Professional Documents

Culture Documents

Huong Dan Tinh Tieu Am Bang Phan Mem Fantech

Uploaded by

Nguyen Anh HungCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Huong Dan Tinh Tieu Am Bang Phan Mem Fantech

Uploaded by

Nguyen Anh HungCopyright:

Available Formats

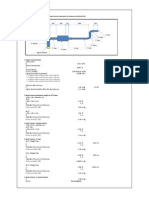

RAPID SYSTEM ANALYSIS EXAMPLE

Rapid Acoustic Design

Job: Sample

Duty: 6m3/s @ 350Pa

System: Car Park Exhaust

Fan: AP0804CA9/21

Enter in-duct sound power level, (Lw) of fan Ref. a.

Enter losses due to transmission through duct

system Ref. b. to f.

Date: 26/03/03

Location: CPEF

Octave Band Centre Frequency (Hz)

Ref. 63

125 250 500 1k

2k

4k

8k

Lw entering system (fan Lw)

a.

91

88

89

87

87

83

79

73

rect. duct 1200 x 1000 x 4m (Fig. 3)

b.

-2

-1

-1

rect. duct 800 x 600 x 4m (Fig. 3)

b.

-2

-2

-1

-1

-1

-1

-1

-1

800 x 600 radius bend

c.

800 x 600 bend w/o turning vanes (Fig. 4)

c.

-2

-5

-5

-3

-3

-3

-3

1200 x 1000 lined duct, 25mm insulation x 1m

d.

-1

-1

-1

-4

-6

-5

-5

-5

e.

+3

+3

+3

+3

+3

+3

+3

+3

f.

-9

-5

-2

g.

80

80

82

80

80

77

73

67

direct Lp sound to grille (Fig. 6) 15%

h.

-8

-8

-8

-8

-8

-8

-8

-8

distance to listener (Fig. 7)

i.

-21

-21

-21

-21

-21

-21

-21

-21

j.

+8

+9

+9

+9

+9

+9

+9

+9

k.

59

60

62

60

60

57

53

47

l.

-3

-3

-3

-3

-3

-3

-3

-3

m.

-3

-3

-3

-6

-7

-8

-11

-13

Largest transition dimension used (Table 1)

tolerance (see note on page H-32)

outlet area (Fig. 5)

Enter sound power level, Lw, leaving system

Ref. a. + (b. to f.) = g.

Enter direct sound pressure, Lp, room

corrections

Ref. h. to j.

0.28m2

Lw leaving system

3m

directivity area (Fig. 10)>0.1 & <1m2

grille position - at edge of 2 surfaces

Enter direct sound pressure, Lp, in room

Ref. g. + (h. to j.) = k.

direct Lp in room

reverberant Lp sound to room (Fig. 11)

50%

Enter reverberant sound pressure, Lp, room

corrections Ref. l. to m.

room type (Fig. 12-16)

Enter reverberant sound pressure, Lp, room

corrections Ref g. + (l. to m.) = n.

reverberant Lp in room

n.

74

74

76

71

70

66

59

51

Calculate difference in Lp, between k and m.

Add correction from Fig. 17 to higher Lp

combined Lp in room (Fig. 17)

o.

74

74

76

71

70

67

60

52

Enter total Lp all systems in room Ref. p.

total all systems in room

p.

74

74

76

71

70

67

60

52

Enter required NR level Ref. q

design criteria (page H-27 or H-37) NR50

q.

75

66

59

53

50

47

45

43

Enter required performance of attenuator

Ref. p. - q = r.

attenuation required

r.

-1

17

18

20

20

15

Enter attenuator selection Ref. s.

attenuator selection RT20E-120-100

s.

11

23

34

38

26

16

10

Enter resultant Lp in room Ref. p.- s. = t

resultant Lp in room

t.

70

63

53

37

32

41

44

42

Compare resultant Lp in room Ref. t. to NR

curve and enter achieved criteria Ref. u.

criteria achieved (page H-37) NR50

u.

75

65

58

53

50

47

45

44

Example

Airflow required = 6000 l/sec

live room

2000m3

room volume

Each Car Park Level

40 x 20 x 2.5m

Estimated static pressure = 300 Pa

Fan selected = AP0804CA9/21

Attenuator selection

- Page H-11

Model RT20E-120-100

700 x 400mm grilles

300L/s ea.

800 x 600 ducting

3000L/s

Pressure drop from graph

- Page H-10

18 Pa

Re-check selection for new duty of

6000 l/sec @ 318 Pa - selection OK.

10 grilles per

duct run.

(20 grilles total)

Attenuator RT20E

4m 1200 x 1000mm

Ducting

1m 25mm L.D.

Fan AP0804CA9/21

6000L/s

FANTECH 2008

4m space before first grille

3 grilles within a 10m radius

NOISE CONTROL PRODUCTS

H-29

You might also like

- Rapid System Analysis Master SheetDocument10 pagesRapid System Analysis Master SheetThanhNo ratings yet

- Prediction of Fan Sound PowerDocument3 pagesPrediction of Fan Sound PowerJoseph Alexander BorgNo ratings yet

- Cooling Towers - Source Prediction, Modelling, Specification and Noise Control (Derrick)Document15 pagesCooling Towers - Source Prediction, Modelling, Specification and Noise Control (Derrick)binho58No ratings yet

- Axial Fans: Noise Prediction: Th. CarolusDocument13 pagesAxial Fans: Noise Prediction: Th. CarolusShaheen S. RatnaniNo ratings yet

- Paper 1578355 SET ProbstDocument8 pagesPaper 1578355 SET ProbstjjirwinNo ratings yet

- Active Noise Control of Axial Fans: Barbu Dragan, Florin TaraboantaDocument4 pagesActive Noise Control of Axial Fans: Barbu Dragan, Florin TaraboantakktayNo ratings yet

- Filter Design Calculation C High Pass Notch High Pass FiltersDocument73 pagesFilter Design Calculation C High Pass Notch High Pass FilterspvenkyNo ratings yet

- Tda2030 18 WattsDocument16 pagesTda2030 18 WattsVictor Manuel Martinez MelendezNo ratings yet

- ONKYO TX910-930 Service ManualDocument31 pagesONKYO TX910-930 Service Manuala.mateNo ratings yet

- MMBT918 PN918: NPN RF TransistorDocument15 pagesMMBT918 PN918: NPN RF TransistorGefry Andres Castro JimenezNo ratings yet

- QRX 7500Document40 pagesQRX 7500hostile89No ratings yet

- LM1894 Dynamic Noise Reduction System DNR: General DescriptionDocument10 pagesLM1894 Dynamic Noise Reduction System DNR: General DescriptionKoszegi AttilaNo ratings yet

- Generator Noise Enclosure MufflerDocument20 pagesGenerator Noise Enclosure Mufflerapop1971No ratings yet

- System Noise and Communications Link Budg EtsDocument39 pagesSystem Noise and Communications Link Budg EtsflowleloNo ratings yet

- Analog Communication Manual TceDocument51 pagesAnalog Communication Manual TceDayanand Gowda KrNo ratings yet

- Back Pressure Calculation 1 PDFDocument2 pagesBack Pressure Calculation 1 PDFRanu Januar100% (6)

- Noise Level Calculations: Example #1Document2 pagesNoise Level Calculations: Example #1Susheel WankhedeNo ratings yet

- Low - Pass FilterDocument8 pagesLow - Pass FilterSaurabh BhiseNo ratings yet

- EECE 211L Experiment 8 - RC and RL Low Pass FiltersDocument4 pagesEECE 211L Experiment 8 - RC and RL Low Pass FiltersHoàng NhậtNo ratings yet

- Halton TsaDocument9 pagesHalton TsaNetri KrisztiánNo ratings yet

- CMOS Mixed Signal Circuit Design by Jacob BakerDocument180 pagesCMOS Mixed Signal Circuit Design by Jacob BakerSharath Sogi0% (1)

- CH Technical Description PDFDocument19 pagesCH Technical Description PDFDANE80100% (2)

- Zeta Converter Applied in Power Factor CorrectionDocument14 pagesZeta Converter Applied in Power Factor CorrectioncamiloNo ratings yet

- Experiment 3Document8 pagesExperiment 3manikNo ratings yet

- Analog Communication Lab ManualDocument60 pagesAnalog Communication Lab Manualjsingh19No ratings yet

- Matlab Tut ThreeDocument8 pagesMatlab Tut ThreeDuy NguyễnNo ratings yet

- Active Noise Control of Axial Fans: Barbu Dragan, Florin TaraboantaDocument4 pagesActive Noise Control of Axial Fans: Barbu Dragan, Florin TaraboantakktayNo ratings yet

- Control System Lab: Practical ManualDocument9 pagesControl System Lab: Practical ManualVats AlokNo ratings yet

- Analog Communication ManualDocument50 pagesAnalog Communication Manualgowrav_hassanNo ratings yet

- Design of Bias Tees For A Pulsed-Bias Pulsed RF Test SystemDocument8 pagesDesign of Bias Tees For A Pulsed-Bias Pulsed RF Test SystemElanchezhian VeeramaniNo ratings yet

- 325 Lab 5 ReportDocument11 pages325 Lab 5 Reportapi-241454978No ratings yet

- Vanoverschele 1975 Punch Through Diode MixerDocument7 pagesVanoverschele 1975 Punch Through Diode MixerDr. Uday Sheorey, Ph.D.No ratings yet

- TDA2030A: 18W Hi-Fi Amplifier and 35W DriverDocument15 pagesTDA2030A: 18W Hi-Fi Amplifier and 35W Driverdborcic61No ratings yet

- Filter Design Method For A PWM Feedback Inverter System: C. C. KosmatopoulosDocument9 pagesFilter Design Method For A PWM Feedback Inverter System: C. C. KosmatopoulosSuvra PattanayakNo ratings yet

- Harmonic Fha C Miniature SpecsheetDocument10 pagesHarmonic Fha C Miniature SpecsheetElectromateNo ratings yet

- ADS Oscillator DesignDocument23 pagesADS Oscillator Designnavvaba100% (1)

- Filt RosDocument15 pagesFilt RosTadeu FelixNo ratings yet

- Heat Pumps Noise Level CalcDocument10 pagesHeat Pumps Noise Level CalcZaid Al RayesNo ratings yet

- Lecture 9-10 - Frequency Response MethodsDocument68 pagesLecture 9-10 - Frequency Response MethodsDerrick Maatla Moadi100% (1)

- Bottom Hole NodalDocument7 pagesBottom Hole NodalKharisma AkbarNo ratings yet

- Tperry Elec484-A3Document37 pagesTperry Elec484-A3AntonioPalloneNo ratings yet

- Bode'S Plot Frequency Response Analysis: Hitech Instruction ManualDocument4 pagesBode'S Plot Frequency Response Analysis: Hitech Instruction ManualnileshsawNo ratings yet

- Additions and Corrections: 2005 FundamentalsDocument4 pagesAdditions and Corrections: 2005 FundamentalsFlorian_AngererNo ratings yet

- S A A O N I S C A C: Imulation ND Nalysis F Oise N Witched Apacitor Mplifier IrcuitsDocument4 pagesS A A O N I S C A C: Imulation ND Nalysis F Oise N Witched Apacitor Mplifier IrcuitsSai KrishnaNo ratings yet

- Sansui AUX 611 AV Service ManualDocument18 pagesSansui AUX 611 AV Service ManualPiero Gonzales OspinaNo ratings yet

- GX-260D Service ManualDocument63 pagesGX-260D Service ManualParkway707No ratings yet

- Active Volume Control For Professional AudioDocument25 pagesActive Volume Control For Professional AudioTrinhNguyentranNo ratings yet

- Triode Emulator by Dimitri DanyukDocument8 pagesTriode Emulator by Dimitri Danyukt_ca100% (2)

- Online Bode PlotsDocument8 pagesOnline Bode PlotsJ a i r o Martînez BNo ratings yet

- Common Emitter Amplifier: S.No Name of The Component/ Equipment Specifications QtyDocument0 pagesCommon Emitter Amplifier: S.No Name of The Component/ Equipment Specifications Qtyagama1188No ratings yet

- Experiment 5Document9 pagesExperiment 5Manar AlbarniNo ratings yet

- Chapter 21Document4 pagesChapter 21Paulo AzañeroNo ratings yet

- Lesson17 2Document34 pagesLesson17 2api-277477207No ratings yet

- 110 Waveform Generator Projects for the Home ConstructorFrom Everand110 Waveform Generator Projects for the Home ConstructorRating: 4 out of 5 stars4/5 (1)

- Catalog Dan Lanh Moi Nhat LGDocument655 pagesCatalog Dan Lanh Moi Nhat LGscribdquyNo ratings yet

- Edmt341410c Rxqtay PDFDocument832 pagesEdmt341410c Rxqtay PDFscribdquyNo ratings yet

- Edfmt391738 Fxmq-Pa PDFDocument64 pagesEdfmt391738 Fxmq-Pa PDFscribdquy71% (7)

- Code A 23052018 1535Document17 pagesCode A 23052018 1535scribdquyNo ratings yet

- Brc1e62 PDFDocument64 pagesBrc1e62 PDFscribdquyNo ratings yet

- Catalogue Ong Nhua PVC Tien PhongDocument124 pagesCatalogue Ong Nhua PVC Tien PhongscribdquyNo ratings yet

- 08-20-2016 - NPD - CT Ban Cong + Bon Hoa Tang 9 PDFDocument1 page08-20-2016 - NPD - CT Ban Cong + Bon Hoa Tang 9 PDFscribdquyNo ratings yet

- 08-20-2016 - NPD - Mat Bang Tang 9 CsDocument1 page08-20-2016 - NPD - Mat Bang Tang 9 CsscribdquyNo ratings yet

- Chiller Partload Down To 20% PDFDocument2 pagesChiller Partload Down To 20% PDFscribdquyNo ratings yet

- 18 Ah41d1 2 - 1206Document8 pages18 Ah41d1 2 - 1206scribdquyNo ratings yet

- SmacnaDocument58 pagesSmacnascribdquyNo ratings yet

- Impulse Current Testing According IECDocument7 pagesImpulse Current Testing According IECscribdquy100% (2)

- Manual HB ISM112 EDocument106 pagesManual HB ISM112 EALFAKNo ratings yet

- Rundown ICTSD 2018 - (Latest)Document9 pagesRundown ICTSD 2018 - (Latest)Annisa Farida HayuningsihNo ratings yet

- Basic SCBA: Self-Contained Breathing ApparatusDocument51 pagesBasic SCBA: Self-Contained Breathing ApparatusPaoloFregonaraNo ratings yet

- Baremos Sexual Desire Inventory MEN WomenDocument1 pageBaremos Sexual Desire Inventory MEN WomenGabriNo ratings yet

- Coord Angle and BearingDocument18 pagesCoord Angle and BearingvNo ratings yet

- Língua Inglesa: Reported SpeechDocument3 pagesLíngua Inglesa: Reported SpeechPatrick AlmeidaNo ratings yet

- Bastidas Et Al, 2010Document8 pagesBastidas Et Al, 2010Panji Satria N.No ratings yet

- Acer Iconia Tab W500 Pegatron EAB00 SchematicsDocument60 pagesAcer Iconia Tab W500 Pegatron EAB00 SchematicsIIIkwarkaNo ratings yet

- Invertebrate ZoologyDocument1,016 pagesInvertebrate ZoologyRACHANA PURKAYASTHA 2140623No ratings yet

- Redlands' 2015 California Public Records RequestsDocument26 pagesRedlands' 2015 California Public Records RequestsBeau Yarbrough100% (1)

- Amotec 12864Q DisplayDocument17 pagesAmotec 12864Q DisplayEdgarNo ratings yet

- Ground Power Unit: GA ModelDocument17 pagesGround Power Unit: GA ModelAngelica Nava0% (1)

- AnorexiaDocument1 pageAnorexiaCHIEF DOCTOR MUTHUNo ratings yet

- TransportationDocument4 pagesTransportationShrinidhi Priyankaa 1912985630No ratings yet

- 1 Aerodynamics Lecture - Viscous FlowDocument70 pages1 Aerodynamics Lecture - Viscous Flowccoyure100% (2)

- Zombieworld PlaytestDocument30 pagesZombieworld PlaytestWellameGranaNo ratings yet

- 15b. FANC - Focused Antenatal Care - Koros E.KDocument71 pages15b. FANC - Focused Antenatal Care - Koros E.KMercy KeruboNo ratings yet

- Example Lab ReportDocument12 pagesExample Lab ReportHung Dang QuangNo ratings yet

- Ix T7AM-CAN - Beijer ElectronicsDocument1 pageIx T7AM-CAN - Beijer ElectronicsKen VikstromNo ratings yet

- S800 SCL SR - 2CCC413009B0201 PDFDocument16 pagesS800 SCL SR - 2CCC413009B0201 PDFBalan PalaniappanNo ratings yet

- Jotafloor: Traffic Deck SystemDocument12 pagesJotafloor: Traffic Deck SystemUnited Construction Est. TechnicalNo ratings yet

- How To Write A Research Paper With Parenthetical DocumentationDocument5 pagesHow To Write A Research Paper With Parenthetical Documentationc9spy2qzNo ratings yet

- H250 H250 H250 H250: Variable Area Flowmeter With 3W2 Angular Position TransmitterDocument40 pagesH250 H250 H250 H250: Variable Area Flowmeter With 3W2 Angular Position TransmitterJustine MarashanyeNo ratings yet

- SVE Event GuideDocument22 pagesSVE Event GuideMadalina MarinacheNo ratings yet

- Berkeley To San JoseDocument88 pagesBerkeley To San JoseTimothy HightowerNo ratings yet

- Cyclic VoltammetryDocument4 pagesCyclic Voltammetryreddynivas100% (1)

- 5276Document52 pages5276Sean PorterNo ratings yet

- Of Love AnalysisDocument8 pagesOf Love AnalysisRica Jane Torres100% (1)

- Case How Innovation Drives Research and DevelopmentDocument4 pagesCase How Innovation Drives Research and DevelopmentMohit KumarNo ratings yet

- A Proposal Study On The Construction of An Automated People Mover APM Inside The New Manila International Airport NMIADocument78 pagesA Proposal Study On The Construction of An Automated People Mover APM Inside The New Manila International Airport NMIAMckyle FaustinoNo ratings yet