Professional Documents

Culture Documents

Welder Slip

Welder Slip

Uploaded by

Shah AlamCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Welder Slip

Welder Slip

Uploaded by

Shah AlamCopyright:

Available Formats

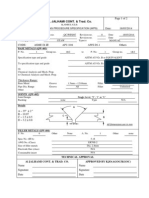

ZAMIL PROCESS EQUIPMENT COMPANY

PO Box 877, Dammam 31421, Kingdom of Saudi Arabia.

Tel : +966-3-812 3855 Fax : +966-3-812 3866

REQUEST FOR WELDING CONSUMABLE Welder Allocation Tag

JOB NO.

PE0287-01

JOINT NUMBER

LS-04

DATE

WELDER ID

IC

WPS

0287-FS 11 A0-01

REV NO.

PROCESS

SAW+FCAW

PRE HEAT TEMP(C)

INTERPASS TEMP(C)

CONSUMABLE BRAND Kiswel K71TLF

POSITION

SHIELDING GAS

PWHT

IMPACT

No

WELD

LAYER

FILLER METAL

PROCESS

CLASS

SIZE

22/11/2015

CO

Yes

FILLER METAL

TYPE POLARITY AMP(A)

VOLT

(V)

TRAVEL

SPEED(mm/mi

MAX HEAT

INPUT(kj/mm)

E71T1

Root +

Hot

FCAW

Root +

Hot

FCAW

1.2

DCEP

160-220

24-30

200 Min

N.A

E71T-1

1.2

DCEP

160 220

24 - 30

200 Min

N.A

FCAW

E71T-1

1.2

DCEP

160-220

24-30

200 Min

N.A

Fill & Cap

FCAW

E71T-1

1.2

DCEP

160 220

24 - 30

200 Min

N.A

Fill & Cap

FCAW

E71T-1

1.6

DCEP

180 240

24 - 30

225 Min

N.A

Fill & Cap

SAW

F7A8-EH12K

3.2

DCEP

320 480

28 - 30

400 Min

N.A

Fill & Cap

SAW

F7A8-EH12K

4.0

DCEP

400 550

28 - 32

500 Min

N.A

Fill & Cap

SAW

E71T-1

1.6

DCEP

180-240 180-240

225 Min

N.A

Back

Welding

FCAW

E71T-1

1.2

DCEP

160 220

24 - 30

200 Min

N.A

Back

Welding

SAW

F7A8-EH12K

3.2

DCEP

320 480

28 - 30

400 Min

N.A

Fill and

Cap

ISSUED BY: ( PRODUCTION / WELDING FOREMAN)

WELDER DETAILS :

NAME :

EMP# :

NAME : Rajeev Kumar

SIGNATURE :

DATE :

DATE : 22/11/2015

EMP# : IC

NOTE :

1) Temperature stick compulsory.

2) This slip should be present with welders while welding. Holding oven lid should be closed.

3) Welding butts should be return to store after completion of weld.

4) Pre heat T uo tp 32 mm is 80 C, between 32 and 50 mmis 100 C, above 50mm is 125 C

Delete Note 4

TOTAL

ELECTRODES

You might also like

- WPS MigDocument3 pagesWPS MigAJOJOY00960% (5)

- Wps 316L SMAW+GTAW R00Document2 pagesWps 316L SMAW+GTAW R00Richard Periyanayagam86% (14)

- 6GR WPS PQRDocument15 pages6GR WPS PQRKiukStaks100% (6)

- WPS FormatDocument1 pageWPS FormatAbdullah AnsariNo ratings yet

- Wps A53 Gtaw R00Document2 pagesWps A53 Gtaw R00Richard PeriyanayagamNo ratings yet

- WpsDocument2 pagesWpsnaseema1100% (1)

- 6GR WPS PQR PDFDocument15 pages6GR WPS PQR PDFerwincalvoNo ratings yet

- 6GR WPS PQRDocument15 pages6GR WPS PQRMohammed NazeerNo ratings yet

- Endress+hauser - 24769 PDFDocument1 pageEndress+hauser - 24769 PDFMaged AbbasNo ratings yet

- WPS002 312Document2 pagesWPS002 312proxywarNo ratings yet

- Welding Procedure Specification: Page 1 of 1Document2 pagesWelding Procedure Specification: Page 1 of 1Harshad100% (1)

- WPS 204 NewDocument6 pagesWPS 204 Newarockiyathass100% (1)

- T 2171 - Diesel Storage TankDocument2 pagesT 2171 - Diesel Storage TankHuynh Thanh TamNo ratings yet

- Syphons: WS, LWS and UWS SeriesDocument2 pagesSyphons: WS, LWS and UWS SeriesOmar AbdussaidNo ratings yet

- First Crew: Metalfab Middle East FZ LLCDocument3 pagesFirst Crew: Metalfab Middle East FZ LLCsalahuddinNo ratings yet

- Saudi Arabian Oil Company: Safety Instruction Sheet - Critical PipingDocument20 pagesSaudi Arabian Oil Company: Safety Instruction Sheet - Critical PipingDana GuerreroNo ratings yet

- HT Motor DatasheetDocument62 pagesHT Motor DatasheetShantanu Dutta100% (3)

- 046-ITP For INSTALLATION OF MAC-BAC-ST MACHINERY UNIT PDFDocument18 pages046-ITP For INSTALLATION OF MAC-BAC-ST MACHINERY UNIT PDFKöksal PatanNo ratings yet

- 10-01265-015-D-061706180619abc-Qc-Wps PQR001 - Moisture Separator WPS PQR and Weld Map - RD PDFDocument65 pages10-01265-015-D-061706180619abc-Qc-Wps PQR001 - Moisture Separator WPS PQR and Weld Map - RD PDFmarghoob100% (1)

- (TSM Al 99 BP M 06 Fg0 905) - 0 - A4 - Natural Gas System Piping MDocument3 pages(TSM Al 99 BP M 06 Fg0 905) - 0 - A4 - Natural Gas System Piping MepbamdadNo ratings yet

- WPS Dissimilar UpdatedDocument3 pagesWPS Dissimilar UpdatedVimin Prakash100% (1)

- WPSDocument3 pagesWPSKhurram Burjees100% (1)

- PWPS - GTSM-73 Rev-ADocument5 pagesPWPS - GTSM-73 Rev-AVimin PrakashNo ratings yet

- Aux. Steam Distribution & Cond. Return Sys. Description: I.P.D.C. Project: Shirvan 6×159 M.W. Gas Turbine Power PlantDocument9 pagesAux. Steam Distribution & Cond. Return Sys. Description: I.P.D.C. Project: Shirvan 6×159 M.W. Gas Turbine Power PlantepbamdadNo ratings yet

- 2173 KG2 3eDocument2 pages2173 KG2 3eNistha ChakrabortyNo ratings yet

- NDT Procedures: Approved KJV NDT Procedures: Page 1 of 1Document1 pageNDT Procedures: Approved KJV NDT Procedures: Page 1 of 1Syed Mahmud Habibur RahmanNo ratings yet

- Notes: Notes:: CADD-02Document1 pageNotes: Notes:: CADD-02Samer YoussefNo ratings yet

- Welding Procedure Specification Joint Venture: Azzawiya Control System Modernization ProjectDocument4 pagesWelding Procedure Specification Joint Venture: Azzawiya Control System Modernization ProjectwentropremNo ratings yet

- SS312 Type310Document4 pagesSS312 Type310Vimin PrakashNo ratings yet

- Shutdown SIS: Truck 777D Truck 3Pr 777D Truck 3PR00001-UP (MACHINE) POWERED BY 3508 EngineDocument2 pagesShutdown SIS: Truck 777D Truck 3Pr 777D Truck 3PR00001-UP (MACHINE) POWERED BY 3508 EngineNijaz SarajlićNo ratings yet

- Weld Description Sheets and Weld MapsDocument13 pagesWeld Description Sheets and Weld MapsMohammad MushtaqNo ratings yet

- July QCD 4 121Document1 pageJuly QCD 4 121adma1No ratings yet

- CTG Hvac CalculationDocument27 pagesCTG Hvac CalculationAmmar Bany AtaNo ratings yet

- Rifox Float Trap VARIO1090Document2 pagesRifox Float Trap VARIO1090HemonNo ratings yet

- WPS GmawDocument2 pagesWPS Gmawasikur100% (6)

- WPS 856110.016 Rev 3Document1 pageWPS 856110.016 Rev 3laz_kNo ratings yet

- 50155-01-2-2 Gfs PDFDocument1 page50155-01-2-2 Gfs PDFJohn MaNo ratings yet

- SRV Detaisl Awa Salawas PDFDocument222 pagesSRV Detaisl Awa Salawas PDFdiwakarngm100% (1)

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345No ratings yet

- Ez01 CW04 Qbec Mec Mas 000074 - 3Document217 pagesEz01 CW04 Qbec Mec Mas 000074 - 3ahmed khalilNo ratings yet

- 03Document5 pages03ROboii FavelaNo ratings yet

- WPS AMC-0195 Rev 01Document3 pagesWPS AMC-0195 Rev 01umer.shariff87No ratings yet

- Welder Job Clearance Card::: ABC??? Welder Symbol ABC???Document1 pageWelder Job Clearance Card::: ABC??? Welder Symbol ABC???Anonymous 7eVc6RNo ratings yet

- PE-D-A06124222143-01-ME-DAS-015-01-E - Net Oil Storage Tanks - TFRJ-33-TK-1101A - BDocument7 pagesPE-D-A06124222143-01-ME-DAS-015-01-E - Net Oil Storage Tanks - TFRJ-33-TK-1101A - B7radu7No ratings yet

- WPS - 004Document12 pagesWPS - 004MAT-LIONNo ratings yet

- Company Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsDocument11 pagesCompany Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsMAT-LIONNo ratings yet

- Pump - Tpe3000 Thermal Oil HeaterDocument57 pagesPump - Tpe3000 Thermal Oil Heaterjadetorres100% (1)

- Groove DesignDocument4 pagesGroove DesignElizabeth SpenceNo ratings yet

- 50155-2-2 Gfs PDFDocument1 page50155-2-2 Gfs PDFJohn MaNo ratings yet

- Duct Catalogue Air-Ducts Jaber HospitalDocument75 pagesDuct Catalogue Air-Ducts Jaber HospitalGurvineet Singh Dhillon100% (1)

- 034-ITP For Air Cooled Steam Condenser PDFDocument41 pages034-ITP For Air Cooled Steam Condenser PDFKöksal PatanNo ratings yet

- Wps ExampleDocument2 pagesWps ExampleAnonymous stV08Js44VNo ratings yet

- Neo Structo Construction Limited Welding Procedure Specifications (WPS) (QW-200.1, SEC IX, ASME Boiler and Pressure Vessel Code)Document6 pagesNeo Structo Construction Limited Welding Procedure Specifications (WPS) (QW-200.1, SEC IX, ASME Boiler and Pressure Vessel Code)rohitbhat2345No ratings yet

- Caterpillar File InformationDocument5 pagesCaterpillar File InformationPancho GarcíaNo ratings yet

- Advanced and Refractory Ceramics for Energy Conservation and EfficiencyFrom EverandAdvanced and Refractory Ceramics for Energy Conservation and EfficiencyHua-Tay LinNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Advances in Solid Oxide Fuel Cells XFrom EverandAdvances in Solid Oxide Fuel Cells XMihails KusnezoffNo ratings yet