Professional Documents

Culture Documents

W D 3 Pile Pile Cap, Height H X: Pile Cap Design Design Input - 3-Pile Pile Cap - Concentrically Loaded Pile Details

Uploaded by

Naba Raj ShresthaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

W D 3 Pile Pile Cap, Height H X: Pile Cap Design Design Input - 3-Pile Pile Cap - Concentrically Loaded Pile Details

Uploaded by

Naba Raj ShresthaCopyright:

Available Formats

Project

Job Ref.

The Pearl

Q09077

Section

Sheet no./rev.

DAR GROUP

QQ

Calc. by

Date

Eng.TK

Chk'd by

09-Mar-08

Date

App'd by

Eng.IC

Date

Dr.AE

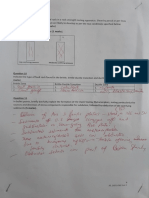

w2

e

dpile

3 Pile Pile Cap,

height h

X

P1

Loaded area ac, bc

Ldiag

0.866s

Y

Y

ac

P2

P3

0.288s

s

w1

bc

X

b

PILE CAP DESIGN

DESIGN INPUT - 3-PILE PILE CAP - CONCENTRICALLY LOADED

Pile details

;

Pile diameter;

d pile = 450.0 mm

Pile capacity (service);

P cap = 750.00 kN

Pile spacing;

s = 1350.0 mm

Pile spacing OK

;

Pile cap overhang ;

e = 500.0 mm

Edge distance OK

Pile cap details

Pile cap dimensions

dimension in x-x axis direction ;

L = sin(60) s+ d pile +2 e = 2.619 m

dimension in y-y axis direction ;

b = s + d pile +2 e = 2.800 m

w 1 = d pile + 2 e = 1.450 m

w 2 = d pile + 2 e = 1.450 m

Diagonal length of sides;

L side_diag = ( (L-w 1 ) 2 + ((b-w 2 )/2)2 ) = 1.350 m

;Overall thickness of pile cap;

h = 750.0 mm

;Pile embedment distance;

e c = 160.0 mm

Embedment distance OK

;

Concrete cover;

d c = 75.0 mm

Trial bar diameter;

d bar = 19.1 mm

Project

Job Ref.

The Pearl

Q09077

Section

Sheet no./rev.

DAR GROUP

QQ

Calc. by

Date

Eng.TK

Chk'd by

09-Mar-08

Date

Eng.IC

App'd by

Date

Dr.AE

Effective depth;

d bx = h - e c - d c - d bar/2 = 505 mm

d by = d bx - 1.0 d bar = 486 mm

d b = (d bx + d by) / 2 = 496 mm

Column details

;

Column width along x-x axis;

a c = 400.0 mm

Column width along y-y axis;

b c = 600.0 mm

Material properties

;

Yield strength of tension reinforcement;

fy = 415 N/mm 2

Concrete strength;

fc = 40.000 N/mm 2

Concrete density;

c = 24.0 kN/m 3

Loading details

Note: The following calculations assume that the centroid of the pile cap coincides with that of the pile group.

;

Column axial dead load;

P dl = 1250.000 kN

Area of pile cap;

A cap = L b - sin(60) L side_diag 2 /2 = 6.54 m 2

W eight of pile cap

P wt = (A cap h - 3 d pile e c /4) c = 115.967 kN

;

Surcharge pressure on cap;

p sur = 0.000 N/mm 2

Surcharge load;

P sur = p sur (L b - (sin(60) L side_diag 2 )/2 - a c b c ) = 0.000 kN

;

Column axial live load;

P ll = 425.000 kN

P n = P dl + P ll = 1675.000 kN

Total column load (unfactored);

The service load per pile;

P n_pile = (P n + P wt + P sur)/3 = 596.989 kN

Pile capacity OK

Total column load (factored);

P u = 1.2 P dl + 1.6 P ll = 2180.000 kN

The ultimate load per pile;

P u_pile = (P u + 1.2 (P wt + P sur))/3 = 773.054 kN

PILE CAP FORCES TIED ARCH METHOD

CRSI Fig. 13-13

d cl_pl = ((s/2) 2 + (0.288*s)2 ) = 778.968 mm

xcl_pl = (d cl_pl2 + d b 2 ) = 923.448 mm

= atan(d cl_pl/(d b )) = 57.516 deg

= acos(( (d b 2 + (0.288 * s)2 ))/xcl_pl) = 46.967 deg

Compression within pile cap;

C max = P u_pile / cos() = 1439.409 kN

Tension within pile cap;

T = C max * sin( )/2 = 526.072 kN

COMPRESSION IN PILE CAP - SUGGESTED ADDITIONAL CHECKS

Check compression diagonal as an unreinforced column, using a core equivalent to 2 pile diameters

Project

Job Ref.

The Pearl

Q09077

Section

Sheet no./rev.

DAR GROUP

QQ

Calc. by

Date

Eng.TK

;;;

09-Mar-08

Chk'd by

Date

Eng.IC

App'd by

Date

Dr.AE

P c = 0.55 0.60 fc ((2 d pile ) 2 )/4 = 8397.477 kN

Compression - OK

ACI 22.5.2

Check bearing capacity of pilecap over piles

A 1 = d pile 2 /4 = 159043 mm 2

;

A 2 = A cap = 6544410 mm 2

P brg = 0.55 0.85 fc A 1 min(2, sqrt( A 2 / A 1 )) = 5948.213 kN

Bearing - OK

ACI 22.5.5

Check bearing capacity of pilecap under column

;;;

A 1 = a c b c = 240000 mm 2

P brg = 0.65 0.85 fc A 1 min(2, sqrt( A 2 / A 1 )) = 10608.000 kN

Column Bearing - OK

ACI 10.17.1

TENSION STEEL IN PILE CAP

Area of tension steel required for tied-arch behavior

;;

A s_T = T / (0.75 fy) = 1690 mm 2

Moment at face of column

xface = max(.577 s - min(a c,b c ) / 2, 0 mm) = 579.0 mm

;;;

Distance from pile to face of column;

;;;

Pressure due to pile cap selfweight and surcharge;

;;;

;W idth at column face; b w = if( xface < L - w 1 , w 2 + 2 .577 xface , b ) = 2.12 m

Ultimate moment at column face

q u = 1.2 (p sur + P wt / A cap ) = 0.021 N/mm 2

M uy = P u_pile xface - q u w 2 xface 2 / 2 + 2 .577 xface 3 /3)= 440.8 kNm

Area of tension steel required for flexure

;

= if(fc < 27.58 N/mm 2 , 0.85, max( .65, 0.85 - 0.05 (fc - 27.58 N/mm 2 ) 6.89 N/mm 2 )) = 0.760

= 0.319 = 0.242

Ru

= t (1 0.588 t) = 0.208

R reqd

= M uy / ( fc d b 2 ) / b w = 0.021153

Section dimensions are OK to be tension-controlled ;

J = sqrt(max(.25 - R reqd / 0.85 / 2.,0) ) + .5 = 0.9874

A sflex = M uy / ( 0.90 fy J d b ) = 2410 mm 2

;

Minimum ratio of tension reinforcement for temperature and shrinkage

ACI 7.12.1

min = 0.001800

ACI 10.5.1

A s_min = max( 3 (fc ) b d b / fy, 200 b d b / fy )

A s_min = 5272 mm 2

A s_43 = (4/3 max(A s_T,A sflex ))

A st_min = if(A s_min > A s_43 , max( min b h, A s_43 ), max( min b h, A s_min ))

Project

Job Ref.

The Pearl

Q09077

Section

Sheet no./rev.

DAR GROUP

QQ

Calc. by

Date

Eng.TK

Chk'd by

09-Mar-08

Date

App'd by

Eng.IC

Date

Dr.AE

A st_min = 3780 mm 2

A s_req_normal = max(A sflex , A st_min , A s_T) = 3780 mm 2

A s_req = A s_req_normal / (2 cos(30)) = 2182 mm 2

;

Try 9 No #6 bar(s);

Each set of bars should be placed in the direction of axis connecting center of piles (triangular pattern)

A s_prov = 2565 mm 2

d bar = D t = 19.0 mm

a con = A s_prov f y / (0.85 fc b) = 11.182 mm

c con = a con / 1 = 0.048

t= 0.003 ((d bx c con ) / c con ) = 0.100

Pass - Ductility OK at ultimate strength. ;

Area of bars - OK ;

CLEAR DISTANCE BETWEEN BARS IN TENSION (ACI 7.6)

;;;;

Assume reinforcing is put into a strip w ith a width equal to 3 pile diameters

Bar spacing, c-c; sp cc = max(0 mm, (3 d pile - d bar)/(L nt - 1)) = 166.4 mm

Clear spacing;

sp clear = max(0 mm, (sp cc - d bar)) = 147.3 mm

sp min = max(d bar, 25.4 mm) = 25.4 mm

ACI 7.6.1

sp max = 457.2 mm

ACI 7.6.5

Bar spacing - OK

DEVELOPMENT OF TENSION STEEL

All bars must be provided with standard 180 end hooks.

Check hook development length (ACI 12.5)

;;;;;;;;; ldh_1 = (0.02 fy (fc )) d bar = 301.076 mm

mod 1 = if(((d bar<=35.814 mm)&&(d c >=63.5 mm)),0.7, 1.0 ) = 0.7

ldh = max(ldh_1 mod 1 , 152.4 mm, 8 d bar) = 210.8 mm

Hook development length OK

SHEAR ACI 15.5

Shear checks

;;;;;;;;;

Punching of single pile must be checked

Punching of pile at corner must be checked

Punching of overlapping piles must be checked

One way shear @d distance in the section parallel to y-y axis is not applicable

One way shear @d distance in the section parallel to x-x axis is not applicable

Punching shear @ d/2 from column face is not applicable

One way shear @ column face in the section parallel to y-y axis direction must be checked

One way shear @ column face in the section parallel to x-x axis must be checked

Punching shear @ column face must be checked

Project

Job Ref.

The Pearl

Q09077

Section

Sheet no./rev.

DAR GROUP

QQ

Calc. by

Eng.TK

Date

Chk'd by

09-Mar-08

Eng.IC

Date

App'd by

Date

Dr.AE

CHECK PUNCHING OF SINGLE PILE (ACI 11.12.2)

;;;;

b o = (d pile + d b ) = 2971.8 mm

V c = 4 (fc) b o d b = 3096.086 kN

V s = 0 kN

V n = 0.75 (V c + V s) = 2322.065 kN

V up = P u_pile = 773.1 kN

Pile punching capacity - OK

CHECK PUNCHING OF SINGLE PILE AT CORNER (ACI 11.12.2)

;;;;;

b o = (d pile + d b )/4 + 2 (e + d pile / 2) = 2192.9 mm

V c = 4 (fc) b o d b = 2284.669 kN

V s = 0 kN

V n = 0.75 (V c + V s) = 1713.502 kN

V up = P u_pile = 773.1 kN

Pile punching capacity at corner - OK

CHECK PUNCHING OF OVERLAPPING PILES (ACI 11.12.2)

;;;;;

b o = (d pile + d b ) + 2 s = 5671.8 mm

V c = 4 (fc) b o d b = 5909.015 kN

V s = 0 kN

V n = 0.75 (V c + V s) = 4431.762 kN

V up = 2 P u_pile = 1546.1 kN

Pile punching capacity at overlap - OK

ONE-WAY (BEAM) SHEAR THREE PILE CAP (ACI 11.12, 15.5)

Design ultimate shear force @ column face

;;;;;;;;;;;;;;;

xd = max( (L - e - d pile /2 - .288 s - a c/2), 0 mm ) = 1305.3 mm

b x = min((w 2 + 2 (e+d pile /2) * tan(30)),((2w 1 2 )))

b x = 2050.6 mm

V u_face = P u_pile = 773.054 kN

VM rat = M uy / (V u_face d b ) = 1.150

Section shear capacity

Concrete strength;

fc = 40.000 N/mm 2

; w = A s_prov / ( b x d b ) = 0.002522

f1 = (d b /xface ) (3.5 - 2.5 VM rat) = 0.536

f2 = 1.9 (fc ) = 0.998 N/mm 2

f3 = 2500 w/ VM rat = 0.038 N/mm 2

V c1 = f1 (f 2 + f3 ) b x d b = 564.493 kN

Project

Job Ref.

The Pearl

Q09077

Section

Sheet no./rev.

DAR GROUP

QQ

Calc. by

Date

Eng.TK

09-Mar-08

Chk'd by

Date

App'd by

Eng.IC

Date

Dr.AE

V c2 = min( V c1 , 10 (fc ) b x d b ) = 564.493 kN

CRSI Eq. 13-2

V c = max( V c2 , 2 (fc) b x d b ) = 1068.189 kN

V s = 0 kN

V n = 0.75 (V c + V s) = 801.142 kN

One-way shear capacity - OK

TWO-WAY (PUNCHING) SHEAR CHECK (ACI 11.12.2)

Total length of shear perimeter at column face (CRSI Design Handbook)

;;;;;;;

Perimeter (@d/2);

b o = 2 (b c + d b + a c + d b ) = 3983.8 mm

Perimeter (@face);

b s = 2 (a c + b c) = 2000.0 mm

Concrete strength;

fc = 40.000 N/mm 2

Punching shear;

V up = P u + (P sur + P wt) (smin(b,s))/L 2 = 2210.810 kN

Shear capacity of concrete

w = max(if(N==3, .577 s, s/2 ) - a c /2, s/2 - b c /2, .001 mm) = 579.0 mm

V c1 = (d b /w) (b o /b s) 2 (fc) b s d b = 1777.704 kN

V c2 = min( V c1 , 32 (fc ) b s d b ) = 1777.704 kN

V c = max( V c2 , 4 (fc) b o d b ) = 4150.500 kN

V s = 0 kN

V n = 0.75 (V c + V s) = 3112.875 kN

Two-way shear capacity - OK

;;

You might also like

- Pile CAP Design Example + 2 PilesDocument3 pagesPile CAP Design Example + 2 PilesTharanga Pradeep100% (1)

- Design of Pile CapDocument120 pagesDesign of Pile Capcivilaskar100% (3)

- Pile Cap For 3 PileDocument3 pagesPile Cap For 3 Pilehemantkle2u50% (2)

- Pile Cap For 4 PilesDocument4 pagesPile Cap For 4 Pileshemantkle2u100% (2)

- Pile Cap DesignDocument228 pagesPile Cap Designraymond80% (5)

- Pile Cap For 1 PilesDocument5 pagesPile Cap For 1 Pileshemantkle2u80% (5)

- Chequered DesignDocument2 pagesChequered DesignSaravana N100% (1)

- Pile Cap Design ExamplesDocument70 pagesPile Cap Design Examplest_solanki200160% (5)

- RC Pile Cap Design (ACI318)Document4 pagesRC Pile Cap Design (ACI318)topukuet75% (4)

- Pile Cap Design - ColumnsDocument6 pagesPile Cap Design - ColumnsSadatcharaMoorthi N100% (1)

- Design of Pile FoundationDocument17 pagesDesign of Pile FoundationNarnindi Venkata Ramananda SagarNo ratings yet

- Pile Cap For 2 PilesDocument5 pagesPile Cap For 2 Pileshemantkle2uNo ratings yet

- Calculation Sheet: 71197 Design For Pile Cap - Two Piles PP DJM MVLDocument3 pagesCalculation Sheet: 71197 Design For Pile Cap - Two Piles PP DJM MVLbhaskardharani50% (2)

- Kda - Factory Ii (Gen - Trias, Cavite) Design of MicropilesDocument4 pagesKda - Factory Ii (Gen - Trias, Cavite) Design of MicropilesRoda Cadiz100% (4)

- Raft DesignDocument33 pagesRaft DesignUma Mahesh100% (1)

- RIV ACI 2-Pile CapDocument12 pagesRIV ACI 2-Pile CapMitra RampersadNo ratings yet

- Staad Stiffness and Stability Waring by Saroj BiswasDocument10 pagesStaad Stiffness and Stability Waring by Saroj BiswasSAROJ BISWAS50% (2)

- RCC Mat Foundation 4 PedestalDocument173 pagesRCC Mat Foundation 4 PedestalKutty Mansoor50% (2)

- Pile Cap Design - 3-PileDocument6 pagesPile Cap Design - 3-PileParth DaxiniNo ratings yet

- Pile Cap Design For 3-Piles Pattern Based On ACI 318-14Document18 pagesPile Cap Design For 3-Piles Pattern Based On ACI 318-14VikasVarmaNo ratings yet

- Design of Pile CapDocument3 pagesDesign of Pile CapVasilescu Cristian93% (15)

- PileCap DESIGNDocument5 pagesPileCap DESIGNSamik SenNo ratings yet

- Pile Cap Design - ColumnsDocument7 pagesPile Cap Design - ColumnsMohit VatsNo ratings yet

- Pile Cap Design SolutionDocument43 pagesPile Cap Design SolutionAbhijit HazarikaNo ratings yet

- Strap #1: Design AssumptionsDocument27 pagesStrap #1: Design AssumptionsLeanna Abdul Wahab100% (4)

- Pile Cap DesignDocument6 pagesPile Cap DesignSree Arvind Harish SomasundaramNo ratings yet

- Raft+foundationDocument8 pagesRaft+foundationMahbub Alam100% (1)

- 2 Piles Cap Design bs8110Document3 pages2 Piles Cap Design bs8110Faizal ImranNo ratings yet

- Design of Combined FootingDocument8 pagesDesign of Combined FootingMac KY100% (2)

- Punching ShearDocument14 pagesPunching Shearshamen amarasekaraNo ratings yet

- Design of Isolated Footing With Vertical Load Only - According To ACI-318-99Document3 pagesDesign of Isolated Footing With Vertical Load Only - According To ACI-318-993cesNo ratings yet

- Rafter Foundation CalculationsDocument8 pagesRafter Foundation CalculationstsapoutshisNo ratings yet

- Pile Cap DesignDocument2 pagesPile Cap DesignsivaNo ratings yet

- Sachpazis - 4 RC Piles Cap Design With Eccentricity Example (BS8110-PART1-1997)Document5 pagesSachpazis - 4 RC Piles Cap Design With Eccentricity Example (BS8110-PART1-1997)Costas SachpazisNo ratings yet

- RC Corbel Design (ACI318)Document2 pagesRC Corbel Design (ACI318)Emad KhanNo ratings yet

- Pile Cap Design OriDocument14 pagesPile Cap Design OriHoihogo Hoi100% (1)

- Pile Cap Design For 4 PILEDocument4 pagesPile Cap Design For 4 PILEParth DaxiniNo ratings yet

- Beam Design To ACI 318-14Document10 pagesBeam Design To ACI 318-14dovermanNo ratings yet

- Pile Design SheetDocument14 pagesPile Design SheetKhader Abu-dagga71% (7)

- Pile Cap Design (4-Piles)Document4 pagesPile Cap Design (4-Piles)Uttam Kumar GhoshNo ratings yet

- Larsen & Toubro Limited: ECC Division - EDRCDocument2 pagesLarsen & Toubro Limited: ECC Division - EDRCselva100% (1)

- RC Column Design (ACI318-05)Document5 pagesRC Column Design (ACI318-05)Rizwan MirzaNo ratings yet

- EC2 Continuous Beam DesignDocument14 pagesEC2 Continuous Beam Designikanyu79No ratings yet

- Steel Column BeamDocument6 pagesSteel Column Beamdharul khairNo ratings yet

- 6 Pile GroupDocument4 pages6 Pile GroupAnonymous nwByj9L100% (1)

- FinalDocument42 pagesFinalVishnu Kumar0% (1)

- Indrumator Metal - EGDocument37 pagesIndrumator Metal - EGhooky1100% (1)

- 111Document3 pages111郑 凯伦 Tey Kai LoonNo ratings yet

- Concrete DesignDocument169 pagesConcrete DesignabuzahrauNo ratings yet

- Gorakhpur Bypass RobDocument9 pagesGorakhpur Bypass RobvivekNo ratings yet

- EC2 Beam DesignDocument4 pagesEC2 Beam Designikanyu79No ratings yet

- Ec9 Ex61 Shear No StiffenersDocument3 pagesEc9 Ex61 Shear No StiffenersimotalpNo ratings yet

- Sloped FootingDocument19 pagesSloped FootingBala ChandarNo ratings yet

- Gantry CraneDocument18 pagesGantry Craneamirthraj7494% (16)

- Doubly Reinforced Concrete Beam Design (ACI 318-14)Document17 pagesDoubly Reinforced Concrete Beam Design (ACI 318-14)John Amir A AguilarNo ratings yet

- Case Study ppt11Document25 pagesCase Study ppt11WHATS APP STATUSNo ratings yet

- RC Beam Analysis & Design (En1992-1) in Accordance With UK National AnnexDocument7 pagesRC Beam Analysis & Design (En1992-1) in Accordance With UK National Annexmishu_cojoNo ratings yet

- PILE FOUNDATION DESIGN Manual Cal - CommentsDocument6 pagesPILE FOUNDATION DESIGN Manual Cal - CommentsDilip PatelNo ratings yet

- RCC Design SheetsDocument40 pagesRCC Design SheetsAnonymous 9iK0i8h0dPNo ratings yet

- Dresser Blackhawk Hot Tap-Line Stop ProductsDocument20 pagesDresser Blackhawk Hot Tap-Line Stop Productskjpatel2No ratings yet

- Aegis Padlock 3 ManualDocument21 pagesAegis Padlock 3 Manualkjpatel2No ratings yet

- Dresser Blackhawk Hot Tap-Line Stop ProductsDocument20 pagesDresser Blackhawk Hot Tap-Line Stop Productskjpatel2No ratings yet

- Dresser Blackhawk Hot Tap-Line Stop ProductsDocument20 pagesDresser Blackhawk Hot Tap-Line Stop Productskjpatel2No ratings yet

- Okonite Engineering HandbookDocument65 pagesOkonite Engineering Handbooktomgilmartin100% (1)

- Dresser Blackhawk Hot Tap-Line Stop ProductsDocument20 pagesDresser Blackhawk Hot Tap-Line Stop Productskjpatel2No ratings yet

- Design Guide For Floor VibrationsDocument56 pagesDesign Guide For Floor Vibrations_at_to_No ratings yet

- AutopipeDocument53 pagesAutopipeAlfonso ChipaNo ratings yet

- Rebar Info - SizesDocument1 pageRebar Info - Sizeskjpatel2No ratings yet

- UA Seismic ParametersDocument1 pageUA Seismic Parameterskjpatel2No ratings yet

- CB&I Horton SpheresDocument6 pagesCB&I Horton Sphereskjpatel2No ratings yet

- Anchoring in Cracked ConcreteDocument11 pagesAnchoring in Cracked Concretekjpatel2No ratings yet

- Section DesignerDocument191 pagesSection DesignergreatwellwisherNo ratings yet

- Center Line Plan & Mat Foundation Detail 10.02.12-ModelDocument1 pageCenter Line Plan & Mat Foundation Detail 10.02.12-Modelkjpatel2No ratings yet

- Section 13206 - Pressurized Steel Tanks City of San Diego, CWP Guidelines Part 1 - GeneralDocument5 pagesSection 13206 - Pressurized Steel Tanks City of San Diego, CWP Guidelines Part 1 - Generalkjpatel2No ratings yet

- Analysis and DesignDocument8 pagesAnalysis and Designkjpatel2No ratings yet

- STAADetcDocument8 pagesSTAADetckjpatel2No ratings yet

- StateadoptionsDocument2 pagesStateadoptionskjpatel2No ratings yet

- Basics of Geotechnical EnggDocument18 pagesBasics of Geotechnical EnggkesharinareshNo ratings yet

- Soil Investigation Report For Pile (Bridge) Gumi Bankakata PDFDocument18 pagesSoil Investigation Report For Pile (Bridge) Gumi Bankakata PDFChandan Kumar DasNo ratings yet

- Seismic Performance PresentationDocument993 pagesSeismic Performance PresentationJuan Carlos Donayre Salas100% (2)

- Bending Properties of Fillet WeldsDocument2 pagesBending Properties of Fillet Weldsadoc_No ratings yet

- Bulging As A Pile ImperfectionDocument5 pagesBulging As A Pile ImperfectionjuznoobNo ratings yet

- Article of Bursting AnalysisDocument9 pagesArticle of Bursting Analysisbhushan5004No ratings yet

- Construction Stage Analysis Reflecting Long-Term DeformationDocument18 pagesConstruction Stage Analysis Reflecting Long-Term DeformationAshish LoyaNo ratings yet

- NDT SolutionDocument1 pageNDT SolutionBalaji DefenceNo ratings yet

- Foundation Design Full TOC by BM DASDocument3 pagesFoundation Design Full TOC by BM DASxan mianNo ratings yet

- Bore Pile DesignDocument4 pagesBore Pile Designraju_mantripragada100% (1)

- Geosynthetics Types and ApplicationsDocument50 pagesGeosynthetics Types and Applicationscivil vlits100% (1)

- Flexural Design of PC Elements Ch4iDocument22 pagesFlexural Design of PC Elements Ch4inagham tariqNo ratings yet

- Tutorial 1 Properties of MaterialDocument19 pagesTutorial 1 Properties of MaterialElany WhishawNo ratings yet

- Base Plate Verification ExampleDocument10 pagesBase Plate Verification ExampleKarthikeyan VediNo ratings yet

- Elasticity PDFDocument8 pagesElasticity PDFrachna chhabraNo ratings yet

- Shear Stresses in Beams PowerPoint SlidesDocument61 pagesShear Stresses in Beams PowerPoint SlidesJordan Davidson83% (6)

- 9 - RC U-Shaped Walls Subjected To In-Plane, Diagonal, and Torsional Loading NewDocument38 pages9 - RC U-Shaped Walls Subjected To In-Plane, Diagonal, and Torsional Loading NewAshwin Muthuraman RamurathinamNo ratings yet

- Preconsolidation Pressure of Champlain Clays. Part 11. Laboratory DeterminationDocument14 pagesPreconsolidation Pressure of Champlain Clays. Part 11. Laboratory DeterminationRodrigo SantosNo ratings yet

- Evaluation of Constitutive Soil Models For Predicting Movements Caused by A Deep Excavation in SandDocument21 pagesEvaluation of Constitutive Soil Models For Predicting Movements Caused by A Deep Excavation in SandAmmar SohailNo ratings yet

- IS 4880-1 (1987) Code of Practice For Design of Tunnels Conveying Water, General DesignDocument7 pagesIS 4880-1 (1987) Code of Practice For Design of Tunnels Conveying Water, General DesignAlok Kumar0% (1)

- Unsymmetrical Bending 4Document41 pagesUnsymmetrical Bending 4f100% (1)

- Fracture Analysis of Wind Turbine Main Shaft: Engineering Failure Analysis December 2013Document12 pagesFracture Analysis of Wind Turbine Main Shaft: Engineering Failure Analysis December 2013FOOTBALL CRICKETNo ratings yet

- Chapter 29Document66 pagesChapter 29Byron MantheyNo ratings yet

- Bracket-Static by ShahbazDocument10 pagesBracket-Static by Shahbazdestiny777No ratings yet

- Axial Load and Cyclic Lateral Load Tests For Composite Columns With Steel AnglesDocument11 pagesAxial Load and Cyclic Lateral Load Tests For Composite Columns With Steel Anglesdurmuş canNo ratings yet

- Seismic Design Canadian Bridge Design Code PDFDocument14 pagesSeismic Design Canadian Bridge Design Code PDFengsalamNo ratings yet

- A Refined Model For The Prediction of Process-Induced Deformations of Composite StructuresDocument24 pagesA Refined Model For The Prediction of Process-Induced Deformations of Composite StructuresCiccio CiccoNo ratings yet

- FSG Test 1 SolutionDocument4 pagesFSG Test 1 SolutionHillson KanapaNo ratings yet

- 15CV 32 Module 2Document17 pages15CV 32 Module 2Karthik A KulalNo ratings yet

- CDP ModelDocument14 pagesCDP ModelOualid BoukerrouNo ratings yet