohn Myint HanNo ratings yet

- Studding Outlet Calculation - PV Elite 2016Document8 pagesStudding Outlet Calculation - PV Elite 2016Liu YangtzeNo ratings yet

- COE10402, Specifying Corrosion Inhibitor ProgramsDocument55 pagesCOE10402, Specifying Corrosion Inhibitor Programsامين100% (4)

- Thk. S.F. K.R.: Dish - Dish 2100Document3 pagesThk. S.F. K.R.: Dish - Dish 2100jayvant jadhavarNo ratings yet

- Design of Tooth Locked Quick Open Die Pressure VesselDocument4 pagesDesign of Tooth Locked Quick Open Die Pressure VesselSEP-PublisherNo ratings yet

- Where, The Temperature Ratio, Capacity Ratio, R A Value of 0.8 Is Generally Not AcceptedDocument43 pagesWhere, The Temperature Ratio, Capacity Ratio, R A Value of 0.8 Is Generally Not AcceptedAditya DeokarNo ratings yet

- Elliptical Head DesignDocument1 pageElliptical Head Designrodriguez.gaytanNo ratings yet

- Girth Flange Load Calculation Using by FEA TechniquesDocument12 pagesGirth Flange Load Calculation Using by FEA TechniqueskingstonNo ratings yet

- Chibro Press Fit Piping Data SheetDocument5 pagesChibro Press Fit Piping Data SheetBoyd Johnston100% (1)

- The Basics of Mechanics of SolidsDocument16 pagesThe Basics of Mechanics of SolidsDipankar borahNo ratings yet

- Lanthides EmissionDocument33 pagesLanthides EmissionashNo ratings yet

- Nozzle FEA CalculationDocument64 pagesNozzle FEA CalculationberylqzNo ratings yet

- Mean Metal TempsDocument1 pageMean Metal TempsThiruppathi RajanNo ratings yet

- Code Case 2901 Nozzle S1 SL No Description Unit Value: Provided Nozzle Flange Is Safe For External LoadingsDocument1 pageCode Case 2901 Nozzle S1 SL No Description Unit Value: Provided Nozzle Flange Is Safe For External LoadingsguravdrNo ratings yet

- Piping Stress AnalysisDocument24 pagesPiping Stress AnalysispratikkapseNo ratings yet

- Process Equipment DesignDocument29 pagesProcess Equipment Designt_prithvi0% (1)

- Section VIII CalDocument22 pagesSection VIII CalthodathersNo ratings yet

- Deaera DesignDocument13 pagesDeaera DesignBhanu K PrakashNo ratings yet

- Heat Exchanger Specification Sheet US Units: 47,5 InchDocument1 pageHeat Exchanger Specification Sheet US Units: 47,5 InchGreisly MarrugoNo ratings yet

- A House Built On A Riverside...Document8 pagesA House Built On A Riverside...ErsanİmamoğullarıNo ratings yet

- Double Pipe HXDocument67 pagesDouble Pipe HXKendin Yap Fikirleri Diy0% (1)

- Double FdexchangerDocument8 pagesDouble FdexchangerBoško IvanovićNo ratings yet

- Half Pipe CalculationDocument3 pagesHalf Pipe CalculationdhavaleshNo ratings yet

- Tubular Heat Exchanger Rating Sheet: Start o 2 o o 3 2 o 2 oDocument1 pageTubular Heat Exchanger Rating Sheet: Start o 2 o o 3 2 o 2 oSIVANo ratings yet

- Design of Heat ExchangersDocument23 pagesDesign of Heat ExchangersKhalid Turki100% (2)

- EhemDocument9 pagesEhemAaron RoyNo ratings yet

- Internal CoilDocument2 pagesInternal CoilwhngomjNo ratings yet

- TUBESHEETDocument5 pagesTUBESHEETMehta MehulNo ratings yet

- Screw Conveyor Size 350, Input Data SR No Description Metric Unit in Fts SrnoDocument2 pagesScrew Conveyor Size 350, Input Data SR No Description Metric Unit in Fts SrnoTheodoros AtheridisNo ratings yet

- Output Data: Design CaseDocument3 pagesOutput Data: Design CaseAnonymous RytT6uvX1No ratings yet

- Chapter 7: Calculations: A Design of A 2 Pass Dry Back Steam Boiler A-Data GivenDocument6 pagesChapter 7: Calculations: A Design of A 2 Pass Dry Back Steam Boiler A-Data GivenWael Abdel-MageedNo ratings yet

- Air Heaters ChokingDocument2 pagesAir Heaters Chokingsirsa11100% (1)

- James Walker Metaflex SGIR - SPG Revision 0 (2009!05!11)Document1 pageJames Walker Metaflex SGIR - SPG Revision 0 (2009!05!11)Dieter BuysseNo ratings yet

- Hysys Tutorials RevisedDocument33 pagesHysys Tutorials RevisedAkhi Sofi100% (2)

- Heat Exchanger Design Aircooled V7.1: File: Untitled - Edr Date: 8/15/2011 Time: 12:00:35 PMDocument26 pagesHeat Exchanger Design Aircooled V7.1: File: Untitled - Edr Date: 8/15/2011 Time: 12:00:35 PMEhsan MoemeniNo ratings yet

- Ligament Efficiency and Thickness of The Support PlateDocument10 pagesLigament Efficiency and Thickness of The Support PlatePankajDhobleNo ratings yet

- 400 KPH Boiler IBR Design Calculations - R1-6-2-13Document8 pages400 KPH Boiler IBR Design Calculations - R1-6-2-13Vishal KandNo ratings yet

- First U.K. National Conference on Heat Transfer: The Institution of Chemical Engineers Symposium Series, Volume 1.86From EverandFirst U.K. National Conference on Heat Transfer: The Institution of Chemical Engineers Symposium Series, Volume 1.86No ratings yet

- Background To Design Rules - Issue of EN13445 EN1591 Part PDFDocument19 pagesBackground To Design Rules - Issue of EN13445 EN1591 Part PDFBenoit LabreNo ratings yet

- Nozzle Load Check As Per TEMADocument2 pagesNozzle Load Check As Per TEMAvm153748763No ratings yet

- Fan Noise EstimateDocument5 pagesFan Noise EstimateBen ClackNo ratings yet

- Pressure Vessels: Choice of The Vessels Depending OnDocument45 pagesPressure Vessels: Choice of The Vessels Depending OnAmol RastogiNo ratings yet

- Ejemplo Tubesheet Asme UHXDocument14 pagesEjemplo Tubesheet Asme UHXPedro Montes MarinNo ratings yet

- Elliptical Head Design ToolDocument1 pageElliptical Head Design ToolssierroNo ratings yet

- Final Energy Balance-Vizag DT 9-6-18Document6 pagesFinal Energy Balance-Vizag DT 9-6-18SUBHOMOYNo ratings yet

- Trunnion 6 TonDocument3 pagesTrunnion 6 TonEngr Khurram Jaan RamayNo ratings yet

- BS 5500 Appendix K and DDocument14 pagesBS 5500 Appendix K and DCRISTIAN SILVIU IANUCNo ratings yet

- ASTM A53 Vs A500 EquivalenceDocument6 pagesASTM A53 Vs A500 Equivalenceemmanuilmoulos6339No ratings yet

- Pillow-Plate Heat Exchangers: Fundamental CharacteristicsDocument13 pagesPillow-Plate Heat Exchangers: Fundamental CharacteristicsnityaNo ratings yet

- 300 - F&D Head Design Tool Ver E4.01Document1 page300 - F&D Head Design Tool Ver E4.01Mo ZeroNo ratings yet

- TANK Module Package: Sample PrintoutDocument20 pagesTANK Module Package: Sample PrintoutSIVANo ratings yet

- Horizontal KO Pot V1.2Document6 pagesHorizontal KO Pot V1.2hk168No ratings yet

- Welding Neck Flanges 1Document3 pagesWelding Neck Flanges 1bikkelbobNo ratings yet

- Pin StressesDocument5 pagesPin Stressesprajakt_pieNo ratings yet

- Burst DiscDocument6 pagesBurst DiscMa AlNo ratings yet

- Tank Design PDFDocument89 pagesTank Design PDFcecgootyNo ratings yet

- Matl Specn.: Matl Temp - in Deg.fDocument15 pagesMatl Specn.: Matl Temp - in Deg.fpandiangvNo ratings yet

- Heat Load Calculation-Rect-Tank-2019Document8 pagesHeat Load Calculation-Rect-Tank-2019Hasmukh DaveNo ratings yet

- Asme Viii Uhx Tubesheet CalcsDocument3 pagesAsme Viii Uhx Tubesheet CalcsjdfdfererNo ratings yet

- Jacketed Reactor Vessel PDFDocument1 pageJacketed Reactor Vessel PDFSH1961No ratings yet

- Air Ingress CalculationsDocument5 pagesAir Ingress CalculationsMallinatha PNNo ratings yet

- Worked Problems Heat ExchangersDocument18 pagesWorked Problems Heat Exchangers521 Balaji ONo ratings yet

- HW 11Document7 pagesHW 11Devendraa MuniandyNo ratings yet

- Heat Transfer ExampleDocument4 pagesHeat Transfer Examplekero_the_heroNo ratings yet

- EKC 216 Wk13 Chapter 10 - Heat Exchanger L1 2017.keyDocument52 pagesEKC 216 Wk13 Chapter 10 - Heat Exchanger L1 2017.keySyazwan WanNo ratings yet

- QRA Presentation 5Document1 pageQRA Presentation 5Baha Eddine GharbiNo ratings yet

- QRA Presentation 3Document1 pageQRA Presentation 3Baha Eddine GharbiNo ratings yet

- Relationship Between Frequency and The Number of People Suffering From A Specified Level of Harm From The Realisation of Specific HazardsDocument1 pageRelationship Between Frequency and The Number of People Suffering From A Specified Level of Harm From The Realisation of Specific HazardsBaha Eddine GharbiNo ratings yet

- QRA Presentation 1Document1 pageQRA Presentation 1Baha Eddine GharbiNo ratings yet

- QRA Presentation 1Document1 pageQRA Presentation 1Baha Eddine GharbiNo ratings yet

- QRA Presentation 3Document1 pageQRA Presentation 3Baha Eddine GharbiNo ratings yet

- MR For Check Valves MR For Globe Valves MR For Ball Valves MR For Ball Valves MR For Globe Valves MR For Check Valves MR For Ball ValvesDocument1 pageMR For Check Valves MR For Globe Valves MR For Ball Valves MR For Ball Valves MR For Globe Valves MR For Check Valves MR For Ball ValvesBaha Eddine GharbiNo ratings yet

- Centifugal Compressor TDS API 617Document1 pageCentifugal Compressor TDS API 617Baha Eddine GharbiNo ratings yet

- Astm STDDocument2 pagesAstm STDBaha Eddine GharbiNo ratings yet

- Gas Composition - Centrifugal Compressor TDS API 617Document2 pagesGas Composition - Centrifugal Compressor TDS API 617Baha Eddine GharbiNo ratings yet

- Carbon Steel Piping SizesDocument10 pagesCarbon Steel Piping SizesBaha Eddine GharbiNo ratings yet

- Syllabus ChBE 3210 Fall 2011Document2 pagesSyllabus ChBE 3210 Fall 2011Erik RenzNo ratings yet

- ThermodynamicsDocument5 pagesThermodynamicsNaimish DetrojaNo ratings yet

- DPP FluidDocument23 pagesDPP FluidAditya SinhaNo ratings yet

- UV Visible SpectrosDocument21 pagesUV Visible SpectrosShar anilNo ratings yet

- Em Adv1Document16 pagesEm Adv1ricodavidNo ratings yet

- Recent Applications of Kirkwood-Buff Theory To Biological SystemsDocument22 pagesRecent Applications of Kirkwood-Buff Theory To Biological SystemsanshuNo ratings yet

- Assignment 2 Pool PDFDocument2 pagesAssignment 2 Pool PDFSambhav JainNo ratings yet

- ChE-1107 Answer Key Midterms Part 1Document4 pagesChE-1107 Answer Key Midterms Part 1Kim Dowell PanganibanNo ratings yet

- Flow Diagram CS230Document2 pagesFlow Diagram CS230Ricardo CarbajalNo ratings yet

- Motivation Experimental: Organic Ink Formulation and Photonic-Based ProbeDocument1 pageMotivation Experimental: Organic Ink Formulation and Photonic-Based ProbejohanNo ratings yet

- The Solubility Product of PBCL From Electrochemical MeasurementsDocument2 pagesThe Solubility Product of PBCL From Electrochemical MeasurementsAitor PastorNo ratings yet

- Plant Physiology Lab 1Document11 pagesPlant Physiology Lab 1khushbakht zamirNo ratings yet

- Ancamine 2726 TdsDocument1 pageAncamine 2726 Tdsnc5r8fkp6zNo ratings yet

- New Approach For Developing Epoxy-Amine Adductcurative With Modified Epoxy ResinsDocument13 pagesNew Approach For Developing Epoxy-Amine Adductcurative With Modified Epoxy Resinsvipin1222No ratings yet

- Ideal Gas: General Chemistry 1Document9 pagesIdeal Gas: General Chemistry 1Daniel Corcino100% (1)

- 16th JCC Conference ProgrammeDocument19 pages16th JCC Conference ProgrammeanisNo ratings yet

- Green Synthesis of Calcium Oxide Nanoparticles Using Murraya Koenigii Leaf (Curry Leaves) Extract For Photo-Degradation of Methyl Red and Methyl BlueDocument6 pagesGreen Synthesis of Calcium Oxide Nanoparticles Using Murraya Koenigii Leaf (Curry Leaves) Extract For Photo-Degradation of Methyl Red and Methyl BlueInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- CHM013 - Module 4 - Chemical BondDocument48 pagesCHM013 - Module 4 - Chemical BondMel Arthor QueditNo ratings yet

- Methods and Conclusion 2Document2 pagesMethods and Conclusion 2Mateo PremarionNo ratings yet

- ICSE Class 10 Chemistry Previous Year Question Paper 2015Document7 pagesICSE Class 10 Chemistry Previous Year Question Paper 2015Study in an easy wayNo ratings yet

- Thermoelectric Properties of R Doped CaMnO3 (R ND, PR, SM) For High Temprature PropertiesDocument6 pagesThermoelectric Properties of R Doped CaMnO3 (R ND, PR, SM) For High Temprature PropertiesAryan BhardwajNo ratings yet

- Hau Tier 2011Document14 pagesHau Tier 2011imaneabdelrhaforNo ratings yet

- Alkali Metals NotesDocument23 pagesAlkali Metals Notesaayush basnetNo ratings yet

- Thermal Equilibrium of The Atmosphere With A Given Distribution of Relative HumidityDocument19 pagesThermal Equilibrium of The Atmosphere With A Given Distribution of Relative HumidityImerson FernandoNo ratings yet

- RAVI AGARWAL (M.SC.) - 9913650950 / 9374727052Document2 pagesRAVI AGARWAL (M.SC.) - 9913650950 / 9374727052Archana AgarwalNo ratings yet