Professional Documents

Culture Documents

Safety in LNG Regasification

Safety in LNG Regasification

Uploaded by

ErwinCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Safety in LNG Regasification

Safety in LNG Regasification

Uploaded by

ErwinCopyright:

Available Formats

Safety in LNG Regasification

SAFETY IN LNG REGASIFICATION

Presented Byy

Man Mohan Ahuja

SR. Vice President (Technical), Petronet LNG Limited

E-mail: ahujamm@petronetlng.com

1

12th Aug, 10

Petrofed Seminar on Safety in Hydrocarbon Sector

Safety in LNG Regasification

SAFETY & ENVIRONMENT PROTECTION

IN OIL & GAS INDUSTRY

A strong concern since the beginning as Oil&gas are considered as hazardous

products. Nevertheless major accidents have occured: Mexico (LPG), Lyon

(France, Raffinery), Sea pollution after various Oil Tankers accidents, IOC

St

Storage

T

Terminal

i l Fire

Fi (Jaipur)

(J i

)

I t

International

ti

l regulations:

l ti

OMI

OMI, SIGTTO

SIGTTO, etc...

t

Oil & Gas companies policies

12th Aug, 10

National

N

ti

l

regulations:

(like OISD in

India)

IInsurance

requirements

Petrofed Seminar on Safety in Hydrocarbon Sector

Safety in LNG Regasification

SAFETY REQUIREMENTS IN LNG INDUSTRY

Since accident in Cleveland (USA) in 1942,

1942 LNG has been considered as

Hazardous product, various regulations have been developped:

Plants & Storages:

g

NFPA 59 A (USA)

49 CFR part 193 (USA)

EN 1473 (Europe)

J G A Rules

Transport by sea: IMO rules,

rules

SIGTTO recommendations, OCIMF rules,

Classification , Insurances requirements.

National regulations, safety and regulatory bodies,

Environment protection bodies & Associations.

12th Aug, 10

Companies

Policies, Engg.

Standards

Petrofed Seminar on Safety in Hydrocarbon Sector

Safety in LNG Regasification

SAFETY REQUIREMENTS IN LNG INDUSTRY

S e y and

Safety

d eenvironment

v o e protection

p o ec o aree considered

co s de ed since

s ce preliminary

p e

y design

des g

studies. Codes and regulations mainly provide:

Design criterias: Seismic design

design,

impounding systems, etc...

Hazardous areas classification: fire-proof

eq ipment Electric & instrumentation

equipment,

instr mentation

equipment classification

12th Aug, 10

Minimum safety

distances: considering

accident scenarios and

consequences: vapour

clouds, fire radiation,

Cold explosion, etc,...

Design & construction rules:

y systems,

y

, Min.

Min. safety

protection, Fabrication,

construction and control stds.

Petrofed Seminar on Safety in Hydrocarbon Sector

Safety in LNG Regasification

SAFETY REQUIREMENTS IN LNG INDUSTRY

Wh t is

What

i LNG ?

Physical properties

Liquefied Natural gas:

Colourless liquid,

Mainly CH4 (>80%),

Cold: temperature -160C,

Density at 1 bar 450 kg/m3

Vapour

V

off LNG

LNG:

Odourless and colourless,

Density at 1 bar and 20C 0.8

0 8 kg/m3

Flamability limits LFL: 5%, UFL:15%

Vapourization of LNG

1 m3 LNG 600 m3 of gas at 20C

12th Aug, 10

LNG in storage

tank is violently

boiling liquid

Petrofed Seminar on Safety in Hydrocarbon Sector

Safety in LNG Regasification

Properties of LNG

Properties of LNG that have safety implications include autoignition temperature,

temperature Low temperature,

temperature heat of vaporization,

vaporization

flammability limits, heat transfer rate of boiling liquid and

specific gravity

The average auto-ignition

auto ignition temperature for pure methane at

atmospheric pressure is 537oC, which is quite high

The lower and upper flammability limit of methane in air is 5% &

15% by

b volume

ol me respectively.

respecti el

In a closed tank, the percentage of methane is 100%, thus it

cannot ignite.

Methane leaking from a tank in a well ventilated area is likely to

rapidly dissipate to less than 5% , thus it is relatively safer as

compared to other fuels

LNG FILIM

6

12th Aug, 10

Petrofed Seminar on Safety in Hydrocarbon Sector

Safety in LNG Regasification

Properties of LNG

The most of Hazardous properties of LNG are due to

extreme low temperatures

The only danger from skin contact with LNG is freezing;

there are no poisonous or toxic effects.

Tissue

Ti

d

damage

f

from

extreme

t

cold

ld is

i similar

i il to

t damage

d

from extreme heat.

Unlike heat burns,

burns a cryogenic burn victim will not feel

pain until the injured part has begun to thaw.

If the skin has surface moisture on it,, contact with cold

objects will result in freezing of the skin to the objects.

Flesh will be torn when the victim tries to remove the

affected area from cold surface

7

12th Aug, 10

Petrofed Seminar on Safety in Hydrocarbon Sector

Safety in LNG Regasification

PROPERTIES OF LNG REACTION ON WATER

Un like other liquid petroleum products LNG reacts

vigorously with water and vapourizes very fast (leaving

nothing behind) posing minimum risk for the marine life

RPT

However LNG reacts violently with water and may cause

explosion due to RPT

8

12th Aug, 10

Petrofed Seminar on Safety in Hydrocarbon Sector

Safety in LNG Regasification

LNG PROPERTIES

LNG VAPOUR CLOUD DISPERSION

Cloud heigth

Continuous

release

e ease

Wind

i d direction

di i

Subsidence Passive

By gravity dispersion

LNG CLOUD

DISPERSION

TEST

Cloud radius

Wind direction

Instantaneous

release

9

12th Aug, 10

Petrofed Seminar on Safety in Hydrocarbon Sector

Safety in LNG Regasification

LNG PROPERTIES

Molarr concentraation

HEAVY GAS CLOUD DISPERSION FC TANKS

1.2

1

0.8

0.6

04

0.4

0.2

0

20

40

60

80

Distance (m)

100

120

Calculation tools :

Integral Model : EVANUM

3D: MERCURE HEAVY

3D:

GAS

10

12th Aug, 10

Petrofed Seminar on Safety in Hydrocarbon Sector

Safety in LNG Regasification

Example of vapors dispersion

12th Aug, 10

Petrofed Seminar on Safety in Hydrocarbon Sector

Safety in LNG Regasification

Example of LNG vaporization

12th Aug, 10

Petrofed Seminar on Safety in Hydrocarbon Sector

Safety in LNG Regasification

Example of LNG pool fire

12th Aug, 10

Petrofed Seminar on Safety in Hydrocarbon Sector

Safety in LNG Regasification

LNG RECEIVING TERMINAL

14

12th Aug, 10

Petrofed Seminar on Safety in Hydrocarbon Sector

Safety in LNG Regasification

LNG TERMINAL DAHEJ

Metering

AIR HEATER

GW PUMP

STV

WATER PUMP

SCV

BOG COMP.

UNLOADING/ VAPOR

RETURN ARMS

SHIP

12th Aug, 10

LP

PUMP

LNG TANK

HW PUMP

R

E

C

O

N

D

E

N

S

O

R

GTG

HP

PUMP

15

Petrofed Seminar on Safety in Hydrocarbon Sector

Safety in LNG Regasification

DESIGN HELP - SPECIAL CODES & STANDARDS

A SAFE & SMOOTHLY OPERATING FACILITY CAN BE

GENERALLY ENSURED,

ENSURED IF THE APPLICABLE CODES &

STANDARDS ARE FOLLOWED IN TRUE SENSE. Some of the

special codes followed for LNG terminals are

National Fire Protection Association ( NFPA-59 A )

British Standard ( BS 7777 )

European Committee for Standardization ( EN 1473 ) :

OCIMF (Oil Companies International Marine Forum):

SIGTTO (Society International Gas Tanker & Terminal

Operators):

OISD STDS 116, 118 & 194

12th Aug, 10

16

Petrofed Seminar on Safety in Hydrocarbon Sector

Safety in LNG Regasification

ISO ACCREDITATION

Certified by DNV on 21st Jan-05

ISO 9001: 2001 QMS

12th Aug, 10

ISO 14001: 1996 EMS

OSHAS 18001: 1999

Petrofed Seminar on Safety in Hydrocarbon Sector

Safety in LNG Regasification

IDENTIFICATION OF RISKS

External Origin

Natural Risks (Earthquakes, flooding, wind, typhoons and

lighting)

Non Natural Risks (from other industry, Marine traffic, Aircraft

crash)

Internal Origin

Release of LNG

o Release from tanker, Spill from un-loading arms

o Failure of transfer line,

line Inner / outer tank failure

o Overfilling of storage tanks, Send out pump failure

Release of NG

o Tank safety valves, Vapouriser safety valves, Flare stack

Process upsets like equipment failure, utility failure, roll over are

not included as these are covered under ESD system

18

12th Aug, 10

Petrofed Seminar on Safety in Hydrocarbon Sector

Safety in LNG Regasification

Two phase releases

Phenomena in case of LNG release

Fraction of LNG will flash (vapors)

A fraction of liquid stays in suspension (aerosol)

The other part of liquid falls on the ground(rainout)

Proportions depend of jet characteristics (pressure,

temperature, leak size, release height)

Different types of releases

Low p

pressure Liquid

q

release

High pressure Gas release

12th Aug, 10

Petrofed Seminar on Safety in Hydrocarbon Sector

Safety in LNG Regasification

LNG leaks: main parameters

Release Characteristics

Upstream Conditions

Pressure, flow rate

Thermodynamic state of LNG

Pressure

Temperature

Overheated or not

12th Aug, 10

Petrofed Seminar on Safety in Hydrocarbon Sector

Safety in LNG Regasification

Example of LNG release

12th Aug, 10

Petrofed Seminar on Safety in Hydrocarbon Sector

Safety in LNG Regasification

RISK / HAZARD CONTROL

M

Measures to

t avoid

id the

th cause off release

l

Measures to reduce the consequence of a release.

LNG Spill Action Plan

Prevent spill

Detect spill, if it happens

Keep the spill volume minimum

Control the Vapours

Detect the fire quickly, if it happens

Control the fire immediately, if it is detected

Protect the other facilities

Extinguish the fire

22

12th Aug, 10

Petrofed Seminar on Safety in Hydrocarbon Sector

Safety in LNG Regasification

FACILITIES : UNLOADING ARMS

Unloading

Arms

designed

following

OCIMF guidelines,

which

i

ensures compatibility

i i i with

i

most of the ships & safe operation

One of the significant feature is

installation of PERC

23

12th Aug, 10

Petrofed Seminar on Safety in Hydrocarbon Sector

Safety in LNG Regasification

Un-loading Arm During Testing

24

12th Aug, 10

Petrofed Seminar on Safety in Hydrocarbon Sector

Safety in LNG Regasification

PERC REACTIVATION DURING TESTING

BACK

25

12th Aug, 10

Petrofed Seminar on Safety in Hydrocarbon Sector

Safety in LNG Regasification

FACILITIES : LNG TANKS

Two nos. 160,000 m3

capacity

Type: Full Containment

Design codes: BS 7777, API

620, EN 1473, NFPA 59A

Dia: 81 m;; Height

g 55 m

26

12th Aug, 10

Petrofed Seminar on Safety in Hydrocarbon Sector

Safety in LNG Regasification

LNG STORAGES TANK-PLL

BOG pipe

Concrete roof

Roof insulation (glass wool)

Suspended deck

Insulation (Perlite)

LNG filling pipes

Prestressed concrete

outer shell

Full containment above ground

LNG Tank

Inner Tank

9% Nickel Steel

Low pressure

submerged pump

(removable)

Boil Off rate: 0.08% capacity/day

Resilient

blancket

Bottom insulation

(foam glass)

Cryogenic

Liner

Concrete slab

Air heating

Piles

Ground level

27

12th Aug, 10

Petrofed Seminar on Safety in Hydrocarbon Sector

Safety in LNG Regasification

TANK SAFETY

Results of Consequence Modeling

Heat flux

due to LNG

Fire

Hazardous

Vapour

Cloud

Remarks

Single

g

Containment Type

Double

At

Luvara

Acceptable

(0.9 Kw/m2)

Acceptable

( nil )

No affect

outside plant

NFPA 59 A

Criteria is

5 KW/m2

At

GCPTCL

Acceptable

(1.2 Kw/m2 )

Acceptable

(0.1 Kw/m2)

No affect

outside plant

Flux causing

structural

damage estimate

is

25 Kw/m2

5 Kw/m2

distance

700 m

300 m

77 m

Minimum

distance to

property line

3 Kw/m2

distance

1200 m

700 m

88 m

Spread

Unacceptable Unacceptable

(2500 m to

(1100 m to

5600 m)

1200 m)

Full

Acceptable

(57 m)

LEL not to

spread outside

battery limit

*** PLL has selected fully contained tanks to ensure MAXIMUM SAFETY

12th Aug, 10

28

Petrofed Seminar on Safety in Hydrocarbon Sector

Safety in LNG Regasification

LNG Regasification

g

For ORVs Sea water characteristics

nott acceptable

t bl

For SCVs high operating cost &

high exhaust gas mission

Open

p Rack

Vapourizer (ORV)

Submerged Combustion

Vapourizer (SCV)

29

12th Aug, 10

Petrofed Seminar on Safety in Hydrocarbon Sector

Safety in LNG Regasification

LNG REGASIFICATION

RLNG

Air Heater

GW Pump

STV

Water Collection

Water to

different users

Water Pump

Glycol Water Circulation

LNG

30

12th Aug, 10

Petrofed Seminar on Safety in Hydrocarbon Sector

Safety in LNG Regasification

FACILITIES : AIR HEATERS & STVs

7 STVs / Air Heaters with 112

fans-16.4 MW each

Close loop system with no

exhaust

Only ambient air heat

No external firing

Most environment friendly

system

STV

31

12th Aug, 10

Petrofed Seminar on Safety in Hydrocarbon Sector

Safety in LNG Regasification

SAFETY ISSUES

PROJECT IMPLEMENTATION

Safety studies

HAZID

H

Hazard

d Identification

Id tifi ti

HAZAN

Hazard Analysis:

Potential Hazards & consequences

HAZOP

Hazard and operability analysis:

Systematic approach to identify hazards

and operability problems

Project Technical reviews

SAFETY CONCEPT

QRA

Quantitative Risk Assessment

Q

Numerical calculation of Risk level

32

12th Aug, 10

Petrofed Seminar on Safety in Hydrocarbon Sector

Safety in LNG Regasification

SAFETY MEASURES

INCORPORATED IN THE DESIGN

State-of-the-Art Technology.

Automatic Safety Shutdown System.

System for early detection of leakage / spillage of LNG

or regasified LNG.

Plant Design and Equipment Layout as per

International & Domestic Safetyy Standards.

Dedicated team to ensure adherence to safety measures.

Safety Audits & Mock Drills

Regular Safety Trainings (Internal & External)

Incedent Reporting & Analysis

33

12th Aug, 10

Petrofed Seminar on Safety in Hydrocarbon Sector

Safety in LNG Regasification

EQUIPMENT LAYOUT

12th Aug, 10

Petrofed Seminar on Safety in Hydrocarbon Sector

Safety in LNG Regasification

REGASIFICATION TERMINAL

EQUIPMENT LAYOUT

EN 1473 & NFPA 59 A provides guideline

Layout to ensure LNG piping is minimezed

Layout to ensure risk does not extend beyond the plot

Main

M i Control

C t l room to

t be

b in

i non-hazardous

h

d

area.

Hazardous area classification may be decided based on

dispersion

i

i calculation

i from

f

possible

i

spills.

i

12th Aug, 10

Petrofed Seminar on Safety in Hydrocarbon Sector

Safety in LNG Regasification

Safety Distance Dahej LNG Plant

The required safety distance form leakage point for HP & LP source are

190m and 168m which could be accommodated within the Allocated plot

12th Aug, 10

Petrofed Seminar on Safety in Hydrocarbon Sector

Safety in LNG Regasification

Safety Distance Kochi LNG Plant

The required safe distances from leakage point from HP & LP source

are 141 & 105 m, which could not be accommodated within the allotted

plot. PLL had to use water curtains to resolve this problem

12th Aug, 10

Petrofed Seminar on Safety in Hydrocarbon Sector

Safety in LNG Regasification

LNG Spill Prevention Methods

Release From Un-loading Arms

Powered Emergency Release Coupling with two step ESD System

o Step 1: - Close the NG / LNG valves

o Step 2: - Disconnect the NG / LNG un-loading Arms

Failure of both the steps only can cause the LNG spill.

LNG Transfer

T

f Lines

Li

Pipes are protected against corrosion, overpressure, Vehicle crash,

equipment fall by design features & mostly being welded pipes

Inner Tank Failure

Design Features (e.g. metallurgy, welding procedures, earthquake

factor, low temperature detectors, no nozzle on side or bottom of

tank, p

provision of VRV etc.) make the failure chance almost rare.

Outer Tank Failure

Pre-stressed concrete outer tank designed to with stand cold LNG &

external aggression due to LNG leak, earthquake, projectile attack

etc.

38

12th Aug, 10

Petrofed Seminar on Safety in Hydrocarbon Sector

Safety in LNG Regasification

LNG Spill Prevention Methods

Release From Valve Packing

Extended Bonnet Valves Have been used

Packing leak can be predicted by early accumulation of

frost

Early detection & tightening procedures are developed to

prevent liquid

p

q

escape

p

Release from piping flanges, Spool Pieces & Hoses

Use of flanges, spool pieces & Hoses for LNG has been

(practically

y zero).

)

minimized (p

Future connections (or other tapings), where flange

connections are necessary, are properly vented

Leaks In Gas Phase Piping

p g

Leaks resulting in the release of cold gas can occur in the

piping associated with the vaporization of natural gas.

This area is provided with extra instrumentation

39

12th Aug, 10

Petrofed Seminar on Safety in Hydrocarbon Sector

Safety in LNG Regasification

HANDLING OF LNG LEAKS & SPILLS

Elaborate Leak detection system

y

Thermal Sensors

Gas Detectors

p

procedures to protect

p

personnel

p

from contract with leaking

g liquid

q

or cold vapor and minimize the chance for vapor contact with

potential source of ignition

Equipment

q p

such as barricades,, Warning

g signs

g and combustible gas

g

indicators are available at the plant

Elaborate Emergency Shut Down (ESD) system & System isolation

ESD1: - Stop

p Ship

p Un-loading

g

ESD2: - Stop Send out system

ESD3: - Stop Complete facility

40

12th Aug, 10

Petrofed Seminar on Safety in Hydrocarbon Sector

Safety in LNG Regasification

ACTIVE EMERGENCY / FIRE PROTECTION

MEASURES

AS

S

Fire

Fi Water

W t System:

S t

Ring

Ri Main,

M i Hydrants,

H d

t Tower

T

Monitors, Remote / manual operated spray system,

Water Curtain

High Expansion Foam System

Clean Agent (Inergen) system

P t bl Fire

Potable

Fi Extinguisher

E ti

i h

Mobile Fire Fighting triple purpose (Water/Foam/DCP)

Tender

Personal Protection Gears & Breathing Apparatus

Oil Spill Handling Equipment

41

12th Aug, 10

Petrofed Seminar on Safety in Hydrocarbon Sector

Safety in LNG Regasification

AN ACTIVE MEAN

OF PROTECTION :

THE WATER CURTAIN

12th Aug, 10

Petrofed Seminar on Safety in Hydrocarbon Sector

Safety in LNG Regasification

Mitigation effects of a water curtain

Mechanical Dispersion (heating,

dilution) Chemical dilution (absorption)

Thermal radiation mitigation

12th Aug, 10

Petrofed Seminar on Safety in Hydrocarbon Sector

Safety in LNG Regasification

Mitigation effects of a water curtain

Example of nozzles ramps

Nozzles characteristics

Diameter

Size of sprays

Momentum of sprays

Curtain geometry

Number of nozzles per linear meter of

curtain

Spacing between the nozzles

Distance between the nozzles ramps

Downward curtain (full cone nozzles)

Upward curtain (peacock tail)

12th Aug, 10

Petrofed Seminar on Safety in Hydrocarbon Sector

Safety in LNG Regasification

Mitigation effects of a water curtain

Field tests (pool fire) Gaz de France

Significant thermal radiation mitigation,

p

g on the water curtain characteristics

depending

12th Aug, 10

Petrofed Seminar on Safety in Hydrocarbon Sector

Safety in LNG Regasification

REDUCING THE FLAMES :

USE OF FOAM

12th Aug, 10

Petrofed Seminar on Safety in Hydrocarbon Sector

Safety in LNG Regasification

SAFETY ISSUES: Foam generation system

Physical foam effects:

Before ignition:

Isolate LNG layer from ambiant air

Reduce the vaporization

Warm-up LNG

G vapours

Increase the dispersion

Air

After ignition:

g

Reduce heat exchanges between

the LNG layer and the flame

Produce steam which reduce the

fl

flame

Reduce combustion ratio

Reduce fire radiation

Foam

Nozzle

Pre-mix

=

Water

+

Emulsifier

3% vol

47

12th Aug, 10

Petrofed Seminar on Safety in Hydrocarbon Sector

Safety in LNG Regasification

Reduction of fire with foam

Evolution of the received flux during the phases of foam

discharging and destruction (50 m

m circular LNG pool fire)

12th Aug, 10

Petrofed Seminar on Safety in Hydrocarbon Sector

Safety in LNG Regasification

SAFETY ISSUES

FIRE FIGHTING SYSTEMS

E

Extinguishing

ti

i hi agent:

t

Chemical powder

Fixed systems:

y

Powder gguns

Mobile systems:

Trucks, 100kg powder

extinguisher

Hand extinguisher: 9kg

Extensive trainingg of

Operators

safety teams

49

12th Aug, 10

Petrofed Seminar on Safety in Hydrocarbon Sector

Safety in LNG Regasification

Spreading and vaporization of pools

Spreading of an LNG pool

Low pressure LNG spills from a pipeline or a vessel

LNG comes into contact with ground

LNG gains some heat from ground

I

Increase

off vaporization

i i

Ground is cooled down

LNG spreads, forming a pool

LNG continues to cool down ground

Temperature differential between ground and LNG decreases, and thus heat

exchange

12th Aug, 10

Petrofed Seminar on Safety in Hydrocarbon Sector

Safety in LNG Regasification

SAFETY - DOCUMENTATION

A Comprehensive

p

set of Documentation is in Place for Safe &

Reliable Operation:

Disaster Management Plan

Oil Spill Contingency Plani.

Port Administration

Port Operations

Health, Safety and Environment (HSE)

Maintenance of Tugs

g and Support

pp

Craft & Jetty

y

Training

Terminal Information & Regulations & Operation Books

51

12th Aug, 10

Petrofed Seminar on Safety in Hydrocarbon Sector

Safety in LNG Regasification

Concluding Remarks

Follow the Codes & Standards leads to safe design &

operation

Studies

St di like

lik HAZOP,

HAZOP QRA,

QRA SIL,

SIL Risk

Ri k Analysis

A l i etc.

t during

d i

the design phase help in ensuring the safety during

construction & operation.

For Key to Success remember

Engineering is easy

Environmental issues, public safety & public perception are

difficult

Carryout detailed modeling studies to establish compliance

with environmental / regulatory requirements in project

development process from the very beginning

52

12th Aug, 10

Petrofed Seminar on Safety in Hydrocarbon Sector

Safety in LNG Regasification

REDUCING THE RISKS AT DAHEJ TERMINAL

DESIGN & CONSTRUCTION

E

Emergency

Release

R l

Coupling

C

li

Full containment Storage Tanks

Some

examples

Lay-out: safety distances

12th Aug, 10

Cold and Gas Detection

Petrofed Seminar on Safety in Hydrocarbon Sector

Safety in LNG Regasification

LNG IS A MATURE INDUSTRY ENJOYING A

VERY HIGH LEVEL SAFETY RECORD

WORLDWIDE

THANK YOU FOR YOUR

ATTENTION

182,000 m3 LNG tanks under construction

Petronet LNG Ltd LNG Terminal Kochi

12th Aug, 10

Petrofed Seminar on Safety in Hydrocarbon Sector

You might also like

- LNG Import Terminal Cost and Schedule BasicsDocument23 pagesLNG Import Terminal Cost and Schedule Basicsjomafeba100% (4)

- Basis of Design LNGDocument148 pagesBasis of Design LNGCal84% (25)

- Mini Mid-Scale LNG PDFDocument22 pagesMini Mid-Scale LNG PDFGeoffreyHunter100% (4)

- LNG Process TrainDocument23 pagesLNG Process TrainMuhammad Shariq Khan100% (11)

- LNG Receiving and Regasification TerminalsDocument122 pagesLNG Receiving and Regasification Terminalssmithwork78% (9)

- Design Concepts For LNG FSRUDocument34 pagesDesign Concepts For LNG FSRU조대제100% (3)

- Crack Width Calculation Is 456Document2 pagesCrack Width Calculation Is 456sansarep100% (6)

- Mazda 4-Rotor Engine Le-MansDocument10 pagesMazda 4-Rotor Engine Le-Mansapi-3810101100% (4)

- Development of Mansuriya Gas Field (Iraq)Document10 pagesDevelopment of Mansuriya Gas Field (Iraq)Dr. Wisam Al-Shalchi83% (6)

- LNG - Fundamental Principles and Plant ExamplesDocument47 pagesLNG - Fundamental Principles and Plant ExampleslizhasayangNo ratings yet

- Concept of Mini LNG Onshore TerminalDocument12 pagesConcept of Mini LNG Onshore TerminalNkantan RamachandranNo ratings yet

- Small and Medium Scale LNG Terminals WartsilaDocument16 pagesSmall and Medium Scale LNG Terminals WartsilaMuhammad Habib100% (6)

- Dynamic Optimization of Boil-Off Gas Fluctuations at An LNG Receiving TerminalDocument9 pagesDynamic Optimization of Boil-Off Gas Fluctuations at An LNG Receiving TerminalKong LingweiNo ratings yet

- AIChE Design LNG Facilities To Minimize Risks From Cryogenic Exposure, 2009Document17 pagesAIChE Design LNG Facilities To Minimize Risks From Cryogenic Exposure, 2009jeremyg998100% (1)

- Overview of The Oil and Gas Industry in NigeriaDocument5 pagesOverview of The Oil and Gas Industry in NigeriaElorm Oben-Torkornoo80% (5)

- Densin c2500 25 DDocument1 pageDensin c2500 25 Dkwakwa4No ratings yet

- Safety Aspects of LNGDocument10 pagesSafety Aspects of LNGNeil AlexNo ratings yet

- LNG Receiving & Regasfication PDFDocument10 pagesLNG Receiving & Regasfication PDFJeff Jeong100% (1)

- Regasification HamworthyDocument19 pagesRegasification HamworthyMoustapha Seye100% (1)

- LNG RegasificationDocument16 pagesLNG RegasificationCal100% (1)

- LNG PresentationDocument46 pagesLNG PresentationDeeran V100% (1)

- LNG TerminalDocument136 pagesLNG TerminalIqbal Muhammad100% (6)

- LNG Terminal Design RelatedDocument14 pagesLNG Terminal Design Relatedpdaga19691383100% (1)

- LNG SafetyDocument13 pagesLNG SafetyAhmedAmer1No ratings yet

- LNG Process Units 200904Document19 pagesLNG Process Units 200904avijitb94% (18)

- B&V Mini LNG PlantDocument84 pagesB&V Mini LNG PlantPugel YeremiasNo ratings yet

- LNG FSRU BOG SystemDocument4 pagesLNG FSRU BOG Systemdmscott10No ratings yet

- LNG Re Liquefaction Systems For LNG CarriersDocument8 pagesLNG Re Liquefaction Systems For LNG Carriersnikoskarandinos100% (1)

- LNG Ship Boil Off GasDocument10 pagesLNG Ship Boil Off Gas123habib123fikri100% (2)

- LNG An IntroductionDocument60 pagesLNG An Introductionsyafiq88% (8)

- Comparisons Between LNG TerminalsDocument26 pagesComparisons Between LNG TerminalsNurcahyo Djati W100% (6)

- Opportunities For Small Scale LNG ArgelDocument20 pagesOpportunities For Small Scale LNG Argelafigueredou100% (1)

- LNG Study Final 10.27Document58 pagesLNG Study Final 10.27Iro Gidakou GeorgiouNo ratings yet

- Liquefied Natural Gas ChainDocument11 pagesLiquefied Natural Gas Chaintsar mitchelNo ratings yet

- LNG Filling StationDocument42 pagesLNG Filling Stationian84No ratings yet

- LNG - Fundamental PrinciplesDocument64 pagesLNG - Fundamental Principlesudin100% (4)

- LNG EconomicsDocument19 pagesLNG EconomicsCal75% (4)

- Operation LNG TankDocument4 pagesOperation LNG TankpramodtryNo ratings yet

- LNG Infrastructure in IndiaDocument79 pagesLNG Infrastructure in IndiaXcdxtv100% (1)

- Technical Challenges With The Small Scale LNG TerminalsDocument83 pagesTechnical Challenges With The Small Scale LNG TerminalsJosé NunesNo ratings yet

- Understanding Natural Gas and LNGDocument23 pagesUnderstanding Natural Gas and LNGCalNo ratings yet

- Scarpa - LNG TErminal AssessmentDocument11 pagesScarpa - LNG TErminal Assessmentyan energia100% (1)

- Design Development of BOG Handling System in LNG-FSRU: Youngsoon Sohn, Donghyuk Kim, Sunghee Choi, Youngmyung YangDocument4 pagesDesign Development of BOG Handling System in LNG-FSRU: Youngsoon Sohn, Donghyuk Kim, Sunghee Choi, Youngmyung YangwdyouQNo ratings yet

- LNG Regasification - Technology Evaluation and Cold Energy UtilisationDocument9 pagesLNG Regasification - Technology Evaluation and Cold Energy UtilisationGSNo ratings yet

- 01 Basic LNG - IntroductionDocument93 pages01 Basic LNG - IntroductionKim Hyun Ho100% (3)

- Ftops 2a - LPG-LNG Hazards and ControlDocument26 pagesFtops 2a - LPG-LNG Hazards and ControlmyscriblkNo ratings yet

- Introduction To LNGDocument33 pagesIntroduction To LNGSatish Dabral0% (1)

- I. LNG Processing - PPT Professional Development Course-Bangladesh - 2015.10.06Document71 pagesI. LNG Processing - PPT Professional Development Course-Bangladesh - 2015.10.06tommyadam100% (1)

- LNG Liquefaction PlantsDocument5 pagesLNG Liquefaction Plantssandystays100% (1)

- LNG RegasificationDocument22 pagesLNG RegasificationVu Duc NguyenNo ratings yet

- Optimization of LNG RegasificationDocument30 pagesOptimization of LNG RegasificationShashwat OmarNo ratings yet

- Simplify BOG Recondenser Design and OperationDocument8 pagesSimplify BOG Recondenser Design and OperationWilfredo Suarez TorresNo ratings yet

- Integrated Risk Assessment For LNG TerminalsDocument15 pagesIntegrated Risk Assessment For LNG TerminalsSinying SiaNo ratings yet

- LNG Databases - Regasification - Sample - Q4 2014Document36 pagesLNG Databases - Regasification - Sample - Q4 2014KhoironSyamdatuNo ratings yet

- LNG Marine TerminalDocument100 pagesLNG Marine TerminalBang Niel100% (2)

- LNG Plant Process UsefulDocument52 pagesLNG Plant Process UsefulMegha RawatNo ratings yet

- Natural Gas Hydrates in Flow AssuranceFrom EverandNatural Gas Hydrates in Flow AssuranceCarolyn Ann KohRating: 5 out of 5 stars5/5 (1)

- The Facilities Manager's Guide To M&E ComplianceDocument22 pagesThe Facilities Manager's Guide To M&E ComplianceTannice HemmingNo ratings yet

- Design Methods For FLNG Safety Engineering - Jerome - HocquetDocument11 pagesDesign Methods For FLNG Safety Engineering - Jerome - HocquetRichard HollidayNo ratings yet

- Fire Safety Requirements For ShipsDocument20 pagesFire Safety Requirements For ShipsZavcky Ataide100% (1)

- Cryogenics Safety Manual: A Guide to Good PracticeFrom EverandCryogenics Safety Manual: A Guide to Good PracticeNo ratings yet

- LNG Road TranportationDocument53 pagesLNG Road TranportationAmarjit SihagNo ratings yet

- Gas Detection at LNG Facilities ETA - MARDocument7 pagesGas Detection at LNG Facilities ETA - MARSaBilScondNo ratings yet

- Kolon Ayağı Ve Ankraj Bulonu Hesabı 1Document14 pagesKolon Ayağı Ve Ankraj Bulonu Hesabı 1magxstone100% (2)

- Presentation On Coal Handling Systems: Prepared By:-Arnab Chakraborty Mba-PmDocument16 pagesPresentation On Coal Handling Systems: Prepared By:-Arnab Chakraborty Mba-PmIgnatius SamrajNo ratings yet

- Report Group 2Document40 pagesReport Group 2Ignatius SamrajNo ratings yet

- Foundation and Tower Installation Manual PDFDocument56 pagesFoundation and Tower Installation Manual PDFIgnatius Samraj100% (1)

- Technical Manual 1Document118 pagesTechnical Manual 1Homero Silva100% (14)

- Design and Execution of Steel Structures and Composite Steel-Concrete BuildingsDocument182 pagesDesign and Execution of Steel Structures and Composite Steel-Concrete BuildingsIgnatius SamrajNo ratings yet

- Design For Flexure and ShearDocument2 pagesDesign For Flexure and ShearIgnatius Samraj100% (2)

- OM14 Sea Water Intake StructuresDocument42 pagesOM14 Sea Water Intake StructuresIgnatius Samraj100% (1)

- Design and Execution of Steel Structures and Composite Steel-Concrete BuildingsDocument182 pagesDesign and Execution of Steel Structures and Composite Steel-Concrete BuildingsIgnatius SamrajNo ratings yet

- Jetty NW WorkDocument260 pagesJetty NW WorkIgnatius SamrajNo ratings yet

- Material Properties of PEDocument12 pagesMaterial Properties of PEIgnatius SamrajNo ratings yet

- Worked ExamplesDocument161 pagesWorked ExamplesIgnatius Samraj100% (1)

- Combined Footing Design PDFDocument11 pagesCombined Footing Design PDFIgnatius SamrajNo ratings yet

- Designing Concrete For Exposure To Seawater - tcm45-342265Document3 pagesDesigning Concrete For Exposure To Seawater - tcm45-342265Ignatius Samraj100% (2)

- Design and Execution of Steel Structures and Composite Steel-Concrete BuildingsDocument182 pagesDesign and Execution of Steel Structures and Composite Steel-Concrete BuildingsIgnatius SamrajNo ratings yet

- Process Flow Diagram-B001Document1 pageProcess Flow Diagram-B001Ignatius SamrajNo ratings yet

- StairsDocument21 pagesStairstomnubiNo ratings yet

- HSI Calculator Excel For Tech Review Jul 30 With GraphicsDocument33 pagesHSI Calculator Excel For Tech Review Jul 30 With GraphicsAnonymous 2TVrNDPgSNo ratings yet

- TTDocument9 pagesTTSreeram EravarathNo ratings yet

- Sebp5407 00 00 AllcdDocument859 pagesSebp5407 00 00 AllcdAbdullahNo ratings yet

- 4 Vacuum PumpDocument126 pages4 Vacuum Pumpapi-3856548100% (2)

- Flyer DP HVDPDocument4 pagesFlyer DP HVDPA MahmoodNo ratings yet

- ITPM01 Rev.1 NPS CT Inspection and Test PlanDocument32 pagesITPM01 Rev.1 NPS CT Inspection and Test PlanRajmohan BabuNo ratings yet

- Valve Stem SealsDocument2 pagesValve Stem SealsBinny Samuel Christy100% (1)

- Scarab Merlin InformationDocument2 pagesScarab Merlin InformationScarab SweepersNo ratings yet

- Penyemenan Ulang AHDocument101 pagesPenyemenan Ulang AHMarrry FlorenciaNo ratings yet

- Letter From 65 Maryland Lawmakers Urging Rejection of Fracked Gas PipelineDocument1 pageLetter From 65 Maryland Lawmakers Urging Rejection of Fracked Gas PipelineDavid MoonNo ratings yet

- Motor 60Z02152 - 03 (1) CAT3306 CrankshaftDocument5 pagesMotor 60Z02152 - 03 (1) CAT3306 CrankshaftIsmael De Jesus AndradeNo ratings yet

- Thermochemical Characteristics of Dimethyl Ether - Alternative FuelDocument13 pagesThermochemical Characteristics of Dimethyl Ether - Alternative FuelAlvaro BenattiNo ratings yet

- 6 HP Evinrude ManualDocument9 pages6 HP Evinrude Manualcainanashton0% (1)

- Eum 20180809Document21 pagesEum 20180809Victor FernandezNo ratings yet

- Eeds Trader GuideDocument39 pagesEeds Trader GuideNagrani PuttaNo ratings yet

- NAEN: Greenland 2016Document35 pagesNAEN: Greenland 2016NunatsiaqNewsNo ratings yet

- Z Energy Caltex Oil Lubricants Guide 2019 FinalDocument72 pagesZ Energy Caltex Oil Lubricants Guide 2019 FinalAdnanNo ratings yet

- Chemical FuelsDocument35 pagesChemical FuelsRaghvan RajivNo ratings yet

- Relief Valve - Wikipedia, The Free EncyclopediaDocument1 pageRelief Valve - Wikipedia, The Free EncyclopediasathachiNo ratings yet

- Spe 120267 PPDocument11 pagesSpe 120267 PPHeron Gachuz MuroNo ratings yet

- SL08 495KNBSL2008 495 PDFDocument6 pagesSL08 495KNBSL2008 495 PDFDenim102No ratings yet

- Orion What Is Carbon BlackDocument48 pagesOrion What Is Carbon Blackgiskaputri0% (1)

- J4 915 SonologDocument1 pageJ4 915 SonologPocholo Mario Pineda ForeroNo ratings yet

- Siemens-Oil-Gas-Overall brochure-ENDocument12 pagesSiemens-Oil-Gas-Overall brochure-ENPrasad MahajanNo ratings yet

- Standard Abbreviation List by Siemens 20Document1 pageStandard Abbreviation List by Siemens 20Pendl PendlNo ratings yet

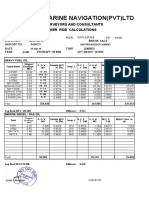

- Bunker CalculationDocument10 pagesBunker CalculationNimesh PereraNo ratings yet