Professional Documents

Culture Documents

Steelwise Anchor Rods

Steelwise Anchor Rods

Uploaded by

Vo Kien Cuong0 ratings0% found this document useful (0 votes)

8 views3 pagesasa

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentasa

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views3 pagesSteelwise Anchor Rods

Steelwise Anchor Rods

Uploaded by

Vo Kien Cuongasa

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

SteelWise

Anchor Rods

Cant live with em, cant live without em.

By Dan Swiatek and Emily Whitbeck with contributions from Victor Shneur, P.E.

Many common anchor rod problems are easier to avoid than you think!

n life there are a few things that are

necessary evils, and anchor rods and

column base plate connections seem to

be one of them. These connections

have caused problems on many building projects, but by looking at the challenges that others have faced and showing how these challenge have been

successfully overcome, perhaps we can

make the use of these important connections more bearable. This article will give

some guidelines on how you can prevent

common problems in the design of

anchor rods and base plate connections,

and will help the designer to avoid

expensive field repairs and schedule

delays. Specifications and design guides

are already in place to aid in the design of

these connections for strength, but issues

of constructability should be considered

on every project, to ease the construction

process. The following chart offers some

common challenges and easy solutions

for how to improve everyday anchor rod

and column base plate connection applications.

Dan Swiatek is a senior civil engineering

student at University of Illinois-UrbanaChampaign and a former AISC intern. Emily

Whitbeck is a senior architectural engineering

student at Penn State University and a former AISC intern. Victor Shneur is chief engineer with LeJeune Steel Co., Minneapolis.

Solutions to 17 Common Anchor Rod and Base Plate Dilemmas

Common Mistakes

Easy Solutions

Specifying ASTM A325 or A490 anchor rods

Standard ASTM A325 and A490 bolts include

defined threaded length and heading requirements and must be special ordered when

their lengths exceed 9 in. This can take up

to four months.

Specify ASTM F1554 anchor rods

This standard covers anchor rods with yield

strengths of 36, 55, and 105-ksi, in hooked,

headed, and threaded/nutted options.

Assuming that all material are available

It is possible that materials of different types

and sizes will not be readily available for your

project.

Contact a local fabricator for availability

Even though most fabricators dont make

their own anchor rods, they will still know

about material availability or possible substitutions. It will save money and time on your

project. If it is impossible to contact your fabricator, ASTM F1554 grade 36 anchor rods

may be specified as a fail-safe option.

Specifying many different anchor rod settings

Specifying a different anchor rod setting pattern and base plate for every column size will

end up leading to complications.

Reduce the variety of anchor rod settings

Specify one anchor rod setting and base plate

for all exterior columns, and one for all interior columns, based on the largest size. This

will be conservative for lighter columns, but it

will greatly simplify detailing and installation.

Specifying many different anchor rod sizes

Similarly to specifying settings, specifying

many different sizes can lead to complications.

Limit anchor rod sizes to one or two

This will be conservative in some cases but

will reduce installation mistakes. Try to make

sure the two sizes differ enough to avoid confusion and mistakes (at least 1/2-in. difference

in diameter).

December 2004 Modern Steel Construction

Solutions to 17 Common Anchor Rod and Base Plate Dilemmas (contd.)

Common Mistakes

Easy Solutions

Specifying odd anchor rod settings

Dont specify settings that are seldom used if

you dont have to.

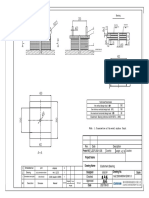

Specify doubly symmetric settings

Keep it simple by making anchor rod settings

and base plates doubly symmetric about column centerlines. Simplicity prevents problems.

Specifying base plates that are too small

This provides no room for errors that are

likely to occur.

Provide sufficient plan dimensions

This will allow for oversized holes and clearances. Field fixes to enlarge holes or to add

plate washers will also be possible.

Specifying standard oversized holes for

anchor rods

Foundation inaccuracies are common. Often,

the standard oversized hole dimensions used

for bolts are not sufficient because there is

not enough tolerance available.

Use AISC anchor rod and base plate hole

recommendations

Use the recommended hole sizes for base

plates shown in AISC Design Guide 1, or in

Table 14-2 of the 3rd Edition Manual. This will

allow for even more tolerance in the foundation for anchor rod placement. Make sure to

use a heavy plate washer over the hole.

Specifying grout holes in small base plates

If the smaller dimension is less than 24 in.,

do not specify grout holes.

Only provide grout holes with large plates

If more than one hole is required, grout holes

need to be spaced approximately 18 in. apart.

Grout holes should be 2 in. to 3 in. in diameter.

Using anchor rods to transfer substantial

shear

Anchor rods cannot be expected to transfer

shear forces due to their larger holes and the

use of grout.

Consider a shear key or an embedded plate

A shear key or embedded plate with welded

side plates can be used to transfer a large

horizontal shear force from the column base

to the foundation.

Welding all around the column and base

plate

Column web-to-flange fillets provide very little

strength and may cause fabrication problems.

10 Welding that wraps around the flange toes for

a column and base plate connection creates

unwanted stress concentrations.

Use one-sided fillet welds for gravity

columns

A typical gravity column only requires a fillet

weld at the flange. Columns in framing systems that experience uplift and shear will

require fillet welds on both sides of the flange

and web.

Specifying a CJP groove weld

If a simple fillet weld can resist uplift or shear,

then using a complete-joint-penetration

11 groove weld for the connection between the

column and base plate is unnecessary and

expensive.

Specify a fillet weld if possible

Use a fillet weld on both sides of a joint than

a CJP groove weld, if possible. Remember

that the fillet weld will benefit from the directional strength increase factor.

Modern Steel Construction December 2004

Solutions to 17 Common Anchor Rod and Base Plate Dilemmas (contd.)

Common Mistakes

Easy Solutions

Always using brackets at base plates

If the column is subjected to uplift, specifying

brackets or stiffener plates are not always

12 necessary. These measures are not only

expensive but also make field corrections

impossible.

Use thicker base plates

This can eliminate the need for brackets or

stiffeners at base plates and will result in

much less labor to fabricate the columns.

Specifying hooked anchor rods for axial

loads

Because a hook can straighten and pull out,

hooked rods should not be used for axial

13 loads. Exceptions include using them to prevent overturning caused by erection loads or

collisions during erection.

Use anchor rods that are headed or

threaded at the end for axial loads

Use rods that are headed or threaded at the

end with a nut for anchorage. Because of the

bigger shear cone, these have a greater pullout strength.

Welding the anchorage nut all around

This includes both sides and the top. Welding

14 the top can reduce the assembly strength.

Tack weld this nut at the bottom

Since the only purpose of this weld is to keep

the rod from turning while the top nut is tightened, a tack weld is more than sufficient. You

can also use a jamb nut.

Assuming precise placement per design

The placement of both the concrete and the

anchor rods cannot guarantee perfect eleva15 tion according to the design or erection

details.

Know the tolerances for anchor rod placement

ACI tolerances for anchorage are very liberal.

Consider specifying the more stringent AISC

Code of Standard Practice tolerances for use

by the concrete contractor.

Assuming anchor rods were installed perfectly

It is very common for an anchor rod to be

16 installed incorrectly. It is even more common

for them to be damaged after installation by

other construction work.

Consider hiring a surveyor

It might be a good idea to hire someone to

inspect anchor rod installation, especially in a

complicated or tightly-scheduled job.

Assuming that walls will not be constructed

It is very possible that walls or other con17 straints will be built before the column is

installed.

Construction sequence should be specified

If there is a chance that the columns might be

installed after a wall, make sure the correct

order is specified before you design the

anchor rods and base plates.

December 2004 Modern Steel Construction

You might also like

- FHWA Geotechnical Engineering Circular No. 6 - Shallow FoundationsDocument296 pagesFHWA Geotechnical Engineering Circular No. 6 - Shallow FoundationsvNo ratings yet

- Structural Defects Reference Manual For Low Rise BuildingsDocument295 pagesStructural Defects Reference Manual For Low Rise BuildingsvNo ratings yet

- Connections in Steel 6 PDFDocument624 pagesConnections in Steel 6 PDFKosnendi Putropranoto50% (2)

- Gang of Four Design Patterns 4.5Document80 pagesGang of Four Design Patterns 4.5pablo@100% (4)

- A Teaching Guide For Structural Steel ConnectionsDocument85 pagesA Teaching Guide For Structural Steel Connectionsv97% (65)

- Steel Tips 1Document40 pagesSteel Tips 1banbanio4680% (5)

- Hydraulic Design of Highway CulvertDocument367 pagesHydraulic Design of Highway CulvertMohammad Saleem Zahidi100% (7)

- Designing HSS Connections PDFDocument4 pagesDesigning HSS Connections PDF112160rbcNo ratings yet

- Steel TipsDocument19 pagesSteel Tipskatepol82640% (1)

- Design and Construction Driven Pile Foundation Vol 2Document450 pagesDesign and Construction Driven Pile Foundation Vol 2v91% (11)

- Weld Symbols PDFDocument2 pagesWeld Symbols PDFSwagat MohapatraNo ratings yet

- Bracing Connections Green BookDocument29 pagesBracing Connections Green BookLesego MatojaneNo ratings yet

- Engineering Journal - 4th Quarter 2010 - Design of Structural Steel Pipe RacksDocument8 pagesEngineering Journal - 4th Quarter 2010 - Design of Structural Steel Pipe Racksger80No ratings yet

- Vicwest DiaphragmsDocument62 pagesVicwest Diaphragmsrmsa17No ratings yet

- Guía de Fallas en Conexiones HSSDocument57 pagesGuía de Fallas en Conexiones HSSlcorao100% (3)

- Aisc ClevisesDocument1 pageAisc ClevisesMark OglesbyNo ratings yet

- Steel DetailerDocument3 pagesSteel DetailerKooroshNo ratings yet

- AISC Connection Teaching AISC ToolkitDocument85 pagesAISC Connection Teaching AISC ToolkitoscarNo ratings yet

- PILE Foundation Analysis - ASCE William Saul-1980 - SearchableDocument22 pagesPILE Foundation Analysis - ASCE William Saul-1980 - Searchablev100% (1)

- Finite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesFrom EverandFinite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesNo ratings yet

- Icbo Es Report-Er2078pDocument65 pagesIcbo Es Report-Er2078peltorro-tNo ratings yet

- V1-Section Properties Design InformationDocument170 pagesV1-Section Properties Design InformationAriel Chavarría HernándezNo ratings yet

- AISC 341-16 - Composite Special Shear Wall (C-SSW)Document4 pagesAISC 341-16 - Composite Special Shear Wall (C-SSW)mrnicusNo ratings yet

- Design of Unstiffened Extended Single Plate Shear ConnectionsDocument14 pagesDesign of Unstiffened Extended Single Plate Shear ConnectionsGonzalo ContrerasNo ratings yet

- Steel Design Guide 40 - Rain Loads and PondingDocument70 pagesSteel Design Guide 40 - Rain Loads and PondingIvan Alejandro Miramontes MunguiaNo ratings yet

- Steel Design Guide 11 - Vibrations of Steel-Framed Structural Systems Due To Human Activity - 2nd. EditionDocument138 pagesSteel Design Guide 11 - Vibrations of Steel-Framed Structural Systems Due To Human Activity - 2nd. EditionIvan Alejandro Miramontes MunguiaNo ratings yet

- Cold-formed Tubular Members and Connections: Structural Behaviour and DesignFrom EverandCold-formed Tubular Members and Connections: Structural Behaviour and DesignRating: 5 out of 5 stars5/5 (2)

- Design of Lifting and Tailing LugsNetsc001Document30 pagesDesign of Lifting and Tailing LugsNetsc001Tshilidzi Irene Netselo100% (1)

- Substation Structures, Valmont NewmarkDocument111 pagesSubstation Structures, Valmont Newmarkdavidfc26No ratings yet

- Boq DSRDocument120 pagesBoq DSRAjay Roy100% (1)

- AISC Plastic Design in SteelDocument2 pagesAISC Plastic Design in Steelc1366No ratings yet

- DEV101 - Student - Guide - 9-13-2016 PDFDocument200 pagesDEV101 - Student - Guide - 9-13-2016 PDFharipriya aerva100% (1)

- AISC - Design Guide 12 - Errata - Modification of Existing Welded Steel Moment Frame Connections For Seismic Resistance PDFDocument2 pagesAISC - Design Guide 12 - Errata - Modification of Existing Welded Steel Moment Frame Connections For Seismic Resistance PDFapuhapuh_153349No ratings yet

- COMPREHENSIVE DESIGN Example For PRESTRESSED CONCRETE (PSC) GIRDER SUPERSTRUCTURE BRIDGE WITH COMMENTARY SI UNITSDocument384 pagesCOMPREHENSIVE DESIGN Example For PRESTRESSED CONCRETE (PSC) GIRDER SUPERSTRUCTURE BRIDGE WITH COMMENTARY SI UNITSvNo ratings yet

- ACI 313R-97: Reported by ACI Committee 313Document20 pagesACI 313R-97: Reported by ACI Committee 313DIDIER ANGEL LOPEZ RINCONNo ratings yet

- SteelwiseDocument3 pagesSteelwiseAnonymous 7MdZQn1No ratings yet

- Anchorage of Steel Building Components To ConcreteDocument7 pagesAnchorage of Steel Building Components To ConcreteGlenn Rey DomingoNo ratings yet

- Recovering A Dead MMI 3G UnitDocument7 pagesRecovering A Dead MMI 3G UnittimonNo ratings yet

- Flange Bending in Single CurvatureDocument21 pagesFlange Bending in Single CurvaturePeterNo ratings yet

- Piled RaftDocument28 pagesPiled Raftmafiapumba100% (1)

- Bolt Spec ReviewDocument2 pagesBolt Spec ReviewameensderajNo ratings yet

- CSS NC 2 Session Plan Coc2Document11 pagesCSS NC 2 Session Plan Coc2Ralfh Pescadero De Guzman100% (7)

- HHS Connection DesignDocument3 pagesHHS Connection Designwii2001No ratings yet

- SteelWise Joists FactsDocument2 pagesSteelWise Joists FactsvNo ratings yet

- Design of Bearing Stiffeners in Cold Formed Steel C-SectionsDocument151 pagesDesign of Bearing Stiffeners in Cold Formed Steel C-SectionsFabio Saraiva BoxNo ratings yet

- FAQs About Headed Reinf Bars - ETN-M-3-14Document8 pagesFAQs About Headed Reinf Bars - ETN-M-3-14MukarramuddinNo ratings yet

- A Fatigue Primer For Structural EngineersDocument139 pagesA Fatigue Primer For Structural Engineersv100% (3)

- AISC Design Guides Steelwise 042010Document4 pagesAISC Design Guides Steelwise 042010Ricardo García G. Ingeniero Electríco100% (1)

- Iec 62056 47 2006 en PDFDocument11 pagesIec 62056 47 2006 en PDFMinh Sơn BùiNo ratings yet

- Old Rebar EDR 48Document4 pagesOld Rebar EDR 48JimBobNo ratings yet

- Base Plates and Anchor Rods - Steel Design AISCDocument3 pagesBase Plates and Anchor Rods - Steel Design AISCpenneng33% (3)

- Night School 23 Session 4Document79 pagesNight School 23 Session 4Luis CortesNo ratings yet

- A11-019 Toshiba R410Document241 pagesA11-019 Toshiba R410list16947No ratings yet

- AISC Design Guide 34 - Steel-Framed Stairway DesignDocument114 pagesAISC Design Guide 34 - Steel-Framed Stairway Designmichael_11No ratings yet

- Al Steel Buildings: Design Guide 1, 2Nd EditionDocument14 pagesAl Steel Buildings: Design Guide 1, 2Nd EditionINNOBUNo7100% (1)

- Development of Design Rules For Composite ConstructionDocument8 pagesDevelopment of Design Rules For Composite ConstructionGraham Dale YukChung BrasicNo ratings yet

- EM 1110-1-1904 - Settlement AnalysisDocument205 pagesEM 1110-1-1904 - Settlement AnalysisPDHLibrary100% (1)

- CIDECT Design Guide 1 2008 - CLDocument142 pagesCIDECT Design Guide 1 2008 - CLChiong Lee100% (1)

- SteelWise Strong Connection To HSSDocument4 pagesSteelWise Strong Connection To HSSv100% (2)

- Articles From Wire Reinforcement InstituteDocument107 pagesArticles From Wire Reinforcement Institutev100% (1)

- Especificacion para Construcciones de AcDocument308 pagesEspecificacion para Construcciones de AcReynaldo Ruiz100% (1)

- Standard For Steel Roof Deck: CSSBI 10M - 08 October 2008Document8 pagesStandard For Steel Roof Deck: CSSBI 10M - 08 October 2008Anonymous P73cUg73LNo ratings yet

- Seismic Design Manual - Google SearchDocument3 pagesSeismic Design Manual - Google Searchchondroc110% (1)

- Steelwise: A Quick Look at PryingDocument2 pagesSteelwise: A Quick Look at Pryingsdutta2591No ratings yet

- Handbook Companion To ACI 318-14 Vol 1Document7 pagesHandbook Companion To ACI 318-14 Vol 1tedpaf33No ratings yet

- Stability Analysis of Pipe Racks For PDFDocument162 pagesStability Analysis of Pipe Racks For PDFkurnoyNo ratings yet

- New Steel Construction Technical Digest 2019Document32 pagesNew Steel Construction Technical Digest 2019tein teinNo ratings yet

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- Lifting Beams: If You've Ever Asked Yourself "Why?"Document2 pagesLifting Beams: If You've Ever Asked Yourself "Why?"sppramNo ratings yet

- Steelwise PDFDocument4 pagesSteelwise PDFJagatheesh RadhakrishnanNo ratings yet

- Design of Unstiffened Extended Single-Plate ShearDocument15 pagesDesign of Unstiffened Extended Single-Plate ShearM. Murat ErginNo ratings yet

- Irjet V8i1007Document5 pagesIrjet V8i1007Diwakar Singh RajputNo ratings yet

- Connections Art, Science, and Information in The Quest For Economy and SafetyDocument13 pagesConnections Art, Science, and Information in The Quest For Economy and SafetyDoctoreNo ratings yet

- Tips & More: For Economical DesignDocument4 pagesTips & More: For Economical DesignLuis Horacio Martínez MartínezNo ratings yet

- MSC October 2011 PDFDocument8 pagesMSC October 2011 PDFYan Naung KoNo ratings yet

- Applications of Pretensioned Anchor Rods in Industrial FacilitiesDocument10 pagesApplications of Pretensioned Anchor Rods in Industrial FacilitiesAndré Luiz NogueiraNo ratings yet

- RRW 410 FDocument90 pagesRRW 410 FvNo ratings yet

- OSHA Rigging Tables-FiguresDocument15 pagesOSHA Rigging Tables-FiguresvNo ratings yet

- Doe Standard: Hoisting and Rigging (Formerly Hoisting and Rigging Manual)Document403 pagesDoe Standard: Hoisting and Rigging (Formerly Hoisting and Rigging Manual)vNo ratings yet

- Emhhhmhhmmhhhl E Hhheeeeon: Bosef: Bean On Shelling Elastic F/G 9/2 NLDocument44 pagesEmhhhmhhmmhhhl E Hhheeeeon: Bosef: Bean On Shelling Elastic F/G 9/2 NLvNo ratings yet

- Singapore. Building and Construction Authority-Structural Precast Concrete Handbook - Building and Construction Authority (2001) PDFDocument174 pagesSingapore. Building and Construction Authority-Structural Precast Concrete Handbook - Building and Construction Authority (2001) PDFShamim Ahsan ZuberyNo ratings yet

- ACB Design Manual Third EditionDocument112 pagesACB Design Manual Third EditionvNo ratings yet

- Moving Load EquationsDocument6 pagesMoving Load EquationsvNo ratings yet

- Stress Analysis of Concrete PipeDocument17 pagesStress Analysis of Concrete PipeAli ÖztürkNo ratings yet

- WRN Oct08Document88 pagesWRN Oct08vNo ratings yet

- Strut and Tie Part 1Document14 pagesStrut and Tie Part 1Turcu Catalin NicolaeNo ratings yet

- Project: Client: Engineer: Remarks:: Your Company Name HereDocument5 pagesProject: Client: Engineer: Remarks:: Your Company Name HerevNo ratings yet

- Parametric Bay Studies V4 - 0 (AISC)Document20 pagesParametric Bay Studies V4 - 0 (AISC)v100% (1)

- Design Guide For Highway Noise BarriersDocument97 pagesDesign Guide For Highway Noise Barriersv100% (1)

- Basic Vibration TheoryDocument11 pagesBasic Vibration TheoryvNo ratings yet

- Foundations For CompressorsDocument7 pagesFoundations For Compressorsv100% (1)

- Calculation of SpringsDocument1 pageCalculation of Springsv100% (1)

- VW3A8306TF10: Product Data SheetDocument2 pagesVW3A8306TF10: Product Data SheetAhmet AyNo ratings yet

- Enterprise Resource Planning (ERP) :: Origin of The TermDocument10 pagesEnterprise Resource Planning (ERP) :: Origin of The TermGoNo ratings yet

- Mythic Manor Walkthrough - v0.8.0 PDFDocument50 pagesMythic Manor Walkthrough - v0.8.0 PDFFirman GustiNo ratings yet

- Thesis Housing ProjectDocument8 pagesThesis Housing Projectjenniferperrysterlingheights100% (2)

- Java Training-Spring CoreDocument95 pagesJava Training-Spring CoreDuy Chuong HuynhNo ratings yet

- Using FreeGlut With Code - Blocks - CodeBlocksDocument7 pagesUsing FreeGlut With Code - Blocks - CodeBlocksCarlosGuerrero1973No ratings yet

- Bitexco Financial Tower June 09Document4 pagesBitexco Financial Tower June 09Roku NguyenNo ratings yet

- Citrix Technical Support - Brief Troubleshooting GuideDocument46 pagesCitrix Technical Support - Brief Troubleshooting GuideArunaigiri NmNo ratings yet

- RN 61Document18 pagesRN 61Ryan BelicovNo ratings yet

- HLTV ReadmeDocument4 pagesHLTV ReadmeJose Luis Puig CuestaNo ratings yet

- List of Architects, Contractor, DeveloperDocument10 pagesList of Architects, Contractor, DeveloperMark AnthonyNo ratings yet

- Appendix 01 Drawings of Elastomeric BearingDocument2 pagesAppendix 01 Drawings of Elastomeric BearingYaselaNo ratings yet

- Al Faisaliah Center - 2019 05 03 08 39 17 PDFDocument1 pageAl Faisaliah Center - 2019 05 03 08 39 17 PDFMartin ZhouNo ratings yet

- VSLTH's Presentation: SOBRR C1-Precast Segmental Viaducts Erection-15 June 2006Document176 pagesVSLTH's Presentation: SOBRR C1-Precast Segmental Viaducts Erection-15 June 2006DrPadipat Chaemmangkang100% (1)

- Elliptical ArchDocument10 pagesElliptical Archdanielhermela9No ratings yet

- CpE Challenge - Rules and MechanicsDocument5 pagesCpE Challenge - Rules and MechanicsMar Christian HerreraNo ratings yet

- LG Therma V MonoblocDocument47 pagesLG Therma V MonoblocMuhidin KozicaNo ratings yet

- What Would Cause A Contactor To Burn in A 14 Month Old Goodman Air Conditioning UnitDocument3 pagesWhat Would Cause A Contactor To Burn in A 14 Month Old Goodman Air Conditioning UnitdocrafiNo ratings yet

- 2013 PLMEurope 24.10.17-13-30 GEORG-PIEPENBROCK SPLM Validation of Plant Performance and Plant Control With Tecnomatix Plant Simulati PDFDocument48 pages2013 PLMEurope 24.10.17-13-30 GEORG-PIEPENBROCK SPLM Validation of Plant Performance and Plant Control With Tecnomatix Plant Simulati PDFRodrigo CalloniNo ratings yet

- CA4Examz - National Parks in IndiaDocument8 pagesCA4Examz - National Parks in IndiaksmNo ratings yet

- Huawei SAP HANA Appliance Single SAP Node Installation Guide (RH5885H and RH8100 V3+Broadwell+Redhat)Document7 pagesHuawei SAP HANA Appliance Single SAP Node Installation Guide (RH5885H and RH8100 V3+Broadwell+Redhat)jimNo ratings yet