Professional Documents

Culture Documents

DV09PUB2 Study Guide

Uploaded by

AmirAmiri0 ratings0% found this document useful (0 votes)

22 views5 pagessme

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentsme

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

22 views5 pagesDV09PUB2 Study Guide

Uploaded by

AmirAmirisme

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 5

Milling & Machining Centers

Fundamental Manufacturing Processes Study Guide, DV09PUB2 - 1 -

Training Objective

After watching the program and reviewing this printed material, the viewer will gain knowledge and

understanding of basic milling theories and procedures. In addition, the viewer will become aware of the use

of CNC technology and the features and functions of machining centers.

the basic vertical knee mill machine is examined

the parameters for successful metal removal are defined

the application of CNC technology to milling is explained

machining center features and functions are highlighted

various cutting tools, workholding, and work-changing devices are detailed

The Milling Process

Milling is the most versatile of machining processes. Metal removal is accomplished through the relative

motions of a rotating, multi-edge cutter and multi-axis movement of the workpiece. Milling is a form of

interrupted cutting where repeated cycles of entry and exit motions of the cutting tool accomplish the actual

metal removal and discontinuous chip generation. Milling has more variations in machine types, tooling, and

workpiece movement than any other machining method.

All milling machines, from compact tabletop models to the standard vertical knee mill and the massive CNC

machining centers, operate on the same principles and operating parameters. The most important of these

operating parameters are:

cutting speed, which is the speed at which the tool engages the work

feed rate, which is the distance the tool edge travels in one cutter revolution

the axial depth of cut, which is the distance the tool is set below an unmachined surface

the radial depth of cut, which is the amount of work surface engaged by the tool

The capabilities of the milling machine are measured by motor horsepower, maximum spindle speeds and

spindle taper size.

Milling Machine Basics

The most basic milling machine is the vertical spindle, ram-type knee mill. Though not well adapted to

production milling, it is ideal for toolmaking and prototype machining. Knee mills are primarily used for

manual operations, but their capabilities can be expanded.

The knee travels vertically, up and down the column, and supports the saddle and table. The saddle moves

in and out from the column, while the table moves side to side of the column. Additionally, the ram, at the top

of the column, supports the milling head which contains the motor, toolhead, speed and feed controls, quill

and spindle. The non-rotating quill holds the rotating spindle. The ram can be moved both in and out from the

column and can be tilted for angular milling and drilling.

Cutting tools are secured in collets or drill chucks held in the spindle. Work is usually secured to the table

using bolts and clamps, or by using vises or fixtures bolted to the table. The work table contains longitudinal

T slots to facilitate the attachment of these devices.

The knee mills capabilities are expanded by the use of digital readout displays and CNC technology. CNC

technology provides three-axis capability to the mill.

Milling & Machining Centers

Fundamental Manufacturing Processes Study Guide, DV09PUB2 - 2 -

CNC Machining Centers

Manual mills require that the operator/machinist set all the required parameters, change tools, and manually

direct all table movement. However, with CNC capability, work is performed much faster, with exceptional

repeatability. In addition, CNC computer programs can be verified and completed graphically before actual

metalcutting begins.

A machining center is a machine for both milling and holemaking on a variety of non-round or prismatic

shapes. The primary types of machining centers are either vertical or horizontal. The vertical type is often

preferred when work is done on a single face. With the use of rotary tables, more than one side of a

workpiece, or several workpieces, can be machined without operator intervention. Vertical machining centers

using a rotary table have four axes of motion. Three are lineal motions of the table while the fourth is the

tables rotary axis.

Horizontal centers with their horizontal spindles are better suited to larger, boxy workpieces. With a

horizontal spindle, a wider variety of workpiece shapes are easier to mount and chips fall out of the way

better. Like vertical machining centers, horizontal centers have multiple-axis table movements. Typically, the

horizontal centers table rotates to present all four sides of a workpiece to the tooling.

Toolchangers & Cutting Tools

The unique feature of the machining center is the tool changer. The tool-changer system moves tools from

storage to spindle and back again in rapid sequence. While most machining centers will store and handle 20

to 40 individual tools, some will have inventories of over 200.

In general, a milling cutter is a rotary tool with one or more cutting edges, each of which removes a small

amount of material as it contacts the workpiece. The variety of cutter types is almost limitless. One of the

more basic is the face mill cutter used for milling flat surfaces. Used at high speeds, face mill cutters range

from a few centimeters to over a half-meter in diameter. Some face mills will simultaneously mill a shoulder

that is square to the surface.

Work that requires edge preparation, shoulders, and grooves, is accomplished with other milling cutters. An

end mill cutter is a tool with cutting edges on its end as well as on its periphery. End mills are used for short,

shallow slots and some edge finishing. Circular grooving or slotting cutters are more adapted to the making

of longer and deeper slots. This is because end mills are susceptible to deflection during heavier cuts.

Chamfers and contour milling are performed with specially shaped end mills.

Cutting tools are chosen not only for their geometries; they are also chosen for their material properties.

More than ever, tougher cutter materials are available that extend tool life and allow faster cutting of tougher,

harder workpiece materials. Standard or coated carbide tools work well in most cutting situations. However,

cubic boron nitride, or CBN, tool inserts may be needed for cutting hardened materials. Additionally, tools

with polycrystalline diamond, or PCD, surfaces may be needed for cutting difficult-to-machine nonferrous

alloys, such as nickel superalloys. The higher costs of these cutting tools must be weighed against their

improvements in speed and tool life.

Milling & Machining Centers

Fundamental Manufacturing Processes Study Guide, DV09PUB2 - 3 -

Workholding & Workchanging

In all kinds of milling, a critical component is the workholding device and the ability to be changed over

quickly to present new work or work surfaces to the tooling. Machining centers can utilize long machine

beds, pallet changers and multi-sided tombstone fixtures to enable new work to be set up and positioned

while previously setup workpieces are being milled.

Machining Center Accessories & Programming

Machining centers can incorporate two very useful accessories. One is the touch-trigger probe which, with its

computer software, will dimensionally check workpiece measurements before removal from the machining

center. The probe is stored with other tooling for quick application. The second accessory is the tool

presetting machine, which allows the technician to assemble the tooling according to the programmed part

requirements before placing tools in the machining centers tool storage.

The choice of toolholder itself can be critical. Chucks, collets and other mechanical-interference toolholders

use applied clamping pressure to set tools for common milling situations. In recent years, shrink-fit

toolholders have become more popular, especially for high-speed machining operations. Here, the toolholder

develops uniform clamping pressure as it contracts around the tool shank, after first being heated and

expanded. Shrink-fit systems require extra equipment, but the cost may be justified by the higher cutting

speeds and feeds that they allow.

The programming and control software for CNC machining centers has become increasingly sophisticated

and easier to use. Programming has also made milling more accurate, allowing higher productivity and better

surface quality on parts. Software can allow a machine tool to learn how to correct for process variations in

its actual tool path, in comparison with its desired programmed path. Other programs suppress machining

vibrations, improving the surface finish of parts.

Simulation programs also can be used to optimize a process by predicting what the cycle time of a

programmed tool path will be before milling begins.

Milling & Machining Centers

Fundamental Manufacturing Processes Study Guide, DV09PUB2 - 4 -

Review Questions

1. In milling, stock removal is accomplished by:

a. repeated cycles of entry and exit motions of the cutting tool

b. continuous chip generation

c. the combination of speed and tool contact pressure

d. continuous cutting tool contact with the work

2. Feed rate is described as:

a. the down pressure by the spindle

b. the travel speed of the work past the cutter

c. the distance the tool edge travels in one cutter revolution

d. the rotational speed of the spindle and cutting tool

3. The vertical spindle, ram-type knee mill is usually:

a. manually operated

b. capable of horizontal conversion

c. CNC controlled

d. used for high production

4. The singularly unique feature found on a machining center is the:

a. spindle arrangement

b. table movement

c. number of possible axes

d. the tool-changer

5. Horizontal machining centers are useful for work that is:

a. small and round

b. long and thin

c. short and thick

d. large and boxy

6. Face mill cutting tools can have diameters ranging from:

a. 3 centimeters to 12 centimeters

b. a few centimeters to over one meter

c. 10 centimeters to 30 centimeters

d. a few centimeters to over a half-meter

7. End mills do not produce accurate slots in heavier cuts due to:

a. problems with lubrication

b. tool chipping

c. deflection

d. limited feed rates

8. A machining center accessory used for checking part dimensions is called:

a. a tool presetting machine

b. a digital readout

c. a touch-trigger probe

d. a dial indicator

Milling & Machining Centers

Fundamental Manufacturing Processes Study Guide, DV09PUB2 - 5 -

Answer Key

1. a

2. c

3. a

4. d

5. d

6. d

7. c

8. c

You might also like

- Milling Machining Centers GuideDocument5 pagesMilling Machining Centers GuideJose JulianNo ratings yet

- Milling Machining Centers GuideDocument5 pagesMilling Machining Centers GuideJose JulianNo ratings yet

- Milling Center Basics: CNC, Tools, ProcessesDocument5 pagesMilling Center Basics: CNC, Tools, ProcessesSelan MatlanNo ratings yet

- CNC MillingDocument8 pagesCNC MillingNashon MutuaNo ratings yet

- DV09PUB1 Study GuideDocument5 pagesDV09PUB1 Study Guidesbbu agraNo ratings yet

- Study of Operational Concepts Of: Conventional and CNC Machines - Lathe & MillingDocument38 pagesStudy of Operational Concepts Of: Conventional and CNC Machines - Lathe & MillingUpender DhullNo ratings yet

- CNC MilingDocument10 pagesCNC MilingAbdul HameedNo ratings yet

- Tool and Cutter GrinderDocument6 pagesTool and Cutter GrinderNav Srinath100% (1)

- Tools and Work Holding Devices of CNC MachinesDocument9 pagesTools and Work Holding Devices of CNC Machinessham javed100% (1)

- Imp Lab ManualDocument36 pagesImp Lab ManualAnas MuhammedNo ratings yet

- IMP Lab Manual - Autumn 2019Document48 pagesIMP Lab Manual - Autumn 2019ZANTHERNo ratings yet

- CAM Notes 1Document10 pagesCAM Notes 1FELIX KEUYANo ratings yet

- Uses of CNC Lathe MachineDocument3 pagesUses of CNC Lathe MachineKhairul IkhwanNo ratings yet

- CNC ManufacturingDocument9 pagesCNC ManufacturingJohn Philip Nadal IIINo ratings yet

- CNC Milling: Dr. Azhar Equbal Dept. of Mechanical EngineerngDocument13 pagesCNC Milling: Dr. Azhar Equbal Dept. of Mechanical EngineerngAzhar EqubalNo ratings yet

- Machine OperationDocument4 pagesMachine OperationMaster BomboNo ratings yet

- CAM Notes 2Document15 pagesCAM Notes 2FELIX KEUYANo ratings yet

- Knowledge of Conventional Techniques & CNCDocument27 pagesKnowledge of Conventional Techniques & CNCTool Room CIPET GHYNo ratings yet

- Report CNC MillingDocument16 pagesReport CNC Millingharislukman100% (5)

- CNC Machining Operations GuideDocument51 pagesCNC Machining Operations GuideEngr.shamiNo ratings yet

- MTM Lab PresentationDocument26 pagesMTM Lab PresentationMuhammad WaseemNo ratings yet

- Report Writing On Milling MachineDocument11 pagesReport Writing On Milling MachineSailesh Pathak100% (1)

- Practical 7Document2 pagesPractical 7AARSHNo ratings yet

- Turning and Lathe - Guia de Estudo - 2016Document10 pagesTurning and Lathe - Guia de Estudo - 2016Anderson R. RojasNo ratings yet

- Note CNC Lathe MachineDocument19 pagesNote CNC Lathe MachineSyafi NafisNo ratings yet

- Module 4 (Machine Shop) : Definition of MachiningDocument27 pagesModule 4 (Machine Shop) : Definition of MachiningHarshit Kumar100% (1)

- Basic Maching Process and Machine Tools Part 1Document47 pagesBasic Maching Process and Machine Tools Part 1prashrit sapkotaNo ratings yet

- Manufacturing Processes - III Manufacturing Processes - III: Outline of PresentationDocument54 pagesManufacturing Processes - III Manufacturing Processes - III: Outline of PresentationnagsenNo ratings yet

- Cutting Tool (Milling Machine) PerformanceDocument12 pagesCutting Tool (Milling Machine) PerformanceLashawn de MelNo ratings yet

- Department of Mechanical Engineering: SJB Institute of TechnologyDocument54 pagesDepartment of Mechanical Engineering: SJB Institute of TechnologyChidu KNo ratings yet

- Machine ToolDocument17 pagesMachine Toolbaziryz123No ratings yet

- Mold Machining Methods, Part 1Document22 pagesMold Machining Methods, Part 1Edenilson FadekNo ratings yet

- Computer Numerical Control: Summer Training Report' "IN" Ordnance Factory MuradnagarDocument12 pagesComputer Numerical Control: Summer Training Report' "IN" Ordnance Factory MuradnagarVishal RajoraNo ratings yet

- Chapter 1Document17 pagesChapter 1shubhanshuNo ratings yet

- Turning and Machining CentresDocument26 pagesTurning and Machining CentresBhado GagoNo ratings yet

- Introduction To SectionsDocument10 pagesIntroduction To Sectionssuresh100% (1)

- Milling MachineDocument20 pagesMilling MachineMohd Radzi Kaki Limo100% (1)

- Laboratory 6Document9 pagesLaboratory 6Andy BirdieNo ratings yet

- Richland CNC Turning BasicsDocument34 pagesRichland CNC Turning BasicsBADINEHALSANDEEPNo ratings yet

- Scott Fall2010 IT208 Chapter19Document79 pagesScott Fall2010 IT208 Chapter19feni4kaNo ratings yet

- Surendra Yadav SirDocument27 pagesSurendra Yadav SirNikhil Sai KammaNo ratings yet

- CNC Machine Tools GuideDocument6 pagesCNC Machine Tools GuideGM Business DevelopmentNo ratings yet

- Power Point PersentationDocument16 pagesPower Point PersentationMD AFSHANNo ratings yet

- 14.automatic Rotating Table With Sequence Operating MachineDocument2 pages14.automatic Rotating Table With Sequence Operating MachineChockalingam AthilingamNo ratings yet

- Module 1 - Machining Science and Jigs & Fixtures (21me42)Document70 pagesModule 1 - Machining Science and Jigs & Fixtures (21me42)Manoj NNo ratings yet

- Buckling AnalysisDocument9 pagesBuckling Analysischandravadiyaketan1504No ratings yet

- Milling ReportDocument5 pagesMilling ReportMuhammad Fadhli80% (5)

- 22 Use of Various Attachments in Machine Tools.Document19 pages22 Use of Various Attachments in Machine Tools.PRASAD326100% (5)

- Turning and Lathe Basics Training ObjectivesDocument8 pagesTurning and Lathe Basics Training ObjectivesSowjanya VenigallaNo ratings yet

- Machining: Machining Is Any of Various Processes in Which A Piece of RawDocument7 pagesMachining: Machining Is Any of Various Processes in Which A Piece of RawAshwin KumarNo ratings yet

- Workshop Technology: Lecture#5 By: Waleed AslamDocument41 pagesWorkshop Technology: Lecture#5 By: Waleed AslamMuhammad ZeerakNo ratings yet

- Cam RepotrtDocument12 pagesCam RepotrtAntony NjorogeNo ratings yet

- Internship Report EditedDocument28 pagesInternship Report EditedRohanRayNo ratings yet

- Lec - 9 - Milling-Gear Cutting-CNCDocument38 pagesLec - 9 - Milling-Gear Cutting-CNCsaxadi4814No ratings yet

- Turning vs Milling readingDocument6 pagesTurning vs Milling readingEnri JaénNo ratings yet

- Production Engineering: Jig and Tool DesignFrom EverandProduction Engineering: Jig and Tool DesignRating: 4 out of 5 stars4/5 (9)

- Turning and Boring A specialized treatise for machinists, students in the industrial and engineering schools, and apprentices, on turning and boring methods, etc.From EverandTurning and Boring A specialized treatise for machinists, students in the industrial and engineering schools, and apprentices, on turning and boring methods, etc.No ratings yet

- Traditional Toolmaking: The Classic Treatise on Lapping, Threading, Precision Measurements, and General ToolmakingFrom EverandTraditional Toolmaking: The Classic Treatise on Lapping, Threading, Precision Measurements, and General ToolmakingRating: 5 out of 5 stars5/5 (2)

- Grinding Overview: Machinist Grinder Interview Questions and AnswersFrom EverandGrinding Overview: Machinist Grinder Interview Questions and AnswersNo ratings yet

- Project Report FinalDocument52 pagesProject Report FinalAmirAmiri0% (1)

- Guidelines: Injection Mold DesignDocument4 pagesGuidelines: Injection Mold DesignAmirAmiriNo ratings yet

- Moldeadora PDFDocument12 pagesMoldeadora PDFAmirAmiriNo ratings yet

- 1320 HP Zr2440w MonitorDocument2 pages1320 HP Zr2440w MonitorAmirAmiriNo ratings yet

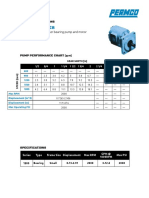

- Technical specifications and performance charts for 1500 series small displacement roller bearing pumpsDocument2 pagesTechnical specifications and performance charts for 1500 series small displacement roller bearing pumpsAmirAmiriNo ratings yet

- Fatigue Testing MachineDocument3 pagesFatigue Testing MachineAmirAmiriNo ratings yet

- D 004663 PDFDocument96 pagesD 004663 PDFAmirAmiriNo ratings yet

- Engineering Plastics..Document55 pagesEngineering Plastics..AmirAmiriNo ratings yet

- Aluminium Alloy 1100 Data SheetDocument1 pageAluminium Alloy 1100 Data SheetKhaja NawasNo ratings yet

- PDM PLMDocument7 pagesPDM PLMAmirAmiriNo ratings yet

- Forging 140519005802 Phpapp02Document38 pagesForging 140519005802 Phpapp02AmirAmiriNo ratings yet

- 1511 04990Document20 pages1511 04990AmirAmiriNo ratings yet

- Te TramerDocument8 pagesTe TramerAmirAmiriNo ratings yet

- Interface: Giving People A VoiceDocument3 pagesInterface: Giving People A VoiceAmirAmiriNo ratings yet

- Injection Moulding: CD Catalogue Online CatalogueDocument1 pageInjection Moulding: CD Catalogue Online CatalogueAmirAmiriNo ratings yet

- Ground Spur Gears Module 0.5 ISO Class 5 8mm Face 20Document2 pagesGround Spur Gears Module 0.5 ISO Class 5 8mm Face 20AmirAmiriNo ratings yet

- Injection Molding Lecture 09-04-08Document20 pagesInjection Molding Lecture 09-04-08viswaforuNo ratings yet

- Honeywell Ekoflush - Airco SpoelenDocument4 pagesHoneywell Ekoflush - Airco SpoelenAmirAmiriNo ratings yet

- Injection Moulding: CD Catalogue Online CatalogueDocument1 pageInjection Moulding: CD Catalogue Online CatalogueAmirAmiriNo ratings yet

- Eastman Polymers - Processing and Mold Design GuidelinesDocument44 pagesEastman Polymers - Processing and Mold Design GuidelinesnimonhNo ratings yet

- Dmls Design GuidelinesDocument8 pagesDmls Design GuidelinesAmirAmiriNo ratings yet

- Scoring Short Ipaq April04Document9 pagesScoring Short Ipaq April04AmirAmiriNo ratings yet

- Training Documents - SolidWorks ComposerDocument2 pagesTraining Documents - SolidWorks ComposerAmirAmiriNo ratings yet

- PrefDocument3 pagesPrefAmirAmiriNo ratings yet

- Plate Design For Husky Manifold SystemsDocument14 pagesPlate Design For Husky Manifold SystemsAmirAmiriNo ratings yet

- Injection MoldingDocument8 pagesInjection MoldingDebasmiti MishraNo ratings yet

- Appendix Nve: RsionsDocument7 pagesAppendix Nve: RsionsAmirAmiriNo ratings yet

- 522541Document8 pages522541AmirAmiriNo ratings yet

- Harmonic Motion of A Maxwell Model: Trigonometric NotationDocument4 pagesHarmonic Motion of A Maxwell Model: Trigonometric NotationAmirAmiriNo ratings yet

- Tool CRMDocument36 pagesTool CRMAmirAmiriNo ratings yet