Professional Documents

Culture Documents

Lecture9 Feb25

Lecture9 Feb25

Uploaded by

trickaeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lecture9 Feb25

Lecture9 Feb25

Uploaded by

trickaeCopyright:

Available Formats

15.

760: National Cranberry Case

1. Admin: Webvan case; UHS case

2. What are the sources of variability in the NCC case?

3. What are the problems NCC is experiencing that should be

addressed?

4. Describe the Process Flow Diagram.

5. Assess possible options for relieving truck waiting.

6. How would you assess converting some dry bins to wet?

7. How would you assess whether you can begin at 8 am?

8. How would you assess labor cost impacts?

9. How would you deal with the distribution of wet/dry and volume

over the days of the season?

10. Can you eliminate/reduce demand peaks?

National Cranberry

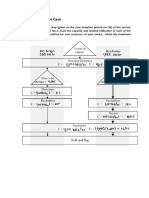

Process Flow Diagram

Unload

weighed/

graded

tested/

sampled

destone

dechaff

dry

separate

Bag

667 bbl/hr

dry

1-16

250 bbls

=4000 bbls

both

17-24

250 bbls

=2000 bbls

wet

25-27

3x400 bbls = 1200 bbls

2 x 1500 bbls/hr

1500 bbls/hr

5-10 min/truck

3 x 200 bbls/hr

3 x 400 bbls/hr

destone

2 x 1500 bbls/hr

dechaff

1500 bbls/hr

Bulk Truck

2000 bbl/hr

Bulk Bins

800 bbl/hr

Freeze

Freeze

dry

wet

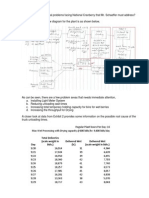

Wet Cranberry Inventory Buildup

Assume: buildup 18000 x 70% wet =12600 bbl/day

12600/12=1050 bbls/hr; Plant begins operations at 11:00;

Drying bottleneck @ 600 bbl/hr

Truck waiting =

7500

6000

4500

3000

1500

4200

7800

1050x4

450x8

-600/hr

4600/600

= 7.67hrs

= 2:40 am

No more trucks

3200/1050

= trucks begin waiting at 10:03 am

16.67 hrs x (4600/2)/75

= 511 hours

7:00 9:00 11:00 13:00 15:00 17:00 19:00 21:00 23:00 1:00 3:00

Plant is empty after 7800/600 = 13 hours after 19:00 or 8 am the next morning

Total run time = 12600/600 = 21 hours

Wet Cranberry Inventory Buildup

Assume: buildup 18000 x 70% wet =12600 bbl/day

12600/12=1050 bbls/hr; Plant begins operations at 7:00;

Drying bottleneck @ 600 bbl/hr

Truck waiting =

7500

6000

4500

3000

1500

450x12

=5400

-600/hr

2200/600

= 3.67hrs

= 20:40 pm

No more trucks

3200/450 = 7.1

= trucks begin waiting at 14:06 pm

8.67 hrs x (2200/2)/75

= 127 hours

7:00 9:00 11:00 13:00 15:00 17:00 19:00 21:00 23:00 1:00 3:00

Plant is empty after 5400/600 = 9 hours after 19:00 or 4 am the next morning

Total run time = 12600/600 = 21 hours

Wet Cranberry Inventory Buildup

Assume: buildup 18000 x 70% wet =12600 bbl/day

12600/12=1050 bbls/hr; Plant begins operations at 7:00;

Drying bottleneck @ 800 bbl/hr

Truck waiting = 0 !!

7500

6000

4500

3000

1500

250x12

=3000

3000/800

= 3.75hrs

= 20:45 pm

Processing complete

No truck buildup

7:00 9:00 11:00 13:00 15:00 17:00 19:00 21:00 23:00 1:00 3:00

Plant is empty after 3000/800 = 3.75 hours after 19:00 or 20;45 the next morning

Total run time = 12600/800 = 15.75 hours; dry berry processing drops to 400/hr

15.760

Basic Concepts in Queueing

System Performance = f(System parameters)

Arrival rate ( )

Output/throughput rate (

(

)

)

Service rate ( )

Inventory Level/Queue Size/

Service time ( M )

Line length

Number of servers ( S )

Waiting Time/Cycle Time ( W )

Queue/Buffer capacity ( R )

Capacity or Server utilization ( )

Capacity or Server utilization ( )

Probability that Queue is full ( P

full

)

Number of Service classes ( K )

Kiwanee Dumpers:Capacity Analysis

Busy Day: Arrival rate =

18,000 bbl/day =

1500bbl/hr = 20

trucks/hr

L=

2

/(1-)

W=

2

/(1-)

Basic Concepts in Queueing:

Nonlinearities in Congestion in Stochastic Systems

If service times

and interarrival

times have

exponential

distributions,

then

L=

2

/(1-)

W=

2

/(1-)

W

A

T

o

t

a

l

w

a

i

t

i

n

t

h

e

q

u

e

u

e

A

B

W

B

0 1

(Arrival Rate / Service Rate = )

= congestion

Management of Queues

The Physics of Waiting Lines

Number and type of servers

Waiting time, service time, and system time

Queue discipline

Number of people in queue

System utilization

Congestion 0

Delay

Cost

Capacity

Cost

Total

Cost

C

o

s

t

A

B

W

A

W

B

0 Congestion

T

o

t

a

l

t

i

m

e

i

n

t

h

e

q

u

e

u

e

1 1

(Arrival Rate / Service Rate) (Arrival Rate / Service Rate)

Management of Queues

SERVERS

The Psychology of Waiting Lines

CUSTOMERS

WAITING LINE

Propositions

1. Unoccupied time feels longer than occupied time

2. Process waits feel longer than in process waits

3. Anxiety makes waits seem longer

4. Uncertain waits seem longer than known, finite waits

5. Unexplained waits are longer than explained

6. Unfair waits are longer than equitable waits

7. The more valuable the service, the longer the customer will wait

8. Solo waits feel longer than group waits

You might also like

- Encyclopedia of Music in The 20th Century (PDFDrive)Document801 pagesEncyclopedia of Music in The 20th Century (PDFDrive)Petros Karatsolis100% (6)

- All Plumbing CalculationDocument46 pagesAll Plumbing Calculationhtranggono100% (2)

- GM Screen Individual PagesDocument8 pagesGM Screen Individual Pagessugma nutzNo ratings yet

- Spirulina Raceway Pond ModalDocument10 pagesSpirulina Raceway Pond Modalkavitha nagulendranNo ratings yet

- Compressor Performance TestDocument13 pagesCompressor Performance Testdhanu_aqua100% (1)

- COSTDocument11 pagesCOSTJNo ratings yet

- All Plumbing CalculationDocument43 pagesAll Plumbing CalculationRoland LewisNo ratings yet

- National Cranberry Case SolutionDocument4 pagesNational Cranberry Case SolutionAli Umer MughalNo ratings yet

- National Cranberry Case SolutionDocument7 pagesNational Cranberry Case SolutionKarthik TirupatiNo ratings yet

- Technical Report FinalDocument16 pagesTechnical Report FinalKenneth Dwight BojaNo ratings yet

- @water & Drainage Equipement DesignDocument46 pages@water & Drainage Equipement DesignDesigner ForeverNo ratings yet

- Are You Fully Charged - Tom RathDocument1 pageAre You Fully Charged - Tom RathHoratiu BahneanNo ratings yet

- CranberryDocument5 pagesCranberrymaverick_659No ratings yet

- National Cranberry CooperativeDocument3 pagesNational Cranberry CooperativeRasheeq RayhanNo ratings yet

- NCC - Case StudyDocument3 pagesNCC - Case StudyDeepika GuptaNo ratings yet

- National Cranberry CaseDocument10 pagesNational Cranberry CaseanshumanNo ratings yet

- Operations Management National Cranberry CaseDocument12 pagesOperations Management National Cranberry CaseKarthik TirupatiNo ratings yet

- Existing Capacity Calculation Sutiable For 13200 TCD (550TCH)Document13 pagesExisting Capacity Calculation Sutiable For 13200 TCD (550TCH)Omar Ahmed Elkhalil67% (6)

- National Cranberry Part IDocument3 pagesNational Cranberry Part IPrateekRaj167% (3)

- 11BM60008 Sec B National Cranberry CooperativeDocument9 pages11BM60008 Sec B National Cranberry CooperativeKunal Verma100% (3)

- NationalCranberryCooperative CaseAnalysisDocument10 pagesNationalCranberryCooperative CaseAnalysisJishnu RoychaudhuriNo ratings yet

- The National Cranberry CooperativeDocument5 pagesThe National Cranberry CooperativeHussein BayramNo ratings yet

- National Cranberries CaseDocument7 pagesNational Cranberries CaseHyper Green MindNo ratings yet

- Data Sheet FOR Pig Signal: Cikande - Bitung Distribution Pipeline Project Pt. Perusahaan Gas Negara Data SheetDocument3 pagesData Sheet FOR Pig Signal: Cikande - Bitung Distribution Pipeline Project Pt. Perusahaan Gas Negara Data Sheetalfa vimalaNo ratings yet

- National Cranberry Cooperative: Operations Management-SCH-MGMT-670Document8 pagesNational Cranberry Cooperative: Operations Management-SCH-MGMT-670Shreyas SatardekarNo ratings yet

- Study Group - 2 NCC CaseDocument7 pagesStudy Group - 2 NCC CaseAchin ChatterjeeNo ratings yet

- IDS 532 - National Cranberry Case Study - AnswersDocument4 pagesIDS 532 - National Cranberry Case Study - AnswersVikas Mani TripathiNo ratings yet

- National Cranberry Cooperative 1996-1 PDFDocument10 pagesNational Cranberry Cooperative 1996-1 PDFnephielive.cnNo ratings yet

- National Cranberry Cooperative CASE STUD PDFDocument10 pagesNational Cranberry Cooperative CASE STUD PDFSahil sangwanNo ratings yet

- Inventory Buit Up With Time Inventory Buildup at TruckDocument3 pagesInventory Buit Up With Time Inventory Buildup at TruckdfreNo ratings yet

- National Cranberry Cooperative Case Answer 1Document6 pagesNational Cranberry Cooperative Case Answer 1PRITEENo ratings yet

- Essay ReviewDocument11 pagesEssay ReviewMilagros AzparrentNo ratings yet

- Phase 3 Roofing Works - Damaki-1Document2 pagesPhase 3 Roofing Works - Damaki-1kabras CyberNo ratings yet

- How To Choose Marine Engine - 1Document10 pagesHow To Choose Marine Engine - 1Kuswanto MarineNo ratings yet

- Description 7.5 HP 3 HP 2 HP LPM As Per Yield Report For 45 Degree V Notch 10.6 10.6 10.6Document2 pagesDescription 7.5 HP 3 HP 2 HP LPM As Per Yield Report For 45 Degree V Notch 10.6 10.6 10.6Ratnakar SeethiniNo ratings yet

- Lift Pump CalculationDocument15 pagesLift Pump CalculationamrNo ratings yet

- Solution - Tutorial 6 - Simpson RulesDocument6 pagesSolution - Tutorial 6 - Simpson RulesSaurav NaskarNo ratings yet

- 100 KG ModuleDocument4 pages100 KG ModuleRonak JoshiNo ratings yet

- Problems On IttigationDocument6 pagesProblems On IttigationSamundra LuciferNo ratings yet

- Helicopter Flying in India - RahimDocument7 pagesHelicopter Flying in India - RahimMaruthi KuchibotlaNo ratings yet

- Assignment Solution Power PlanningDocument9 pagesAssignment Solution Power PlanningTahir KedirNo ratings yet

- Water & Drainage Equipement DesignDocument46 pagesWater & Drainage Equipement DesignsenghouNo ratings yet

- 048 - Revisi Tugas Kel 1 Akubi - Annisa Br. Pasaribu - Am 3B MalamDocument10 pages048 - Revisi Tugas Kel 1 Akubi - Annisa Br. Pasaribu - Am 3B Malam68zprcgw7tNo ratings yet

- Diesel Power Plant Problem Solving Examination NAME: Vincent Rey Olario Y. Bsme - 5 Show Complete Solutions. Solve The Following: Problem 1Document4 pagesDiesel Power Plant Problem Solving Examination NAME: Vincent Rey Olario Y. Bsme - 5 Show Complete Solutions. Solve The Following: Problem 1BensoyNo ratings yet

- Mining and Earthmoving: Estimating Production Off-the-Job Example Problem (English) Example Problem (Metric)Document4 pagesMining and Earthmoving: Estimating Production Off-the-Job Example Problem (English) Example Problem (Metric)ali alilouNo ratings yet

- Process Costing ProjectDocument7 pagesProcess Costing ProjectMathew KanichayNo ratings yet

- WSTT Ise ReportDocument6 pagesWSTT Ise ReportSushant KhandekarNo ratings yet

- 13 MCQ NcaDocument7 pages13 MCQ NcaTrang TranNo ratings yet

- Actual Material Standard Material Actual Labor Predetermined Overhead Yes Yes Yes YesDocument6 pagesActual Material Standard Material Actual Labor Predetermined Overhead Yes Yes Yes YesSarah SarmientoNo ratings yet

- Export Tariff PDFDocument3 pagesExport Tariff PDFNitin GoelNo ratings yet

- Slection of TransformerDocument6 pagesSlection of TransformerkennyjumanneNo ratings yet

- Cost of Production of SugercaneDocument3 pagesCost of Production of SugercaneDrsaabNo ratings yet

- Capacities of Various Plant and MachineryDocument7 pagesCapacities of Various Plant and MachineryBujjibabu KattaNo ratings yet

- Book 1Document8 pagesBook 1Zitheeq UmarNo ratings yet

- Solution To Homework Set #4 CE 327 - Spring 2009: Assigned Mo, 4/20 Due Mo, 4/27 Problem 1Document6 pagesSolution To Homework Set #4 CE 327 - Spring 2009: Assigned Mo, 4/20 Due Mo, 4/27 Problem 1amunyela hilyaNo ratings yet

- PowerCon PICCDocument2 pagesPowerCon PICCrlo77No ratings yet

- Ferry Service Data (1) 21.9.17Document2 pagesFerry Service Data (1) 21.9.17mukhleshNo ratings yet

- NCC Case Writeup 2020Document7 pagesNCC Case Writeup 2020rajuNo ratings yet

- SPE 136967 Evaluation of Compressibility Factor Correlations For Niger Delta Gas ReservoirsDocument9 pagesSPE 136967 Evaluation of Compressibility Factor Correlations For Niger Delta Gas ReservoirsekeneNo ratings yet

- 1393316341213Document9 pages1393316341213Saikat ChatterjeeNo ratings yet

- Shell ScriptDocument3 pagesShell ScriptRough MetalNo ratings yet

- EVA Momentum The One Ratio That Tells The Whole StoryDocument15 pagesEVA Momentum The One Ratio That Tells The Whole StorySiYuan ZhangNo ratings yet

- Ipe Short Notes - SUEDocument3 pagesIpe Short Notes - SUEMunch ChiniNo ratings yet

- 11 Appendix 1 Highway Safety Inspection Manual October 2016Document50 pages11 Appendix 1 Highway Safety Inspection Manual October 2016Philip EvansNo ratings yet

- Presentation 4Document18 pagesPresentation 4Dipayan BiswasNo ratings yet

- Ethernet IP Via 1761 NET ENI To SLC503Document21 pagesEthernet IP Via 1761 NET ENI To SLC503benito1No ratings yet

- Illustration - 2022-02-16T110618.998Document3 pagesIllustration - 2022-02-16T110618.998mosarafNo ratings yet

- Foundation (Engineering)Document4 pagesFoundation (Engineering)hulalaNo ratings yet

- Quick Reference Price List 2017: Where To Find Our Head Office How To Contact UsDocument2 pagesQuick Reference Price List 2017: Where To Find Our Head Office How To Contact UsbogdanyuNo ratings yet

- Prepositional PhrasesDocument13 pagesPrepositional PhrasesBerlianova Cahya CantikaNo ratings yet

- ID Tindakan Koperasi Simpan Pinjam Yan Mengakibatkan Perbuatan Tindak PidanaDocument7 pagesID Tindakan Koperasi Simpan Pinjam Yan Mengakibatkan Perbuatan Tindak PidanaAyu Pratiwi SatriyoNo ratings yet

- X Series x13 g2 20jul09Document4 pagesX Series x13 g2 20jul09Laiq ZamanNo ratings yet

- Turkey: National Olympiad First Round 1998Document5 pagesTurkey: National Olympiad First Round 1998booby fischerNo ratings yet

- Thesis On Accounting and Finance PDFDocument5 pagesThesis On Accounting and Finance PDFNicole Heredia100% (2)

- Lombok Daily TourDocument9 pagesLombok Daily Tourazmi LombokNo ratings yet

- Preptest2010 PDFDocument2 pagesPreptest2010 PDFJohnkent FloresNo ratings yet

- Lecture9A - CpE 690 Introduction To VLSI DesignDocument20 pagesLecture9A - CpE 690 Introduction To VLSI DesignjvandomeNo ratings yet

- 2020 Spring Newsletter WisDocument8 pages2020 Spring Newsletter Wisapi-353949457No ratings yet

- Job EnrichmentDocument44 pagesJob EnrichmentSeema RahulNo ratings yet

- Soal Us B Inggris 2022-2023Document8 pagesSoal Us B Inggris 2022-2023Septia AnggraeniNo ratings yet

- Bard 3 Entertainer Bobby Lee Human CG: StrengthDocument1 pageBard 3 Entertainer Bobby Lee Human CG: StrengthClyde McFreeNo ratings yet

- Test Procedure Offer 019-14V 3015Document5 pagesTest Procedure Offer 019-14V 3015sohaibNo ratings yet

- Silicon NPN TransistorDocument4 pagesSilicon NPN TransistordaneloNo ratings yet