Professional Documents

Culture Documents

Wps Gtaw

Wps Gtaw

Uploaded by

Lalit Bom MallaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wps Gtaw

Wps Gtaw

Uploaded by

Lalit Bom MallaCopyright:

Available Formats

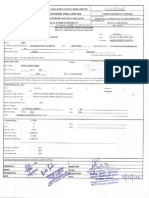

QW -482 WELDING PROCEDURE SPECIFICATION

(WPS)

(SEE QW 201.1, SECTION IX, ASME BOILER

AND PRESSURE VESSEL CODE

SHEET 1 OF 2

Company Name DCMS ENGINEERING CO.

Welding Procedure Specification No DCMS/WPS/099 Rev-0 Date : 19/04/2012

Supporting PQR no. (S) DCMS/PQR/099 Rev - 0 Date : 7.05.2012

Welding Process (es) GTAW Type (s) Manual

(Automatic, Manual, Machine or semi Automatic)

JOINTS (QW-402)

Joints Design Single V Groove Joint

Backing Yes ___________ No ____X______

Backing Material (Type) _ARGON GAS______

(Refer to both backing & retailers).

Metal Nonfusing Metal

Non Metallic Other

DETAILS

* BASE METAL (QW 403)

P.No. 8 Group no. 1 to P.no. 8 Group no. 1

OR

Specification type and grade Plates ASTM-A-240 Gr 304L

To specification type and grade Plates ASTM-A-240 Gr 304L

OR

Chem. Analysis and Mech. Prop ___________NA___________________________

To Chem Analysis and Mech. Prop ________NA___________________________

Thickness Range :-

Base Metal :- Groove 1.6 to 12 mm Fillet All thickness, all sizes & all diameters

Other WPS shall be applicable for both without and with backing (Stainless Steel Material)

FILLER METALS (QW-404)

Spec No. (SFA) SFA-5.9

AWS No. (Class) ER-308L

F-No. 6

A-No 8

Size of Filler Metals 1.6mm

Weld Metal

Thickness Range

Groove 1.6 mm to 12mm

Fillet All thicknesses

Electrode-Flux (Class) N.A.

Flux Trade Name N.A.

Consumable Insert N.A.

N.A.

POSITION (QW-405)

Position (s) of Groove All Positions(Test piece 1G)

Welding Progression : Up Uphill Down NA

Position (s) of Fillet All Positions

POST WELD HEAT TREATMENT (QW-407)

Temperature Range ____NA_____

Time Range _____NA____

Plates ASTM-A240-Gr 304L

(S.S. to S.S.)

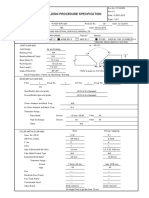

QW-482

WPS NO : DCMS/WPS/099 Dated 19/4/2012

REV : 0

SHEET 2 OF 2

PREHEAT (QW-406)

Preheat Temp. Min NA__________

Interpass Temp. Max _________125

0

C________

Preheat maintenance _________NA__________

(Continuous or special heating where applicable should

be recorded)

GAS (QW-408)

Percent Composition

Shielding (Mixtures) Flow Rate

Shielding Argon 99.99% Pure 12-15Ltr./min

Trailing Argon --

Backing Argon 99.99% Pure 5-10Ltr./min

ELECTRICAL CHARCTERISTICS (QW-409)

Current AC or DC _DC_ Polarity, DCEN (STRAIGHT)

Amp (Range) 65-85 Amp Volts (Range) 10-12 Volts

(Amp and volts range should be recorded for each electrode size, positions and thickness etc.)

Tungsten Electrodes Size & Type 1.6mm, 2.4mm, 2% Thoriated Tungsten Electrodes

(Pure tungsten 2% Thoriated etc.)

Mode to metal transfer for GMAW ____________ NA ________________________

(Spray arc short circulating arc etc.)

Electrodes Wire feed speed range ____________ NA ________________________

TECHNIQUE (QW-410)

String or weave bead Root (stringer) & Final (weaving).

Orifice or Gas Cup Size ceramic nozzle of

Initial and Inter pass (Cleaning Brushing, Grinding etc.)Degreasing with acetone, wire brushing, if required grinding of all pass.

Method of Back Gouging _____NA ______________

Oscillation 2.5 times of size of filler wire_____________

Contact Tube to Work Distance _____NA______________

Single Pass (per side) __ Multiple____________

Multiple or Single Electrode __Single_____________

Travel Speed (Range) 40-65 mm/min.__

Peening Not Allowed

Other _NA__________________

WELD

LAYER(S)

PROCESS

FILLER METAL CURRENT

VOLT

RANGE

TRAVEL

SPEED

RANGE

(mm/min)

OTHER

CLASS DIAMETER TYPE /

POLARITY

AMP

RANGE

Root

(1

st

Pass)

GTAW ER 308-L 1.6mm DCEN 65-75 10-12 40-50

2

nd

Pass GTAW ER 308-L 1.6mm DCEN 75-85 10-12 55-65

3

rd

&

Subsequent

Passes

GTAW ER 308-L 1.6mm DCEN 75-85 10-12 55-65

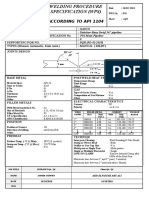

QW-483PROCEDURE QUALIFICATION RECORD

(PQR)

(SEE QW200.2, SECTION IX ASME BOILER AND

PRESSURE VESSEL CODE)

RECORD ACTUAL CONDITION USED TO WELD TEST

COUPON

SHEET 1 OF 3

Company Name M/S. DCMS Engineering Ltd. Mumbai

Procedure Qualification Record No. DCMS / PQR/099 Date : 7/5/2012 Rev 0

WPS No. DCM/WPS/099 Date : 19/4/2012 Rev. 0

Welding Process(es) GTAW

Types (Manual, Automatic, Semi-Automatic) Manual

JOINTS (QW-402)

Plates ASTM - A -240 Gr. 304L to Plate ASTM A - 240 Gr. 304L

Groove Design of Test Coupon

BASE METAL (QW-403)

Material Spec. SA - 240

Type of Grade 304 L

P.No. ________8________ to P. No. ______8_________

Thickness of Test Coupon 6mm

Diameter of Test Coupon NA

Other Weld thickness range qualified 1.6 mm to 12 mm

POST WELD HEAT TREATMENT (QW-407)

Temperature ___NA_______

Time ___NA_______

Other ___NA_______

FILLER METALS (QW-404) GAS (QW-408)

Percent Composition

Shielding (Mixtures) Flow Rate

Shielding Argon 99.99% Pure 12-15Ltr./min

Trailing ----

Backing Argon 99.99% Pure 12-15Ltr./min

SFA Specification 5.9

AWS Classification ER 308-L

Filler Metal F-No 6

Weld Metal Analysis A-No 8 ELECTRICAL CHARACTERISTICS (QW-409)

Current __________DC_____________

Polarity STRAIGHT (DCEN)

Amps. 85-90 Amp. Volts 12 (Refer Annexure)

Tungsten Electrode Size ________2.4mm ___________

Other NA____

Size of Filler Metal 1.6mm &

2mm

Other

Weld Metal Thickness 6mm

POSITION (QW-405)

Position of Groove __________1G___________

Weld Progression (Uphill, Downhill) N.A.

Others __________________N.A.___________

TECHNIQUE (QW-410)

Travel Speed 48.8 to 66.7 mm /min (Refer Annexure)

String or Weave Bead _Root(stringer) ,Final(weave)

Oscillation final pass weaving not exceeding 2.5 times dia of filler

wire.

Multipass or Single Pass (Per Side) ___Multipass____

Single or Multiple Electrodes _________Single ______

Other -------------------------------------

PREHEAT (QW-406)

Preheat Temperature (Minimum) __N.A _

InterpassTemperature (Maximum) 125

0

C

Other ________________N.A._______________

2007 SECTION IX

QW -483

PQR

Tensile Test (QW 150) Page 2 of 3

Specimen

No.

Width

mm

Thickness

mm

Area

mm

2

Ultimate

Total Load N

Ultimate Unit

Stress N/mm

2

Type of Failure and

Location

T-1 19 5.90 112.10 70400 628.01 weld metal

T-2 18.80 5.94 99.75 62400 625.56 weld metal

Guided Bend Tests (QW-160) Mandrel dia 24 mm (4t)

Type and Figure No. Result

Root Bend RB -1 Satisfactory

Root Bend RB -2 Satisfactory

Face Bend FB -1 Satisfactory

Face Bend FB -2 Satisfactory

Toughness Tests (QW-170)

Specimen

No.

Notch

Location

Specimen

Size

Test

Temperature

Impact Values Drop Weight Break (Y/N)

ft.lb % Shear Mills

NA

Comments ________________________________________NA__________________________________

Fillet Weld Test (QW-180)

Result Satisfactory Yes _________No. _________ Penetration into Parent Metal Yes ______ No. ___

Macro Results_________________ NA ___________________________________________________

Other Tests

Type of Test ___________________________________________________________________________

Deposit Analysis _________ _______________ NA __________________________________________

Other _________________________________________________________________________________

Welders Name N. MADHAVAN Stamp/ID: NMV

Test Conducted by Geo Chem Lab(P)Ltd. Laboratory Test No. M LD /12/04/2012 dt.4.5.2012

We Certify that the statement in this record are correct and that the test welds were prepared, welded, and

tested in accordance with the requirements of Section IX of the ASME BOILER AND PRESSURE VESSEL

CODE.

Manufacture By DCMS Engg. Co.

Date:7.05.2012

Details of record of tests are illustrative only and may be modified to confirm to the type and number of tests

required by the Code.

PQR No. DCMS/WPS/099

Dt. 8/5/2012 Rev - 0

Page 3 of 3

Annexure to PQR No. DCMS/PQR/099 Date: 7/5/2012 Rev: 0

Name of Welder: N. MADHAVAN Stamp/ID: NMV Process: GTAW

Numbers

of Runs /

Weld

Passes

Electrode

Th 2%

(Tungsten)

Filler Wire

Gas

Shielding

ltrs / min

Backing

Gas

Ltrs./min

Current

Speed

mm/min

Volts Amp

1

st

(Root)

2.4 mm

1.6 mm dia

ER 308-L

14 12 11 72 48.8

2

nd

pass

2.4mm

1.6 mm dia

ER 308-L

14

12

12

87

66.7

3

rd

pass

2.4mm

1.6 mm dia

ER 308-L

14

12

12

87

53.04

4

th

pass

2.4mm

1.6 mm dia

ER 308-L

14

12

12

87

49.4

Prepared By Reviewed By Accepted By

Abhishek Nag P.V.Khambatkone Client

(QC Engineer) (Ex-NPCIL QA)

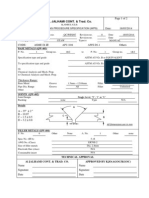

QW-484 MANUFACTURERS RECORD OF WELDER OR

WELDING OPERATOR PERFORMANCE

QUALIFICATION TESTS (SEE QW-301, SECTION XI,

ASME BOILER AND PRESSURE VESSEL CODE)

WELDER NAME PURAN SINGH Stamp/ID: PN

Welding process(es) used GTAW

Identification of WPS followed by welder during welder during welding of test coupon : DCMS/WPS/099Rev-0 dt.15.09.11

Base material(s) welded SA-240 Gr 304L Thickness 6mm Thick Plate

Manual for Each Process (QW-350) Actual Values Range Qualified

Backing (Metal, weld metal, welded from both sides, flux etc.)

(QW-402)

Without with or without

ASME P.No. 8 to ASME P.No. 8 (QW-403)

( ) Plate (X ) Pipe (enter diameter, if pipe) 6 mm thk plate 1.6 to 12mm Plate

Filler metal specification (SFA) : 5.9 and 5.1 Classification

(QW-404)

ER-308L

A No.8

ER-308L

A.No.8

Filler metal F No. 6 6

Filler Metal variety for GTAW, PAW (QW 404) NA N.A.

Consumable insert for GTAW or PAW NA N.A.

Weld deposit thickness for each welding process 1.6mm GTAW 1.6 mm (GTAW)

Welding position (1G,5G, etc) (QW-405) 1G 1G & all fillet welds

Progression (uphill/downhill) N.A. N.A.

Backing gas for GTAW, PAW or GMAW : Fuel gas for QFW

(QW-408)

Argon Gas

99.995%

Argon Gas

99.995%

GMAW transfer mode (QW-409) N.A. N.A.

GTAW welding current type / polarity DCEN (GTAW) DCEN (GTAW)

Machine Welding Variables for the Process Used (QW-360) Actual Values Range Qualified

Direct / remote visual control

Automatic voltage control (GTAW)

Automatic joint tracking NA

Welding position (1G, 5G, etc)

Consumable insert

Backing (metal, weld metal, welded from both sides, flux etc.)

GUIDED BEND TEST RESULTS

Guided Bend Tests Type ( ) QW- 462.2 (Side) Results ( ) QW 462.3 (a) (Trans. R & F) Type ( ) QW-462.3

(b) (Long, R & F) Results

FB-1 Satisfactory RB-1 Satisfactory

FB-2 Satisfactory RB-2 Satisfactory

Visual examination results (QW-302.4): Satisfactory

Radiographic test results (QW-304 and QW-305): Satisfactory

(For alternative qualification of groove welds by radiography)

Fillet Weld Fracture test N.A. Length and percent of defects NA

Macro test fusion NA Fillet leg size NA in X inch Concavity / convexity NA in.

Welding test conduced by DCMS Engineering Co. Ltd.

Radiographic tests conducted by M/s. Geo chem Lab, Mumbai. Laboratory Test No. MLD/11/08/06896

DT.17.9.2011

We certify that the statements in this record are correct and that the test coupons were prepared

welded and tested in accordance with the requirements of Section IX of the ASME Code

DCMS Engineering Co. CLIENT

Date __________ Date _________________

You might also like

- Poposed Welding Procedure Specification (PWPS) : ASME Section IX, ASME Boiler and Pressure Code Ed.2015Document12 pagesPoposed Welding Procedure Specification (PWPS) : ASME Section IX, ASME Boiler and Pressure Code Ed.2015MulPXNo ratings yet

- BK5TQ4 248 094 - WPS For Ducting & Support Structure Stainless Steel V Groove WeldDocument2 pagesBK5TQ4 248 094 - WPS For Ducting & Support Structure Stainless Steel V Groove WeldHarkesh RajputNo ratings yet

- Crude Oil Storage Tanks-BasicsDocument176 pagesCrude Oil Storage Tanks-BasicsPandipperumal Sankaralingam100% (44)

- 329 Banned FDC Drugs Wef 12.09.2018Document10 pages329 Banned FDC Drugs Wef 12.09.2018The Indian Express100% (16)

- Sa 516 GR 70 WPSDocument5 pagesSa 516 GR 70 WPSRajesh Owaiyar71% (7)

- What Every Engineer Should Know About Welding ProceduresDocument13 pagesWhat Every Engineer Should Know About Welding Proceduresarash59_4uNo ratings yet

- WPS FormatDocument2 pagesWPS FormatAmit SarkarNo ratings yet

- Metrode WPS SuperduplexDocument4 pagesMetrode WPS SuperduplexClaudia Mms100% (3)

- Welding Procedure SpecificationDocument27 pagesWelding Procedure SpecificationGopakumar K100% (3)

- AWS D1.1 - Example PQR & WPS DocumentsDocument4 pagesAWS D1.1 - Example PQR & WPS DocumentsPaul Cassells0% (1)

- Procedure Qualification Record (PQR)Document3 pagesProcedure Qualification Record (PQR)Senthil KumaranNo ratings yet

- Wps Magi Tig ExempleDocument6 pagesWps Magi Tig ExempleDanem HalasNo ratings yet

- WPSDocument6 pagesWPSYASH BARDHAN SinghNo ratings yet

- Book RustDocument271 pagesBook RustNICOLAS CASSIO DOS SANTOSNo ratings yet

- WPS and PQRDocument4 pagesWPS and PQRdandiar1No ratings yet

- WPS Dissimilar UpdatedDocument3 pagesWPS Dissimilar UpdatedVimin Prakash100% (1)

- WPS PQR-09Document11 pagesWPS PQR-09Ranjan KumarNo ratings yet

- WPSDocument3 pagesWPSKhurram Burjees100% (1)

- 19403955-WPS M.S. Is 2062Document10 pages19403955-WPS M.S. Is 2062Varun Malhotra100% (1)

- Sample WPS SMAW Stainless SteelDocument7 pagesSample WPS SMAW Stainless Steeldaemsal100% (4)

- WPS For Structure Mild Steel Fillet WeldDocument2 pagesWPS For Structure Mild Steel Fillet WeldHarkesh Rajput76% (17)

- Wps 316L SMAW+GTAW R00Document2 pagesWps 316L SMAW+GTAW R00Richard Periyanayagam86% (14)

- WPS GTAW Stainless SteelDocument4 pagesWPS GTAW Stainless SteelAnand NarayananNo ratings yet

- Welding Procedure Specification-1Document8 pagesWelding Procedure Specification-1Suresh Rathod100% (2)

- WPS PQRDocument23 pagesWPS PQRHashim Khan88% (8)

- Welding Procedure Specification (WPS) : According To Api 1104Document1 pageWelding Procedure Specification (WPS) : According To Api 1104Maged Lotfy Abdel-aal100% (1)

- Smaw Wps FinalDocument3 pagesSmaw Wps FinalsheikmoinNo ratings yet

- WPSDocument2 pagesWPSJuli Agus50% (2)

- Flange Weight ChartDocument1 pageFlange Weight Chartabhishek198327No ratings yet

- Wps For Steel RodsDocument5 pagesWps For Steel RodsHamid MansouriNo ratings yet

- WPS 316 LDocument4 pagesWPS 316 Llaz_k100% (2)

- Wps Magi Tig Exemple PDFDocument6 pagesWps Magi Tig Exemple PDFJaime PatrónNo ratings yet

- WPS Pipe 08'' SHD 40 SMAW REV02Document2 pagesWPS Pipe 08'' SHD 40 SMAW REV02Amine MaalejNo ratings yet

- WPS (AsmeDocument8 pagesWPS (AsmeMohammad Elhedaby100% (6)

- Defence Expo2022Document111 pagesDefence Expo2022Jyotsna Pandey50% (2)

- Qap For DCP Tank: 1. Material IdentificationDocument5 pagesQap For DCP Tank: 1. Material Identificationabhishek198327No ratings yet

- Reports - QAQC - R0Document10 pagesReports - QAQC - R0talupurumNo ratings yet

- WPS PQR A36.20Document5 pagesWPS PQR A36.20gchaves504100% (2)

- P91 Profile WpsDocument6 pagesP91 Profile WpsZead Ali Adal100% (2)

- Wps A53 Gtaw R00Document2 pagesWps A53 Gtaw R00Richard PeriyanayagamNo ratings yet

- Welding Procedure Specification: Page 1 of 1Document2 pagesWelding Procedure Specification: Page 1 of 1Anderson Perez Martinez100% (1)

- Welding Procedure Specification For 24'' PipeDocument2 pagesWelding Procedure Specification For 24'' Pipeenels77100% (2)

- Ilcs-Smaw-D1.3-Deck (G) WPSDocument3 pagesIlcs-Smaw-D1.3-Deck (G) WPSRoss100% (1)

- PQR FormatDocument2 pagesPQR Formatravi0009880% (5)

- Fcaw 16 THKDocument5 pagesFcaw 16 THKparesh2387No ratings yet

- Welding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Document5 pagesWelding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Rajesh Owaiyar100% (1)

- Helium Leak Testing GuideDocument2 pagesHelium Leak Testing Guideabhishek198327100% (1)

- Proposed WPSDocument2 pagesProposed WPSChisom Ikengwu100% (2)

- WPS Sitelca S002Document2 pagesWPS Sitelca S002Jose Antonio GomezNo ratings yet

- SS312 Type310Document4 pagesSS312 Type310Vimin PrakashNo ratings yet

- WPSDocument6 pagesWPSNur Wijianto100% (1)

- Page No: 01: SA 240 GR 304 SA 240 GR 304Document5 pagesPage No: 01: SA 240 GR 304 SA 240 GR 304jobertNo ratings yet

- 7 Structures Jim Stear PDFDocument22 pages7 Structures Jim Stear PDFAndi SuntoroNo ratings yet

- 6GR WPS PQRDocument15 pages6GR WPS PQRKiukStaks100% (6)

- Welding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateDocument2 pagesWelding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateAmjad Pathan100% (1)

- Wps p91 - BhelDocument2 pagesWps p91 - BhelAshish Gupta100% (4)

- Welding Procedure Specification Krishna Steel Industries: Electrical Characterstics (Qw-409)Document2 pagesWelding Procedure Specification Krishna Steel Industries: Electrical Characterstics (Qw-409)Harshit AdwaniNo ratings yet

- Welder Monitoring SheetDocument1 pageWelder Monitoring SheetQC apollohx100% (1)

- AAU5726 Installation GuideDocument73 pagesAAU5726 Installation GuideBerSerk100% (1)

- WPS & PQRDocument46 pagesWPS & PQRJohn Candidate CIns88% (8)

- WPS Multi GMAW FCAW PDFDocument2 pagesWPS Multi GMAW FCAW PDFwentroprem75% (4)

- Welding Procedure Specification SampleDocument2 pagesWelding Procedure Specification Samplesamer_saif8456100% (1)

- Manual MstowerDocument264 pagesManual MstowerPaul_delgado75% (8)

- PWPS For Piping-API 1104Document6 pagesPWPS For Piping-API 1104Nguyen Tien Luong100% (1)

- Smaw PQR FinalDocument3 pagesSmaw PQR Finalsheikmoin100% (1)

- Flange Weight Chart PDFDocument4 pagesFlange Weight Chart PDFl kishore100% (2)

- PT Kuwera Karya Me: PanduDocument2 pagesPT Kuwera Karya Me: PanduGalang Pratama PutraNo ratings yet

- 03 WPS CS 1Document3 pages03 WPS CS 1mohammadNo ratings yet

- 653 WPS-PQR PDFDocument4 pages653 WPS-PQR PDFETSNo ratings yet

- Automatic, Manual, Machine, or Semi-Auto.Document10 pagesAutomatic, Manual, Machine, or Semi-Auto.ChE_MattNo ratings yet

- Des QC 8505 Ab 08Document3 pagesDes QC 8505 Ab 08Touseef RafiqueNo ratings yet

- Sample WPS For SSDocument2 pagesSample WPS For SSSachin S. SalunkheNo ratings yet

- CR Equivalent Ni Equivalent Ferrite Number 20.57 Md30 Temperature Acc. To NoharaDocument2 pagesCR Equivalent Ni Equivalent Ferrite Number 20.57 Md30 Temperature Acc. To Noharaabhishek198327No ratings yet

- Article - Stress Relieving Heat Treatments For Austenitic Stainless SteelsDocument2 pagesArticle - Stress Relieving Heat Treatments For Austenitic Stainless Steelsabhishek198327No ratings yet

- Welding Rod Selection 1 PDFDocument1 pageWelding Rod Selection 1 PDFabhishek198327100% (2)

- Nozzle THKDocument6 pagesNozzle THKabhishek198327No ratings yet

- TrolleyDocument1 pageTrolleyabhishek198327No ratings yet

- Stress ConcentrationDocument4 pagesStress Concentrationabhishek198327No ratings yet

- Qap For Inconel Process VesselDocument3 pagesQap For Inconel Process Vesselabhishek198327No ratings yet

- Kjlced09 Sec01 Pages129-145 Bellowstubing&WeldfittingsDocument17 pagesKjlced09 Sec01 Pages129-145 Bellowstubing&Weldfittingsabhishek198327No ratings yet

- Glasswool Spec PDFDocument3 pagesGlasswool Spec PDFabhishek198327No ratings yet

- Tema EnqDocument24 pagesTema Enqabhishek198327No ratings yet

- AGI Accounting FraudDocument9 pagesAGI Accounting Fraudayushaslaliya110No ratings yet

- Letter of Recommendation - Josh SethiDocument1 pageLetter of Recommendation - Josh Sethiapi-346224560No ratings yet

- MMC Questions For Division Finals Grade 10 PDFDocument2 pagesMMC Questions For Division Finals Grade 10 PDFMaricel DayritNo ratings yet

- Physics Katete Grade 10Document68 pagesPhysics Katete Grade 10joshua witika100% (1)

- 2 Grade Inquiry-Based Lesson South Africa vs. Slaton, TXDocument31 pages2 Grade Inquiry-Based Lesson South Africa vs. Slaton, TXSamantha MelvinNo ratings yet

- SPP (605 - A) Planning Studio Iii (Site Planning) Residential - LUDHIANADocument4 pagesSPP (605 - A) Planning Studio Iii (Site Planning) Residential - LUDHIANApoojagnduNo ratings yet

- Guía de Inglés Grado Sexto-Periodo 2 - Indicador 1.Document2 pagesGuía de Inglés Grado Sexto-Periodo 2 - Indicador 1.Harold ÁlvarezNo ratings yet

- QUIZ#2Document2 pagesQUIZ#2Elmera Lene CaballesNo ratings yet

- CPS 4 Advanced ConceptsDocument312 pagesCPS 4 Advanced ConceptssudharaghavanNo ratings yet

- Draft Ucg ImmDocument24 pagesDraft Ucg Immzoel tekmiraNo ratings yet

- KilambakkamDocument1 pageKilambakkamdeboline mitraNo ratings yet

- PD ReportDocument46 pagesPD ReportNoor SultanNo ratings yet

- Slide - Egg-87489-Background Mickey Mouse PowerPointDocument11 pagesSlide - Egg-87489-Background Mickey Mouse PowerPointGlamang ES (R XII - South Cotabato)No ratings yet

- Tupperware-Ultimo Lifestyle CatalougesDocument12 pagesTupperware-Ultimo Lifestyle CatalougesPradeep Kumar SinghNo ratings yet

- FYP Report MDocument33 pagesFYP Report MSumaira SaifNo ratings yet

- Postgraduate Programs in Disaster Management (PPDM) : Sample Questions For Admission TestDocument5 pagesPostgraduate Programs in Disaster Management (PPDM) : Sample Questions For Admission Testomi sunNo ratings yet

- Soft Computing Fundamentals and Applications EbookDocument4 pagesSoft Computing Fundamentals and Applications EbookGrammarly AccountNo ratings yet

- PWC Kenya Graduate Recruitment 2012 BrochureDocument28 pagesPWC Kenya Graduate Recruitment 2012 BrochureJackpin Ole Ntummantan GalfenNo ratings yet

- Limit State Response of Composite Columns and Beam-Columns Part 1: Formulation of Design Provisions For The 2005 AISC SpecificationDocument19 pagesLimit State Response of Composite Columns and Beam-Columns Part 1: Formulation of Design Provisions For The 2005 AISC SpecificationvardhangargNo ratings yet

- Extrude PDF Vector in 3ds MaxDocument2 pagesExtrude PDF Vector in 3ds MaxJenniferNo ratings yet

- Elfmatic G3Document1 pageElfmatic G3Pancho CamposNo ratings yet

- MBA Project Resdffdport On Job Satisfaction of EmployeesDocument13 pagesMBA Project Resdffdport On Job Satisfaction of EmployeesJames BlackNo ratings yet

- Donald Barthelme's Snow White SummaryDocument26 pagesDonald Barthelme's Snow White SummaryAnu Elezabath VarugheseNo ratings yet

- Vampires Zombies Are They Real Yazhi Swaruu and Aneeka ExplainDocument5 pagesVampires Zombies Are They Real Yazhi Swaruu and Aneeka ExplainWentworth Scofield IINo ratings yet