Professional Documents

Culture Documents

ESSAY (100 Marks) : Pages 2 of 8

ESSAY (100 Marks) : Pages 2 of 8

Uploaded by

Kelvin Yip0 ratings0% found this document useful (0 votes)

5 views7 pagesjjkkkkkkkkk

Original Title

DEC_2011

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentjjkkkkkkkkk

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

5 views7 pagesESSAY (100 Marks) : Pages 2 of 8

ESSAY (100 Marks) : Pages 2 of 8

Uploaded by

Kelvin Yipjjkkkkkkkkk

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 7

Pages 2 of 8

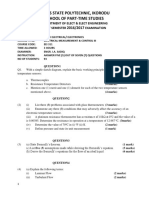

ESSAY (100 marks)

Instruction: This section consists of SIX (6) essay questions. Answer only FOUR (4)

questions.

QUESTION 1

(a) Give the definitions for quality and zero defect.

(3 marks)

(b) Inspection of products is important to ensure the products quality level.

State and elaborate TWO (2) types of products inspection.

(6 marks)

(c) In a manufacturing steel industry, steel rods are produced through the pultrusion

process. The average of steel rod diameter is 3.20 cm and standard deviation is

0.05 cm. The acceptance level is 3.200.06 cm. Based on this case, sketch and

label a normal curve.

(4 marks)

Calculate:

i. The percentage of rejected rods. (4 marks)

ii. The percentage of the rods reworked. (4 marks)

iii. The percentage of accepted rods. (4 marks)

Pages 3 of 8

QUESTION 2

(a) Define the following terms:

i. Control Charts for Variables (3 marks)

ii. Assignable causes variation (3 marks)

iii. Random variation (3 marks)

(b) Define process capability (Cp) and illustrate cases where process variability

exceeds specifications.

(4 marks)

(c) Table 1 shows some sampling data. By using the table,

i. Determine the mean and range (X and R). (4 marks)

ii. Determine the upper and lower control limit (UCL and LCL). (4 marks)

iii. Draw a control chart from the data. (4 marks)

TABLE 1

Sample

number

Observations (mm)

1 28.28 33.95 30.47 28.87

2 26.92 27.66 31.47 29.67

3 28.46 28.30 29.00 31.14

4 32.43 26.10 29.84 37.20

5 28.84 30.52 32.24 30.47

6 30.75 33.00 28.08 26.20

7 31.26 24.29 35.46 28.41

8 31.25 28.58 35.01 31.24

9 31.42 35.80 33.61 27.82

10 32.20 32.02 32.71 29.38

Pages 4 of 8

QUESTION 3

(a) Differentiate between defect and defective and briefly describe types of attributes

control charts related to each of them.

(10 marks)

(b) Define the word attributes by giving suitable examples.

(5 marks)

(c) Table 2 represents the observed number of defects from an inspection of 30

successive chocolate wafers, each containing 100 chips.

determine :

i. The average number of defects (c)

(4 marks)

ii. The upper and lower control limits ( UCL and LCL)

(6 marks)

TABLE 2

Number of

Chocolate Wafers

Number of defects Number of

Chocolate Wafers

Number of defects

1 19 16 16

2 17 17 14

3 14 18 28

4 16 19 16

5 15 20 12

6 13 21 20

7 14 22 10

8 16 23 12

9 11 24 10

10 20 25 17

11 15 26 10

12 13 27 12

13 10 28 13

14 15 29 18

15 16 30 11

Pages 5 of 8

QUESTION 4

(a) Give TWO (2) types of Control Chart.

(2 marks)

(b) Explain how to choose a control chart suitable for a specific data.

(4 marks)

(c) Table 3 is a data compilation of the length of steel bars.

TABLE 3

Date Time No. of Inspected Bars (mm) Mean Range

B1 B2 B3 B4

1/8/05

9.00

10.00

11.00

12.00

1.00

2.00

3.00

5.85

5.75

5.80

5.65

5.75

5.60

5.65

5.65

5.85

5.80

5.75

5.70

5.75

5.80

5.65

5.75

5.75

5.60

5.65

5.65

5.60

5.70

5.85

5.70

5.70

5.80

5.70

5.60

2/8/05

9.00

10.00

11.00

12.00

1.00

2.00

3.00

5.80

5.75

5.80

5.65

5.85

5.60

5.70

5.75

5.85

5.80

5.65

5.75

5.60

5.80

5.85

5.75

5.80

5.65

5.85

5.70

5.60

5.65

5.75

5.80

5.65

5.75

5.60

5.70

3/8/05

9.00

10.00

11.00

12.00

1.00

2.00

3.00

5.80

5.75

5.80

5.65

5.85

5.80

5.60

5.80

5.75

5.80

5.65

5.85

5.60

5.70

5.80

5.75

5.80

5.65

5.85

5.60

5.65

5.80

5.75

5.80

5.65

5.85

5.80

5.60

Pages 6 of 8

i. Determine the mean and range (X and R). (4 marks)

ii. Determine the central line and control limits. (6 marks)

iii. Plot the points of the chart. (5 marks)

iv. Analyze the plotted points to determine if the process is in

control. Give a reason for your answer. (4 marks)

Pages 7 of 8

QUESTION 5

(a) Differentiate producers risk and consumers risk.

(4 marks)

(b) In sampling inspection products that do not meet specifications would be rejected.

Explain in detail THREE (3) actions that are usually taken against the rejected

lot.

(9 marks)

(c) Using Table 4, inspector needs to determine the Single Sampling Plans for the

following information:

TABLE 4

INSPECTION

LEVEL

INSPECTION AQL LOT SIZE

i) II Tightened 1.5% 1,400

ii) I Normal 65% 115

iii) III Reduced 0.40% 160,000

(9 marks)

(d) Explain the sampling plan determined in QUESTION 5 (c) iii. if 6

nonconforming units are found in the sample.

(3 marks)

Pages 8 of 8

QUESTION 6

(a) i. State FOUR (4) types of quality cost. (4 marks)

ii. Explain TWO (2) types of quality cost. (4 marks)

iii. Draw and label the curve of quality cost. (2 marks)

(b) i. State the uses of Pareto Diagram. (2 marks)

iii. Using Table 5, construct the Pareto Diagram and discuss

the results. (10 marks)

TABLE 5

Types of defections Number of nonconforming units

Scratch 42

Broken 20

Color not uniform 108

Short mould 10

Flashing 35

Pin hole 15

etc 5

(c) Give the terms for ISO 9000:2000 listed below.

i. ISO 9000

ii. ISO 9001

iii. ISO 9004

( 3 marks)

You might also like

- HND 1 Electrical Measurement and Control EEI 311 2016Document2 pagesHND 1 Electrical Measurement and Control EEI 311 2016iskeel75% (4)

- Chapter 18 Multiple Choice Questions With Answers 2Document3 pagesChapter 18 Multiple Choice Questions With Answers 2Prabhakar Sharma68% (19)

- Pages From Harris - Quantitative Chemical Analysis - 8th EditionDocument2 pagesPages From Harris - Quantitative Chemical Analysis - 8th EditionJorge LunaaNo ratings yet

- STRUCTURED/ESSAY (100 Marks) : Page 2 of 10Document9 pagesSTRUCTURED/ESSAY (100 Marks) : Page 2 of 10Iskandar IbrahimNo ratings yet

- Sem Pendek QCDocument6 pagesSem Pendek QCIskandar IbrahimNo ratings yet

- Business Statistics L3 Past Paper Series 2 2011Document7 pagesBusiness Statistics L3 Past Paper Series 2 2011Haznetta HowellNo ratings yet

- T.E. (Production S/W) (Semester II) Examination, 2009 Process Planning and Industrial StatisticsDocument54 pagesT.E. (Production S/W) (Semester II) Examination, 2009 Process Planning and Industrial StatisticsShahzeb NusratNo ratings yet

- Emg 3212 Metrology Exam DraftDocument4 pagesEmg 3212 Metrology Exam DraftkiokocurtisNo ratings yet

- Soalan Quality ControlDocument5 pagesSoalan Quality ControlIskandar Ibrahim100% (1)

- rr312002 Metrology and Quality ControlDocument8 pagesrr312002 Metrology and Quality ControlSRINIVASA RAO GANTANo ratings yet

- Advanced Manufacturing ProcessDocument2 pagesAdvanced Manufacturing Processmukesh3021No ratings yet

- 10me848qpset Design For Manufacturing and AssemblyDocument13 pages10me848qpset Design For Manufacturing and AssemblyDr. N. S. Sriram100% (1)

- 1617 Dec SKMM2713Document17 pages1617 Dec SKMM2713Shah MalikNo ratings yet

- Bda 30502 Sem 2 1213Document5 pagesBda 30502 Sem 2 1213Iskandar BellNo ratings yet

- Quality Engg.Document16 pagesQuality Engg.Nilankan KumarNo ratings yet

- Mech3002y 3 2007 2 PDFDocument6 pagesMech3002y 3 2007 2 PDFKeshav GopaulNo ratings yet

- 11496-132239-Mqp - Metrology and Quality ControlDocument2 pages11496-132239-Mqp - Metrology and Quality ControlRuby SmithNo ratings yet

- PR 2303Document4 pagesPR 2303Karthik Srinivas0% (1)

- Mech3002y 3 2010 2 PDFDocument5 pagesMech3002y 3 2010 2 PDFKeshav GopaulNo ratings yet

- 2017 Winter Question PaperDocument5 pages2017 Winter Question PaperMahesh SelokarNo ratings yet

- Emg 3212 Metrology SuppDocument4 pagesEmg 3212 Metrology SuppkiokocurtisNo ratings yet

- UHU033Document2 pagesUHU033Kshitij GulatiNo ratings yet

- CHT206 FDocument3 pagesCHT206 FAkshay A BijuNo ratings yet

- WWW - Manaresults.Co - In: Set No. 1Document4 pagesWWW - Manaresults.Co - In: Set No. 1Chanumolu DushyanthNo ratings yet

- Set No. 1Document8 pagesSet No. 1ajay7892No ratings yet

- Final Exame of Statoistics PDFDocument9 pagesFinal Exame of Statoistics PDFandersonNo ratings yet

- BTME 2nd Year AssignmentDocument15 pagesBTME 2nd Year AssignmentshishunalNo ratings yet

- Examination,: Degree NoyemberDocument2 pagesExamination,: Degree NoyemberDeepak MisraNo ratings yet

- Metrology QPDocument3 pagesMetrology QPFaizur RahmanNo ratings yet

- r05320302 Metrology and Surface EngineeringDocument4 pagesr05320302 Metrology and Surface EngineeringSRINIVASA RAO GANTANo ratings yet

- ME-mit Admission FormDocument1,057 pagesME-mit Admission FormBittu50% (2)

- University of Mauritius Faculty of EngineeringDocument4 pagesUniversity of Mauritius Faculty of EngineeringKeshav GopaulNo ratings yet

- SQC Final Exam June 2010Document4 pagesSQC Final Exam June 2010endu wesenNo ratings yet

- 2023 June CHT206-EDocument3 pages2023 June CHT206-EGouri K SNo ratings yet

- Industrial Engineering and Quality Control MSBTEDocument5 pagesIndustrial Engineering and Quality Control MSBTEJaydip Jadhav100% (2)

- Bit2201 Bbit308 Simulation and ModelingDocument3 pagesBit2201 Bbit308 Simulation and ModelingMark Joe AburNo ratings yet

- M&SE Dec 2011Document4 pagesM&SE Dec 2011simalaraviNo ratings yet

- ME2Document478 pagesME2आकाश संगीता प्रकाश पवारNo ratings yet

- E D1080 Pages: 3: Answer Any Three Questions. Each Question Carries 10 MarksDocument3 pagesE D1080 Pages: 3: Answer Any Three Questions. Each Question Carries 10 MarksDrRoja A RNo ratings yet

- QP April2011 32 Mec MseDocument4 pagesQP April2011 32 Mec MseSurendra Babu Koganti0% (1)

- STASTICS PP 1Document3 pagesSTASTICS PP 1Getrude HioNo ratings yet

- 141210-141901-Mechanical Measurement and MetrologyDocument2 pages141210-141901-Mechanical Measurement and Metrologysameer_m_daniNo ratings yet

- Manufacturing Process 2 Jan 2014Document2 pagesManufacturing Process 2 Jan 2014Prasad C MNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityVraj ShahNo ratings yet

- 2019 Winter Question Paper (Msbte Study Resources)Document4 pages2019 Winter Question Paper (Msbte Study Resources)1042 Arun NagariyaNo ratings yet

- Universiti Teknologi Malaysia Fakulti Kejuruteraan Mekanikal Final Examination Semester Ii, Session 2008/2009Document14 pagesUniversiti Teknologi Malaysia Fakulti Kejuruteraan Mekanikal Final Examination Semester Ii, Session 2008/2009Shah MalikNo ratings yet

- Metrologyand Surface EngineeringDocument4 pagesMetrologyand Surface EngineeringshivkrnNo ratings yet

- 2023 Winter Question Paper (Msbte Study Resources)Document4 pages2023 Winter Question Paper (Msbte Study Resources)Rohan ChavanNo ratings yet

- Metalwork: Cambridge International Examinations General Certificate of Education Ordinary LevelDocument12 pagesMetalwork: Cambridge International Examinations General Certificate of Education Ordinary Levelmstudy123456No ratings yet

- Metrology and Surface Engineering PDFDocument4 pagesMetrology and Surface Engineering PDFbathinsreenivasNo ratings yet

- Exercise 1 Sem 2 201718Document6 pagesExercise 1 Sem 2 201718Ahmad MunawirNo ratings yet

- Tema1 EjerciciosDocument21 pagesTema1 EjerciciosJust SomebodyNo ratings yet

- Mech3002y 3 2011 2 PDFDocument5 pagesMech3002y 3 2011 2 PDFKeshav GopaulNo ratings yet

- Mechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandMechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesDileep SinghNo ratings yet

- GARCH Models: Structure, Statistical Inference and Financial ApplicationsFrom EverandGARCH Models: Structure, Statistical Inference and Financial ApplicationsRating: 5 out of 5 stars5/5 (1)

- Attainable Region Theory: An Introduction to Choosing an Optimal ReactorFrom EverandAttainable Region Theory: An Introduction to Choosing an Optimal ReactorNo ratings yet

- Structural Steel Design to Eurocode 3 and AISC SpecificationsFrom EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsNo ratings yet

- (") (B) I. Ii. Iii.: Ffit. (.QDocument1 page(") (B) I. Ii. Iii.: Ffit. (.QIskandar IbrahimNo ratings yet

- Huraikan (2) Kos Kualiti. Quality Cosfs (4Document1 pageHuraikan (2) Kos Kualiti. Quality Cosfs (4Iskandar IbrahimNo ratings yet

- Soalan Quality ControlDocument5 pagesSoalan Quality ControlIskandar Ibrahim100% (1)

- Department of Mechanical EngineeringDocument1 pageDepartment of Mechanical EngineeringIskandar IbrahimNo ratings yet

- Cover Page 1Document1 pageCover Page 1Iskandar IbrahimNo ratings yet

- Ary RyeDocument4 pagesAry RyeIskandar IbrahimNo ratings yet

- Tobacco Pipes Cataloging ManualDocument18 pagesTobacco Pipes Cataloging Manualchippewa05100% (1)

- New Coleccion Harmony DJ AcademyDocument6 pagesNew Coleccion Harmony DJ AcademyvictoredjNo ratings yet

- Upside Down Pineapple Cake Parsi Style by Tanaz Daruwalla Medhora - Bawi BrideDocument2 pagesUpside Down Pineapple Cake Parsi Style by Tanaz Daruwalla Medhora - Bawi BridefatduckNo ratings yet

- AutomataDocument31 pagesAutomataRodrigo DiazNo ratings yet

- English SummaryDocument9 pagesEnglish Summaryyaminshehadeh14No ratings yet

- Students' Point of View On The Use of Whatsapp Group To Elevate Writing AbilityDocument7 pagesStudents' Point of View On The Use of Whatsapp Group To Elevate Writing AbilityAl HakimNo ratings yet

- SQL DBXDocument52 pagesSQL DBXRaphael de BemNo ratings yet

- Computer ManualDocument33 pagesComputer ManualZoran KovacevicNo ratings yet

- Competency Assessment-SurveyorDocument1 pageCompetency Assessment-SurveyorShailendra SanapNo ratings yet

- Fox Multiplus FS240 TDS - EngDocument3 pagesFox Multiplus FS240 TDS - EngAhmad Al-BeikNo ratings yet

- Cpar M2Document64 pagesCpar M2Allan AñonuevoNo ratings yet

- JETQUICK Protocol, Plasmid IsolnDocument10 pagesJETQUICK Protocol, Plasmid IsolnmelvinMAPNo ratings yet

- Performance Task # 7Document2 pagesPerformance Task # 7Aileen Reign MalonzoNo ratings yet

- Eternal Distribution BookDocument107 pagesEternal Distribution BookShappan Abd AllhaNo ratings yet

- Front Elevation: 760 M.M Above Roof SurfaceDocument1 pageFront Elevation: 760 M.M Above Roof SurfaceAbid AyubNo ratings yet

- Barjatya Ji 1185Document3 pagesBarjatya Ji 1185Adinath InfrastructureNo ratings yet

- Vitamin D Larut AirDocument21 pagesVitamin D Larut AirCatherineYavonitaPutriEzafganismeNo ratings yet

- Skimming Protection Solution DsDocument2 pagesSkimming Protection Solution DsBach Chau TuongNo ratings yet

- LEED GA Exam Questions Set 2Document22 pagesLEED GA Exam Questions Set 2CEG BangladeshNo ratings yet

- Comparatrive Between Pneumatic & Electromagnetic VibratorDocument2 pagesComparatrive Between Pneumatic & Electromagnetic VibratorpankajNo ratings yet

- Subject: Data Structures Topic: QueueDocument32 pagesSubject: Data Structures Topic: QueueRahna RwpcNo ratings yet

- Principles of Marketing: North South UniversityDocument3 pagesPrinciples of Marketing: North South UniversitySamin Yasar ShoupalNo ratings yet

- English, Science, Mathematics and Health Electromagnetic RadiationDocument3 pagesEnglish, Science, Mathematics and Health Electromagnetic RadiationSofia GabrellaNo ratings yet

- Microsoft Frontpage Notes Made By: Sir Naseem Ahmed Khan Dow Vocational & Technical Training CentreDocument64 pagesMicrosoft Frontpage Notes Made By: Sir Naseem Ahmed Khan Dow Vocational & Technical Training Centreveere_arunNo ratings yet

- Chief Architect x6 Users Guide House TutorialDocument40 pagesChief Architect x6 Users Guide House TutorialTrish AntoniNo ratings yet

- 3M DP 810 MSDSDocument25 pages3M DP 810 MSDSvivek jayswalNo ratings yet

- IAO's Accreditation For School.Document20 pagesIAO's Accreditation For School.International Accreditation OrganizationNo ratings yet

- IEEE PES Aug 18 - Corrosion - TDGDocument66 pagesIEEE PES Aug 18 - Corrosion - TDGtekno foniNo ratings yet

- 51895-Case CX160 Crawler ExcavatorDocument634 pages51895-Case CX160 Crawler ExcavatorHarold McNabb100% (5)