Professional Documents

Culture Documents

Busbar Design

Busbar Design

Uploaded by

SurajKurupOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Busbar Design

Busbar Design

Uploaded by

SurajKurupCopyright:

Available Formats

David Chapman

Copper Development Association

david.chapman@copperdev.co.uk

Copper Development Association

Busbar Design Basics

www.leonardo-

energy.org

Copper Development Association

www.cda.org.uk

High electrical conductivity

only silver is better than copper

Good thermal conductor

heat reaches surface quickly

Strong (at working temperature)

to withstand short circuit stresses

low creep

Easy to joint

resistant to corrosion

Materials for Busbar Systems

www.leonardo-

energy.org

Copper Development Association

www.cda.org.uk

Busbar System Current Ratings

usbar ratings are determined only by the

ma!imum desired working temperature

"t working temperature#

heat generated $ heat lost

www.leonardo-

energy.org

Copper Development Association

www.cda.org.uk

Busbar System Current Ratings

usbar ratings depend on#

% &orking and ambient temperatures

% Heat lost from the busbar

' by convection

' by radiation

% Heat generated in the busbar

www.leonardo-

energy.org

Copper Development Association

www.cda.org.uk

25 . 0

25 . 1

66 . 7

v

P

cv

=

(ower dissipated by convection is given by#

where

is the temperature rise above ambient

v is the vertical height of the surface

Busbar System Current Ratings

P

cv1

P

cv2

v

www.leonardo-

energy.org

Copper Development Association

www.cda.org.uk

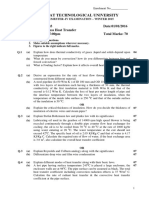

Power dissipation per metre length v Vertical height

0

40

80

120

160

0 50 100 150 200

Vertical height (mm

P

o

w

e

r

d

i

s

s

i

p

a

t

i

o

n

p

e

r

m

e

t

r

e

l

e

n

g

t

h

(

!

)onvection (for *+ ) temperature rise)

Busbar System Current Ratings

www.leonardo-

energy.org

Copper Development Association

www.cda.org.uk

Power dissipated by radiation is given by

( )

8 4

1

4

2

10 7 . 5

= T T P

r

where

(

r

is the power dissipated per square metre

,

-

is the working temperature. /

,

0

is the ambient temperature. /

is the emissivity

Busbar System Current Ratings

P

r

P

r

www.leonardo-

energy.org

Copper Development Association

www.cda.org.uk

,he emissivity. . describes how effectively

the surface radiates heat

1or a perfectly polished surface. the value is

close to 2ero 3 a very poor radiator

1or a matt black surface. the value is close to

0 3 a very good radiator

Busbar System Current Ratings

www.leonardo-

energy.org

Copper Development Association

www.cda.org.uk

right copper has an emissivity of about +40

5uring use. the emissivity of the copper

surface increases 3 and the current rating

increases 3 as the copper darkens to reach an

emissivity value of about +46

,in plated copper has an emissivity of about

+47 to +48

ut painting bars reduces the current rating9

Busbar System Current Ratings

www.leonardo-

energy.org

Copper Development Association

www.cda.org.uk

Busbar System Current Ratings

P

r

P

r

P

r

P

r

P

r

P

r

!o radiation heat loss

"rom internal sur"aces

www.leonardo-

energy.org

Copper Development Association

www.cda.org.uk

"adiation power dissipation v !or#ing temperat$re

0

20

40

60

80

100

2%& &2& &%&

A'sol$te !or#ing (emperat$re ()

P

o

w

e

r

d

i

s

s

i

p

a

t

i

o

n

(

!

p

e

r

s

*

m

:adiation (for 7+ ) ambient)

Busbar System Current Ratings

www.leonardo-

energy.org

Copper Development Association

www.cda.org.uk

for 0++ mm vertical height. 7+ ) ambient

(otal power dissipation v !or#ing temperat$re

0

100

200

&00

400

500

600

%00

800

+00

1000

40 60 80 100 120 140

!or#ing temperat$re (C

P

o

w

e

r

d

i

s

s

i

p

a

t

i

o

n

(

!

p

e

r

s

*

m

Convection

"adiation

(otal

Busbar System Current Ratings

www.leonardo-

energy.org

Copper Development Association

www.cda.org.uk

R I P

2

=

a

l

I P

2

=

,he power generated by current in the busbar is#

where

is the resistivity of the material

a is the cross sectional area

l is the length

Busbar System Current Ratings

www.leonardo-

energy.org

Copper Development Association

www.cda.org.uk

"t some temperature. the heat generated in the

busbar is equal to the total heat lost by convection

and radiation4

[ ] [ ]

r c i

P P P + =

Busbar System Current Ratings

www.leonardo-

energy.org

Copper Development Association

www.cda.org.uk

)alculation method#

0 Select working and ambient temperatures

- "ssume initial current density of * amps;mm

-

7 1ind appropriate si2e in standard range

< )alculate heat generated due to current

8 )alculate heat loss at working temperature

= >f <?8. increase si2e and return to <

&hen <$@8. this is smallest possible si2e

Minimum size calculation

www.leonardo-

energy.org

Copper Development Association

www.cda.org.uk

,he most economic si2e gives the lowest

lifetime cost4 >t is the minimum total cost of

%material

%installation and

%energy costs

over the circuit lifetime4

Higher purchase cost 3 lower running costs

Best economic sizing

www.leonardo-

energy.org

Copper Development Association

www.cda.org.uk

Best economic sizing

Cost o, 'ar

0

5

10

15

0 100 200 &00 400 500 600

Cross sectional area (s*mm

C

o

s

t

o

,

'

a

r

p

e

r

m

e

t

r

e

(

-

www.leonardo-

energy.org

Copper Development Association

www.cda.org.uk

Best economic sizing

Cost o, losses . 5 /ears

0

10

20

&0

0 100 200 &00 400 500 600

Cross sectional area (s*mm

C

o

s

t

o

,

l

o

s

s

e

s

o

v

e

r

5

/

e

a

r

s

(

-

www.leonardo-

energy.org

Copper Development Association

www.cda.org.uk

Economic Sizing of Busbars

(otal cost . 5 /ears

0

10

20

&0

0 100 200 &00 400 500 600

Cross sectional area (s*mm

0

i

,

e

t

i

m

e

c

o

s

t

p

e

r

m

e

t

r

e

(

-

Cost o, 'ar

Cost o, loss

(otal

www.leonardo-

energy.org

Copper Development Association

www.cda.org.uk

Busbar calculation software

www.leonardo-

energy.org

Copper Development Association

www.cda.org.uk

Busbar calculation software

www.leonardo-

energy.org

Copper Development Association

www.cda.org.uk

Busbar calculation software

www.leonardo-

energy.org

Copper Development Association

www.cda.org.uk

Further considerations

Having calculated the si2e of the bar. there

are three further considerations#

voltage drop

skin effect

'increases apparent resistance by reducing

effective area 3 important for#

thick busbars

high frequencies

harmonics generated by non3linear loads

short circuit current

www.leonardo-

energy.org

Copper Development Association

www.cda.org.uk

Summary of Busbar Material Characteristics

High )onductivity

% low loss. low voltage drop

% ?0+048 A >")S

Easy 1ormability

% due to small grain si2e and advanced production

technology

% easy to bend without surface deformation

Good 1latness

% simple reliable jointing

Good Straightness

% easy installation. lower joint stress

David Chapman

Copper Development Association

david.chapman@copperdev.co.uk

Copper Development Association

You might also like

- Test Bank For Frommers Radiology For The Dental Professional 10th Edition by Stabulas SavageDocument6 pagesTest Bank For Frommers Radiology For The Dental Professional 10th Edition by Stabulas SavageGeorgianne Lawrence100% (33)

- Clearance Creepage Distance in Electrical EquipmentDocument5 pagesClearance Creepage Distance in Electrical EquipmentNghiemNo ratings yet

- N N N N: - PF Is Not Given, So Assume 0.85 and - Efficiency 88 %Document6 pagesN N N N: - PF Is Not Given, So Assume 0.85 and - Efficiency 88 %Rane SiddeshNo ratings yet

- Busbar Design Basics: David Chapman Copper Development Association David - Chapman@copperdev - Co.ukDocument25 pagesBusbar Design Basics: David Chapman Copper Development Association David - Chapman@copperdev - Co.ukkapil100% (1)

- Busbar CalculationDocument8 pagesBusbar Calculationdsilvasaucedo100% (4)

- Busbar Design GuideDocument22 pagesBusbar Design Guidejohnwu_2009100% (6)

- Busbar Calculation Ref1Document5 pagesBusbar Calculation Ref1Muhammad KahlilNo ratings yet

- Busbar Dimension Calculation: AmpereDocument5 pagesBusbar Dimension Calculation: AmpereMuhammad Kahlil100% (1)

- Bus Bar Current Carrying CapacityDocument8 pagesBus Bar Current Carrying CapacityMichael Zhang0% (1)

- Busbar RatingDocument64 pagesBusbar RatingAbdulla Nashith100% (1)

- 8BK88 PLUS Catalogue 4-3-04 PDFDocument36 pages8BK88 PLUS Catalogue 4-3-04 PDFRitesh Maheshwari100% (1)

- Current Calculation For BusbarsDocument41 pagesCurrent Calculation For Busbarsraghuveeranush0% (1)

- Cable Resistance & Reactance Calculations - Open ElectricalDocument5 pagesCable Resistance & Reactance Calculations - Open Electricalgadgil_vikrant67% (3)

- SLDDocument8 pagesSLDHARIS AHAMMEDNo ratings yet

- LV SWG Verification IEC 61439 - 2009 (Siemens)Document42 pagesLV SWG Verification IEC 61439 - 2009 (Siemens)RudanekNo ratings yet

- Busbar Trunking SystemDocument21 pagesBusbar Trunking SystemJordan Ansh50% (2)

- 17july10 WDC Busbar SizingDocument8 pages17july10 WDC Busbar Sizingtceterex100% (1)

- Parameters: Calculation For Al Bus Bar Suitable For 50ka Fault LevelDocument1 pageParameters: Calculation For Al Bus Bar Suitable For 50ka Fault Levelanand_girgaonkarNo ratings yet

- Busbar Sizing CalculationDocument7 pagesBusbar Sizing Calculationchenshiva100% (1)

- Copper Busbar Sizing CalculationDocument5 pagesCopper Busbar Sizing CalculationAnantharamakrishnan VenkatramanNo ratings yet

- Busbar Sizing CalculationDocument13 pagesBusbar Sizing CalculationPower Solution100% (2)

- Cable Thermal Analysis Short Circuits EADocument19 pagesCable Thermal Analysis Short Circuits EAErsiAgoNo ratings yet

- Busbar Clearance BarrierDocument2 pagesBusbar Clearance BarrierSundaresan Sabanayagam100% (1)

- 1ph Control Panel Short Circuit CalculationsDocument16 pages1ph Control Panel Short Circuit Calculationsmelvyn9692100% (2)

- Voltage Drop PresentatnDocument16 pagesVoltage Drop PresentatnmajortayNo ratings yet

- Anti-Nuisance Tripping RCDs and RCCBsDocument6 pagesAnti-Nuisance Tripping RCDs and RCCBsmatanveerNo ratings yet

- Temperature Rise Calculation For 4000A BusbarDocument1 pageTemperature Rise Calculation For 4000A BusbarPrasad33% (3)

- Busbar Calulation For 2000a Copper BusbarsDocument3 pagesBusbar Calulation For 2000a Copper Busbarsbalaallied100% (5)

- Electrical Parameters 40 MW (33kV Double Circuit Line)Document1 pageElectrical Parameters 40 MW (33kV Double Circuit Line)Suresh KumarNo ratings yet

- Earthing Resistance Value: Size of Capacitor For Power Factor CorrectionDocument17 pagesEarthing Resistance Value: Size of Capacitor For Power Factor Correctiondhruv100% (2)

- Optimal Power Transformer Sizing: Case StudyDocument18 pagesOptimal Power Transformer Sizing: Case Studyali hakan çolaker (Commissioning Engineer)No ratings yet

- Voltage Drop and Short CircuitDocument39 pagesVoltage Drop and Short CircuitMinerva Abanto100% (1)

- Calculate Transformer Size and MotorDocument2 pagesCalculate Transformer Size and MotorThirumalNo ratings yet

- ABB (Pro-E Type Test) - PanelDocument16 pagesABB (Pro-E Type Test) - Panelari bowoNo ratings yet

- Deltabar BuswayDocument24 pagesDeltabar BuswayMuneer YousofNo ratings yet

- Voltage Drop CalculationDocument1 pageVoltage Drop Calculationrjshnair75% (4)

- Short Circuit CalculationDocument42 pagesShort Circuit Calculationgraduadoesime100% (17)

- AuCom Bus Bar SystemsDocument4 pagesAuCom Bus Bar SystemsZineddine BENOUADAHNo ratings yet

- 6SL3224-0BE37-5AA0 Datasheet enDocument2 pages6SL3224-0BE37-5AA0 Datasheet enpimentel.o.alexandreNo ratings yet

- DS Ltch00601daa0 R05Document4 pagesDS Ltch00601daa0 R05rajareddy235No ratings yet

- Busbar DesignDocument25 pagesBusbar DesigngusgifNo ratings yet

- Ansi MV Gis 8dadb Flyer enDocument2 pagesAnsi MV Gis 8dadb Flyer enabbastceNo ratings yet

- A Study of Meachanisms of Esd Damge To Reticles Presentation ION Sya LevitDocument27 pagesA Study of Meachanisms of Esd Damge To Reticles Presentation ION Sya LevitNilesh NarkhedeNo ratings yet

- Royal 6010Document1 pageRoyal 6010Santosh SharmaNo ratings yet

- Gerneral Characteristics Maximum Ratings: Electron Tube FU-612F and FU-613F (Equivalent To 3CX2500F3 and 3CX2500H3)Document2 pagesGerneral Characteristics Maximum Ratings: Electron Tube FU-612F and FU-613F (Equivalent To 3CX2500F3 and 3CX2500H3)Ricardo Jose PirelaNo ratings yet

- Gerneral Characteristics Maximum Ratings: Electron Tube FU-612F and FU-613F (Equivalent To 3CX2500F3 and 3CX2500H3)Document2 pagesGerneral Characteristics Maximum Ratings: Electron Tube FU-612F and FU-613F (Equivalent To 3CX2500F3 and 3CX2500H3)Ricardo Jose PirelaNo ratings yet

- Gerneral Characteristics Maximum Ratings: Electron Tube FU-612F and FU-613F (Equivalent To 3CX2500F3 and 3CX2500H3)Document2 pagesGerneral Characteristics Maximum Ratings: Electron Tube FU-612F and FU-613F (Equivalent To 3CX2500F3 and 3CX2500H3)Ricardo Jose PirelaNo ratings yet

- DHR C10Document3 pagesDHR C10marcoNo ratings yet

- Tmax T8: Annex To The Technical CatalogueDocument50 pagesTmax T8: Annex To The Technical CatalogueFlorin OaeNo ratings yet

- Series M50 Diode: - High Surge Current Rectifier Circuits - Up To 1600 Volt Blocking StandardDocument2 pagesSeries M50 Diode: - High Surge Current Rectifier Circuits - Up To 1600 Volt Blocking Standardfaraz24No ratings yet

- 6SL3210-1PE33-7AL0 Datasheet enDocument2 pages6SL3210-1PE33-7AL0 Datasheet enDennisNo ratings yet

- Specifications - 700-HD RelaysDocument1 pageSpecifications - 700-HD RelaysArif KhanNo ratings yet

- 6SL3210-1PE32-5UL0 Datasheet enDocument2 pages6SL3210-1PE32-5UL0 Datasheet enmattila91No ratings yet

- 6SL3210-1PE31-8AL0 Datasheet enDocument2 pages6SL3210-1PE31-8AL0 Datasheet enSuparerk MalithongNo ratings yet

- Bus Cal - 2500aDocument11 pagesBus Cal - 2500aPCE PROJECTS PVT. LTD.No ratings yet

- 6SL3225-0BE33-0AA0 Datasheet enDocument2 pages6SL3225-0BE33-0AA0 Datasheet enLucas PaulaNo ratings yet

- Maestro 800 F 1000 F 1200 FDocument4 pagesMaestro 800 F 1000 F 1200 FYogendra ReddyNo ratings yet

- Electrochemical Measurement of Toxic Metal Contaminants in The Waters of The Golden Triangle AreaDocument21 pagesElectrochemical Measurement of Toxic Metal Contaminants in The Waters of The Golden Triangle AreaOmar ReynosoNo ratings yet

- Predicting Temperature Rise of Ferrite Cored TransformersDocument25 pagesPredicting Temperature Rise of Ferrite Cored Transformerslehaphuong03No ratings yet

- PredicttempriseDocument25 pagesPredicttempriseCHUKARONo ratings yet

- Practical Applications of Electrical ConductorsDocument12 pagesPractical Applications of Electrical ConductorsHans De Keulenaer100% (5)

- Copper: A Smart ChoiceDocument4 pagesCopper: A Smart ChoiceHans De KeulenaerNo ratings yet

- Business Models For Copper Campaigns.. ..Or Why Co-Funding Will Remain An Eternal Discussion PointDocument10 pagesBusiness Models For Copper Campaigns.. ..Or Why Co-Funding Will Remain An Eternal Discussion PointHans De KeulenaerNo ratings yet

- Design and Analysis of Supercapacitors Energy Storage System For Energy Stabilization of Distribution NetworkDocument19 pagesDesign and Analysis of Supercapacitors Energy Storage System For Energy Stabilization of Distribution NetworkHans De Keulenaer100% (6)

- Achieving More With Less Final ReportDocument62 pagesAchieving More With Less Final ReportHans De Keulenaer100% (3)

- Michelin Active WheelDocument7 pagesMichelin Active WheelHans De Keulenaer100% (1)

- Overview of EHV Underground Power Cables Feb 2008Document26 pagesOverview of EHV Underground Power Cables Feb 2008Hans De KeulenaerNo ratings yet

- Energy Efficiency in HotelsDocument21 pagesEnergy Efficiency in HotelsHans De Keulenaer100% (23)

- Centralised Reactive Power CompensationDocument6 pagesCentralised Reactive Power CompensationHans De Keulenaer100% (1)

- The Smart Grid - An IntroductionDocument48 pagesThe Smart Grid - An IntroductionHans De Keulenaer88% (8)

- Summary Comparison of National Energy Management StandardsDocument46 pagesSummary Comparison of National Energy Management StandardsHans De KeulenaerNo ratings yet

- 02 - Smartscreen Handout 28 - Heating Controls-1Document5 pages02 - Smartscreen Handout 28 - Heating Controls-1Daniel HollandsNo ratings yet

- Numerical Analysis For Energy Performance Optimization of Hollow Bricks For Roofing. Case Study - Hot Climate of AlgeriaDocument10 pagesNumerical Analysis For Energy Performance Optimization of Hollow Bricks For Roofing. Case Study - Hot Climate of Algeriamah0809No ratings yet

- Daikin Condensing Units Ecpen11-203 - tcm135-193371Document10 pagesDaikin Condensing Units Ecpen11-203 - tcm135-193371Denise Koh Chin HuiNo ratings yet

- ARBE4102 Lecture7 (1) - v2 PDFDocument80 pagesARBE4102 Lecture7 (1) - v2 PDFMeolah ChenNo ratings yet

- Parabolic Trough Solar CollectorDocument42 pagesParabolic Trough Solar CollectorMahrukh ZAIDI100% (2)

- Personnel Monitoring Services (PMS) Providers For Radiation FacilitiesDocument1 pagePersonnel Monitoring Services (PMS) Providers For Radiation FacilitiesSudhir ShindeNo ratings yet

- B257.OL3 - 004 - HT - Primary - Secondary Circuit - Rev01Document80 pagesB257.OL3 - 004 - HT - Primary - Secondary Circuit - Rev01megapoulpeNo ratings yet

- Fluid Mechanics LectureDocument70 pagesFluid Mechanics LectureAyush KumarNo ratings yet

- Remote Sensing Essentials: Electromagnetic Spectrum, Solar Reflection and Thermal EmissionDocument18 pagesRemote Sensing Essentials: Electromagnetic Spectrum, Solar Reflection and Thermal EmissionTrambak BhattacharyaNo ratings yet

- Indirect Adiabatic Cooling: Galina KukushkinaDocument39 pagesIndirect Adiabatic Cooling: Galina KukushkinaSloba H TD-VR-BG-MOSNo ratings yet

- Final Year Project ReportDocument89 pagesFinal Year Project ReportUsama JavedNo ratings yet

- Week 30 RPH Physics F4Document2 pagesWeek 30 RPH Physics F4Mohamad Shahir Ismail100% (1)

- Passive Cooling Technique in Composite ClimateDocument34 pagesPassive Cooling Technique in Composite ClimateUmang VashisthaaNo ratings yet

- Unit 6 S2Phy Thermal Transfer PracticeDocument8 pagesUnit 6 S2Phy Thermal Transfer PracticeWilly TanNo ratings yet

- Refrigeration and Air ConditioningDocument22 pagesRefrigeration and Air ConditioningDhairya GohilNo ratings yet

- Heat Trasnfer Lab. GF N. 109Document24 pagesHeat Trasnfer Lab. GF N. 109Aljebre MohmedNo ratings yet

- MEBS7012 2021 03-ComfortDocument83 pagesMEBS7012 2021 03-ComfortSam C M HuiNo ratings yet

- Heat Sink Selection in ElectronicsDocument12 pagesHeat Sink Selection in ElectronicsPravat Kumar BeheraNo ratings yet

- A Study of Thermal Energy Storage Systems With Conjugate Turbulent Forced ConvectionDocument9 pagesA Study of Thermal Energy Storage Systems With Conjugate Turbulent Forced ConvectionLiviu BadeaNo ratings yet

- Training Manual On Application of Building InsulationDocument47 pagesTraining Manual On Application of Building InsulationAthish KumarNo ratings yet

- Memmert Price List: Valid: October 2013Document1 pageMemmert Price List: Valid: October 2013Anugerah ErlautNo ratings yet

- Blackbody Radiation Experiment 7Document4 pagesBlackbody Radiation Experiment 7kashawna fujiwaraNo ratings yet

- (238866464) PaperDocument12 pages(238866464) PaperNatalia Cornejo MardonesNo ratings yet

- MHI Centrifugal Chillers: 16-5, Konan 2-Chome, Minato-Ku, Tokyo 108-8215, JapanDocument12 pagesMHI Centrifugal Chillers: 16-5, Konan 2-Chome, Minato-Ku, Tokyo 108-8215, JapanAbdulSattarNo ratings yet

- Heat TransferDocument2 pagesHeat TransferSMIT CHRISTIANNo ratings yet

- Optimal Fin Shapes & Profiles: Geometrical Optimization Is The Basic Goal of Optimal DesignDocument32 pagesOptimal Fin Shapes & Profiles: Geometrical Optimization Is The Basic Goal of Optimal DesignDawar ZaidiNo ratings yet

- And Thermal Conductivity and Uses The VBA Functions For Those PropertiesDocument6 pagesAnd Thermal Conductivity and Uses The VBA Functions For Those PropertiesselisenNo ratings yet

- Tropical Architecture: Green ArchitrendsDocument2 pagesTropical Architecture: Green ArchitrendsBRIAN DIQUIATCONo ratings yet

- 19 Flakt Woods TechDocument1 page19 Flakt Woods TechpejscottNo ratings yet