Professional Documents

Culture Documents

Simulation of A PMSM Motor Control System For EPS Controllers

Simulation of A PMSM Motor Control System For EPS Controllers

Uploaded by

Ccoris JMOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Simulation of A PMSM Motor Control System For EPS Controllers

Simulation of A PMSM Motor Control System For EPS Controllers

Uploaded by

Ccoris JMCopyright:

Available Formats

1

Simulation of A

PMSM Motor Control System

for EPS Controllers

July 23, 2003

by

Guang Liu

Alex Kurnia

Ronan De Larminat

2

OUTLINE

1. Introduction

2. System block diagram

3. Simulink models of system elements

4. Simulation and experimental results

5. Conclusion

3

1. INTRODUCTION

4

1. INTRODUCTION

Simplified Block Diagram of An EPS System

EPS

Steering

mechanism

5

2. SYSTEM BLOCK

DIAGRAM

6

2. SYSTEM BLOCK DIAGRAM

7

3. SIMULINK MODELS OF SYSTEM ELEMENTS

3. SIMULINK MODELS OF

SYSTEM ELEMENTS

8

3. SIMULINK MODELS OF SYSTEM ELEMENTS

Permanent Magnet Synchronous Motor (PMSM) Model

9

q

dt

d

e q d

dt

d

d d s d

i L i L i R v + = )]

3

4

cos( )

3

2

cos( cos [

3

2

+ + =

c b a d

v v v v

)]

3

4

sin( )

3

2

( sin sin [

3

2

=

c b a q

v s v v v

PM e d

dt

d

e d q

dt

d

q q s q

i L i L i R v + + + =

] ) ( [

2

3

q d q d q PM e

i i L L i P T + =

m m f L e

dt

d

J K T T + + =

sin cos

q d a

i i i =

)

3

2

sin( )

3

2

cos(

=

q d b

i i i

)

3

4

sin( )

3

4

cos(

=

q d c

i i i

3. SIMULINK MODELS OF SYSTEM ELEMENTS

Permanent Magnet Synchronous Motor (PMSM) Equations

D-Q axis electric circuit equations Park transformation equations

Torque equations

Inverse Park transformation equations

10

3. SIMULINK MODELS OF SYSTEM ELEMENTS

Motor Position Sensor Model

Complete Sensor:

Error generator:

11

3. SIMULINK MODELS OF SYSTEM ELEMENTS

Current Sensing Model

V

V_A

V_B

V_C

V1

V2 V3

(3)

(1)

(5)

(4)

(6)

(2)

12

3. SIMULINK MODELS OF SYSTEM ELEMENTS

PI Controller Model

13

3. SIMULINK MODELS OF SYSTEM ELEMENTS

Inverse Park and SVM Model

14

4. SIMULATION & EXPERIMENTAL RESULTS

4. SIMULATION AND

EXPERIMENTAL RESUTLS

15

4. SIMULATION & EXPERIMENTAL RESULTS

0 0.5 1 1.5 2 2.5 3 3.5 4

0

0.5

1

1.5

T

o

r

q

u

e

(

N

.

m

.

)

Time (Sec.)

Resolution =6 count per rev.

0 0.5 1 1.5 2 2.5 3 3.5 4

-30

-20

-10

0

10

20

30

P

h

a

s

e

c

u

r

r

e

n

t

(

A

)

Time (Sec.)

Simulated torque ripple with 6-count resolution

Torque ripple = 1 N.m., current becomes square wave.

16

4. SIMULATION & EXPERIMENTAL RESULTS

Simulated torque ripple with 48-count resolution

0.5 1 1.5 2 2.5 3 3.5 4

0.985

0.99

0.995

1

1.005

T

o

r

q

u

e

(

N

.

m

.

)

Time (Sec.)

Resolution =48 count per rev.

0 0.5 1 1.5 2 2.5 3 3.5 4

-30

-20

-10

0

10

20

30

P

h

a

s

e

c

u

r

r

e

n

t

(

A

)

Time (Sec.)

Torque ripple = 0.012 N.m.

17

0.5 1 1.5 2 2.5 3 3.5 4

0.996

0.998

1

1.002

T

o

r

q

u

e

(

N

.

m

.

)

Time (Sec.)

Resolution =4096 count per rev.

0 0.5 1 1.5 2 2.5 3 3.5 4

-30

-20

-10

0

10

20

30

P

h

a

s

e

c

u

r

r

e

n

t

(

A

)

Time (Sec.)

4. SIMULATION & EXPERIMENTAL RESULTS

Simulated torque ripple with 4096-count resolution

Torque ripple = 0.006 N.m.

18

4. SIMULATION & EXPERIMENTAL RESULTS

Measured torque ripple with 48-count resolution

Phase A current is 10A/div. Average torque = 1.05 N.m.

Torque ripple = 0.023 N.m. (peak to peak)

19

0.5 1 1.5 2 2.5 3 3.5 4

0.435

0.44

0.445

0.45

0.455

0.46

0.465

T

o

r

q

u

e

(

N

.

m

.

)

Time (Sec.)

Current sense error =0.15 (A)

0 0.5 1 1.5 2 2.5 3 3.5 4

-15

-10

-5

0

5

10

15

M

o

t

o

r

c

u

r

r

e

n

t

(

A

)

Time (Sec.)

4. SIMULATION & EXPERIMENTAL RESULTS

Simulated current sensing with 0.15A error

3-per-rev torque ripple is about 0.017 N.m

20

4. SIMULATION & EXPERIMENTAL RESULTS

Measured torque ripple with current sense error

3-per-rev torque ripple is about 0.020 N.m

Phase A current is 10A/div.

21

4. SIMULATION & EXPERIMENTAL RESULTS

Measured torque ripple with current error eliminated

3-per-rev torque ripple is eliminated

Phase A current is 10A/div.

22

4. SIMULATION & EXPERIMENTAL RESULTS

Simulated d-axis step response

Rise time is about 2 ms.

There is no overshoot.

23

Measured d-axis step response

Rise time is 1.8 ms.

There is no overshoot.

4. SIMULATION & EXPERIMENTAL RESULTS

24

5. CONCLUSION

CONCLUSION

A complete PMSM drive model has been

presented.

Experimental results are provided to validate the

simulation models.

The effect of position sensor resolution and

current measurement errors are simulated and

validated.

The current loop step response is simulated and

validated.

The simulation work helps reduce product cost

and development time.

You might also like

- SIMULATION MODEL of Permanent Magnet Synchronous MotorDocument9 pagesSIMULATION MODEL of Permanent Magnet Synchronous MotorSri MathiNo ratings yet

- Industrial DrivesDocument1 pageIndustrial DrivesSatish NurukurthiNo ratings yet

- FLC&NN Control of DC MotorDocument37 pagesFLC&NN Control of DC MotorR.SRIKANTHNo ratings yet

- Power Electronics Converters and their Control for Renewable Energy ApplicationsFrom EverandPower Electronics Converters and their Control for Renewable Energy ApplicationsArezki FekikNo ratings yet

- Modelling and Simuation of BLDC Motor in MATLAB GUIDocument5 pagesModelling and Simuation of BLDC Motor in MATLAB GUIvishiwizardNo ratings yet

- State Variable Analysis 1 FinalDocument75 pagesState Variable Analysis 1 Finalprabhabathi deviNo ratings yet

- Dcmotors and Their RepresentationDocument61 pagesDcmotors and Their RepresentationSoeprapto AtmariNo ratings yet

- Simulation Study of Conventional Control Versus MTPA-Based For PMSM ControlDocument4 pagesSimulation Study of Conventional Control Versus MTPA-Based For PMSM Controlpersian67No ratings yet

- PX7203-Special Electrical Machines PDFDocument11 pagesPX7203-Special Electrical Machines PDFvaishnavisriNo ratings yet

- Introduction To Electrical DrivesDocument18 pagesIntroduction To Electrical DrivesRohidah SaimunNo ratings yet

- Unit Iii Induction Motor Drives: Dept. of EEEDocument17 pagesUnit Iii Induction Motor Drives: Dept. of EEEmanoj kumarNo ratings yet

- Circuit Simulation of A BLDC MotorDocument4 pagesCircuit Simulation of A BLDC Motorjpmacabasco100% (1)

- Ch7 Induction MotorDocument82 pagesCh7 Induction MotorMuhammad R ShihadehNo ratings yet

- 1 Field Oriented Control of Induction Motor 12/6/2015Document36 pages1 Field Oriented Control of Induction Motor 12/6/2015Belal Ashraf100% (1)

- Modeling and Simulation of Reluctance Motor Using Digital ComputerDocument5 pagesModeling and Simulation of Reluctance Motor Using Digital ComputerroyourboatNo ratings yet

- Differential Transformation Method for Mechanical Engineering ProblemsFrom EverandDifferential Transformation Method for Mechanical Engineering ProblemsNo ratings yet

- 14.4 Bode Plots: Frequency Response 589Document12 pages14.4 Bode Plots: Frequency Response 589Luis Lizana100% (1)

- Unit 2 PDFDocument170 pagesUnit 2 PDFSaurabh RajNo ratings yet

- Stepper MotorsDocument26 pagesStepper MotorsRam Kumar GogadaNo ratings yet

- Electric DrivesDocument2 pagesElectric DrivesnikunjNo ratings yet

- Wound-Field Synchronous Machine DrivesDocument62 pagesWound-Field Synchronous Machine DrivesKorlpate BhaskarNo ratings yet

- Basic SVPWMDocument6 pagesBasic SVPWMVAMSIKRISHNAEEENo ratings yet

- DC-DC ConverterDocument24 pagesDC-DC ConverterkandularanjithNo ratings yet

- Chapter 1 DC Drives Part1Document46 pagesChapter 1 DC Drives Part1Mohammad MunzirNo ratings yet

- Permanent Magnet Brushless DC MotorDocument18 pagesPermanent Magnet Brushless DC MotorBala SubramanianNo ratings yet

- Novel Dual-Excitation Permanent Magnet Vernier Machine: Akio Toba Thomas A. LipoDocument6 pagesNovel Dual-Excitation Permanent Magnet Vernier Machine: Akio Toba Thomas A. LipoNenad Kostadinovic50% (2)

- Technical Reference: SubjectDocument18 pagesTechnical Reference: SubjectPeter DyckNo ratings yet

- The Basics of Stepping MotorsDocument6 pagesThe Basics of Stepping MotorsSherif EltoukhiNo ratings yet

- 50.solar Tracking System For Optimal Power GenerationDocument4 pages50.solar Tracking System For Optimal Power GenerationRavi Teja Varma KunaparajuNo ratings yet

- Unit 3Document5 pagesUnit 3Narasimman DonNo ratings yet

- Can You Find What Is The Type of Motor Used For These Applications?Document17 pagesCan You Find What Is The Type of Motor Used For These Applications?nandhakumarme0% (1)

- AC DC DrivesDocument13 pagesAC DC Drives322399mk7086No ratings yet

- Switched Reluctance Motor PDFDocument79 pagesSwitched Reluctance Motor PDFHAMID SULIAMANNo ratings yet

- Finite-Element Models For Electrical Machines by HennebergerDocument12 pagesFinite-Element Models For Electrical Machines by HennebergermuhassadiNo ratings yet

- Switched Reluctance Reluctance Motors and ControlDocument47 pagesSwitched Reluctance Reluctance Motors and ControlSreerag Kunnathu Sugathan100% (1)

- Asynchronous and Synchronous Machines (EL-208) (IV SEM EL Session 2017-18) Tutorial Sheet 1 (Dated 08.01.2018) (3 Phase Induction MotorsDocument10 pagesAsynchronous and Synchronous Machines (EL-208) (IV SEM EL Session 2017-18) Tutorial Sheet 1 (Dated 08.01.2018) (3 Phase Induction MotorsKushagra BhatiaNo ratings yet

- Vector Control of Induction MotorDocument11 pagesVector Control of Induction MotorTushar GargNo ratings yet

- EE2403 Special Electrical MachinesDocument19 pagesEE2403 Special Electrical MachinesvasanthavananNo ratings yet

- BLDCDocument4 pagesBLDCsathishNo ratings yet

- Speed Control of Switched Reluctance Motor-LibreDocument9 pagesSpeed Control of Switched Reluctance Motor-LibreIndrajithSrNo ratings yet

- Lecture Notes On Permanent Magnet Brushless DC Motor Drive For Light Electric Vehicle ApplicationDocument24 pagesLecture Notes On Permanent Magnet Brushless DC Motor Drive For Light Electric Vehicle ApplicationAshish KumarNo ratings yet

- Fundamentals of Lyapunov TheoryDocument9 pagesFundamentals of Lyapunov Theorygoitom01No ratings yet

- Comparison of FOC and DTCDocument6 pagesComparison of FOC and DTCchienbkaNo ratings yet

- NR 410202 Power Semiconductor DrivesDocument8 pagesNR 410202 Power Semiconductor DrivesSrinivasa Rao GNo ratings yet

- Sepic Converter: Prepared ByDocument30 pagesSepic Converter: Prepared BychaitanyaNo ratings yet

- Electric Machines and Drives 1st EditionDocument16 pagesElectric Machines and Drives 1st EditionBellaaNo ratings yet

- Design and Simulation of Control System For Bearingless Synchronous Reluctance Motor PDFDocument5 pagesDesign and Simulation of Control System For Bearingless Synchronous Reluctance Motor PDFKrishnam NaiduNo ratings yet

- 3 Phase-Controlled DC Motor DrivesDocument45 pages3 Phase-Controlled DC Motor DrivesgilmartNo ratings yet

- Final Phase 1 PPT Major ProjectDocument21 pagesFinal Phase 1 PPT Major ProjectSpandana priyaNo ratings yet

- Induction Motor DrivesDocument73 pagesInduction Motor DrivesSai Pranahita KulithalaiNo ratings yet

- Power Electronics Final Year EEE Projects 2018 2019Document16 pagesPower Electronics Final Year EEE Projects 2018 2019PannerNo ratings yet

- Improved Indirect Power Control (IDPC) of Wind Energy Conversion Systems (WECS)From EverandImproved Indirect Power Control (IDPC) of Wind Energy Conversion Systems (WECS)No ratings yet

- Cs Pole Placement DesignDocument15 pagesCs Pole Placement Design18U208 - ARJUN A100% (1)

- Practical - 3 - Four Quadrant Chopper Fed DC DriveDocument15 pagesPractical - 3 - Four Quadrant Chopper Fed DC Drivekiran navaleNo ratings yet

- Electronics 3 Checkbook: The Checkbooks SeriesFrom EverandElectronics 3 Checkbook: The Checkbooks SeriesRating: 5 out of 5 stars5/5 (1)

- Post-COVID Transitioning of Work in Remote and Flexible EnvironmentDocument10 pagesPost-COVID Transitioning of Work in Remote and Flexible EnvironmentMELVINNo ratings yet

- Steps in Writing Business Research ProposalDocument4 pagesSteps in Writing Business Research ProposalMELVINNo ratings yet

- Earthing Design Substation IEEE 80Document2 pagesEarthing Design Substation IEEE 80MELVIN0% (1)

- Easy Pact Schneider 8Document1 pageEasy Pact Schneider 8MELVINNo ratings yet

- ISM Module 4Document133 pagesISM Module 4MELVINNo ratings yet

- ISM Module 1Document53 pagesISM Module 1MELVINNo ratings yet

- ISM Module 3Document83 pagesISM Module 3MELVINNo ratings yet

- Battery Ah Sizing ClaculationDocument18 pagesBattery Ah Sizing ClaculationMELVINNo ratings yet

- KNEE Point Voltage Calculation REF ProtectionDocument1 pageKNEE Point Voltage Calculation REF ProtectionMELVINNo ratings yet

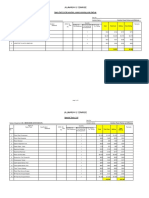

- Field Data: Item Description Symbol Unit Value Step 1 Rectangle-1 (GIS Hall)Document2 pagesField Data: Item Description Symbol Unit Value Step 1 Rectangle-1 (GIS Hall)MELVINNo ratings yet

- Hostel WiringDocument3 pagesHostel WiringMELVIN75% (4)

- Military Handbook Grounding, Bonding, and Shielding For Electronic Equipments and Facilities Volume 1 of 2 Volumes - Basic TheoryDocument812 pagesMilitary Handbook Grounding, Bonding, and Shielding For Electronic Equipments and Facilities Volume 1 of 2 Volumes - Basic Theorybal3xNo ratings yet

- Insulation Resistance of Power TransformerDocument16 pagesInsulation Resistance of Power TransformerMELVIN100% (3)

- 1MVADocument1 page1MVAMELVINNo ratings yet

- Solar Photovoltaics: Principles, Application and Case StudyDocument57 pagesSolar Photovoltaics: Principles, Application and Case StudyMELVIN100% (1)

- Name Plate Details of 3 MVADocument1 pageName Plate Details of 3 MVAMELVINNo ratings yet

- Volt DropDocument1 pageVolt DropMELVINNo ratings yet

- Power SystemDocument155 pagesPower SystemMELVINNo ratings yet

- AutomationDocument598 pagesAutomationMELVINNo ratings yet

- The Not So Short Introduction To L Tex 2Ε: Orl Tex 2Ε In MinutesDocument168 pagesThe Not So Short Introduction To L Tex 2Ε: Orl Tex 2Ε In MinutesGeorge De ContoNo ratings yet

- Power Electronic-EE IIT KharagpurDocument677 pagesPower Electronic-EE IIT Kharagpuraldipdg95% (19)

- Al-Amara 4 X 125Mw 9E: Spare Part List For Erection, Commissioning, and Start-UpDocument8 pagesAl-Amara 4 X 125Mw 9E: Spare Part List For Erection, Commissioning, and Start-UpElias Abu FakherNo ratings yet

- Lubricated Bumper Subs PDFDocument20 pagesLubricated Bumper Subs PDFnasr yassinNo ratings yet

- EASA-TCDS-E.042 Rolls - Royce Plc. RB211 Trent 700 Series Engines-02-29112013 PDFDocument9 pagesEASA-TCDS-E.042 Rolls - Royce Plc. RB211 Trent 700 Series Engines-02-29112013 PDFObakengNo ratings yet

- Thermolator Conair ManualDocument115 pagesThermolator Conair ManualLuiz RegaladoNo ratings yet

- CV BQDocument2 pagesCV BQBram StyawanNo ratings yet

- GE Energy Products - Europe: 9E - GT - M - M02 - C02 - V2 - A Revision: (A) Date: 03/09Document10 pagesGE Energy Products - Europe: 9E - GT - M - M02 - C02 - V2 - A Revision: (A) Date: 03/09Mohammad Ibnul HossainNo ratings yet

- Engineering Fracture Mechanics - 2019 PDFDocument403 pagesEngineering Fracture Mechanics - 2019 PDFAtheena PaulsonNo ratings yet

- Excercises Ae17Document12 pagesExcercises Ae17Honie Liane Tagose VillamorNo ratings yet

- 6001H Service Manual Tier III DUMPERDocument300 pages6001H Service Manual Tier III DUMPERAlberto100% (3)

- Datasheet MRS SeriesDocument6 pagesDatasheet MRS SeriesSantiago OspinaNo ratings yet

- Engineering: About Me ContactDocument1 pageEngineering: About Me ContactDebbie DebzNo ratings yet

- Cummins Mercruiser Diesel Marine Performance Curves 8206 17-Aug-04 5.9 Liter (359 In) 102 MM (4.02 In) 120 MM (4.72 In) 6 220B M-90760 D402013MX02Document2 pagesCummins Mercruiser Diesel Marine Performance Curves 8206 17-Aug-04 5.9 Liter (359 In) 102 MM (4.02 In) 120 MM (4.72 In) 6 220B M-90760 D402013MX02คุณชายธวัชชัย เจริญสุข100% (1)

- Hidrosil CylindersDocument17 pagesHidrosil CylindersAyman AlhalfawyNo ratings yet

- Dsi Suspa Systems Eta 07 0186 Suspa Wire Ex enDocument48 pagesDsi Suspa Systems Eta 07 0186 Suspa Wire Ex enAnonymous TxhyGfNo ratings yet

- Unit-1 Theory Questions and AnsweresDocument5 pagesUnit-1 Theory Questions and AnsweresAbinash PandaNo ratings yet

- Problem Sheet - 2 Topic: Stress Submission Date: 27/08/2019Document3 pagesProblem Sheet - 2 Topic: Stress Submission Date: 27/08/2019Beesam Ramesh KumarNo ratings yet

- Tesla Turbomachinery, 1991Document12 pagesTesla Turbomachinery, 1991timmyjim333100% (1)

- MC Feed-Through Packers: Remotely Isolate Zones in Marginal or Mature AssetsDocument2 pagesMC Feed-Through Packers: Remotely Isolate Zones in Marginal or Mature AssetsEdwin Javier Garavito HernándezNo ratings yet

- Hanger Detail Collector Pipe: Plan SectionDocument1 pageHanger Detail Collector Pipe: Plan Sectionmaj31No ratings yet

- Mechanics of Materials Chap 2-II 2Document68 pagesMechanics of Materials Chap 2-II 2彭莉棋No ratings yet

- Ch. VIII Potential Flow and Computational Fluid Dynamics: Review of Velocity-Potential ConceptsDocument5 pagesCh. VIII Potential Flow and Computational Fluid Dynamics: Review of Velocity-Potential ConceptsGerson Daniel Vargas PoloNo ratings yet

- Hyster H1.5-3.5XT Operators ManualDocument127 pagesHyster H1.5-3.5XT Operators ManualAchmad WaluyoNo ratings yet

- Vespa PX 125 150 Euro3 (EN)Document101 pagesVespa PX 125 150 Euro3 (EN)Manualles100% (3)

- Keyence Clamp On Gas Flow MeterDocument32 pagesKeyence Clamp On Gas Flow Meterpditzel8599No ratings yet

- BD70CR30-017 Issue 0Document14 pagesBD70CR30-017 Issue 0Panneer SelvamNo ratings yet

- Particle TechnologyDocument40 pagesParticle Technologyasharab70No ratings yet

- Lift ArtifDocument20 pagesLift ArtifCesar Augusto Vera JaimesNo ratings yet

- Statics: Vector Mechanics For Engineers: StaticsDocument6 pagesStatics: Vector Mechanics For Engineers: StaticsJarren Michael Baybay CamerinoNo ratings yet

- Woodward Tg13e Tg17e Actuators Overhauling Calibration PDFDocument44 pagesWoodward Tg13e Tg17e Actuators Overhauling Calibration PDFSyed Mohammad NaveedNo ratings yet

- BSI Standards Publication: BS EN ISO 15609 1:2019Document34 pagesBSI Standards Publication: BS EN ISO 15609 1:2019Ирина Михайлова57% (7)