Professional Documents

Culture Documents

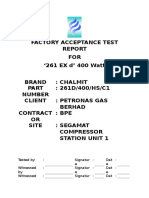

Factory Acceptance Testing (FAT) : Preface

Uploaded by

rw992049Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Factory Acceptance Testing (FAT) : Preface

Uploaded by

rw992049Copyright:

Available Formats

Factory Acceptance Testing (FAT)

Preface

The Factory Acceptance Test (FAT) is a major project milestone in a

laboratory automation project where the equipment and/or system

integrator demonstrates that the system design and manufacturing

meets the contract or Purchase Order (P.O.) specifications (derived

from the Functional Requirements Document (FRD), created by the

system owner/project manager/project team). Generally a substantial

financial payment to the vendor is triggered by a successful FAT,

therefore the FAT must be conducted formally and be witnessed by

the system owner and/or project manager, with a formal record of

discrepancies and non conformities and how they are to be handled.

Unfortunately some vendors are often poorly prepared for FAT, and

the FAT is often rushed though in order to ship the equipment as soon

as possible, realize a milestone payment in the vendors's financial

reporting period, or move expensive inventory off a vendor's books.

But a poor FAT can delay observation of non conformities until after

the equipment is installed when less time is available to correct the

problems without consequences to the project schedule, and when

there is sometimes less flexibility for effecting technical solutions.

This document is an overview of what the system owner/project

manager should consider with respect to equipment FATs.

Contract/Purchase Order

Incude the project teams Functional Requirements Document, as part

of any contract or purchase order with the system vendor or

integrator.

Include in the contract / purcahse order the requirement for a

FAT and that:

The FAT must be witnessed by the system owner, project

manager or designee.

The equipment should be fully pretested by the vendor before

the witnessed FAT.

The FAT include all equipment being supplied by the vendor.

The FAT procedure is to be presented to the system owner for

approval at least two weeks before the witnessed FAT, and

should be derived from validation specifications as laid out in the

Functional Requirements Document.

Pre FAT

The testing included in a FAT procedure should be largely derived from

the performance criteria defined in the Functional Requirements

Document (FRD), which is created by the project team early in the

project planning process. The FRD should be the focal point for

discussions when interviewing potential system integrators / vendors

and should be included in the contract/purchase order package. These

requirements should, therefore, be well known and understood well

before time to develop the actual FAT protocol.

The vendor/system integrator should prepare and submit a FAT

procedure well in advance of the FAT. This procedure should be

reviewed and approved by the system owner/project manager. It

should attempt to include testing of as much functionality as is

practical in the factory, and check of all interfaces among equipment

and systems. Where possible the procedure should show pass/fail

criteria or desired results for each item.

The vendor should also provide a schedule for the FAT showing

all timing and sequence of testing.

Prior to FAT all design approvals should be complete. This is to

remove technical ambiguity from the FAT and prevent disputes

over work that continues after FAT.

The vendor should prepare a test facility that can be effectively

used to conduct the FAT testing, including calibrated test

equipment and any special test equipment.

The vendor should compile a document set that can support the

testing and serve as a reference for the test results, including:

Contract specifications and copies of all references called out in

the specification.

All drawings for the project, including drawings received from

other vendors that describe interfaces.

Detailed testing check list, including pass/fail criteria.

The vendor is to pretest the system before FAT. Failure to do

this can result in wasted time during FAT, and potentially a

prolonged extension of FAT while fixes are effected.

If the system in question is large enough to impact the system owners

facilities, laboratory layout or utilities or if there are any questions

regarding moving the system into the owners facility, it is highly

recommened that a person responsible for for the owners physical

plant/facility be invited to attend FAT.

FAT

Attendance by vendor/system integrator, and by the system owner

and/or project manager. Depending on the scope of the project, the

owners FAT team could include owners site facilities staff, informatics

staff or other techncial staff that may be involved in daily operation of

the system. Inspection of the equipment is an important step that can

be done at any convenient point. The inspection is generally

Review the specification line by line while checking the

equipment or drawings for compliance with the specification,

including any change orders.

Inspect for workmanship

Inspect for problems that can occur during installation or use of

the equipment, for example, lifting points and safe access to

components for maintenance, etc.

Test of the equipment per the vendors approved procedure;

these should include functionality testing and regulatory testing.

Ad hoc testing may be required to define any major non-

conformities revealed by testing.

Note the software and firmware versions in the equipment being

tested.

Post Testing Activities

Check of documentation

Review draft manuals and note any deficiencies.

Confirm that the vendor has and will deliver records of hardware

and software sourcing and traceability.

Confirm vendors schedule for completing all documentation.

Punch Lists

All discrepancies and non conformities of the system should be

compiled into a Non Conformities List, including a time to

complete column, for example, before shipment. Items

incomplete, or not available for inspection or FAT are to be

included on the Non-Conformities List.

The Non-Conformities List should be issued to the vendor at the

end of FAT for discussion to confirm agreement with the time to

complete.

The Non-Conformities List helps to prioritize and focus work to

complete the system with minimum impact on the project critical

path. It needs to be followed up with the vendor periodically to

insure continued attention.

Substantial non-conformities can influence the vendors eligibility

to receive the full FAT progress payment. Project management

should review this on a case by case basis.

You might also like

- Factory Acceptance Test ProtocolDocument28 pagesFactory Acceptance Test ProtocolShabbir Hussain Palitanawala100% (6)

- Certified Automation Professional A Complete Guide - 2020 EditionFrom EverandCertified Automation Professional A Complete Guide - 2020 EditionNo ratings yet

- FAT and SAT ProcedureDocument3 pagesFAT and SAT ProcedureSoe SintthuNo ratings yet

- Factory Acceptance Test (FAT) GuideDocument6 pagesFactory Acceptance Test (FAT) GuideOmar Angulo100% (1)

- FAT Procedure Rev.1Document9 pagesFAT Procedure Rev.1Rahul Deva100% (1)

- QP-ENG-PRC-008 - QP Procedure For Site Acceptance Test - Rev 00Document13 pagesQP-ENG-PRC-008 - QP Procedure For Site Acceptance Test - Rev 00salem elhajNo ratings yet

- Completion Manager Job DesDocument2 pagesCompletion Manager Job DesjrladduNo ratings yet

- SAT Sample For BoilerDocument15 pagesSAT Sample For Boilerjpmaurya77No ratings yet

- FATDocument36 pagesFATSanjay Kumar ChaubeyNo ratings yet

- J1525-HW1-010 SAT Procedure - Rev ADocument16 pagesJ1525-HW1-010 SAT Procedure - Rev Aluis HernandezNo ratings yet

- Mechanical Completion and Handover ProcedureDocument3 pagesMechanical Completion and Handover Procedureleong100% (1)

- Sample FAT ProtocolDocument6 pagesSample FAT ProtocolUmer Al-Faisal50% (2)

- Template Commissioning Plan v5Document6 pagesTemplate Commissioning Plan v5anton100% (1)

- Site Acceptance Test (SAT)Document23 pagesSite Acceptance Test (SAT)Arfan Athafariz100% (2)

- Factory Acceptance Test PDFDocument2 pagesFactory Acceptance Test PDFStephanie0% (3)

- Factory Acceptance Test FAT ProtocolDocument1 pageFactory Acceptance Test FAT ProtocolBalakrishnan S NadarNo ratings yet

- FAT ChecklistDocument17 pagesFAT ChecklistNoe Jimenez100% (2)

- Hydrotest Check ListDocument1 pageHydrotest Check ListSaut Maruli Tua SamosirNo ratings yet

- FAT Procedure & ChecklistDocument3 pagesFAT Procedure & ChecklistARSHI ASLAM100% (3)

- Lubricant Oil and Grease List, MSDS For ChemicalsDocument19 pagesLubricant Oil and Grease List, MSDS For ChemicalsMuhammadPurnamaSugiriNo ratings yet

- Pre Commisioning Check ListDocument22 pagesPre Commisioning Check ListFardyanto, BNo ratings yet

- Factory Acceptance Test New Sample ReportDocument13 pagesFactory Acceptance Test New Sample ReportJafarov VuqarNo ratings yet

- Commissioning Observation and Testing Report: 1. General Project InformationDocument1 pageCommissioning Observation and Testing Report: 1. General Project InformationHumaid ShaikhNo ratings yet

- U R T System (I) : SER Equirements Emplate FOR A Nsert Your System Description HereDocument25 pagesU R T System (I) : SER Equirements Emplate FOR A Nsert Your System Description HereVinodh KumarNo ratings yet

- F-Qa-03a Material - Receiving - Storage and Handling Inspection ChecklistDocument1 pageF-Qa-03a Material - Receiving - Storage and Handling Inspection ChecklistHilal mohamedNo ratings yet

- 02 Master List of Machine & EquipmentsDocument1 page02 Master List of Machine & EquipmentsVipul Panchal50% (2)

- Z 007 5913722 PDFDocument56 pagesZ 007 5913722 PDFLegend AnbuNo ratings yet

- Template For User Requirement Specifications - Pharmaceutical GuidanceDocument6 pagesTemplate For User Requirement Specifications - Pharmaceutical GuidanceMSL IndiaNo ratings yet

- AM2755 - Testing, Commissioning and Handover Template Rev T0Document40 pagesAM2755 - Testing, Commissioning and Handover Template Rev T0Schuldich Schwarz0% (1)

- VVISUAL INSPECTION Check CHECKLIST PDFDocument2 pagesVVISUAL INSPECTION Check CHECKLIST PDFDanny BoysieNo ratings yet

- Equipment Data Record Analyzer Transmitter: AIT-100 VRU 100 H2S DetectionDocument57 pagesEquipment Data Record Analyzer Transmitter: AIT-100 VRU 100 H2S DetectionFedilino P. FornollesNo ratings yet

- Model Qap Cable TrayDocument2 pagesModel Qap Cable Trayveerendra100% (3)

- Site Acceptance Test Contract No.: 537856: 863013-VPS-PQM-E-DS-0002Document16 pagesSite Acceptance Test Contract No.: 537856: 863013-VPS-PQM-E-DS-0002Andry YanuarNo ratings yet

- Method Statement Loop CheckDocument4 pagesMethod Statement Loop CheckMohamed Rafih100% (1)

- Commissioning Template PDFDocument5 pagesCommissioning Template PDFHadjon PhillNo ratings yet

- P27-Factory Acceptance Test Report - HV SWGR - 0Document49 pagesP27-Factory Acceptance Test Report - HV SWGR - 0caigithe852456100% (4)

- TEMPLATE FOR OPERATIONAL QUALIFICATION PROTOCOL - Pharmaceutical GuidanceDocument7 pagesTEMPLATE FOR OPERATIONAL QUALIFICATION PROTOCOL - Pharmaceutical GuidanceMSL India100% (2)

- KP-00+++-CQ712-G0011 - Rev.0 - ITP For For Cathodic Protection WorksDocument7 pagesKP-00+++-CQ712-G0011 - Rev.0 - ITP For For Cathodic Protection WorksUtku Can KılıçNo ratings yet

- Mandrelling Test / Checklist: Pmqs Construction Solutions, IncDocument1 pageMandrelling Test / Checklist: Pmqs Construction Solutions, IncAbnar KumplishaNo ratings yet

- A.S. A. Ap117: (Instrument & Control Engineer) & Spi (Intools) Specialist ObjectiveDocument5 pagesA.S. A. Ap117: (Instrument & Control Engineer) & Spi (Intools) Specialist ObjectiveAkoKhalediNo ratings yet

- Example of Factory Acceptance TestDocument3 pagesExample of Factory Acceptance TestLuqman BostNo ratings yet

- Instrument ITPDocument4 pagesInstrument ITPVictor Biacolo100% (2)

- Packaging PDFDocument48 pagesPackaging PDFDebasis Kumar SahaNo ratings yet

- Annex 1 System Completion and Handover FlowDocument1 pageAnnex 1 System Completion and Handover FlowIndra MulyanaNo ratings yet

- S-000-5138-302 - B Design Change Procedure PDFDocument6 pagesS-000-5138-302 - B Design Change Procedure PDFMahadevan MahalingamNo ratings yet

- Site Acceptance Test (SAT) Protocol: Project No. 2205 100 GPM Amine Sweetening Unit PlantDocument28 pagesSite Acceptance Test (SAT) Protocol: Project No. 2205 100 GPM Amine Sweetening Unit PlantIsaias de la CruzNo ratings yet

- Compressor Performance TestDocument9 pagesCompressor Performance TestPartha Pratim GhoshNo ratings yet

- Loop Checking and Field Instrument Testing ProcedureDocument7 pagesLoop Checking and Field Instrument Testing Procedurecharzree0% (1)

- Statement For CCTV System Testing & CommissioningDocument9 pagesStatement For CCTV System Testing & CommissioningAnonymousNo ratings yet

- Testing and Commissioning Procedure FOR Catering Equipment Installation IN Government Buildings OF The Hong Kong Special Administrative RegionDocument29 pagesTesting and Commissioning Procedure FOR Catering Equipment Installation IN Government Buildings OF The Hong Kong Special Administrative RegionAzam Faiez MokhtarNo ratings yet

- FAT Procedure GresikDocument56 pagesFAT Procedure GresikAriz Joelee Artha100% (1)

- Check List For CommissioningDocument18 pagesCheck List For CommissioningAnil RadheshwarNo ratings yet

- Particle Count SOPDocument2 pagesParticle Count SOPSubodh Murkewar100% (1)

- Mels Constuction Limitada: Commercial Management Mechanical Completion CertificateDocument1 pageMels Constuction Limitada: Commercial Management Mechanical Completion CertificateDeonNo ratings yet

- ITP For Hydraulic BarrierDocument4 pagesITP For Hydraulic Barriermoytabura96No ratings yet

- 3.2 Develop The Material Control PlanDocument9 pages3.2 Develop The Material Control Planjesus_bs100% (1)

- Guidelines On Testing DP SystemsDocument28 pagesGuidelines On Testing DP SystemsFrancis ButlerNo ratings yet

- Factory Acceptance TestDocument8 pagesFactory Acceptance Testpsn_kylm100% (2)

- An Intro To Boiler Control SystemsDocument35 pagesAn Intro To Boiler Control SystemsShankarMukherjeeNo ratings yet

- 3P04 Tutorial 5 MockQuiz 2008Document4 pages3P04 Tutorial 5 MockQuiz 2008Khaled KamalNo ratings yet

- 3P04 Tutorial 7 SingleLoop 2008Document19 pages3P04 Tutorial 7 SingleLoop 2008Khaled KamalNo ratings yet

- 3P04 Tutorial 4 Post 2008Document8 pages3P04 Tutorial 4 Post 2008Khaled KamalNo ratings yet

- 03a. Industrial Control SystemsDocument25 pages03a. Industrial Control SystemsKhaled KamalNo ratings yet

- 3P04 Tutorial 2 Causeeffectvalve 2008Document34 pages3P04 Tutorial 2 Causeeffectvalve 2008Khaled KamalNo ratings yet

- 3P04 Tutorial 3 Why Model 2008Document12 pages3P04 Tutorial 3 Why Model 2008Khaled KamalNo ratings yet

- I Thought We Were Only Considering Pure Strategy Equilibria.Document1 pageI Thought We Were Only Considering Pure Strategy Equilibria.Khaled KamalNo ratings yet

- 3P04 Tutorial 1 SensorFlow 2008Document28 pages3P04 Tutorial 1 SensorFlow 2008Khaled KamalNo ratings yet

- Commisioning Guidelines EPADocument29 pagesCommisioning Guidelines EPAAndy MoviemakersNo ratings yet

- Bueno de MesquitaDocument33 pagesBueno de MesquitaDiegoNo ratings yet

- Control of BoilersDocument1 pageControl of BoilersKhaled KamalNo ratings yet

- Electrical Licensing For InstrumentationDocument6 pagesElectrical Licensing For InstrumentationKhaled KamalNo ratings yet

- Isa Event Location and Date Request FormDocument1 pageIsa Event Location and Date Request FormKhaled KamalNo ratings yet

- Communication and Design Portafolio - Vanessa CerviniDocument34 pagesCommunication and Design Portafolio - Vanessa CerviniVanCerRNo ratings yet

- People v. Bandojo, JR., G.R. No. 234161, October 17, 2018Document21 pagesPeople v. Bandojo, JR., G.R. No. 234161, October 17, 2018Olga Pleños ManingoNo ratings yet

- EIB Pan-European Guarantee Fund - Methodological NoteDocument6 pagesEIB Pan-European Guarantee Fund - Methodological NoteJimmy SisaNo ratings yet

- Retirement SpeechDocument11 pagesRetirement SpeechRayan Castro100% (1)

- Final Seniority List of HM (High), I.s., 2013Document18 pagesFinal Seniority List of HM (High), I.s., 2013aproditiNo ratings yet

- List of Departed Soul For Daily PrayerDocument12 pagesList of Departed Soul For Daily PrayermoreNo ratings yet

- EAD-533 Topic 3 - Clinical Field Experience A - Leadership AssessmentDocument4 pagesEAD-533 Topic 3 - Clinical Field Experience A - Leadership Assessmentefrain silvaNo ratings yet

- Sailpoint Training Understanding ReportDocument2 pagesSailpoint Training Understanding ReportKunalGuptaNo ratings yet

- Power of Attorney UpdatedDocument1 pagePower of Attorney UpdatedHitalo MariottoNo ratings yet

- Tally Trading and Profit Loss Acc Balance SheetDocument14 pagesTally Trading and Profit Loss Acc Balance Sheetsuresh kumar10No ratings yet

- Short Run Decision AnalysisDocument31 pagesShort Run Decision AnalysisMedhaSaha100% (1)

- DLF New Town Gurgaon Soicety Handbook RulesDocument38 pagesDLF New Town Gurgaon Soicety Handbook RulesShakespeareWallaNo ratings yet

- Chapter 2 - AuditDocument26 pagesChapter 2 - AuditMisshtaCNo ratings yet

- GHMC Results, 2009Document149 pagesGHMC Results, 2009UrsTruly kotiNo ratings yet

- Coorg Chicken CurryDocument1 pageCoorg Chicken CurryAnitha VinukumarNo ratings yet

- Developing A Business Plan For Your Vet PracticeDocument7 pagesDeveloping A Business Plan For Your Vet PracticeMujtaba AusafNo ratings yet

- General Concepts and Principles of ObligationsDocument61 pagesGeneral Concepts and Principles of ObligationsJoAiza DiazNo ratings yet

- CMAT Score CardDocument1 pageCMAT Score CardRaksha RudraNo ratings yet

- Final Draft RTS On SADocument84 pagesFinal Draft RTS On SAjose pazNo ratings yet

- Kesari Tours and Travel: A Service Project Report OnDocument15 pagesKesari Tours and Travel: A Service Project Report OnShivam Jadhav100% (3)

- Nuclear Power Plants PDFDocument64 pagesNuclear Power Plants PDFmvlxlxNo ratings yet

- Italian Budgeting Policy Between Punctuations and Incrementalism Alice Cavalieri Full ChapterDocument51 pagesItalian Budgeting Policy Between Punctuations and Incrementalism Alice Cavalieri Full Chapterjames.philson408No ratings yet

- Dividend Discount ModelDocument54 pagesDividend Discount ModelVaidyanathan Ravichandran100% (1)

- PTE GURU - Will Provide You Template For Following SST, SWT, RETELL, DI and ESSAY and at The End Some Good Knowledge of Scoring SystemDocument6 pagesPTE GURU - Will Provide You Template For Following SST, SWT, RETELL, DI and ESSAY and at The End Some Good Knowledge of Scoring Systemrohit singh100% (1)

- MPDF Gayatri JapamDocument12 pagesMPDF Gayatri JapamS84SNo ratings yet

- Metaphors of GlobalizationDocument3 pagesMetaphors of GlobalizationShara Christile ColanggoNo ratings yet

- 2015 3d Secure WhitepaperDocument7 pages2015 3d Secure WhitepapersafsdfNo ratings yet

- Turnaround ManagementDocument16 pagesTurnaround Managementpaisa321No ratings yet

- Restrictive Covenants - AfsaDocument10 pagesRestrictive Covenants - AfsaFrank A. Cusumano, Jr.No ratings yet

- Types of Business LettersDocument11 pagesTypes of Business LettersernewstNo ratings yet

- 300+ PMP Practice Questions Aligned with PMBOK 7, Agile Methods, and Key Process Groups - 2024: First EditionFrom Everand300+ PMP Practice Questions Aligned with PMBOK 7, Agile Methods, and Key Process Groups - 2024: First EditionRating: 5 out of 5 stars5/5 (1)

- A Place of My Own: The Architecture of DaydreamsFrom EverandA Place of My Own: The Architecture of DaydreamsRating: 4 out of 5 stars4/5 (242)

- Building a Second Brain: A Proven Method to Organize Your Digital Life and Unlock Your Creative PotentialFrom EverandBuilding a Second Brain: A Proven Method to Organize Your Digital Life and Unlock Your Creative PotentialRating: 4.5 out of 5 stars4.5/5 (240)

- The PARA Method: Simplify, Organize, and Master Your Digital LifeFrom EverandThe PARA Method: Simplify, Organize, and Master Your Digital LifeRating: 4.5 out of 5 stars4.5/5 (3)

- The PARA Method: Simplify, Organize, and Master Your Digital LifeFrom EverandThe PARA Method: Simplify, Organize, and Master Your Digital LifeRating: 5 out of 5 stars5/5 (36)

- Q & As for the PMBOK® Guide Sixth EditionFrom EverandQ & As for the PMBOK® Guide Sixth EditionRating: 4.5 out of 5 stars4.5/5 (18)

- Project Management All-in-One For DummiesFrom EverandProject Management All-in-One For DummiesRating: 5 out of 5 stars5/5 (6)

- The Manager's Path: A Guide for Tech Leaders Navigating Growth and ChangeFrom EverandThe Manager's Path: A Guide for Tech Leaders Navigating Growth and ChangeRating: 4.5 out of 5 stars4.5/5 (99)

- Project Management: The Ultimate Guide for Managing Projects, Productivity, Profits of Enterprises, Startups and Planning with Lean, Scrum, Agile.From EverandProject Management: The Ultimate Guide for Managing Projects, Productivity, Profits of Enterprises, Startups and Planning with Lean, Scrum, Agile.Rating: 4.5 out of 5 stars4.5/5 (3)

- PMP Exam Prep: Master the Latest Techniques and Trends with this In-depth Project Management Professional Guide: Study Guide | Real-life PMP Questions and Detailed Explanation | 200+ Questions and AnswersFrom EverandPMP Exam Prep: Master the Latest Techniques and Trends with this In-depth Project Management Professional Guide: Study Guide | Real-life PMP Questions and Detailed Explanation | 200+ Questions and AnswersRating: 5 out of 5 stars5/5 (2)

- Real Life: Construction Management Guide from A-ZFrom EverandReal Life: Construction Management Guide from A-ZRating: 4.5 out of 5 stars4.5/5 (4)

- Harvard Business Review Project Management Handbook: How to Launch, Lead, and Sponsor Successful ProjectsFrom EverandHarvard Business Review Project Management Handbook: How to Launch, Lead, and Sponsor Successful ProjectsRating: 4.5 out of 5 stars4.5/5 (16)

- The Aqua Group Guide to Procurement, Tendering and Contract AdministrationFrom EverandThe Aqua Group Guide to Procurement, Tendering and Contract AdministrationMark HackettRating: 4 out of 5 stars4/5 (1)

- The Strategist: Be the Leader Your Business NeedsFrom EverandThe Strategist: Be the Leader Your Business NeedsRating: 4.5 out of 5 stars4.5/5 (48)

- Administrative Procedures and ManagementFrom EverandAdministrative Procedures and ManagementRating: 5 out of 5 stars5/5 (1)

- The Complete Project Management Exam Checklist: 500 Practical Questions & Answers for Exam Preparation and Professional Certification: 500 Practical Questions & Answers for Exam Preparation and Professional CertificationFrom EverandThe Complete Project Management Exam Checklist: 500 Practical Questions & Answers for Exam Preparation and Professional Certification: 500 Practical Questions & Answers for Exam Preparation and Professional CertificationNo ratings yet

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedFrom EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedRating: 5 out of 5 stars5/5 (1)

- Agile Project Management: Scrum for BeginnersFrom EverandAgile Project Management: Scrum for BeginnersRating: 4 out of 5 stars4/5 (7)

- Building Physics -- Heat, Air and Moisture: Fundamentals and Engineering Methods with Examples and ExercisesFrom EverandBuilding Physics -- Heat, Air and Moisture: Fundamentals and Engineering Methods with Examples and ExercisesNo ratings yet

- Managing Time (HBR 20-Minute Manager Series)From EverandManaging Time (HBR 20-Minute Manager Series)Rating: 4.5 out of 5 stars4.5/5 (47)

- Crossing the Chasm, 3rd Edition: Marketing and Selling Disruptive Products to Mainstream CustomersFrom EverandCrossing the Chasm, 3rd Edition: Marketing and Selling Disruptive Products to Mainstream CustomersRating: 4.5 out of 5 stars4.5/5 (19)

- Scrum: Understanding Scrum at a Deeper Level and Mastering Agile Project ManagementFrom EverandScrum: Understanding Scrum at a Deeper Level and Mastering Agile Project ManagementRating: 3.5 out of 5 stars3.5/5 (2)

- The PMP Project Management Professional Certification Exam Study Guide - PMBOK Seventh 7th Edition: Proven Methods to Pass the PMP Exam With Confidence - Complete Practice Tests With AnswersFrom EverandThe PMP Project Management Professional Certification Exam Study Guide - PMBOK Seventh 7th Edition: Proven Methods to Pass the PMP Exam With Confidence - Complete Practice Tests With AnswersRating: 5 out of 5 stars5/5 (1)

- PMP Exam Prep: How to pass the PMP Exam on your First Attempt – Learn Faster, Retain More and Pass the PMP ExamFrom EverandPMP Exam Prep: How to pass the PMP Exam on your First Attempt – Learn Faster, Retain More and Pass the PMP ExamRating: 4.5 out of 5 stars4.5/5 (3)

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AFrom EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANo ratings yet

- Principles of Welding: Processes, Physics, Chemistry, and MetallurgyFrom EverandPrinciples of Welding: Processes, Physics, Chemistry, and MetallurgyRating: 4 out of 5 stars4/5 (1)