Professional Documents

Culture Documents

ADWEA Water Drainage Systems

ADWEA Water Drainage Systems

Uploaded by

Sreepathy Rangarajan0 ratings0% found this document useful (0 votes)

65 views15 pagesADWEA Water Drainage Systems

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentADWEA Water Drainage Systems

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

65 views15 pagesADWEA Water Drainage Systems

ADWEA Water Drainage Systems

Uploaded by

Sreepathy RangarajanADWEA Water Drainage Systems

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 15

0 02-02-2002 Approved Issue

rev. date Description/issued for prepared authorised

client:

ADWEA

project:

STANDARD SPECIFICATIONS FOR WATER WORKS

title:

SPECIFICATION FOR WATER DRAINAGE SYSTEMS

tender: project: document:

W-C-SS-011

rev:

0

sheet:

1

of:

15

SPECIFICATION FOR WATER

DRAINAGE SYSTEMS

Client

ADWEA

Project:

STANDARD SPECIFICATIONS FOR WATER WORKS

Title:

SPECIFICATION FOR WATER DRAINAGE SYSTEMS

tender: project: document:

W-C-SS-011

rev:

0

sheet:

2

of:

15

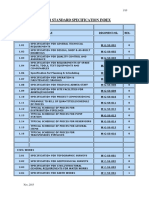

Table of Contents page

1. SCOPE...................................................................................................3

1.1 Introduction..................................................................................3

1.2 Approval ......................................................................................3

2. CODES AND STANDARDS ..................................................................3

2.1 Environmental Conditions............................................................3

3. DEFINITIONS ........................................................................................3

4. CLIMATIC CONDITIONS.......................................................................3

5. TECHNICAL REQUIREMENTS.............................................................4

5.1 General Drainage Requirements.................................................4

5.2 Surface Water Drainage..............................................................7

5.3 Foul Water Drainage ...................................................................8

5.4 Contaminated Water Drainage..................................................13

6. INSPECTION, TESTING AND COMMISSIONING..............................14

6.1 Inspection Requirements...........................................................14

6.2 Testing.......................................................................................15

6.3 Commissioning..........................................................................15

Client

ADWEA

Project:

STANDARD SPECIFICATIONS FOR WATER WORKS

Title:

SPECIFICATION FOR WATER DRAINAGE SYSTEMS

tender: project: document:

W-C-SS-011

rev:

0

sheet:

3

of:

15

1. SCOPE

1.1 Introduction

This specification covers the requirements for the design, inspection, testing, supply,

installation and commissioning of the water drainage systems.

The CONTRACTOR shall prepare all necessary detailing and construction drawings and

details for ADWEA/ENGINEER approval, based upon this specification together with project

drainage layouts, process layouts, schematics and general arrangement drawings.

1.2 Approval

Where ADWEA/ENGINEER approvals are required in this document, it shall mean that the

ADWEA/ENGINEER reserves the right to approve. However the ADWEA/ENGINEER may

elect to waive approval of certain aspects as will be informed in writing by the

ADWEA/ENGINEER.

2. CODES AND STANDARDS

GENERAL:

Reference shall be made to the following British and International Standards :

BS 6297 Small Sewage Treatment Work & Cess pools

BS 8301 Building Drainage

BS EN 124 Gully Tops & Manhole Tops

BS EN 752-1 Sewerage

BS EN 12056-2 Sanitary Pipework

2.1 Environmental Conditions

All field installations shall be suitable for operation in an outdoor, industrial, humid and salty

atmosphere under ambient conditions as specified in the Tender Documents.

The design rainfall rate is to be considered as the maximum rate as defined in the Tender

Documents.

3. DEFINITIONS

Refer to Specification for General Technical Requirements.

4. CLIMATIC CONDITIONS

Refer to Specification for General Technical Requirements.

Client

ADWEA

Project:

STANDARD SPECIFICATIONS FOR WATER WORKS

Title:

SPECIFICATION FOR WATER DRAINAGE SYSTEMS

tender: project: document:

W-C-SS-011

rev:

0

sheet:

4

of:

15

5. TECHNICAL REQUIREMENTS

5.1 General Drainage Requirements

5.1.1 Setting out

Deviations from pipework levels shown on the approved drawings shall not be greater than

+20 mm. Gradients shall generally not be steeper than 1 in 75 nor flatter than 1 in 250

generally and with a permissible deviation not greater than 1/20 of the given gradient.

Sight rails shall be set in position, using a surveyor's level and properly established bench

marks alongside the work. The practice of "transferring" levels by means of a straight edge

and spirit level will not be permitted.

Where long lengths of sewers are to be constructed in trenches, sight rails shall be fixed

across the trench at intervals of at least 20 metres and, at a height equal to the length of the

looning rod to be used, above the required invert level of the drain or sewer, at the point

where the sight rail is fixed. There shall at no time be less than three sight rails in position on

each length of sewer or drain under construction at any one gradient.

5.1.2 Laying Drains and Ducts

All pipe laying shall be done by skilled and experienced personnel.

The drains shall be accurately laid in straight lines and to self-cleansing gradients. Pipes

shall be laid singly and the level of each pipe shall be tested in a approved manner using

sight rails erected at manholes and at intermediate positions as necessary. Pipes shall be

laid with the sockets facing upstream.

Immediately prior to laying, all pipes and fittings shall be examined carefully to ensure that

they are sound. No damaged or defective pipes shall be used. Any part length used shall be

cut squarely and cleanly at the end. All pipes shall be clean before laying and jointing.

All service systems shall include bends, tapers, junctions and other special pipes of a

particular pattern as required.

When pipes pass through walls a flexible joint is to be fitted, situated as close as possible to

the outside face and permitting a minimum deflection between adjacent pipes of 3

o

.

Pipes which are laid, or built into walls and manholes, but not immediately connected up, shall

be fitted with suitable temporary stoppers or seals, and the position of such pipes shall be

clearly defined by means of stakes or training wires properly marked or labelled.

Wherever the depth of cover to the pipe laid under a road or driveway is less than 1.20 m, a

concrete cover slab spanning the trench width shall be provided.

Before the commencement and for the smooth progress of the pipeline work, the

CONTRACTOR shall coordinate and finalise the routes, ground/invert levels, positions of the

manholes etc. with the ADWEA/ENGINEER.

Client

ADWEA

Project:

STANDARD SPECIFICATIONS FOR WATER WORKS

Title:

SPECIFICATION FOR WATER DRAINAGE SYSTEMS

tender: project: document:

W-C-SS-011

rev:

0

sheet:

5

of:

15

All changes in the design shall be subject to the approval of the ADWEA/ENGINEER.

5.1.3 Pipe Bedding Material

When the as dug material is suitable, the bottom of the trench shall be trimmed and loosened

to form the bed otherwise the trench shall be excavated to a depth below the invert level to

allow for the thickness of bedding material.

When as dug material is not suitable, imported granular material as per the table given below

shall be used to provide a 50mm bedding and side fill.

Table - Requirements for imported material for bedding and surrounding

Nominal pipe size Material (complying with BS 882: Pt.2).

110 mm 10 mm nominal single sized aggregate.

160 mm 10 or 14 mm nominal single sized or

5 to 14 mm graded aggregate.

225 mm and over 10, 14 or 20 mm single sized or 5 to 14

or 5 to 20 mm graded aggregate.

If the as dug material contains stones larger than 40 mm the bedding material must be

extended 100 mm above the circumference of the pipe. Alternatively the backfill can be

graded to eliminate stones exceeding 40 mm and this selected backfill used for the first 300

mm above the circumference of the pipe.

5.1.4 Manholes, Sump Pits and Inspection Chambers

All drainage related concrete and steel structures shall be carried out in accordance with the

relevant codes and specifications :

Manholes shall be constructed of reinforced concrete or of solid concrete blocks. Manholes

shall be designed for the vehicular or other loading to which they will be subjected.

Foundations to manholes shall be of concrete complying with the relevant clauses of the

Concrete Specification and shall finish flush with the manhole sides unless specifically

otherwise required.

Concrete block walls shall be bedded and jointed in cement and sand 1:4 mortar and the

joints on the internal faces raked out to form a key for rendering. Walls shall be constructed

in stretcher bond.

The bottoms of all manholes shall be provided with half round main channels, tapered or

curved where necessary and half round and three quarter section branch bends of requisite

radii. These shall be bedded and jointed in cement sand 1:1 mortar and shall be benched in

concrete vertically from the channels to a height equal to the soffit of the outgoing pipe and

thence upwards to the sides of manholes at a slope of 1 in 6 and floated in cement and sand

1:1 mortar to a smooth and even surface.

Client

ADWEA

Project:

STANDARD SPECIFICATIONS FOR WATER WORKS

Title:

SPECIFICATION FOR WATER DRAINAGE SYSTEMS

tender: project: document:

W-C-SS-011

rev:

0

sheet:

6

of:

15

The internal surfaces of concrete block walls shall be rendered with cement and sand 1:2

mortar 10mm thick and the rendering shall be finished with a smooth and even surface.

The CONTRACTOR shall prepare comprehensive manhole schedule drawings for each

drainage system using the area layout and general arrangement drawings. These shall be

submitted for ADWEA/ ENGINEER approval and shall follow the proforma schedule drawings

as issued.

The ends of all pipes shall be neatly built into the blockwork and finished flush with mortar.

Moderately sulphate resisting portland cement conforming to ASTM Type II may be used for

all concrete, concrete blocks, mortar and render. However Type of cement used for concrete

mixes is to be selected as per relevant soil condition.

Where the depth of invert of manholes exceeds one metre below the finished ground level,

aluminum steps as specified in BS 1247 part 3 shall be built in at vertical intervals of 300mm,

with alternate steps in line vertically and at 225mm centre to centre horizontally.

Entry to deep manhole chambers (> 2500 mm) shall be by means of one or more caged

vertical aluminium ladders.

Manhole covers and frames shall be coated cast-iron complying with BS EN 124 or approved

equal and shall be designed for the loading category to which they will be subjected. The

CONTRACTOR shall bed and haunch frames in cement and sand 1:3 mortar and seal covers

with thick grease. Two sets of keys shall be delivered to the ADWEA/ENGINEER for each

pattern of cover supplied.

5.1.5 Gully Gratings and Frames

Gullies shall consist of a concrete pit with cover.

Gully gratings and frames shall comply with the requirements of BS EN 124 (Grade A) or

equal with straight bars. The CONTRACTOR shall bed and haunch frames in cement and

sand 1:3 mortar.

The finish of steel components shall be given 2 coats of black coal tar epoxy paint with a

minimum thickness of 250 microns.

5.1.6 Continuous Trench Soakaways

Continuous trench soakaways shall be constructed as per design. The filter membrane

adopted for the soakaway surround shall be geotextile of appropriate guage. The

CONTRACTOR shall take every care to avoid damage to the membrane. In the event of

damage to the membrane during construction, the CONTRACTOR shall make good the

damage with a minimum lap of 500 mm all to be carried out at the CONTRACTOR's expense.

Client

ADWEA

Project:

STANDARD SPECIFICATIONS FOR WATER WORKS

Title:

SPECIFICATION FOR WATER DRAINAGE SYSTEMS

tender: project: document:

W-C-SS-011

rev:

0

sheet:

7

of:

15

5.1.7 Local Soakaways

Local soakaways shall be provided at locations determined by the ENGINEER and to details

as approved by him and shall be similar to the soakaway to be provided at the septic tank

(refer section 5.3.6).

5.1.8 Joints

All joints shall have adequate strength which shall be demonstrated by the CONTRACTOR.

Pipe joints shall be fully flexible and capable of bearing the same pressure that can be borne

by the pipes. Prior to importing any pipes, fittings or jointing rings to the site, the

CONTRACTOR shall submit a works test certificate from the manufacturer, as to their

conformity with the Specification, for the approval of the ADWEA/ENGINEER.

The CONTRACTOR shall ensure that there is adequate suitable equipment on site to enable

the works to be carried out to the specified standard, as approved by the

ADWEA/ENGINEER.

5.1.9 Valve Pits

All below ground valve pits and chambers shall have their invert laid to fall towards collection

sumps to allow pump out of accumulated rain water etc.

5.2 Surface Water Drainage

5.2.1 General

Surface water drainage is required to collect and direct rain water from apron and paving

areas and roof run-offs and will also be required to dispose of external washdown.

5.2.2 System Characteristics

The surface to be drained shall be laid to fall at a minimum slope of 1:250 generally. The

collected rainwater, wash water is to be drained by means of surface falls only towards local

soakaways at appropriate locations.

Roof run-offs to be collected by means of gullies, hoppers & downpipes discharging to grade

level local soakaways at appropriate locations.

All roads, aprons and paving shall be delineated by kerbs and laid to fall towards soakaways.

Parking area to be similarly drained towards soakaways.

5.2.3 Areas Contributing Surface Water Drainage

The following areas contribute to the Surface Water Drainage :

1) Roof of Pump Station

2) Roof of Service Block

Client

ADWEA

Project:

STANDARD SPECIFICATIONS FOR WATER WORKS

Title:

SPECIFICATION FOR WATER DRAINAGE SYSTEMS

tender: project: document:

W-C-SS-011

rev:

0

sheet:

8

of:

15

3) Paving Around the Building

4) Roads & Aprons within the Plot

5) Parking and Approach Road

6) Roof of Chlorination Building

7) Other areas as applicable

Unpaved areas are to be terraced and gravel (size 20 mm average) finished to allow insitu

soakaway of rain water or washwater.

5.2.4 Surface Water Drain Manhole

Manholes shall be provided as shown on the referred Surface Water System layout or as

required by the detail design of the CONTRACTOR.

5.2.5 Road Gully

Road gullies are to be provided with silt trap, heavy duty manhole, ductile iron grating non

rocking cover with frame and retaining bar as per the drawings. Road gullies shall be

provided as indicated on the Surface Water System layouts or as required by the detail

design of the CONTRACTOR.

5.2.6 Road Curb Gully

Road curb gullies are to be provided with silt trap, standard ductile iron cover and frame with

retaining bar. as per the layouts and CONTRACTOR's drawings. Road curb gullies are to be

provided as indicated in the Surface Water System layouts or as required by the detail design

of the CONTRACTOR.

5.2.7 Roof Drain Pipe

Roof drain pipes shall be provided as indicated in the individual building details and the storm

water drain system layout or as required by the details of the CONTRACTOR. The roof drain

pipes shall be provided with an inlet hopper, support brackets, stack and a splay end

terminating 150mm above local paving level and directing water away from the building

towards local soakaways as per the drawings.

5.3 Foul Water Drainage

5.3.1 General

The Foul Water Drainage System is required to collect the foul wastewater from the buildings.

The toilets, sinks, showers and kitchens are to be connected and routed to a septic tank and

local soakaway or connected to the main drainage of the power station. The scope of this

work shall include all septic tank/soakaway pits and foul drainage system pipework.

Client

ADWEA

Project:

STANDARD SPECIFICATIONS FOR WATER WORKS

Title:

SPECIFICATION FOR WATER DRAINAGE SYSTEMS

tender: project: document:

W-C-SS-011

rev:

0

sheet:

9

of:

15

5.3.2 System Characteristics

The Foul Waste from Toilets, Washrooms and Kitchens shall be collected in the foul drainage

manholes & subsequently routed to the septic tank & soakaway pits. The system is to be

suitably trapped & externally vented. The Foul Water System is to be laid to fall at a minimum

slope of 1:100 generally.

5.3.3 Areas Connected to Foul Water System

The following sources shall be considered for the Foul Water System :

i) Toilets

ii) Kitchens

iii) Washroom sinks and showers

Note : Chemical storage & other industrial sinks shall be routed separately (refer 5.4.3).

5.3.4 Piping Requirements

Pipes and Fittings

All pipes & fittings to be used on the project shall comply with the requirements of the latest

relevant British/other standards approved by ADWEA/ENGINEER.

The pipes and fitting for pipe diameter sizes upto 300 mm shall be of uPVC conforming to BS

4660 and BS 5955. The joint sealing rings shall conform to BS 2494. Products to be

procured with BSI certification. The dimension & pressure rating of the pipes shall be in

accordance with ISO 161/1.

The pipes and fittings for pipe sizes equal to or greater than 300 mm shall be GRP pipes.

Requirements as per BS 5480 are to be followed for the pipes & pipe fittings. The pressure

rating of the pipes shall be a minimum of 10 bar.

Jointing Systems

The surface preparation to consist of the minimum following steps :

- Surface to be jointed are to be cleared of glass fibre and to be ensured to be free of

grease, humidity or dust.

- Surface to be ground, external layer of resin to be taken off and first glass fibre

uncovered.

- Surface to be rubbed with an emery cloth and cleaned with a volatile solvent so as to

remove all traces of grease, dust & humidity.

(No gluing shall be undertaken during sand storm or rainfall).

Client

ADWEA

Project:

STANDARD SPECIFICATIONS FOR WATER WORKS

Title:

SPECIFICATION FOR WATER DRAINAGE SYSTEMS

tender: project: document:

W-C-SS-011

rev:

0

sheet:

10

of:

15

- The minimum requirements for adhesive are as follows :

- Adhesives shall be compatible with the resin and shall not be of a type affected by

hydrocarbon or inorganic contaminants that may be present.

- Type of adhesive shall be submitted by the CONTRACTOR for ADWEA/ENGINEER

approval.

- Adhesives shall be two component, cold polymerization type. The two components will

be maintained within allowable temperature and mixed to form a homogenous mixture

just before application to the prepared joint.

- The joints shall have adequate strength and this shall be demonstrated by the

CONTRACTOR.

Pipe joints shall be fully flexible and capable of bearing the same pressure that can be borne

by the pipes. Prior to importing any pipes, fittings or joining rings to the site, the

CONTRACTOR shall submit a works test certificate from the manufacturer, as to their

conformity with the specification, for the approval of the ADWEA/ENGINEER.

The CONTRACTOR shall ensure that there is adequate suitable equipment on site to enable

the works to be carried out to the specified standard, as approved by the

ADWEA/ENGINEER.

For the uPVC piping, the following minimum steps are to be taken while making a joint:

i) Proper alignment of the two pipes to be ensured.

ii) The surfaces to be joined are to be thoroughly prepared using sandpaper.

iii) Surfaces to be cleaned with solvent.

iv) Even layer of cement is to be applied.

v) Joint to be made.

It should be ensured the joint is held till the required drying time based on ambient conditions.

A minimum of 24 hrs. is required before pressure testing.

The joint shall be fully flexible and capable of bearing the same pressure as the pipes. The

joint strength shall be demonstrated by the CONTRACTOR.

5.3.5 Foul Water Drain Manholes

Manholes shall be provided as shown on approved Foul Water System Layouts or as required

by the detail design of the CONTRACTOR. The details of the manholes are to be as per

drawings.

Client

ADWEA

Project:

STANDARD SPECIFICATIONS FOR WATER WORKS

Title:

SPECIFICATION FOR WATER DRAINAGE SYSTEMS

tender: project: document:

W-C-SS-011

rev:

0

sheet:

11

of:

15

5.3.6 Soakaways

Soakaways shall be constructed using precast/cast insitu concrete manhole rings to

designated dimensions and depths.

The concrete in the rings may be made using moderately sulphate resistant portland cement

in accordance with ASTM C 150 designation type II. However Type of cement is to be verified

as per relevant soil condition.

The rings shall be constructed with 75mm diameter holes at 410mm centres in rows spaced

300mm apart.

The bottom ring shall be founded on an in situ concrete base, to the approval of the

ADWEA/ENGINEER.

The soakaway shall be surrounded by granular material which shall in fill the whole void

between the soakaway and the undisturbed ground around the excavation. The granular

material shall be laid and tamped by hand in 300mm layers and shall be clean, crushed rock

to the approval of the ADWEA/ ENGINEER and shall be 20-40mm nominal size with little or

no fines.

Manhole covers and frames shall be coated cast-iron complying with BS EN 124 or approved

equal and shall be designed for the loading category to which they will be subjected. The

CONTRACTOR shall bed and haunch frames in cement sand 1 : 3 mortar and seal covers

with thick grease. Two sets of keys shall be delivered to the ADWEA/ENGINEER for each

pattern of cover supplied.

Filter fabric material lining to soakaway excavation shall be Geotextile of approved guage &

make. Placing and lapping sheets to be in accordance with MANUFACTURER/SUPPLIER's

recommendations.

All pipes and fittings shall be assembled strictly in accordance with the written instructions of

the MANUFACTURER/SUPPLIER and to the satisfaction of the ADWEA/ENGINEER.

5.3.7 Continuous Trench Soakaways

Continuous trench soakaways shall be constructed at the location and to the details as shown

on the drawings. The CONTRACTOR shall take every care to avoid damage to filter

membrane. In the event of damage to the membrane during construction, the

CONTRACTOR shall make good the damage with a minimum lap of 500 mm all to be carried

out at the CONTRACTOR's expense.

5.3.8 Floor Drains

All floor drains shall be supplied and installed at the locations and to the details shown on the

drawings and as specified herein.

Each floor drain shall be of heavy duty uPVC with "S" or "P" trap complete with chrome plated

heavy duty, 200 x 200mm, bronze strainer. The strainer shall be screwed to the body of the

Client

ADWEA

Project:

STANDARD SPECIFICATIONS FOR WATER WORKS

Title:

SPECIFICATION FOR WATER DRAINAGE SYSTEMS

tender: project: document:

W-C-SS-011

rev:

0

sheet:

12

of:

15

drain. All floor drains shall have chrome plated removable covers to their strainers or heavy

duty aluminium cover.

5.3.9 Clean Outs

All clean outs shall be supplied and installed at the locations and to the details shown on the

Drawings and wherever specified herein.

Each clean-out shall be of the same material and dimensions as the pipe to be cleaned, and

shall be placed in walls, slabs or floors as required for ease of operation.

Where cleanouts terminate in floors, a bronze cleanout tile 200 x 200mm, with screwed and

sealed cover shall be provided. Tile and cover shall be chrome plated.

5.3.10 Vent Caps

Vent caps shall be supplied and installed on all waste, soil and vent stacks at the locations

and to the details shown on the drawings and in accordance with this specification.

Each vent cap shall be of uPVC and shall be solvent cemented onto the waste, vent and soil

stack.

5.3.11 Septic Tank

General

This shall be a rectangular chamber of concrete built underground and to dimension and

depth as shown on the drawings.

Construction

The base, walls and roof shall be of reinforced concrete construction. Concrete shall be to

grade C40.

The base shall be constructed on layer of 100mm blinding. For specification relating to

concrete, refer to Specification for Concrete Works.

One aluminum ladder shall be provided to access inside each section of the tank for cleaning

purposes from time to time. A 600mm x 600mm manhole opening shall be provided on the

roof of the septic tank. Adequate manhole cover of minimum size 680mm x 680mm with

hand grip shall be provided as described for soakaways. The floor of the tank shall slope 1 in

30 towards one side or centre to facilitate cleaning of sludge and the manhole shall be located

directly over this.

Commissioning

Initially the septic tank shall be filled with water to its outlet level before sewage is allowed to

enter the tank.

Client

ADWEA

Project:

STANDARD SPECIFICATIONS FOR WATER WORKS

Title:

SPECIFICATION FOR WATER DRAINAGE SYSTEMS

tender: project: document:

W-C-SS-011

rev:

0

sheet:

13

of:

15

A small quantity of decaying organic matter should preferably be put into the septic tank to

start the initial reaction.

5.4 Contaminated Water Drainage

5.4.1 General

The Contaminated Water drainage system is required to collect specific discharges of

predominantly contaminated water together with floor spillages within the buildings and other

contaminant spillages. Flow rates, salinity, other contaminant levels and temperatures of the

contaminated drainage shall be determined.

Sources of possible spillage are to be routed via tundishes and hard piped systems above-

ground as detailed by the CONTRACTOR'S piping/mechanical department, discharging to

suitable lined reinforced concrete gullies and trenches from where the contaminated material

shall be routed to the main drain sump outwith the building from where it shall be pumped to

outfall remote from the plant.

5.4.2 Areas Connected to Contaminated Sump Pits

The following areas are to be served by the contaminated water drainage system :

i) Pump Station

ii) Service Block

iii) Battery Room

iv) Chlorination Building

v) Others as applicable

5.4.3 Facilities Connected to Contaminated Water System

The following facilities are connected to the saline contaminated water drainage system :

i) Floor gullies, drain trenches and cut-off drain channels.

ii) Safety shower outlets (if applicable).

iii) Tundishes & Industrial sinks.

iv) Others as applicable

5.4.4 Piping Requirements

For details of all pipes and fittings refer to Section 5.3.4.

Client

ADWEA

Project:

STANDARD SPECIFICATIONS FOR WATER WORKS

Title:

SPECIFICATION FOR WATER DRAINAGE SYSTEMS

tender: project: document:

W-C-SS-011

rev:

0

sheet:

14

of:

15

5.4.5 Floor Gullies, Drain Trenches and Cut-Off Drain Channels

Refer to Section 5.3.8 generally.

Note : linings, covers and frames shall be suitably chemically resistant.

5.4.6 Clean Outs

Refer to Section 5.3.9 generally.

Note : linings, covers and frames shall be suitably chemically resistant.

5.4.7 Tundishes

Tundishes and their hard piping systems shall be provided at locations and to details as

determined by the CONTRACTOR's detailed design and shall be subject to the approval of

the ADWEA/ ENGINEER.

5.4.8 Industrial Sinks

Industrial sinks shall be provided at the locations and to the details shown upon the drawings

and shall drain to the contaminated water drainage system.

6. INSPECTION, TESTING AND COMMISSIONING

6.1 Inspection Requirements

6.1.1 Civil Works

The following items shall be subject to field inspection in respect of setting out, excavation,

concrete works including reinforcement, protective membranes and linings, benching and

inserts rack filling and finishes, covers and frames, handrailing and access provisions:

Manholes, Inspection Chambers, Septic Tank, Soakaway Pits, Drain Sump, Floor Gullies,

Drain Trenches, Cut off Drain Channels.

6.1.2 Pipes and Pipe Fittings

(A) GRE/GRP Pipes & Pipe Fittings

As a minimum the following acceptance tests shall be performed at site:

i) Visual inspection

ii) Dimension check

iii) Curing

iv) Glass content

Client

ADWEA

Project:

STANDARD SPECIFICATIONS FOR WATER WORKS

Title:

SPECIFICATION FOR WATER DRAINAGE SYSTEMS

tender: project: document:

W-C-SS-011

rev:

0

sheet:

15

of:

15

v) Hydrostatic pressure test

vi) Impact resistance test

(B) uPVC Pipes & Pipe Fittings

The minimum number and type of acceptance tests at site is to be as per BS 5955 : Part 6 .

The pressure testing at site is to be carried out in two phases, the preliminary phase is

required to allow for the elastic characteristics and the relatively high thermal expansion of the

uPVC piping. Care should be taken to evacuate all air from the piping to avoid surge

pressures.

6.2 Testing

The CONTRACTOR shall test all drainage pipelines, joints and fittings before carrying out

haunching of surrounding pipes or backfilling trenches. The tests shall be carried out

between two manholes in the presence and to the satisfaction of the ADWEA/ENGINEER.

Water shall be passed in the pipes to be tested, of whatever diameter, so that air is expelled,

and the pipes filled with water so that the highest point in the line shall be subject to the

pressure of a 1.5 metre high water head. The line shall be considered acceptable if no

leakage is visible from pipes, connections or fittings and if the above water head in a testing

pipe of 75 mm diameter is not reduced by more than 15mm per minute for each 30 metre

length of pipe. The CONTRACTOR shall, after filling the pipes, allow some time before

conducting the test in order to allow the pipes their first natural saturation with water. If any

damage is noticed in the pipeline the CONTRACTOR shall repair such damage to the

approval of the ADWEA/ ENGINEER.

If in the opinion of the ADWEA/ENGINEER any damage has occurred to the pipelines during

the processes of pouring concrete or backfilling, he shall have the right to order retesting of

the doubtful part. If a second testing proves that the pipe is not serviceable, then the

CONTRACTOR shall locate the damage, make it good and carry out retesting until meeting

ADWEA/ENGINEER approval.

The ADWEA/ENGINEER may instruct the CONTRACTOR to carry out tests to the manholes

to establish their watertightness, prior to backfilling around manholes, and any damage

revealed by such tests shall be made good.

The CONTRACTOR shall provide all necessary testing equipment and shall carry out such

other tests as may be required by the ADWEA/ENGINEER. Ground water shall not be used

for the purpose of testing.

6.3 Commissioning

All traps and flooded systems shall be charged and periodically refilled until final handover.

During commissioning flows shall be confirmed for all major runs.

You might also like

- Domestic Appliance Troubleshooting: Troubleshooting Of: Electric Iron Rice Cooker Electric FanDocument67 pagesDomestic Appliance Troubleshooting: Troubleshooting Of: Electric Iron Rice Cooker Electric FanCharl Cua100% (3)

- Regulationsof Internal Water Installationsand ConnectionDocument66 pagesRegulationsof Internal Water Installationsand ConnectionHenrik Gal de OcampoNo ratings yet

- Water Installation CodeDocument34 pagesWater Installation CodeDăňĩêĺ RăĵăNo ratings yet

- Saso 2203 2015Document22 pagesSaso 2203 2015Qatada1100% (1)

- AppH-1 SESDocument372 pagesAppH-1 SESBoc VictaNo ratings yet

- Air Valve Chamber Details Type (1) For 16 BarsDocument1 pageAir Valve Chamber Details Type (1) For 16 BarsHesham Elbana100% (1)

- QCS-2010 Section 19 Part 2 Water DistributionDocument12 pagesQCS-2010 Section 19 Part 2 Water Distributionbryanpastor106100% (1)

- Protection Work EstimationDocument24 pagesProtection Work EstimationkmmansafNo ratings yet

- MOH-MOWE Sewer PDFDocument251 pagesMOH-MOWE Sewer PDFmasoodae100% (1)

- Specs For General Civil Construction - 08dec2010Document20 pagesSpecs For General Civil Construction - 08dec2010apvalenzuelaNo ratings yet

- 08-Division 15-Section 15060 Package Engine Generator-Version 2.0Document19 pages08-Division 15-Section 15060 Package Engine Generator-Version 2.0Roshan ShanmughanNo ratings yet

- 2-1-2 - General Specification of Main Laying Materials For Waterworks LatestDocument112 pages2-1-2 - General Specification of Main Laying Materials For Waterworks LatestRaulSaavedra0% (1)

- Hiring List FGDocument6 pagesHiring List FGFaisal Aziz Malghani100% (1)

- Di Pipe DrawingsDocument6 pagesDi Pipe DrawingsZatul Akmal ZamilNo ratings yet

- Specification For Non Toxicity Requirements For Paints and CoatingsDocument5 pagesSpecification For Non Toxicity Requirements For Paints and CoatingsVJ QatarNo ratings yet

- DMA AD Lighting Handbook 1sted Elec - Ver Part 2Document244 pagesDMA AD Lighting Handbook 1sted Elec - Ver Part 2zeliteNo ratings yet

- Wild Air Meaning and PurposeDocument3 pagesWild Air Meaning and PurposeSrdjan KitanovicNo ratings yet

- National Building Code of India 2016Document4 pagesNational Building Code of India 2016xahidlala100% (3)

- York Yeaj Chiller ManualDocument99 pagesYork Yeaj Chiller Manualmk saravananNo ratings yet

- 15-Division 2-Section 02600 Sewer Rehabilitation-Version 2.0Document34 pages15-Division 2-Section 02600 Sewer Rehabilitation-Version 2.0Avaan IvaanNo ratings yet

- 05-Division 2-Section 02200 GRP Pipelines Materials-Ver 2.0Document30 pages05-Division 2-Section 02200 GRP Pipelines Materials-Ver 2.0Avaan IvaanNo ratings yet

- Tips On Kiln OperationDocument10 pagesTips On Kiln OperationElwathig Bakhiet100% (2)

- W C Ss 011 (Water Dranage)Document14 pagesW C Ss 011 (Water Dranage)zfrlNo ratings yet

- Sewer DescriptionDocument27 pagesSewer Descriptionroco_3213No ratings yet

- W C Ss 007Document25 pagesW C Ss 007Adrianto HermawanNo ratings yet

- Tag - A - 07-DG-Section 7A STEP Deep Tunnel Sewer Route Safeguarding-Version 0 PDFDocument19 pagesTag - A - 07-DG-Section 7A STEP Deep Tunnel Sewer Route Safeguarding-Version 0 PDFtiago calderNo ratings yet

- Abu Dhabi Sewerage Services Company (Adssc) : Adssc/Gscw Section 02600 Sewer Rehabilitation Rev: 02 Jan. 2011 Page 1 of 34Document34 pagesAbu Dhabi Sewerage Services Company (Adssc) : Adssc/Gscw Section 02600 Sewer Rehabilitation Rev: 02 Jan. 2011 Page 1 of 34MȜtaz HammadNo ratings yet

- W-I-SS-001 R4 For Field Instruments - ADDCDocument39 pagesW-I-SS-001 R4 For Field Instruments - ADDCRonaldo JuniorNo ratings yet

- General Requirements For ValvesDocument16 pagesGeneral Requirements For ValvesKrishna Prasad R100% (1)

- BACKDROP MANHOLE DETAILS FROM 3000mm To 6000mmDocument1 pageBACKDROP MANHOLE DETAILS FROM 3000mm To 6000mmHesham ElbanaNo ratings yet

- Design Package Deliverable S 90Document5 pagesDesign Package Deliverable S 90Viet Nguyen HungNo ratings yet

- Series 20: Installation and Maintenance ManualDocument25 pagesSeries 20: Installation and Maintenance ManualArivup PavalanNo ratings yet

- Plastic PipeDocument4 pagesPlastic Pipesethu1091No ratings yet

- Appendices Public Realm Design ManualDocument167 pagesAppendices Public Realm Design ManualAra NorharaNo ratings yet

- Slab Foundation-Refer To Section 4.1 of ACI 360R: Project Job RefDocument2 pagesSlab Foundation-Refer To Section 4.1 of ACI 360R: Project Job Refmpj1998No ratings yet

- Method Statement For Laying of MCC Duct and Civil Works For MCC NetworkDocument26 pagesMethod Statement For Laying of MCC Duct and Civil Works For MCC NetworkVenkadesh PeriathambiNo ratings yet

- Water Standard Specification Index As On Dec 2015Document10 pagesWater Standard Specification Index As On Dec 2015afp15060% (1)

- ADDC System Safety RulesDocument166 pagesADDC System Safety RulesksarawanNo ratings yet

- Water and Sewerage AuthorityDocument43 pagesWater and Sewerage AuthorityCarl Crow100% (1)

- prEN 1992-4 2013 PDFDocument98 pagesprEN 1992-4 2013 PDFMalik AtikNo ratings yet

- Specification For Construction, Testing & Commissioning of High Density Polyethylene (Hdpe) Pipe SystemDocument35 pagesSpecification For Construction, Testing & Commissioning of High Density Polyethylene (Hdpe) Pipe SystemCristel Diane Dela CruzNo ratings yet

- 10.section 4.0 - Sewerage WorksDocument19 pages10.section 4.0 - Sewerage WorksNarain Muthukrishnan100% (1)

- w-p-ss-001 R4Document23 pagesw-p-ss-001 R4Unni CyriacNo ratings yet

- Drainage Handbook (02-17) PDFDocument177 pagesDrainage Handbook (02-17) PDFHéctor M. PauthNo ratings yet

- Conduit and Cable ScheduleDocument1 pageConduit and Cable ScheduleFarhan SaadatNo ratings yet

- 00-Division 15-Section 15001 General M&E Requirements-Version 2.0Document69 pages00-Division 15-Section 15001 General M&E Requirements-Version 2.0skzubsNo ratings yet

- 12-Division 2-Section 02400 Pipeline by NDM-V 2.0Document26 pages12-Division 2-Section 02400 Pipeline by NDM-V 2.0Avaan IvaanNo ratings yet

- 06-Div 2-Sec02205 - uPVCDocument17 pages06-Div 2-Sec02205 - uPVCSheeba BensonNo ratings yet

- Pages From 02b. Specifications-Concrete MixDocument1 pagePages From 02b. Specifications-Concrete MixbinunalukandamNo ratings yet

- S-AAA-ELMS-HVAC+VENT (Rev.0-2015)Document30 pagesS-AAA-ELMS-HVAC+VENT (Rev.0-2015)Swathish SivaprasadNo ratings yet

- 05-DG-Section 5 Recycled Water-Version 5.0Document15 pages05-DG-Section 5 Recycled Water-Version 5.0Jamshed AlamNo ratings yet

- 13-Division 2-Section 02500 Roadworks and Paving-Version 2.0Document6 pages13-Division 2-Section 02500 Roadworks and Paving-Version 2.0Avaan IvaanNo ratings yet

- 4 - UPVC PIPES Mitrec Dim PDFDocument41 pages4 - UPVC PIPES Mitrec Dim PDFTASNEEMNo ratings yet

- DM Automatic Irrigation System SpecsDocument56 pagesDM Automatic Irrigation System SpecsSarfraz AhmadNo ratings yet

- ManholesDocument116 pagesManholesSrinivas ChalumuriNo ratings yet

- 04-Division 3-Section 03400 Precast Concrete-Version 2 0Document13 pages04-Division 3-Section 03400 Precast Concrete-Version 2 0BassemMNo ratings yet

- QCS 2010 Part 6.03 EarthworksDocument21 pagesQCS 2010 Part 6.03 EarthworksRotsapNayrb100% (2)

- ADM Specs GRP Enclosures and KiosksDocument3 pagesADM Specs GRP Enclosures and KiosksMahiBoumNo ratings yet

- Pipe Jacking - Herren PDFDocument2 pagesPipe Jacking - Herren PDFnurNo ratings yet

- BS 4660 2000 Drainage Ancillary Fittings For Nominal Sizes 110 - 160 Below GradeDocument16 pagesBS 4660 2000 Drainage Ancillary Fittings For Nominal Sizes 110 - 160 Below GradeFenner ElectromechanicalNo ratings yet

- Pr9902 - Specification For Civil and EarthworksDocument67 pagesPr9902 - Specification For Civil and EarthworksRegret WhistleNo ratings yet

- Specification PDFDocument54 pagesSpecification PDFsothilingamnNo ratings yet

- 04-DG-Section 4 Sewage Treatment Works-Version 5.0Document24 pages04-DG-Section 4 Sewage Treatment Works-Version 5.0Jamshed AlamNo ratings yet

- 18-Division 2-Section 02900 PP Pipelines, Materials, Installation & TestingDocument19 pages18-Division 2-Section 02900 PP Pipelines, Materials, Installation & TestingAvaan IvaanNo ratings yet

- Major Works Design Technical GuidelineSep19 v17Document63 pagesMajor Works Design Technical GuidelineSep19 v17MAHESH CHANDNo ratings yet

- Ministry of Water - SewerDocument250 pagesMinistry of Water - Sewerfaisal100% (1)

- Potable Water PumpsDocument17 pagesPotable Water PumpsNijasNo ratings yet

- Standard Specification No. Kpc-A-10 Standard Specification For Plumbing FOR PT Kaltim Prima Coal Project at East Kalimantan, IndonesiaDocument7 pagesStandard Specification No. Kpc-A-10 Standard Specification For Plumbing FOR PT Kaltim Prima Coal Project at East Kalimantan, Indonesiabarian karopebokaNo ratings yet

- Ezprene 9085aDocument2 pagesEzprene 9085aalejandrocharlescollNo ratings yet

- Tutorial 4Document1 pageTutorial 4Kevin TanNo ratings yet

- Evolution of Fatigue HistoryDocument11 pagesEvolution of Fatigue Historyiama nubertNo ratings yet

- Chapter 3.roman and Greek Architecture.Document6 pagesChapter 3.roman and Greek Architecture.Cypris Mae MasongNo ratings yet

- 626 - JL 09 Summer 7 PDFDocument20 pages626 - JL 09 Summer 7 PDFRejoice SamboNo ratings yet

- World Class Pre FabDocument16 pagesWorld Class Pre FabHariKrishnaNo ratings yet

- E-400 - Construction Specification - ElectricalDocument82 pagesE-400 - Construction Specification - ElectricalDinesh RajNo ratings yet

- ExampleDocument43 pagesExampleSabri Bri EDNo ratings yet

- Prefabricated Installation Pit in Filled-Chamber Design: Maintenance Pit For Trucks and BusesDocument2 pagesPrefabricated Installation Pit in Filled-Chamber Design: Maintenance Pit For Trucks and Buseskhristian nathan lee anesNo ratings yet

- Salon Tipi 1 Faz ServisDocument51 pagesSalon Tipi 1 Faz ServisaydintarakNo ratings yet

- Selection of Restorative Materials and TechniquesDocument56 pagesSelection of Restorative Materials and Techniquesaram meyedyNo ratings yet

- Fineset 2119R - H Single Component Thixotropic Epoxy ResinDocument3 pagesFineset 2119R - H Single Component Thixotropic Epoxy ResinBabyboy2010No ratings yet

- Effect of Ca2+ Ion Concentration On Adsorption of Poly (Carboxylate Ether) - Based (PCE) Superplasticizer On MicaDocument7 pagesEffect of Ca2+ Ion Concentration On Adsorption of Poly (Carboxylate Ether) - Based (PCE) Superplasticizer On Mica董鑫No ratings yet

- Rcu2e Ag2 & Rhu2e Ag2 PDFDocument192 pagesRcu2e Ag2 & Rhu2e Ag2 PDFKostas AstrinisNo ratings yet

- Asahimas-Sustainable Products For Green Buildings (MKSR)Document64 pagesAsahimas-Sustainable Products For Green Buildings (MKSR)BINAZIRNo ratings yet

- Hand Calculation by ACI CodeDocument11 pagesHand Calculation by ACI CodeFarag Hussein Alhassi100% (1)

- 3M Dual-Lock ReclFastrsDesignSelectGuideDocument8 pages3M Dual-Lock ReclFastrsDesignSelectGuidePhil MartinNo ratings yet

- BOMBA Passive and Active Fire Protection DrawingsDocument3 pagesBOMBA Passive and Active Fire Protection DrawingsFaisal NoorazmanNo ratings yet

- Sunsheetal Heat Reflective Paint: A Study Report On The Scope of in Dairy Market Presented By: AnchalDocument29 pagesSunsheetal Heat Reflective Paint: A Study Report On The Scope of in Dairy Market Presented By: AnchalAnchal RazdanNo ratings yet

- Casting ProcessDocument40 pagesCasting Processharish3742No ratings yet

- Fretting SolutionDocument8 pagesFretting SolutionRohan MalkarNo ratings yet

- CT 1-3 - Basic Construction Materials: Homework CT 1-3 Submitted By: Ma. Antonette D. Del Sol, CEDocument8 pagesCT 1-3 - Basic Construction Materials: Homework CT 1-3 Submitted By: Ma. Antonette D. Del Sol, CEAnthony Del SolNo ratings yet