Professional Documents

Culture Documents

Force Combination FPSO

Force Combination FPSO

Uploaded by

amitrai86Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Force Combination FPSO

Force Combination FPSO

Uploaded by

amitrai86Copyright:

Available Formats

ABS TECHNICAL PAPERS 2008

Structural Design and Analysis of FPSO Topside Module

Supports

Lars O. Henriksen (M), Boyden. D. Williams (M), Xiaozhi Wang (M), Donald Liu (F)

Presented at SNAME 2008 Annual Meeting and Expo, held in Houston, TX, October 2008 and reprinted with the

kind permission of the Society of Naval Architects and Marine Engineers (SNAME).

This paper addresses the unique structural challenges associated with the design and analysis of

topside module support structures for installation on FPSO decks. Specifically, this paper addresses

the loading on the interface stool structures while subjected to loads originating from hull girder

deformation, FPSO tank pressure loads, and topside inertial loads due to vessel motions. The results of

an advanced finite element based analysis approach is presented and compared to the results of a

simple design method. The effects of hull girder deformation due to vertical bending moment loading

are compared to the effects of local deck deformation due to loading induced by the FPSO tank

structures and topside modules.

Structural Design and Analysis of FPSO Topside Module Supports

155

ABS TECHNICAL PAPERS 2008

KEY WORDS: FPSO or FSO Vessels; Floating

Production Storage and Offloading; Structural Design and

Assessment; Spectral Fatigue Assessment; Advanced

Finite Element Analysis; Classification Calculations,

Topside Installations.

Description

Gussets at

each frame

NOMENCLATURE

ABS

B

DLP

FEA

FPSO

FSO

PHASE B

SAGA

Software

American Bureau of Shipping

Moulded Breadth

Dominant Load Parameter

Finite Element Analysis

Floating Production Storage and Offloading

Floating Storage and Offloading

ABS SafeHull Program, Version 10.0

Viking Systems Structural Assessment

INTRODUCTION

This paper discusses the use of advanced methods to

determine the interaction between the topside installations

and the hull structure of FPSO units. The purpose of the

paper is to present results of a method developed to

accurately assess the response of the hull and the stool

interface structure when subjected to loads originating

from the hull structure loading and the topside structure

loading. The paper first discusses the strength and loading

parameters involved in the structural design of hull

supports and stools considering the following: hull girder

loads, hull girder strength, local deck stiffness due to

frame and stiffener spacing, proximity to bulkheads,

acceleration loads, inclination loads, internal tank fluid

loads, and topside installation method of connections

such as welded and sliding connections.

Additional considerations affecting the topside design

include clearance requirements under the modules for

piping and inspection, frame spacing and longitudinal

spacing of the FPSO hull structure, and explosion

scenarios.

STOOL DESIGN TYPES

A module is installed on the FPSO deck via deck stools

of varying type and size, and is typically employed in a

system as shown in Table 1.

Stools span

two frames

Number

of

Stools

3-6

long.

2-4

transv.

3-4

long.

2

transv.

Stool

Design

Size and

Stiffness

Welded,

small,

flexible

Slides,

large,

stiff

Deck

Reinforcement

Expected

No

Possibly

See Figs. 1-4 for a schematic drawing of each stool-tomodule connection type or, in the case of the gusset, the

connection to the deck. The connection between the deck

and the stool or gusset is assumed to be welded. The

actual connection design to the deck is typically

comprised of welding along transverse frames and

longitudinal stiffeners.

Fig 1. Schematic of Connection Type A

Types A and C typically do not require under deck

structure modification or reinforcement, whereas Type B

typically requires deck plating inserts and under deck

reinforcement.

Typically, deck stools or gussets are arranged to allow

welding to the ship structure at structurally sound

locations such as web frames and transverse bulkheads in

the longitudinal direction, and at longitudinal stiffener

and longitudinal bulkhead locations in the transverse

direction.

Table 1. Stool Design Types

156

Description

Stools at

each frame

Stools span

two frames

Number

of

Stools

3-6

long.

2-4

transv.

2 long.

2

transv.

Stool

Design

Size and

Stiffness

Slides,

small,

stiff

Welded,

large,

stiff

Deck

Reinforcement

Expected

No

Yes

Fig 2. Schematic of Connection Type B

Structural Design and Analysis of FPSO Topside Module Supports

ABS TECHNICAL PAPERS 2008

Table 2. Dominant Hull Girder Loads

Load

Hull Girder Bending

Hull Girder Shear

Differential Pressure on

Transverse Bulkheads

Differential Pressure on

Longitudinal Bulkheads

Fig 3. Schematic of Connection Type C

Components

Still Water and Wave

Induced

Still Water and Wave

Induced

Static and Inertia

Pressure

Static and Inertia

Pressure

Dominant Topside Module Loads

The loads from the topside modules as shown in Table 3

result in force-induced loading.

Table 3. Dominant Topside Loads

Load

Components

Module Reaction Loads from

Hull Deflection and Tank Loads

Static and

Dynamic Loads

Loads due to FPSO Inclination

Static and

Dynamic

Accelerations

Loads due to FPSO Acceleration

Dynamic

Accelerations

Module Mass Distribution and

Center of Gravity

Static and

Dynamic

Accelerations

Module Location on FPSO, i.e

each module gets unique

combination of 6 degree of

freedom accelerations and hull

girder loads

Static and

Dynamic

Accelerations

Fig 4. Schematic of Connection Type D

INTERACTION LOADS

Topside structures are subject to the hull girder

deflections of the FPSO as a result of still water bending

and wave-induced bending. In addition, hull girder shear

force changes across transverse bulkheads can introduce

local deflections between deck stools. The differential

pressure loads on transverse and longitudinal bulkheads

also produce deck deflections which in turn load the

topside structure via the deck stools.

The hull girder structure loading is affected by the mass

of the topside modules and its static and dynamic load

effect on the resulting hull girder shear force and bending

moment. In addition, the local mass distribution of the

modules affects the deck structure locally from static and

dynamic loads. Finally, due to the strength of the topside

supporting structure, the hull girder loads introduce forces

into the topside structure which in turn produce forces

back to the ship deck locally via the deck stools. The

sliding connection design reduces the effect of the topside

module supporting structure on the hull girder by

allowing movement when the connection friction is

overcome by the horizontal force. A summary of the

loads is listed in Tables 2 and 3.

Dominant Hull Girder Loads

The loads in Table 2 provide interacting loads from hull

deflection-induced loading on the deck structure, and

from the tank pressure loading acting on the deck via

bulkhead structures.

Structural Design and Analysis of FPSO Topside Module Supports

ANALYSIS PROCEDURE

The analysis procedure consists of finite element model

creation, load development, solving, and assessment of

results.

Finite Element Modeling

The finite element model creation typically consists of a

full length FPSO model, a cargo block model, or a 3-hold

model type as in ABS SafeHull Phase B. The partial

models are loaded at their cut sections with still water and

wave-induced hull girder shear force, bending moment

and torsional moment to represent the loading from the

structure that is not modeled. The model loads are then

balanced to reduce error from load imbalance. The

models are restrained entirely at one of the cut ends, or by

a few restraints that are free to undergo hull deformation.

In the case of the cut models, the absolute deflection level

will not match that of the actual unit or the full model,

157

ABS TECHNICAL PAPERS 2008

however the relative deflections will be practically the

same, justifying the use of partial models.

Finite Element Loading

It is preferred that the loads be established using a direct

analysis procedure for calculating wave-induced hull

pressures, motions-induced inertia loads of the hull and

topside structure, and tank loads and fluids in the topside

modules. The preferred choice is a hydrodynamic

analysis method such as presented in Ref. 1 (Henriksen,

2007) using the magnitude and phase lag definition of

each response of motions, accelerations and pressure to

define the maximum response Dominant Load Parameter

(DLP) for a number of maximum load events using either

short-term or long-term responses. The DLPs must be

combined with actual FPSO loading conditions to

develop maxima of still water and wave-induced loads for

each structure to be validated. Alternatively, rule based

programs such as ABS Phase B can be used.

Relative

Deflection

Mode

Severity

Vertical

Medium

Load

Origin

Hull

Vertical

Bending

The topside modules and hull structures will be subjected

to the loads shown in Tables 2 and 3. In addition, the

stiffness of the topside modules and the hull structures

will also affect the local response in vicinity of bulkheads

and the variation in the topside stools as used throughout

the deck of the FPSO. The interaction loads between the

hull and the topside modules are shown in Tables 4 and 5,

where the severity of the interaction loading is also

assessed qualitatively.

Table 4. Foundation Effect on Topside Modules from

Hull Girder Deflection

Relative

Deflection

Mode

Longitudinal

Severity

Low for

Slide

Types

A,D

High for

Welded

Types B,

C

Load

Origin

Still Water

and Wave

Hull

Girder

Vertical

and

Horizontal

Bending

Primary Factors

Hull Breadth

Longitudinal

Strength

Transverse

Minor

Transverse

Bending

Transverse

Strength

Topside

Installation

Height

Topside Module

Width

The loads imparted to the deck from the topside structure

are also a function of the module supporting system

(Types A, B, C, and D) which may include sliding pads

designed to isolate the longitudinal or transverse

deflections resulting from hull girder bending.

Table 5. Topside Module Effect on Hull

Force

Direction

Severity

Load Origin

Primary

Factors

Longitudinal

Low

Surge, Pitch,

Yaw

Topside

Module Mass

Inclination

and

Acceleration

Topside

Module CG

Heave, Pitch,

Roll

Topside

Module Mass

Inclination

and

Acceleration

Topside

Module CG

Vertical

High

Hull Length

Hull Breadth

Block Coefficient

Longitudinal

Strength

Topside

Module

Width

Topside

Module

Length

Topside

Installation

Height

Transverse

158

Hull Length

Block Coefficient

The loads correspond to operating conditions or transit

conditions.

Interaction Load Assessment

Primary Factors

Medium

Sway, Roll,

Yaw

Topside

Module Mass

Inclination

and

Acceleration

Topside

Module CG

Structural Design and Analysis of FPSO Topside Module Supports

ABS TECHNICAL PAPERS 2008

Interface Structure Modeling

For the connection modeling of the interface structure, a

number of finite element properties can be used as

described in Fig. 5 as block, sheet, and wire.

The choice of beam elements with different properties for

simulation of sliding connection conditions is made to

allow for keeping the same finite element, and changing

only the properties, to allow an easy elemental

assessment of the connection conditions during each step.

Finite Element Results Assessment

Fig 5. Connection Beam Element Property Types

In cases where welded connections are used, a block

type must be used. The use of the block element allows

for assessing the reaction loads between the hull and the

topside modules. In addition, deflections can be assessed

for use by the topside module steel design effort.

In the special case of sliding connections being installed

on top of the modules to separate the hull girder

longitudinal deflections from the topside modules, an

iterative approach can be used as follows:

1.

Create chart of stool connector types, i.e.

welded, partial restraint, or sliding

2.

Start by assigning Block type beam element

properties to all Module Connectors

3.

Solve the model, inspect results from each case

4.

For elements showing uplift at sliding

connectors, change Module Connector to Wire

type

5.

Re-solve model, inspect results.

6.

Check if any new uplift at sliding connectors

occurs; if so, repeat steps 4-5, otherwise go to

step 7

7.

Calculate the ratio of shear force divided by

axial force for longitudinal direction

8.

Calculate the ratio of shear force divided by

axial force for transverse direction

9.

If ratios in the steps above are greater than the

friction coefficient, change to Sheet type

10. In case both directions slip, then change to

Block type, but use rod element (or use

Block element with small inertias)

11. Maintain welded or restrained connections

defined in step 1

12. Re-solve model, inspect results

13. Repeat Steps 7-11 until there is convergence

14. Finally inspect if steps 6 and 9 are met; if so, the

solution is complete, otherwise go back to step 2

The global response can be used to determine the

maximum stresses in the hull structure and the stool or

gusset supporting structures. The global model

assessment of the responses incorporating usage factors

are applied to the yield stress of the material for

assessment of yield and buckling of the structures.

CASE STUDY

The following serves as a case study of a recent project

where the topside modules are installed using a

combination of welded connections and sliding

connections. The module selected in this case study is a

heavy module with 21 stools. Note that similar results

have been obtained for lighter modules and for other

locations on the deck of the FPSO.

Deflection Based Loads on the Topside

Stools

As described in the loading section above, the dominant

load on the topside modules, the topside stools, and the

interface between the structures results from the hull

deflections in way of the module supports. The following

section describes an approach developed to determine the

impact of the many load components on the resulting

deflections in way of the topside supports.

The deflections at the top of the stools, in way of the

interface between the stool and topside module structure,

depend on the relative stiffness of the hull, main deck,

stool, and topside module structure. Therefore, an

integrated global FEA model is used to evaluate the

response of the combined structure to the combination of

static loading and design environmental conditions.

The integrated global FEA model used in this case study

includes the hull structure for the entire length of the

cargo block, the stools, the pipe rack, and the first level

framing structure up to and including the process deck for

the topside modules. The module supports in the case

study include six (6) welded anchor stools (three stools in

way of each of the two transverse frames near the center

longitudinal center of the module). The stools in way of

the other frames, near the forward and aft ends of the

modules include steel-on-steel sliding connections that

allow for fore and aft movement at the stool / module

interface. In the initial global model analysis, it is

assumed that the longitudinal sliding force present in the

sliding connections is not sufficient to overcome the

friction force, and the connections are modeled with

block elements as if they were welded connections.

In this case study, the global FEA model analysis

considers 10 static operating conditions, which are

Structural Design and Analysis of FPSO Topside Module Supports

159

ABS TECHNICAL PAPERS 2008

combined with 100 year extreme environmental loads to

create a series of 46 combined design load cases for the

operating site. A similar series of environmental loads are

combined with the transit loading condition with dry

topside modules to evaluate the effect of the voyage to

the operating site on the structure; however, for clarity,

the remainder of this case study will focus on the results

of the site design load cases.

Longitudinal Deflections

The resulting nodal deflections from the analysis of the

46 design load cases on the integrated global FEA model

are used to evaluate the magnitude of the longitudinal

deflection present in the main deck structure and at the

stool / topside module interface.

The resulting longitudinal deflections in the main deck, at

the base of the topside stools, are plotted in Figure 6 for

the 46 design load cases along the length of the cargo

block. The deflections are presented in mm and are

plotted as the relative deflection between each frame and

the transverse bulkhead at the aft end of the cargo block.

Fig 6. Relative Longitudinal Deflection at Main Deck

Level

The deflection results shown in Figure 6 indicate that the

longitudinal deflection in the main deck resulting from

the maximum hogging condition at the operating site are

approximately 0.715 mm / m, while the maximum

sagging condition will induce approximately 0.606 mm /

m of longitudinal deflection.

The resulting longitudinal deflections at the interface

level at the top of the stools are plotted in Figure 7 below

for the 46 design load cases along the length of the cargo

block. The deflections in Figure 7 illustrate the effect of

the topside module stiffness vs. the stiffness of the main

deck and stool supports.

The deflection results shown in Figure 7 indicate that the

longitudinal deflection at the top of the stools, in way of a

topside module, resulting from the maximum hogging

condition at the operating site are approximately 0.210

mm / m, while the maximum sagging condition will

induce approximately 0.175 mm / m of longitudinal

deflection.

160

Fig 7. Relative Longitudinal Deflection at Top of Stools

The differences between the longitudinal deflections in

the main deck and at the top of the stools illustrate the

amount of longitudinal deflection that will be experienced

by the topside stools if the sliding connections do not

slide. The topside module presented in this case study is

approximately 31 m long, and is therefore subjected to

the following deflections shown in Table 6:

Table 6. Summary of Longitudinal Deflection in Stools

Longitudinal Deflection over

the Length of the Module

Load

Deflection

Case

in Stools *

Top of

Main Deck

Stool

Max

22.2 mm

6.5 mm

15.7 mm

Hog

Max

18.8 mm

5.4 mm

13.4 mm

Sag

* The total deflection in the stools will be shared between

the forward and aft stools with each experiencing

approximately half of the total deflection.

The fore and aft force generated at the interface between

the top of the stool and the topside module structure is the

sliding force, which will initiate the slide between the

module and stool if the friction force between the

structures is overcome. Additional information on the

development of the friction force is provided in the next

section.

Vertical Deflections

As described in the loading section above, the vertical

deflection in way of the topside support stools is the

result of the overall hull girder deflections, the local

deflection of the main deck structure resulting from the

loads imposed by the topside module, and the local

deflection of the main deck structure resulting from the

pressure loading in the tank boundaries below the deck.

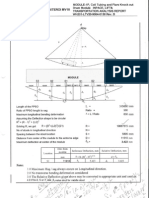

The layout of the module support stools for the module

used in this case study and their relationship to the main

supporting members under the main deck are shown in

Figures 8 and 9 below.

Structural Design and Analysis of FPSO Topside Module Supports

ABS TECHNICAL PAPERS 2008

Relative Vertical Deflection Comparison - Site Loading Conditions

Middle Stool Location

6.0

5.0

4.0

3.0

2.0

1.0

0.0

-1.0

Fig 8. Typical Transverse Section in way of Topside

Module

75

76

77

78

79

80

81

82

83

-2.0

-3.0

-4.0

Fig 11. Relative Vertical Deflection (mm) at Middle

Stool Location from Frames 76 to 82

Fig 9. Typical Longitudinal Section in way of Topside

Module

The resulting nodal deflections from the analysis of the

46 design load cases on the integrated global FEA model

are used to evaluate the magnitude of the vertical

deflection present in way of the topside support stools.

The resulting vertical deflections for the 46 design load

cases are plotted in Figure 10 for the inboard stool

location. The vertical deflections are also plotted for the

middle stool location in Figure 11 to illustrate the effect

of the under deck structure on the resulting vertical

deflections in way of the support stools.

Relative Vertical Deflection Comparison - Site Loading Conditions

Inboard Stool Location

6.0

5.0

4.0

3.0

2.0

1.0

0.0

-1.0

75

76

77

78

79

80

81

82

83

-2.0

-3.0

-4.0

Fig 10. Relative Vertical Deflection (mm) at Inboard

Stool Location from Frames 76 to 82

As seen in Figure 10, the presence of the transverse

bulkhead at Frame 81 introduces a stiff support point in

the deck structure and creates a local hogging deflection

around the transverse bulkhead. While the local effect of

the transverse bulkhead is evident in Figure 10 in way of

the inboard stool, the effect is more pronounced in Figure

11 in way of the middle stool.

Structural Design and Analysis of FPSO Topside Module Supports

As shown in Figure 8, the transverse location of the

inboard stool is relatively close to the longitudinal

bulkhead, which provides a stiff under deck support and

mitigates the local effect of the transverse bulkhead. The

middle stool is located near the mid span of the side tank

deck transverse, away from the longitudinal bulkheads,

and is subjected to greater variations in vertical deflection

resulting from the impact of the topside module on the

flexible main deck support structure.

The vertical force generated at the interface between the

top of the stool and the topside module structure is a

function of the loads applied to the model, the distribution

of mass in the module, and the relative deflections in the

main deck support stools. The vertical force in the

support stools dictates the magnitude of the friction force

between the structures that must be overcome before the

sliding connections will slip.

Iterative Analysis Procedure Results

An iterative analysis procedure, as described in the

beginning of this paper, has been performed using Viking

Systems SAGA Software on the topside module

presented in this case study. The results of the study

indicate that when subjected to 100-year extreme

environmental loads, the longitudinal force present at the

interface between the topside modules and the support

stools will be sufficient to overcome the friction force in

the sliding module connections, and the connections will

slide and relieve the longitudinal forces applied to the

modules and stools.

A comparison of the FEA deflection results from the case

study module before and after the iterative analysis

procedure is shown in Figures 12 and 13. The model in

Figure 12 shows the results for the maximum sagging

condition with all fixed connections in way of the anchor

stools and in way of the sliding connections. The model

in Figure 13 shows the result for the same loading

condition after the final stage of the iterative analysis

procedure to adjust the physical properties of the

connection elements in way of the stool and topside

module interface to account for the presence of uplift and

/ or sliding.

161

ABS TECHNICAL PAPERS 2008

Main Deck Transverse Webs / Bulkheads

Main Deck Plating

Main Deck Longitudinal Stiffeners

Topside Support Stools

The maximum yielding evaluation ratios for each of the

four structural groups, before and after the iterative

analysis procedure, are presented in Table 8 below.

Fig 12. FEA Model Results for All Fixed (Welded)

Connections.

Fig 13. FEA Model Results for Final Iteration

representing a sliding system.

Note in Figure 12, that the stools bend since they are

more flexible than the deck and the topside beams. Note

in Figure 13, that the stools do not bend since the topside

beams were able to slide, thus minimizing the effects of

the hull girder deformation on the module stools

Table 8. Results of All Fixed vs. Iterative Analysis

Stress Ratio

Stress Ratio

Location

Max. Fixed Max. Iterative

Transverse Web Frames

0.58

0.58

Main Deck Plating

0.55

0.51

Main Deck

1.16

0.60

Longitudinals

Support Stools

0.77

0.84

As seen in Table 8, the all fixed connection assumption

provides an accurate assessment of the maximum stress

results for the transverse web frames and main deck

plating. The all fixed connection assumption underestimates the maximum resulting stresses in the stool

structure by approximately 10%, and over-estimates the

resulting stress in the main deck longitudinal stiffeners by

nearly 50%. The distributions of the maximum yield

evaluation ratios for the seven support frames for the case

study module are shown in Figures 14 through 17 for the

main structural groups.

Site Loads - Maximum Yield Eval Ratio - Deck Transverse

0.65

0.60

0.55

The final connection details at the completion of the

iterative analysis procedure for the elements representing

the interface between the topside modules and support

stools for the maximum sagging condition shown in

Figure 13 are provided in Table 7 below.

0.50

0.45

0.40

0.35

0.30

Table 7. Final Connection Details from Iterative Analysis

Frame 76

Inboard SupportSlip

Middle SupportSlip

Outboard SupportSlip

Frame 77

SupportSlip

SupportSlip

SupportSlip

Frame 78

Frame 79

SupportStuck SupportStuck

SupportStuck SupportStuck

SupportStuck SupportStuck

Frame 80

SupportSlip

SupportSlip

SupportSlip

BHD 81

SupportSlip

SupportSlip

SupportSlip

Frame 82

SupportSlip

SupportSlip

SupportSlip

As shown in Table 7, the longitudinal force has overcome

the friction force at all sliding connections.

Impact of Iterative Analysis Procedure on Resulting

Stress

The FEA results for the analysis model with the all fixed

connections and the final connections resulting from the

final step of the iterative analysis procedure have been

evaluated for all 46 site loading conditions to determine

the effectiveness of the analysis procedure on the design

and verification of the structure.

0.25

75

76

77

78

79

80

81

82

Outboard Stool - All Fixed

Middle Stool - All Fixed

Inboard Stool - All Fixed

Outboard Stool - Iterative

Middle Stool - Iterative

Inboard Stool - Iterative

83

Fig 14. Effect of Sliders on Stress in Deck Transverse

As seen in Figure 14, the stress in the deck transverses is

relatively low and the maximum stress is not significantly

affected by assuming whether the design is all welded or

fitted with sliding connections.

As seen in Figure 15, the stress in the deck plating is

relatively low and the maximum stress is not significantly

affected by assuming whether the design is all welded or

fitted with sliding connections.

The stress results for the four following structural groups

have been evaluated to determine the impact of having

sliders installed:

162

Structural Design and Analysis of FPSO Topside Module Supports

ABS TECHNICAL PAPERS 2008

reinforcements.

Site Loads - Maximum Yield Eval Ratio - Deck Plating

0.60

0.58

Site Loads - Maximum Yield Eval Ratio - Stool Structure

0.56

1.00

0.54

0.90

0.52

0.50

0.80

0.48

0.70

0.46

0.60

0.44

0.42

0.50

0.40

75

76

77

78

79

80

81

82

Outboard Stool - All Fixed

Middle Stool - All Fixed

Inboard Stool - All Fixed

Outboard Stool - Iterative

Middle Stool - Iterative

Inboard Stool - Iterative

83

0.40

0.30

75

Fig 15. Effect of Sliders on Stress in Deck Plating

76

77

78

79

80

81

82

Outboard Stool - All Fixed

Middle Stool - All Fixed

Inboard Stool - All Fixed

Outboard Stool - Iterative

Middle Stool - Iterative

Inboard Stool - Iterative

83

Fig 17. Effect of Sliders on Stress in Stools

Site Loads - Maximum Yield Eval Ratio - Deck Longitudinals

1.20

1.10

1.00

0.90

0.80

0.70

0.60

0.50

0.40

75

76

77

78

79

80

81

82

Outboard Stool - All Fixed

Middle Stool - All Fixed

Inboard Stool - All Fixed

Outboard Stool - Iterative

Middle Stool - Iterative

Inboard Stool - Iterative

83

Fig 16. Effect of Sliders on Stress in Deck Longitudinal

Stiffeners

As shown in Figure 16, the assumption of all fixed

connections between the topside module and the

supporting stools leads to a significant increase in the

deck longitudinal stiffener stresses. At either end of the

topside module, the stress in the deck longitudinal

stiffeners increases by approximately 100% over the

mean stress level at the center of the module. The

increase in stress is a result of the bending loads imposed

by the stools at the deck connection due to hull girder

deformation.

The results of the iterative analysis show the benefit of a

sliding connection between the topside module and

support stools, as the stress in the deck longitudinals is

fairly constant over the length of the module, and is not

significantly affected by the presence of the topside

module. This result proves that the use of sliding

connections like Type A or D (or a flexible system like

Type C) allow the use of standard stiffener sizes to resist

the topside module loading. This is of importance in

tanker conversions to FPSO service where the

reinforcement of longitudinals would be costly. For

newbuilding the use of Type B connections are often

preferred to reduce the amount of connections, but this

connection typically requires additional under deck

Structural Design and Analysis of FPSO Topside Module Supports

The stress in the stool structure is dependent on the

number, and location, of stools that slide and those that

do not. In the analysis with the all fixed assumption, the

longitudinal reaction forces created by the hull girder

bending are distributed among all of the fixed

connections. With the iterative analysis, the stools that

slide are no longer effective in restraining the longitudinal

reaction forces from the module. This can increase the

total reaction force on the individual stools that do not

slide, and results in the increased stress levels shown in

Figure 17.

CONCLUSIONS

The design of topside module supporting structures using

stools and gussets requires an early assessment of the

preferred stool design type. This early decision is likely

based on an existing design which is believed to work

well from experience and feed back from installations in

service, rather than actual engineering calculations on a

number of different possible solutions. All methods

shown in this paper can potentially be made to work on

any FPSO deck foundation, but in each case, advanced

methods must be employed to validate the design. As

described in this paper, the factors at play affecting the

design are many-fold as they come from both FPSO tank

loading conditions, assignment of still water shear force

and bending allowables, site and transit loads, motions,

constructability, and survivability from explosion

scenarios.

From the strength and loading interaction combinations

between the hull and topside modules, it is therefore

concluded that the design of stools and hull

reinforcements must be evaluated by advanced analysis

methods using a procedure like the one presented in this

paper.

The conclusion from the case study presented in this

paper and similar case studies performed by the authors

on a range of hull types, environment loading, and

topside module weights indicate that the effect on the hull

163

ABS TECHNICAL PAPERS 2008

structure of sliding connections in the interface between

the topside modules and support stools can be evaluated

with an all fixed analysis model to allow for a simpler

analysis method. As shown in Table 8, the maximum

yielding evaluation ratios for the transverse webs and

main deck structure are accurately predicted with the all

fixed connection analysis.

The stress in the main deck longitudinal stiffeners in way

of the support stools is over-estimated with the all fixed

connection analysis, and is considered to be very

conservative. If the simpler all-fixed connection analysis

provides acceptable results in the main deck

longitudinals, the structure can be considered adequate

for the design loading conditions. However, if the results

of the all fixed connection analysis produce unacceptable

stress results in the main deck longitudinals, an advanced

iterative analysis procedure can be employed to evaluate

the effect of the sliding connections. As shown in this

paper, the advanced analysis can lead to substantial

reductions in the resulting stress in the deck longitudinals.

As shown in Table 8, the stress in the support stool

structure is under-estimated with the all fixed connection

analysis. In the all fixed analysis, the longitudinal hull

deflections are applied to the module through the fixed

connections at all stools. In the iterative analysis

procedure, as the sliding connections at some stools begin

to slide, the other stools that do not slide pick up a greater

share of the force resulting from the longitudinal hull

deflections. As a result, the stools that are subjected to the

greatest vertical load (as the result of stiff under deck

structure, applied load, or module mass distribution)

provide the greatest resistance to sliding, and can receive

a greater level of stress than is predicted with the all fixed

analysis. Based upon the experience gained from this case

study and others, it is recommended that a 15% factor of

safety be applied to the stress results from the all fixed

analysis when evaluating the support stool structure for a

system fitted with sliders.

164

The use of an all fixed connection approximation in the

analysis of the stool design is only valid if the same stool

design is used at all longitudinal locations. If the structure

of the support stools is optimized to have unique

geometry or scantlings at each frame, a full iterative

analysis procedure is recommended to evaluate the

impact of the sliding connection on the stools at each

frame, as the location of the maximum stress response

will move between stools as the connections begin to

slide.

If the same structure is used for all support stools, the allfixed connection analysis can be used in conjunction with

the applicable safety factor on the support stool stress to

validate the design.

It is recommended that the fatigue analysis uses an allfixed connection type whether the design employs sliding

connections or welded connections. The fixing of sliding

connections for fatigue analysis is considered most

appropriate since the majority of the fatigue damage will

come from less severe loads that are less likely to

introduce sliding of the connection.

ACKNOWLEDGEMENTS

The authors wish to thank Ms. Ashleigh Price, Viking

Software, Inc. for her valuable contributions during the

execution phase of several designs employing the

iterative procedure shown in this paper. We also wish to

thank Mr. Pixin Zhang and Mr. Ping Liao, both of ABS

for their valuable contribution with assessments of the

procedure using SafeHull Phase B.

REFERENCES

1. HENRIKSEN, L. O. 2 Tankers for Offshore FPSO

and FSO Service. PRADS 2007.

Structural Design and Analysis of FPSO Topside Module Supports

You might also like

- Super m2 New Offshore RigDocument50 pagesSuper m2 New Offshore RigcatullusNo ratings yet

- LR0059 FPSO1 IntroductionDocument65 pagesLR0059 FPSO1 IntroductionSuwardi Cakra Ningrat100% (1)

- DeepC FPSO TutorialDocument33 pagesDeepC FPSO TutorialZou Jiawei100% (1)

- FPSO Overall DesignDocument8 pagesFPSO Overall DesignZee Chien ChewNo ratings yet

- Offshore Analysis ProcedureDocument110 pagesOffshore Analysis Procedurerenganathank1987No ratings yet

- Floating Production SystemsDocument53 pagesFloating Production Systemsmimi_chan_17100% (1)

- FPSO Related Piping and Pipe Stress AspectsDocument43 pagesFPSO Related Piping and Pipe Stress AspectsSmith780512100% (3)

- ABS CLASS ChecklistDocument36 pagesABS CLASS Checklistapi-372122995% (22)

- Ageing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityFrom EverandAgeing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityNo ratings yet

- Ballasting Calculation For The Transportation of PLEMsDocument17 pagesBallasting Calculation For The Transportation of PLEMsBolarinwa100% (1)

- Fpso Design and TechnologyDocument57 pagesFpso Design and Technologyjokots100% (1)

- Rig Description and Equipment SpecificationDocument64 pagesRig Description and Equipment SpecificationSrikanth BammidiNo ratings yet

- LR FPSO DesignDocument34 pagesLR FPSO Designcxb07164No ratings yet

- FPSO Topside Modules DynamacDocument28 pagesFPSO Topside Modules DynamacJames100% (1)

- FPSO - Fabrication of Topsides Structural PDFDocument18 pagesFPSO - Fabrication of Topsides Structural PDFdndudc100% (2)

- Introduction To Bridge EngineeringDocument125 pagesIntroduction To Bridge Engineeringjaffna100% (1)

- FPSO Lessons LearntDocument21 pagesFPSO Lessons LearntAnant Arvind Kulkarni100% (6)

- FPSODocument143 pagesFPSORagunath KarthickNo ratings yet

- LR FPSO Basic Principle TrainingDocument75 pagesLR FPSO Basic Principle TrainingBenjamin Yohan100% (4)

- U90m - Steel Vessels Under 90 Meters (295 Feet) in LengthDocument8 pagesU90m - Steel Vessels Under 90 Meters (295 Feet) in Lengtharg_christianNo ratings yet

- Inplace - Copy123Document110 pagesInplace - Copy123Panneer Selvam EaswaranNo ratings yet

- Staad OffshoreDocument64 pagesStaad OffshoreAtul Kumar Engineer100% (6)

- (2013.05.21) Loads On Offshore Structures Webinar: This Webinar Was Originally Presented On May 21st, 2013Document8 pages(2013.05.21) Loads On Offshore Structures Webinar: This Webinar Was Originally Presented On May 21st, 2013Nabigh NabiylNo ratings yet

- Brfie To Bridge - AASHTO LRFDDocument124 pagesBrfie To Bridge - AASHTO LRFDTharach Janesuapasaeree100% (2)

- Dy DockDocument50 pagesDy DockRuben Gading WisnumurtiNo ratings yet

- Offshore Jacket Inplace Analysis For Beginners With Sacs 1614129844Document63 pagesOffshore Jacket Inplace Analysis For Beginners With Sacs 1614129844Sholeh Khuddin A MadridistaNo ratings yet

- Design of Floating Offshore Platform: January 2021Document29 pagesDesign of Floating Offshore Platform: January 2021vucokt100% (2)

- Fpso Design and TechnologyDocument57 pagesFpso Design and Technologyamirhosseine0083% (6)

- FPSO PresentationDocument30 pagesFPSO Presentationmechmonkey007100% (1)

- Pgca-St-Bod-1-001 - C1 Topsides Design BasisDocument69 pagesPgca-St-Bod-1-001 - C1 Topsides Design BasisAnil kumarNo ratings yet

- UKOOA FPSO Design Guidance NotesDocument176 pagesUKOOA FPSO Design Guidance Notesnazwan14100% (5)

- Statoil PPT On Fpso DesignDocument44 pagesStatoil PPT On Fpso Designcxb0716467% (3)

- FPSODocument18 pagesFPSOCarly Rheman100% (3)

- Fpso Design Document: Marie C. Mcgraw Roberto J. Mel Endez Javier A. RamosDocument20 pagesFpso Design Document: Marie C. Mcgraw Roberto J. Mel Endez Javier A. RamosYan Laksana100% (2)

- OLO - FPSO Best PracticeDocument11 pagesOLO - FPSO Best PracticePatrick Crocket100% (3)

- Offshore StructureDocument124 pagesOffshore Structureanggoronadhi100% (9)

- Hog and Sag CalcDocument1 pageHog and Sag CalcMarie SaundersNo ratings yet

- FPSOs - Design Considerations For The Structural Interface Hull and TopsidesDocument7 pagesFPSOs - Design Considerations For The Structural Interface Hull and TopsidesLuong Bang Giang67% (3)

- Offshore JacketDocument13 pagesOffshore Jacketsatishchemeng100% (1)

- Notes On FPSO and FatigueDocument6 pagesNotes On FPSO and Fatiguedtr17No ratings yet

- Barge TransportationDocument6 pagesBarge TransportationBoy FirdausNo ratings yet

- 15A10 - Superstructures I (Topside)Document23 pages15A10 - Superstructures I (Topside)Viktor DươngNo ratings yet

- Design of Fixed Offshore PlatformsDocument37 pagesDesign of Fixed Offshore PlatformsgrahazenNo ratings yet

- Mudmat Bearing CapacityDocument11 pagesMudmat Bearing CapacityMathew Simon100% (1)

- Offshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsFrom EverandOffshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsNo ratings yet

- Marine Structural Design CalculationsFrom EverandMarine Structural Design CalculationsRating: 4.5 out of 5 stars4.5/5 (13)

- Detail Design of Bridge Piers On Pile FoDocument98 pagesDetail Design of Bridge Piers On Pile FoMukovhe MuvhaliNo ratings yet

- Guide For Building and Classing High Speed CraftDocument296 pagesGuide For Building and Classing High Speed CraftHamish Adamson100% (1)

- 0397 Mi20 9006 0050 ADocument20 pages0397 Mi20 9006 0050 AGalih Suksmono Adi100% (2)

- Topside Loadout at Ulsan-Re.1Document28 pagesTopside Loadout at Ulsan-Re.1richardykeNo ratings yet

- Shaft Alignment Guide - E-Jan05Document21 pagesShaft Alignment Guide - E-Jan05Brian FreemanNo ratings yet

- Pacificat Fast Ferry ConversionDocument273 pagesPacificat Fast Ferry ConversionkstapletNo ratings yet

- Jacket Topside Transportation Sea Fastening InstallationDocument5 pagesJacket Topside Transportation Sea Fastening InstallationMermaid co100% (1)

- FPSO Design and Conversion A Designer Approach PDFDocument21 pagesFPSO Design and Conversion A Designer Approach PDFJezzNo ratings yet

- Always Moving Forward: Shipbuilding DivisionDocument31 pagesAlways Moving Forward: Shipbuilding DivisionАлиса ПестроваNo ratings yet

- Uwild GuideDocument8 pagesUwild GuideChenna RaoNo ratings yet

- Enhanced Hull SurveyDocument31 pagesEnhanced Hull SurveyArjun KarkeraNo ratings yet

- GOMO Complete Document December 2022Document309 pagesGOMO Complete Document December 2022Luana Marchiori100% (1)

- Ship Structural Design NotesDocument115 pagesShip Structural Design NotesMohamed100% (3)

- Ehouse MCC Switchgear BuildingDocument15 pagesEhouse MCC Switchgear BuildingSARAVANA100% (1)

- Structual Analysis Design of VesselsDocument3 pagesStructual Analysis Design of VesselsRPDeshNo ratings yet

- Structural Design and Analysis of FPSO Topside Module SupportsDocument10 pagesStructural Design and Analysis of FPSO Topside Module SupportsSettuNo ratings yet

- OTC 15313 Development of Load-Out Methodology For On-Ground-Build FSODocument5 pagesOTC 15313 Development of Load-Out Methodology For On-Ground-Build FSOhiyeonNo ratings yet

- Superstructure of Ships-Module4Document9 pagesSuperstructure of Ships-Module4Pramod Kumar MallyaNo ratings yet

- Fatigue and Failure Evaluation of Modular FRP Composite Bridge DeckDocument6 pagesFatigue and Failure Evaluation of Modular FRP Composite Bridge DeckSantanu GhoshNo ratings yet

- Paper 3.2 Design Development of Corrugated BulkheadsDocument13 pagesPaper 3.2 Design Development of Corrugated BulkheadsBill Erick CastilloNo ratings yet

- Connection Hull-Topsides: Principles, Designs and Returns of ExperienceDocument17 pagesConnection Hull-Topsides: Principles, Designs and Returns of ExperienceneelcorNo ratings yet

- Evaluation of Ultimate Ship Hull Strength: Po@.-Collapse Loss F10@Document16 pagesEvaluation of Ultimate Ship Hull Strength: Po@.-Collapse Loss F10@maaathanNo ratings yet

- Lecture No.2Document125 pagesLecture No.2Ali AliNo ratings yet

- Lec - 2 - Load On BridgeDocument6 pagesLec - 2 - Load On Bridgeم.علي سعدي الجنابيNo ratings yet

- Hull Deformation KorbetisDocument12 pagesHull Deformation KorbetisCorbeanu CatalinNo ratings yet

- Chapter 3Document31 pagesChapter 3maddih gayeNo ratings yet

- 1 s2.0 S0029801804002264 Main PDFDocument29 pages1 s2.0 S0029801804002264 Main PDFPrasetyanto UtomoNo ratings yet

- 152 Lifting Appliances Apr 2019Document240 pages152 Lifting Appliances Apr 2019thomas1313No ratings yet

- Ship Vibration GN E-Jan15 PDFDocument83 pagesShip Vibration GN E-Jan15 PDFDwi PramonoNo ratings yet

- Sfa Fpso Guide e Feb14Document45 pagesSfa Fpso Guide e Feb14A_saravanavelNo ratings yet

- ABS Pub102 CrewHabitabilityDocument96 pagesABS Pub102 CrewHabitabilityacallevillNo ratings yet

- Doc. No. 05 - 42 19 AB023 - FIDocument41 pagesDoc. No. 05 - 42 19 AB023 - FIAfanda Dwi R RNo ratings yet

- Sewage Treatment PlantDocument5 pagesSewage Treatment Plant123100% (1)

- Systems Verification Guide eDocument67 pagesSystems Verification Guide eJim HawkinsNo ratings yet

- 3 - For CMHL - 2021 OnlyDocument24 pages3 - For CMHL - 2021 Onlysnikraftar1406No ratings yet

- ABS Part5 - SPECIFIC VESSEL TYPES (CHAPTERS 1-6) PDFDocument901 pagesABS Part5 - SPECIFIC VESSEL TYPES (CHAPTERS 1-6) PDFmelis2100% (2)

- Sime Disc BrakesDocument200 pagesSime Disc Brakeskatlego01No ratings yet

- Abs Academy Ilt Prospectus PDFDocument60 pagesAbs Academy Ilt Prospectus PDFIchsan SuryansyahNo ratings yet

- ABS RECORD FPSO NGOMA Complete April 2023Document27 pagesABS RECORD FPSO NGOMA Complete April 2023arkar.mwinNo ratings yet

- ABS Fire and Safety Features For MODU - Part5Document40 pagesABS Fire and Safety Features For MODU - Part5Eyoma Etim100% (1)

- User Manual - X-904 - Rev. 2023.0Document31 pagesUser Manual - X-904 - Rev. 2023.0Sajith VenkitachalamNo ratings yet

- Abs Typeapp Fiberbond 20fr16 y 16 CDocument2 pagesAbs Typeapp Fiberbond 20fr16 y 16 CLeonardo AlayolaNo ratings yet

- Naval Blek enDocument12 pagesNaval Blek enGabriela DanaNo ratings yet

- Ihm-Guide-Oct18 ABS GuideDocument73 pagesIhm-Guide-Oct18 ABS Guidefarid asadiNo ratings yet