Professional Documents

Culture Documents

Casing Design Hand Calculation Design Example

Uploaded by

ChilledambienceCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Casing Design Hand Calculation Design Example

Uploaded by

ChilledambienceCopyright:

Available Formats

Casing Design

What casing size?

Set by Pump, Packer, Tubing Requirements and

Limited by meeting pressure and economic objectives.

Where is the largest tubing? The casing has to

accommodate the tubing.

Are kickoffs planned? what size tubular is in the kickoff?

What about pump and other equipment needs and sizes.

How many casing strings are needed to make depth?

A casing string is designed from the bottom to

the top and from the inside to the outside.

3/14/2009

George E. King Engineering

GEKEngineering.com

1

Slim Hole Wells

Slim hole wells are often drilled and

completed to try to meet economic goals.

From completion, stimulation, reliability, lift

and workover considerations, a slim hole well

is often the very worst choice.

Choose wisely!

3/14/2009

George E. King Engineering

GEKEngineering.com

2

Casing Design Example

Simple hand-worked design using collapse,

burst and tensile in the design.

First example a multiple weight/grade pick

to show where strength is required avoid

this design in the real world if possible.

Second calculation of a single pipe weight

and grade that can be used.

NOTE - This example problem is not intended to teach casing design, nor is it a

replacement for modern casing design methods. More modern equations (e.g., API

equations) are available as are a variety of computer simulations that are much more

accurate that this approximation.

3/14/2009 3

George E. King Engineering

GEKEngineering.com

Buoyancy brine offsets part of all of

the pipe weight

W

b

= W

a

(1

f

/

s

)

W

b

= buoyed weight of casing in a fluid

W

a

= air weight of casing

f

= density of fluid, lb/gal

s

= density of steel = 65 lb/gal

3/14/2009 4

George E. King Engineering

GEKEngineering.com

Simple Buoyancy Example

10,000 ft string, 7, 26 lb/ft, 12 lb/gal mud

W

air

= (10,000 ft) (26 lb/ft) = 260,000 lb

W

buoyed

= (260,000 lb) (1- (12/65.4)) =

= 212,294 lb

For larger pipe strings and heavier brine, the

effect of buoyancy is increased. Very large pipe in

heavy brine can actually float.

3/14/2009 5

George E. King Engineering

GEKEngineering.com

Calculated Hook Load Changes

3/14/2009

George E. King Engineering

GEKEngineering.com

6

Mud in Hole

Mud in Csg

212,300 lb

Mud in Hole

Cmt in Csg

283,600 lb

Cmt in Hole

Cmt in Csg

195,600 lb

Cmt in Hole

Water in Csg

65,936 lb

Downhole Causes of Axial

Compression

Sources of Axial Compression:

Buoyancy before cement sets

Poissons effect if casing is landed or sticks

Reverse ballooning too much outside pressure

Thermal expansion only if both ends fixed

Borehole friction deviated holes and doglegs

Drag same as friction in most cases

Slack-off same as landing

3/14/2009 7

George E. King Engineering

GEKEngineering.com

Axial (Tensile) Force versus Depth in a

Casing String

12,000 ft, 9-5/8, 53.5 lb/ft casing (0.545 wall),

suspended in 16 lb/gal mud.

W

a

= (12,000 ft) (53.5 lb/ft) = 642,000 lb

W

buoyed

= (642,000 lb) (1- (16/65.4)) =484,935 lb

Buoyancy force = 642,000 484,935 = 157.065 lb

3/14/2009 8

George E. King Engineering

GEKEngineering.com

Wa

Wb

- 0 +

Wt on pipe at depth

Surface

Weight

Buoyancy

Neutral point is a

calculated position

on the pipe that

shows offset of

string weight by

buoyancy.

3/14/2009 9

George E. King Engineering

GEKEngineering.com

Buoyancy Neutral Point remember this is a calculation aid, not a real

point in the well.

1. Casing below the neutral point is considered to be in compression

for the purposes of the calculations and collapse forces dominate the

casing strength design.

2. Casing above the neutral point is in tension and burst strength

dominates the design. However, casing in tension must be derated

for the effect of tension on collapse rating.

3/14/2009 10

George E. King Engineering

GEKEngineering.com

Collapse Design Be careful, this type of

design considers only initial, static froces

and does not consider dynamic, production

and thermal forces

Pcx=0.052

f

Dx

Pcx=collapse pressure exerted by the mud at a depth Dx

f

=density of mud, lb/gal

Dx=depth

With this formula a collapse pressure at an estimated depth is calculated

(safety factor has not been applied yet).

3/14/2009 11

George E. King Engineering

GEKEngineering.com

Casing Design Example Note this is the old

method that uses multiple picks of string weight and

grade it is useful for showing how a simple design

works, but many pipe grades and weights would create

confusion at the well during casing running.

Design a 10,000 ft string of 7 casing.

Pore pressure =8000 psi at 10,000 ft.

Mud weight =16.3 lb/gal.

Fracgradient =0.9 psi/ft.

Convert to gradients:

Pore pressure =8000/10,000 =0.8 psi/ft

Mud weight =16.3 lb/gal * (0.052) =0.85 psi/ft

Fracgradient =0.9 psi/ft

3/14/2009 12

George E. King Engineering

GEKEngineering.com

Calculate the Theoretical Buoyancy Neutral Point.

N.P. =Dx(1- (fluid density/steel density)

=10,000 ft (1 (16.3/65.4)

=7500 ft

This is the equivalent amount of the string weight at the

surface. If a heavier fluid was used, the N.P. would be

shallower in the well (more of the pipe weight would be

offset by the buoyancy).

3/14/2009 13

George E. King Engineering

GEKEngineering.com

Maximum Collapse Force

Pcx =(10000 ft) * (0.85 psi/ft) =8500 psi

Since it is a force and not a rating, the safety factor is multiplied:

Pcx =(8500) * (1.1) =9350 psi

Now, select a pipe with a collapse pressure minimum that will handle

the load. No need to derate the pipe number, the safety factor has

already been applied on the force (or load).

First pick 7, 32 lb/ft, C-95, Pc =9730 psi.

This is the bottom joint there is less strength required as the

strength analysis comes up the well until it nears the top. The

strength required is maximum at the bottom (collapse is maximum)

and at the top (burst is maximum).

Although this method would lead to many different weights and

grades, the best approach is a single selection of strong casing.

3/14/2009 14

George E. King Engineering

GEKEngineering.com

Casing Strength Pick

Start with a casing of the right alloy, and select

the first pick in the middle of the range.

Weight,

lb/ft

Collapse,

psi

Grade

23 4150 C-95

26 5870 C-95

29 7820 C-95

32 9730 C-95

35 11,640 C-95

28 13,420 C-95

3/14/2009 15

George E. King Engineering

GEKEngineering.com

Next, select a lower strength string

Pick 7, 29 lb/ft, C-95, Pc = 7820 psi

Pcx = 7820/1.1 = 7109 psi collapse strength

How deep can it be set?

Depth = 7109 psi/0.85 psi/ft = 8360 ft

3/14/2009 16

George E. King Engineering

GEKEngineering.com

Set Point for the 32 lb/ft top

The bottom of the 29 lb/ft sets the top of the

32 lb/ft. Note the 32 lb/ft string can be run

higher but the 29lb/ft is theoretically cheaper

and lighter.

The 32 lb/ft runs from 8360 to 10,000 ft.

3/14/2009 17

George E. King Engineering

GEKEngineering.com

Select a third string..

7, 26 lb/ft, C-95, Pc = 5870 psi

Safety factor = 1.1, Pcx = 5870/1.1 = 5330 psi

Set depth = 5330/0.85 = 6270 ft

Neutral Point = 7500 ft since this depth is above the

N.P., the calculations switch to burst design rather

than collapse design.

Deration of the collapse for tension effects is common

use 4% deration as a starting point, but the final

effect is usually between 1% and 2% except in

extreme cases.

3/14/2009 18

George E. King Engineering

GEKEngineering.com

Effect of axial loads on collapse and burst

Casing in tension is weaker

in collapse and stronger in

burst consider it for

collapse calculations.

Casing in compression is

weaker in burst and stronger

in collapse ignore it for

collapse calculations.

3/14/2009 19

George E. King Engineering

GEKEngineering.com

Derate for collapse:

1. Derate maximum depth by 4% (this is an experience estimate, the

correct value is usually between 2% and 4%).

2. Calculate unit tensile stress:

St =(7500 ft 6020 ft) * 26 lb/ft =38480 lb

3. Axial load factor =(unit tensile stress/tensile body strength)

=(38480 / 717,000) =0.054

4. Derating factor (from deration tables for casing) =0.985

5. Pc =(5330 psi)(0.985) =5280 psi

6. Collapse check =(5250 / 0.85) = 6176 ft,

first guess of 6020 ft is OK.

3/14/2009 20

George E. King Engineering

GEKEngineering.com

Design to this point:

Interval Weight Grade

10,000 to 8360 32 lb/ft C-95

8360 to 6020 29 lb/ft C-95

6020 to ? 26 lb/ft C-95

Since the depth is now above the buoyancy neutral point, burst becomes

the basis for design.

3/14/2009 21

George E. King Engineering

GEKEngineering.com

Safety Factors

Safety factors used in the calculations vary with the

application. The following as general estimates for this

example. Safety factors must be set by engineering

experts well versed in your application.

For this problem:

Collapse risk: lose a section of the well, safety factor of

1.1 is typical.

Burst risk: life endangered justifies a must higher safety

factor, 1.2 to 1.4 is typical.

Tension risk: dropping the string. Because of variances in

coupling make-up strength, a safety factor is 1.5 to 1.7.

3/14/2009 22

George E. King Engineering

GEKEngineering.com

Burst Design

Worst case blow out with gas bubble in the hole.

At Surface:

Ps = (0.052

p

Dx) (Gg Dx)

p

= pore pressure equivalent wt., lb/gal

Dx = depth to pay

Gg = Gas gradient, 0.1 psi/ft for this problem

3/14/2009 23

George E. King Engineering

GEKEngineering.com

Calculate a Surface Pressure Estimate.

Lesser of:

Fracture gradient less a gas gradient

Ps = (0.9 0.1)psi/ft * 10,000 ft = 8,000 psi

Formation pressure less a gas gradient (0.1 psi/ft)

Ps = (0.8 0.1) * 10,000 ft = 7,000 psi

Use 7,000 psi as maximum surface pressure

3/14/2009 24

George E. King Engineering

GEKEngineering.com

Now, how shallow can the 26 lb/ft C-95 be set?

Pb = 8600 psi, with safety factor of 1.4

Pb = 8600/1.4 = 6140 psi

Shallowest set depth:

Dx = [(7000 psi 6140 psi) / (0.8 0.1)]

Dx = 1230 ft

26 lb/ft runs from 6020 ft to 1230 ft.

Need a stronger pipe to run to surface..

3/14/2009 25

George E. King Engineering

GEKEngineering.com

A stronger pipe must be set to surface.

Select 26 lb/ft, P-110

Pb = 9960 psi, safety factor of 1.4

Pb = 9960/1.4 = 7110 psi

Dx = [(7000 7110) / (0.8 0.1)] < 0

The P-110 can be run to surface.

3/14/2009 26

George E. King Engineering

GEKEngineering.com

Why would a multiple weight or multiple

grade casing string be a problem?

Hard to keep the weight and grades in correct

order would take much longer to run the

string.

A multiple inside diameter string would also

create setting problems for packers.

3/14/2009

George E. King Engineering

GEKEngineering.com

27

Monobore:

mixed

grades,

same

weight

Mixed

grades

and

weights

Mixed

weights,

same

grade

Casing Design Options think about running and setting packers.

3/14/2009 28

George E. King Engineering

GEKEngineering.com

What happens if a

joint of the

heaviest weight

casing (smallest

ID) is accidently

set at the surface?

Tensile Ratings

Two ratings for tensile rating:

Body Yield = used in collapse rating calculations

Joint Yield = used in tensile design

Connection Strength

API connection, body stronger than threads

Premium connections, joint often stronger than body

3/14/2009 29

George E. King Engineering

GEKEngineering.com

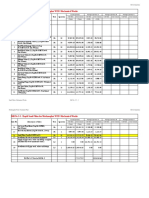

Tension Design (just pipe above the neutral

point shown), s.f. = 1.7 for the example.

Pipe Length Wt/ft Grade Load

lb

Cummul

ative

lb

Joint Rating

lb

7500 6020 ft 29 C-95 42,920 42,920 683,000/1.7 = 487,850

6020 1230 ft 26 C-95 124,540 167,460 593,000/1.7 = 348,820

1230 0 ft 26 P-110 31,980 199,440 693,000/1.7 = 495,000

3/14/2009 30

George E. King Engineering

GEKEngineering.com

Final Design multiple casing

Interval, ft Wt/ft Grade Connection

0 1230 26 P-110 LT&C

1230 6020 26 C-95 LT&C

6020 8360 29 C-95 LT&C

8360 10,000 32 C-95 LT&C

3/14/2009 31

George E. King Engineering

GEKEngineering.com

A Better Design?

A simpler approach that yields a reliable

design may be to use one weight and grade of

casing that can handle the forces anywhere in

the well.

Exceptions:

Very long strings.

Corrosion control changes along the well.

Limitations of rig lifting power,

Etc.

3/14/2009

George E. King Engineering

GEKEngineering.com

32

Single String Quick Look

Take the 32 lb/ft, 7, C-95 that was suitable for the

bottom section (collapse resistance).

Check it against the burst requirement at surface: Pb =

11760 psi / 1.4 = 7685 psi, which is more than the 7,000

psi max Ps OK

Check the tensile rating: 768,000 / 1.7 = 451,764 lb

capacity (max string weight was 199, 440.

The 32 lb/ft., C-95, 7 can be run from bottom to top,

satisfying simple loads of collapse, burst and tensile.

3/14/2009 33

George E. King Engineering

GEKEngineering.com

Quiz Casing Problem

1. For a 10000 ft deep well, with 9.0 lb/gal mud.

Select a single casing size (minimum 6.1 ID), grade

and weight that can be run to bottom in a 9-1/4

hole and will withstand the collapse pressure of the

mud to a 1.1 safety factor and the burst pressure

(3600 psi is maximum surface pressure from the

zone, 4600 psi is BHP) to a 1.4 safety factor. Make

assumptions as needed, but record the

assumptions with the solution.

3/14/2009 34

George E. King Engineering

GEKEngineering.com

You might also like

- Advanced Drilling Practices - Casing DesignDocument92 pagesAdvanced Drilling Practices - Casing DesignAnonymous H9n5g3aaCENo ratings yet

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Measurement While Drilling: Signal Analysis, Optimization and DesignFrom EverandMeasurement While Drilling: Signal Analysis, Optimization and DesignNo ratings yet

- Casing and Casing Design 1Document60 pagesCasing and Casing Design 1Albert Wilson DavidNo ratings yet

- Casing DesignDocument28 pagesCasing DesignTarek Hassan100% (2)

- Wave Propagation in Drilling, Well Logging and Reservoir ApplicationsFrom EverandWave Propagation in Drilling, Well Logging and Reservoir ApplicationsNo ratings yet

- Casing ExerciseDocument9 pagesCasing ExerciseYesar Bin Mustafa AlmalekiNo ratings yet

- Anadrill - Stuck PipeDocument65 pagesAnadrill - Stuck PipeebluemaniaNo ratings yet

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsFrom EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsRating: 4 out of 5 stars4/5 (9)

- Basic Tubing ForcesDocument21 pagesBasic Tubing ForcesOzzie GonzalezNo ratings yet

- Applied Drilling Circulation Systems: Hydraulics, Calculations and ModelsFrom EverandApplied Drilling Circulation Systems: Hydraulics, Calculations and ModelsRating: 5 out of 5 stars5/5 (4)

- Casing Setting Depth DesignDocument26 pagesCasing Setting Depth Designehsan100% (1)

- Drill String DesignDocument13 pagesDrill String DesignTarek Hassan67% (3)

- 2.1 Casing Seat SelectionDocument25 pages2.1 Casing Seat Selectionkounhetsov100% (3)

- L8-Drill String Design in Directional WellsDocument25 pagesL8-Drill String Design in Directional WellsLaxmi Kant PrasadNo ratings yet

- TorqueDrag AnalysisDocument26 pagesTorqueDrag Analysisjinyuan74No ratings yet

- Cavings Poster-1 SLBDocument1 pageCavings Poster-1 SLBEric Espiritu100% (3)

- Tubing Movement Calculation Montrose v1.0 03.05.2003Document33 pagesTubing Movement Calculation Montrose v1.0 03.05.2003titiche1100% (3)

- Drill String Design 4.11Document23 pagesDrill String Design 4.11Ryan Tan Ping Yi100% (1)

- Understanding The Difference Between Biaxial and Triaxial in Terms of Casing DesignDocument12 pagesUnderstanding The Difference Between Biaxial and Triaxial in Terms of Casing DesignHamed NazariNo ratings yet

- Oilwell Cementing CalculationDocument68 pagesOilwell Cementing CalculationRishi Ramnath100% (3)

- 8-Casing Setting Depth DesignDocument27 pages8-Casing Setting Depth Designthiban1309910% (1)

- Drillstring DesignDocument1 pageDrillstring DesignMobeen MurtazaNo ratings yet

- Tubing Length Change CalculationsDocument33 pagesTubing Length Change CalculationsOmer Khalid100% (2)

- Common Well Control Hazards: Identification and CountermeasuresFrom EverandCommon Well Control Hazards: Identification and CountermeasuresRating: 4.5 out of 5 stars4.5/5 (4)

- Shale Shaker and Drilling Fluids Systems:: Techniques and Technology for Improving Solids Control ManagementFrom EverandShale Shaker and Drilling Fluids Systems:: Techniques and Technology for Improving Solids Control ManagementRating: 4.5 out of 5 stars4.5/5 (2)

- Methods for Petroleum Well Optimization: Automation and Data SolutionsFrom EverandMethods for Petroleum Well Optimization: Automation and Data SolutionsNo ratings yet

- Tubing DesignDocument12 pagesTubing Designakshitppe11No ratings yet

- Hole Cleaning PDFDocument68 pagesHole Cleaning PDFHarold AldayNo ratings yet

- Well Completion Design GuideliDocument108 pagesWell Completion Design GuideliTogoumas Djide100% (2)

- 6.mud Hydraulics Fundamentals PDFDocument11 pages6.mud Hydraulics Fundamentals PDFمعلومات ممتعه mohammedNo ratings yet

- CementingDocument53 pagesCementingUgochukwu Fidelis100% (1)

- Torque and Drag CalculationsDocument67 pagesTorque and Drag Calculationssivakmu100% (22)

- Rig HydraulicsDocument9 pagesRig Hydraulicsmihir1810100% (1)

- New Drill Pipe DesignDocument9 pagesNew Drill Pipe DesignModebelu EbubeNo ratings yet

- Casing and Cement ManualDocument248 pagesCasing and Cement ManualAnonymous ocBLoeAOh467% (3)

- Triaxial Stress AnalysisDocument7 pagesTriaxial Stress Analysisbymohamed100% (1)

- Pore PressureDocument51 pagesPore Pressuredriller22100% (6)

- Well PlanningDocument4 pagesWell PlanningSibte Hassan ButtNo ratings yet

- Casing CalculationsDocument10 pagesCasing CalculationsKimiko ShopNo ratings yet

- L7 - Wellbore Deflection & BHA SelectionDocument32 pagesL7 - Wellbore Deflection & BHA SelectionLaxmi Kant Prasad100% (1)

- Tubing SelectionDocument51 pagesTubing SelectionImam Zulkifli SNo ratings yet

- Bit HydraulicsDocument1 pageBit HydraulicsstevebeardsleyNo ratings yet

- Casing Design WorkshopDocument52 pagesCasing Design WorkshopNikita Axyonov100% (1)

- BHA Design CalculationDocument26 pagesBHA Design CalculationRema OmarNo ratings yet

- SPE-10709 Physics Based Well Design - Beyond The Learning CurveDocument5 pagesSPE-10709 Physics Based Well Design - Beyond The Learning Curvedrilling moneytreeNo ratings yet

- Well Engineering LearnDistance Package PDFDocument218 pagesWell Engineering LearnDistance Package PDFrafiullah353No ratings yet

- Casing DesignDocument28 pagesCasing DesignHeris SitompulNo ratings yet

- Casing and Liners for Drilling and Completion: Design and ApplicationFrom EverandCasing and Liners for Drilling and Completion: Design and ApplicationRating: 5 out of 5 stars5/5 (3)

- JAR-KING 1 Operations ManualDocument20 pagesJAR-KING 1 Operations ManualkrishnsgkNo ratings yet

- Well PlanningDocument30 pagesWell PlanningDaniel Enrique Serna Guevara100% (2)

- 11 2Document4 pages11 2Logadhasan SuwedanNo ratings yet

- 02 Preparation For Construction PDFDocument61 pages02 Preparation For Construction PDFMiguel David100% (2)

- Ti Alloys For Biomedical ApplicationsDocument9 pagesTi Alloys For Biomedical ApplicationsHugo FernándezNo ratings yet

- 10-11 - Shear in BeamsDocument7 pages10-11 - Shear in BeamsOsama TamariNo ratings yet

- Q Q345 345E (China / GB) E (China / GB) : Les Propriétés Des Matériels Les Propriétés Des MatérielsDocument2 pagesQ Q345 345E (China / GB) E (China / GB) : Les Propriétés Des Matériels Les Propriétés Des MatérielsAbdelkader DraïNo ratings yet

- Fluid KinematicsDocument49 pagesFluid KinematicsJM Jusay CarabLeNo ratings yet

- Chirag Patil ConzultancyDocument2 pagesChirag Patil ConzultancynitinkumarsinghalNo ratings yet

- Column Beam StairDocument44 pagesColumn Beam StairSananda BanikNo ratings yet

- 42NH Ductable in Room Fan Coil With Multi Speed Motor: Performance Summary For Soba Za IgruDocument2 pages42NH Ductable in Room Fan Coil With Multi Speed Motor: Performance Summary For Soba Za Igruvelikimag87No ratings yet

- Letter 01050Document30 pagesLetter 01050DEENo ratings yet

- Davit Cal 2251B Davit Arm CalculationDocument4 pagesDavit Cal 2251B Davit Arm CalculationKarina RoquelNo ratings yet

- SPIRAX MANUAL - Steam Pipes and Pipe Sizing GCM - 75Document22 pagesSPIRAX MANUAL - Steam Pipes and Pipe Sizing GCM - 75stankoub100% (1)

- Curee Eda02 PublicDocument0 pagesCuree Eda02 PublicFilip CosminNo ratings yet

- AD 418 - Web-Post Buckling in Composite Beams With Rectangular and Elongated Web Openings, May 2018Document2 pagesAD 418 - Web-Post Buckling in Composite Beams With Rectangular and Elongated Web Openings, May 2018symon ellimacNo ratings yet

- Civil715 S2 2018Document9 pagesCivil715 S2 2018Cheng FuNo ratings yet

- Pressure Loss in Schedule 40 Steel PipesDocument11 pagesPressure Loss in Schedule 40 Steel PipesAnonymous qrSsYuxyoYNo ratings yet

- Electriochemical Kinetics of CorrosionDocument2 pagesElectriochemical Kinetics of CorrosionrafaelNo ratings yet

- Gri 33125000707782Document396 pagesGri 33125000707782Aref MalkawiNo ratings yet

- Paper - Pengelolaan Air Tanah Berbasis Konservasi BoyolaliDocument12 pagesPaper - Pengelolaan Air Tanah Berbasis Konservasi BoyolaliBellagus SasmitaNo ratings yet

- Filter MideaDocument22 pagesFilter MideaMahibul HasanNo ratings yet

- Fire Fighting System For NALCO ProjDocument2 pagesFire Fighting System For NALCO ProjtechbhazNo ratings yet

- SS 557-2010Document64 pagesSS 557-2010jclimkanghaiNo ratings yet

- News Release: Aisi Publishes 2013 Edition of Cold-Formed Steel Design ManualDocument3 pagesNews Release: Aisi Publishes 2013 Edition of Cold-Formed Steel Design ManualBONDHON-2 APARTMENT0% (1)

- Theater InstallationDocument7 pagesTheater InstallationtemamNo ratings yet

- Analysis of Doubly Reinforced Concrete BeamDocument4 pagesAnalysis of Doubly Reinforced Concrete BeamAnton_Young_1962No ratings yet

- GFC Appfly Tanks 05.12Document2 pagesGFC Appfly Tanks 05.12Robert Eshwer100% (1)

- Synopsis of Changes in Section IV E2023Document40 pagesSynopsis of Changes in Section IV E2023yathi sNo ratings yet

- Closure of Tidal BasinsDocument30 pagesClosure of Tidal BasinsAyman Al HasaarNo ratings yet

- 11 - Concrete Flexural DesignDocument20 pages11 - Concrete Flexural Designleona Grace MendozaNo ratings yet

- CIVL4720 2014 Assign 5Document4 pagesCIVL4720 2014 Assign 5rivai sargawiNo ratings yet