Professional Documents

Culture Documents

Centrifugal Pump Selection and Sizing

Centrifugal Pump Selection and Sizing

Uploaded by

RamkrishnaSutharCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Centrifugal Pump Selection and Sizing

Centrifugal Pump Selection and Sizing

Uploaded by

RamkrishnaSutharCopyright:

Available Formats

Centrifugal Pump Selection and Sizing

2009 Calgary Pump Symposium

Chris Gilmour, P.Eng.

Pump types being Considered

One and two stage centrifugal pumps

-

OH2, OH3/4, BB1, BB2

most common pumps used

Pumps not considered in this

presentation:

-

OH5 close-coupled VIL

OH6 high-speed integral gear VIL

vertically-suspended pumps

multi-stage centrifugal pumps

low-flow pumps (Ns < 500)

2

Pump types Vertical In-line Pump

Pump types Horizontal Overhung

Pump types Between-Bearing Pump

(radially split)

Pump types Between-Bearing Pump

(axially split)

Pump Selection Old School

Pump Selection

The Goal

We want to select and purchase pumps that

are:

Reliable

- Reasonably priced

- Efficient

-

What type of plant?

Class of Plant

Class 1 : low first cost, lower on-stream factor

- Class 2: a Class 1 plant with selective upgrades

- Class 3: higher first cost, higher on-stream factor

-

Construction (wrt pumps)

-

Modularized or not modularized

10

Pump Selection order of preference

1. Vertical inline pump

2. Horizontal Overhung Pump

3. Between Bearing Pump

11

Pump Selection

The smallest, least expensive, most

efficient pump is an overhung pump

(vertical inline, or horizontal overhung)

running at 3600 rpm

-

higher speed = smaller diameter for same head

higher speed = higher Ns = higher efficiency

smaller diameter = smaller casing size = less $

12

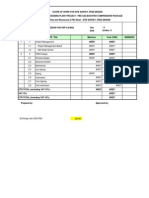

Relative Costs example 1

200 m3/h @ 150 m w/ >7m NPSHa (880

gpm @490 ft w/ > 23 ft NPSHa)

-

150 HP motor, single seal

Pum

size

rpm eff rel $ + Install $

p

OH3 4x6x13 3600 78% 1.00 base support

OH2 4x6x13 3600 78% 1.35 + fdn, grouting

BB2

4x6x13 3600 70% 2.30 +fdn, grouting

13

Relative Costs example 2

200 m3/h @ 150 m w/ 4m NPSHa (880

gpm @490 ft w/ 13 ft NPSHa)

-

150 HP motor, single seal

Pum

size

rpm eff rel $ + Install $

p

OH3 6x8x23 1800 66% 1.00 base support

OH2 6x8x23 1800 66% 1.07 + fdn, grouting

BB2

4x6x13 3600 70% 1.04 +fdn, grouting

14

Relative Costs example 3

200 m3/h @ 150 m w/ 4m NPSHa (880

gpm @490 ft w/ 13 ft NPSHa)

-

150 HP motor, dual seal w/ Plan 53a

Pum

size

rpm eff rel $ + Install $

p

OH3 6x8x23 1800 66% 1.00 base support

OH2 6x8x23 1800 66% 1.06 + fdn, grouting

BB2

4x6x13 3600 70% 1.33 +fdn, grouting

15

Why not always buy a 3600 rpm O/H

pump?

An O/H pump is not always available in

the size required

An O/H pump is not always an

appropriate selection

3600 rpm may not be an appropriate

speed for the process conditions

16

Overhung Pumps Typical Coverage

Pump

Size

(Dis x Suc)

1-1/2x3

2x3

3x4

4x6

6x8

8x10

10x12

12x16

16x20 *

20x24 *

Impeller Diameter (inches)

7

2

2

2

2

11

13

2,4

2,4

2,4

2,4

2,4

2,4

2,4

2,4

2,4

2,4

2,4

2,4

3600 rpm (2-pole)

1800 rpm (4-pole)

1200 rpm (6-pole)

15

2,4

2,4

2,4

4

17

20

23

27

4,6

4,6

4,6

4,6

4,6

4,6

4,6

4,6

4,6

4,6

4,6

4,6

4,6

4,6

4,6

4,6

4,6

4,6

30 *

6

6

6

* OH2 only

17

Overhung Pumps Typical Limits

Tip Speed

-

u = RPM/60 x PI x Diameter , units m/s, m

Issue is vibration

Typical limit is 62 m/s (205 ft/s) for Class 3 plant

- 13 diameter impeller at 3550 rpm

- 27 diameter impeller at 1750 rpm

Consider increasing for Class 1 plant

18

VIL Pumps Typical Limits

Tip Speed: issue is vibration

-

Typical limit is 62 m/s (205 ft/s) for Class 3 plant

- 13 diameter impeller at 3550 rpm

- 27 diameter impeller at 1750 rpm

Power: issue is vibration, reliability

-

Typical limits for Class 3 plant are:

- 200HP at 3600 rpm

- 400HP at 1800 rpm

- 600HP at 1200 rpm

Process Fluid Temperature: issues are shaft

sealing, bearing cooling, and motor cooling

-

Typical upper limit is 200 C (400F) for Class 3 plant

19

VIL Pumps: Bearing-bracket (OH3) type

Other considerations

How to lubricate the bearing bracket?

-

best is oil mist, if available

using oil in a vertical bearing bracket hasnt always

worked well, depends on the arrangement

grease is an option for cooler services, but requires

regular monitoring

20

VIL Pumps: Rigidly-coupled (OH4) type

Other considerations

Fluid-lubricated radial bearing

-

Motor shaft runout

-

need to consider the cleanliness and lubricating properties of

the fluid

requires tight tolerance on motor shaft runout

Reliability / seal life ?

some companies have had poor seal MTBR with these

pumps

- Shell Canada experience has been reasonably good

-

21

Pump Sizing

22

Specific Speed (Ns)

a dimensionless parameter describing geometric similarity

- evaluated at BEP, maximum diameter

- Ns = rpm x gpm^0.5 / ft^0.75 , use Q for double suction

- useful for sizing/selecting pumps

-

23

24

Specific Speed - Guidelines

typical process pumps have Ns between 500 and 1,800

- limited choices of supplier below 500

- pumps with Ns 1,800 2,400 are less desirable (reduced

range of acceptable operation)

- Pumps with Ns > 2,400 should be avoided

-

25

Suction Specific Speed (Nss)

-

a dimensionless parameter describing impeller eye geometry

evaluated at BEP, max diameter

Nss = rpm x gpm^0.5 / NPSHr^0.75 , use Q for double suction

impeller

consider this example: 500 gpm pump at 3550 rpm

- Nss = 9,000 when NPSHr = 18.2 ft

- Nss = 11,000 when NPSHr = 13.9 ft

- Nss = 13,000 when NPSHr = 11.2 ft

for the same pump, lower NPSHr achieved by one or more of:

- sharpening the impeller inlet edges

- increasing the impeller inlet area by: decreasing # of blades; and

/or, increasing blade inlet angle; and /or, increasing inlet area

26

Suction Specific Speed (Nss) - Guidelines

typical range is 7,000 to 16,000 (and higher)

higher Nss results in restricted range of acceptable operation

for pumps with Ns 500 1800, max Nss up to 11,000 is

acceptable

for pumps with Ns 1,800 2,400, max acceptable Nss should

be reduced to about 9,000

pumps with Ns above 2,400 should be avoided

27

Minimum Flow

Minimum flow issues:

-

temperature rise

internal recirculation

increased flow separation

increased pressure fluctuation

increased vibration levels (both radial and axial)

Avoiding these issues

-

method from WH Fraser (ref: Flow Recirculation in

Centrifugal Pumps, 1981 Texas A&M Turbomachinery

Symposium), ensure pump selection has acceptable range

(ie. operation at flows above onset of recirculation)

28

Minimum Flow - Guidelines

Recirculation (% of QBEP)

WH Fraser, "Flow Recirculation in Centrifugal Pumps"

Ns 500-2500

100.0

90.0

Multi-stage

80.0

Double-Suction

70.0

Single-Suction

60.0

50.0

6000

8000

10000

12000

14000

16000

18000

Nss (US customary units, at BEP)

for Q<2500 gpm and Hd<150 ft, use 50% of curve for continuous

and 25% for intermittent operation

for HC service, use 60 % for continuous and 25% for intermittent

operation

29

Limited Range at Higher Nss

S u c ti o n S p e c i fi c S p e e d

(rp m , g p m , ft)

Minimum Flow (single-suction impeller)

14000

13000

12000

11000

10000

9000

8000

7000

6000

Non-HC

HC

20

30

40

50

60

70

80

90

100

Q - % of BEP

30

Other Considerations

Nozzle Velocities typical limits

-

suction < 20 ft/s

discharge < 40 ft/s

Q-rated & Q-normal relative to BEP

-

typically Q-rated = Q-normal x 1.1, but sometimes

(eg. reflux service) Q-rated = Q-normal x 1.25

best is to straddle BEP with Q-normal and Q-rated,

especially if Q-rated >> Q-normal

- need to consider: NPSHa, min flow

31

1232

H e a d (ft)

739

1760

739

0

500

1232

1000

1500

1760

2000

50

45

40

35

30

25

20

15

10

5

0

2500

Full Diameter

95% Head

N P S H r (ft)

500

450

400

350

300

250

200

150

100

50

0

BEP

Q-min (non-HC)

Q-min (HC)

Qr=1.1xQn

Qr=1.25xQn

NPSHr

Flow (gpm)

32

Lets Size some pumps!

33

Equations & Correlations

Head, H = 2.31 x dP / SG , (ft, psi)

Sp Speed, Ns = N x Q^1/2 / H^3/4 , (rpm, gpm, ft)

Suc Sp Speed, Nss = N x Q^1/2 / NPSHr^3/4 , (rpm,

gpm, ft)

Head Coefficient, HC = H / (u^2 / 2g) , (ft, ft/s, ft/s^2)

-

methodology in The Pump Handbook,

Tip Speed, u = (H x 2g / HC)^0.5 , (ft/s, ft, ft/s^2)

Diameter, D = u x 12 / PI / (RPM/60) , (in, ft/s, rpm)

Power, P = H x Q x SG / (3960 x n) , (hp, ft, gpm)

From Curves: efficiency, expected nozzle size, min

flow

34

Estimating the Head Coefficient

using the correlations in The Pump Handbook, 2nd

edition, Karassik, et al, Ch 2.1

Head Coefficient vs Specific Speed

Head Coefficient

1.40

1600 m3/h

800 m3/h

1.20

400 m3/h

200 m3/h

1.00

100 m3/h

50 m3/h

0.80

0

500

1000

1500

2000

2500

Ns (rpm, gpm, ft)

35

Required Information

Require this info as a minimum:

-

flow, Q

head, H

NPSHa (or to know that it is ample)

Also desirable to know:

-

SG (to calculate power; assume = 1 if not provided)

viscosity (to check if viscous corrections are reqd)

HC or non-HC (for minimum flow calculation)

continuous or intermittent service (for min flow calc)

36

Worked Example: H= 170 ft, Q= 2000

gpm, NPSHa= 20 ft, water

rpm

1780

3550

3550 / dbl

Ns (=RPM x gpm^0.5 / ft^3/4)

1,876

3,742

2,646

< 9,000

17,800

12,586

Nss (=RPM x gpm^0.5/NPSH^3/4)

efficiency, from curve

0.84

0.83

Head Coeff, from curve

0.93

0.83

Tip Spd, fps, = (H x 2g /HC)^0.5

108.2

114.6

Dia, in, = u x 12 / PI / (RPM/60)

13.9

15.7

HP = H x Q x SG / (3960 x n)

102

103

Min Nozzle (suc 20 fps, dis 40 fps)

6x8

6x8

Min Flow (non-HC, continuous op)

58%

88%

37

Typical Casing Sizes

Q (GPM)

0

100

200

300

500

700

1000

1500

2000

2500

3500

4500

5500

7000

10000

Pump Speed

1160

1780

3x4

2x3

3x4

2x3

4x6

3x4

4x6

3x4

4x6

4x6

6x6

6x6

6x8

6x6

8x8

6x8

8x8

8 x 10

8 x 10

8 x 10

10 x 12

10 x 12

12 x 14

10 x 12

14 x 16

12 x 14

16 x 20

12 x 14

16 x 20

14 x 16

3550

1.5 x 2

1.5 x 2

2x3

3x4

4x6

4x6

6x6

6x6

6x8

8 x 10

38

Overhung Pumps Typical Coverage

Pump

Size

(Dis x Suc)

1-1/2x3

2x3

3x4

4x6

6x8

8x10

10x12

12x16

16x20 *

20x24 *

Impeller Diameter (inches)

7

2

2

2

2

11

13

2,4

2,4

2,4

2,4

2,4

2,4

2,4

2,4

2,4

2,4

2,4

2,4

3600 rpm (2-pole)

1800 rpm (4-pole)

1200 rpm (6-pole)

15

2,4

2,4

2,4

4

17

20

23

27

4,6

4,6

4,6

4,6

4,6

4,6

4,6

4,6

4,6

4,6

4,6

4,6

4,6

4,6

4,6

4,6

4,6

4,6

30 *

6

6

6

* OH2 only

39

40

Worked Example: H= 500 ft, Q= 4500

gpm, NPSHa= 20 ft, hydrocarbon

rpm

1160

1780

1780 / dbl

Ns (=RPM x gpm^0.5 / ft^3/4)

736

1,129

799

< 9,000

12,622

< 9,000

efficiency, from curve

0.77

0.84

0.77

Head Coeff, from curve

1.09

1.04

1.09

Tip Spd, fps, = (H x 2g /HC)^0.5

171.5

175.8

171.7

Dia, in, = u x 12 / PI / (RPM/60)

33.9

22.6

22.1

HP = H x Q x SG / (3960 x n)

741

677

742

Min Nozzle (suc 20 fps, dis 40 fps)

8 x 10

8 x 10

8 x 10

Min Flow (non-HC, continuous op)

35%

49%

40%

Nss (=RPM x gpm^0.5/NPSH^3/4)

41

Typical Casing Sizes

Q (GPM)

0

100

200

300

500

700

1000

1500

2000

2500

3500

4500

5500

7000

10000

Pump Speed

1160

1780

3x4

2x3

3x4

2x3

4x6

3x4

4x6

3x4

4x6

4x6

6x6

6x6

6x8

6x6

8x8

6x8

8x8

8 x 10

8 x 10

8 x 10

10 x 12

10 x 12

12 x 14

10 x 12

14 x 16

12 x 14

16 x 20

12 x 14

16 x 20

14 x 16

3550

1.5 x 2

1.5 x 2

2x3

3x4

4x6

4x6

6x6

6x6

6x8

8 x 10

42

Overhung Pumps Typical Coverage

Pump

Size

(Dis x Suc)

1-1/2x3

2x3

3x4

4x6

6x8

8x10

10x12

12x16

16x20 *

20x24 *

Impeller Diameter (inches)

7

2

2

2

2

11

13

2,4

2,4

2,4

2,4

2,4

2,4

2,4

2,4

2,4

2,4

2,4

2,4

3600 rpm (2-pole)

1800 rpm (4-pole)

1200 rpm (6-pole)

15

2,4

2,4

2,4

4

17

20

23

27

4,6

4,6

4,6

4,6

4,6

4,6

4,6

4,6

4,6

4,6

4,6

4,6

4,6

4,6

4,6

4,6

4,6

4,6

30 *

6

6

6

* OH2 only

43

44

Worked Example: H= 380 ft, Q= 1750

gpm, NPSHa= 8 ft, hydrocarbon

rpm

1160

1780

1780 / dbl

Ns (=RPM x gpm^0.5 / ft^3/4)

564

865

612

< 10,168

15,602

< 11,032

Nss (=RPM x gpm^0.5/NPSH^3/4)

efficiency, from curve

0.70

0.70

Head Coeff, from curve

1.0

1.02

Tip Spd, fps, = (H x 2g /HC)^0.5

156.4

155.0

Dia, in, = u x 12 / PI / (RPM/60)

30.9

20

HP = H x Q x SG / (3960 x n)

240

217

Min Nozzle (suc 20 fps, dis 40 fps)

6x6

6x6

Min Flow (non-HC, continuous op)

39%

49%

45

Worked Example: H= 380 ft, Q= 1750

gpm, NPSHa= 13 ft, hydrocarbon

rpm

1160

1780

1780 / dbl

Ns (=RPM x gpm^0.5 / ft^3/4)

564

865

612

< 9,000

10,905

< 9,000

efficiency, from curve

0.70

0.77

0.70

Head Coeff, from curve

1.0

1.05

1.02

Tip Spd, fps, = (H x 2g /HC)^0.5

156.4

152.4

155.0

Dia, in, = u x 12 / PI / (RPM/60)

30.9

19.6

20

HP = H x Q x SG / (3960 x n)

240

217

217

Min Nozzle (suc 20 fps, dis 40 fps)

6x6

6x6

6x6

Min Flow (non-HC, continuous op)

39%

42%

49%

Nss (=RPM x gpm^0.5/NPSH^3/4)

46

47

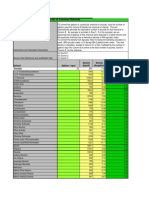

Sizing Spreadsheet

Arrange the calculations in a

spreadsheet

-

enter: Q, H, NPSHa, SG, viscosity

calculate all parameters for typical speeds (1150,

1750, 3550 rpm), and for single or double suction

impellers

- Ns, Nss, expected efficiency, diameter,

expected nozzle sizes, power

if ambitious, could also calculate: minimum flow,

suction energy, viscosity corrections, motor sizes,

etc

48

Buying Pumps Marrying the Hydraulic Selections with the

Pump Standards

49

Pump Standards (North American)

API 610 for heavy duty pumps

ASME/ANSI B73.1 and B73.2

standards, essentially dimensional

interchangeability standards for

chemical process pumps

Hydraulic Institute (HI) standards for

general service pumps

50

Pump Standards - Applicability

API 610

VIL

Hor O/H

Btwn Brg

ANSI B73.1

ANSI B73.2

Hydr Inst

(HI)

Y

51

General Info - API 610-10th

Per (5.3.5) minimum casing pressure design

conditions are 600 psig at 100 F (4000 kPag at 38 C),

or at least a Class 300 flange rating per B16.5

Per (5.3.9), radially split casings are required for:

T > 200C

- flammable or hazardous fluid with SG < 0.7 at pumping temp

- flammable or hazardous fluid at rated P-dis > 100 bar

-

Per (5.3.11), centre-line mounting required, except

that per (8.2.1.2) between-bearing pumps with T <

150C may be foot mounted

Per (8.1.2.7), the bearing housing temp for grease

lubricated OH3 pumps shall be <= 82C at T-amb of

43C

52

General Info ANSI/ASME B73 pumps

Casing pressure-temperature rating per B16.5

Class 150 flange rating

Typical application limits (per API 610 8th ed)

-

service is non-flammable and non-toxic

P-dis <= 19 barg, P-suc <= 5 barg

T-max <= 150 C

Head <= 120 m

N <= 3600 rpm

diameter <= 330 mm (13 in) for overhung pumps

Typical Company limits

Low process-fluid temperature limit

- Driver size limit for Vertical inline pumps

-

53

ANSI B73.1 Typical Coverage

ANSI

Pump

Size

(Dis x Suc)

1x1-1/2

1-1/2x3

2x3

3x4

4x6

6x8

8x10

Impeller Diameter (inches)

6

2,4

2,4

2,4

2,4

2,4

2,4

2,4

10

13

15

17

2,4

2,4

2,4

2,4

2,4

2,4

2,4

4

4

4

4

4

4

4

4

4

VIL Pump Coverage

2 = 3600 rpm (2-pole)

4 = 1800 rpm (4-pole)

ref: B73.1, Table 4 "Approximate Performance

Standards for Pumps (60 hz)"

54

What type of plant?

Class of Plant

Class 1 : low first cost, lower on-stream factor

- Class 2: a Class 1 plant with selective upgrades

- Class 3: higher first cost, higher on-stream factor

-

Construction (wrt pumps)

-

Modularized or not modularized

55

Questions?

56

You might also like

- Pump Knowledge - Centrifugal Pump Part 1Document61 pagesPump Knowledge - Centrifugal Pump Part 1surawutwijarnNo ratings yet

- CTR-InPK Fertilizer Plant Project-FEED DesignDocument7 pagesCTR-InPK Fertilizer Plant Project-FEED DesignNoman Abu-FarhaNo ratings yet

- Centrifugal - Pump - Hand Book PDFDocument150 pagesCentrifugal - Pump - Hand Book PDFbarun1977100% (1)

- Pump SelectionDocument14 pagesPump Selectionas3ateNo ratings yet

- PRV-1 StepxStep PDFDocument8 pagesPRV-1 StepxStep PDFmiltonNo ratings yet

- Hydraulic CalculationsDocument12 pagesHydraulic CalculationsIsmid Maulana100% (1)

- Designing Compressed Air SystemsDocument8 pagesDesigning Compressed Air SystemsZaki AnwerNo ratings yet

- Pump SpecificationDocument1 pagePump SpecificationFrancis FeiNo ratings yet

- Project Report On Gear PumpDocument20 pagesProject Report On Gear PumpSunil Kumar Yadav100% (3)

- The Solar Inverter For Grid Connected PV SystemsDocument12 pagesThe Solar Inverter For Grid Connected PV Systemssalem BEN MOUSSANo ratings yet

- Fluid Power FormulasDocument7 pagesFluid Power FormulasKiran Kumar K TNo ratings yet

- Goulds-Pumps Fundamentals PDFDocument140 pagesGoulds-Pumps Fundamentals PDFAgustinus Made Theo Dwijaya100% (2)

- Centrifugal Pumps & Fluid Flow Practical Calculations: Pdhonline Course M388 (3 PDH)Document53 pagesCentrifugal Pumps & Fluid Flow Practical Calculations: Pdhonline Course M388 (3 PDH)Prad1979100% (6)

- Pump CalculationsDocument9 pagesPump CalculationsMohamad TantawyNo ratings yet

- Pump SelectionDocument112 pagesPump SelectionSIVAPATHASEKARAN100% (6)

- (Oto-Hui - Com) en - Hydraulic CoursesDocument47 pages(Oto-Hui - Com) en - Hydraulic Courseseng_ebrahim_2000100% (1)

- Boiler Feed Water Pump Inspection at Jubail TM.P. Workshop PDFDocument17 pagesBoiler Feed Water Pump Inspection at Jubail TM.P. Workshop PDFAlaina Hood100% (1)

- How to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesFrom EverandHow to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesRating: 5 out of 5 stars5/5 (1)

- NPSHDocument17 pagesNPSHcrazynup100% (2)

- How To Size A PumpDocument90 pagesHow To Size A PumpDaani Olora100% (5)

- Suction Side of Centrifugal PumpsDocument11 pagesSuction Side of Centrifugal PumpsTanishk KumarNo ratings yet

- Centrifugal Pump Selection and SizingDocument50 pagesCentrifugal Pump Selection and SizingmariasofiarossiNo ratings yet

- Pump NotesDocument9 pagesPump NotesGauravNo ratings yet

- 090768.232 3.00 018 A e - ADocument111 pages090768.232 3.00 018 A e - ANoman Abu-FarhaNo ratings yet

- Centrifugal Pump Design - Rev 2Document11 pagesCentrifugal Pump Design - Rev 2jehadyam100% (1)

- Two Phase Separator SizingDocument5 pagesTwo Phase Separator SizingNoman Abu-FarhaNo ratings yet

- NPSH - A Calculation SheetDocument1 pageNPSH - A Calculation SheetjakjakNo ratings yet

- Centrifugal Pump Sizing, Selection and Design Practices (Hay)Document77 pagesCentrifugal Pump Sizing, Selection and Design Practices (Hay)Scribd_del75% (8)

- Pump CurvesDocument8 pagesPump CurvesKrishna Chaitanya KalagaNo ratings yet

- Pumps CalculationDocument16 pagesPumps CalculationEkundayo JohnNo ratings yet

- Centrifugal Pump Affinity Law-BDHDocument14 pagesCentrifugal Pump Affinity Law-BDHMachineryengNo ratings yet

- Velocity of Compressed AirDocument1 pageVelocity of Compressed AirLucky Karunia Setyawan PratamaNo ratings yet

- Skills Workshop: Centrifugal PumpDocument3 pagesSkills Workshop: Centrifugal PumpchayanunNo ratings yet

- How To Size A Pump Blackmonk Engineering PDFDocument9 pagesHow To Size A Pump Blackmonk Engineering PDFRajesh KrishnamoorthyNo ratings yet

- PDOC-596-PEP-01 Project Execution Plan (Rev 3)Document89 pagesPDOC-596-PEP-01 Project Execution Plan (Rev 3)Noman Abu-Farha100% (2)

- NPSH For Metering PumpsDocument7 pagesNPSH For Metering PumpsRahul S. ChandrawarNo ratings yet

- BoilerDocument45 pagesBoilerEr Prem PrincepsNo ratings yet

- Navigating Pump CurvesDocument7 pagesNavigating Pump Curvescastingforge4875No ratings yet

- 6.pumps and Pumping SystemsNDocument35 pages6.pumps and Pumping SystemsNRanjani J DeepakNo ratings yet

- AFBC Cold Startup ProcedureDocument4 pagesAFBC Cold Startup ProcedureManimaran Guna100% (1)

- Centrifugal Pump DesignDocument15 pagesCentrifugal Pump Designzakibrant23No ratings yet

- Siemens Steam TurbinesDocument8 pagesSiemens Steam TurbinesDario StefaniNo ratings yet

- API Vs ANSI PumpsDocument6 pagesAPI Vs ANSI PumpsRS100% (2)

- 11-4080 HYSYS Relief Valve Sizing Demo Guide FinalDocument18 pages11-4080 HYSYS Relief Valve Sizing Demo Guide FinalNoman Abu-FarhaNo ratings yet

- API 610 Pump Selection and Curve EvaluationDocument4 pagesAPI 610 Pump Selection and Curve EvaluationbbmokshNo ratings yet

- Parker (T6, T6CC) Hydraulic Vane PumpsDocument12 pagesParker (T6, T6CC) Hydraulic Vane PumpsEduardo Valladares DuranNo ratings yet

- Fan Performance CurveDocument4 pagesFan Performance CurvemuddogNo ratings yet

- PumpsDocument46 pagesPumpsRiyadh SalehNo ratings yet

- Basic Pump FundamentalDocument99 pagesBasic Pump FundamentalJimit Shah100% (1)

- ME ProductCatalogDocument20 pagesME ProductCatalogNoman Abu-FarhaNo ratings yet

- Emerging Technologies and Material ChallengesDocument70 pagesEmerging Technologies and Material ChallengesJohn HarlandNo ratings yet

- Pump Training 1Document45 pagesPump Training 1Anonymous CMS3dL1T100% (1)

- 06-Pump Fundamentals & SpecialApplicationsDocument41 pages06-Pump Fundamentals & SpecialApplicationsmatias_ignacioNo ratings yet

- Impeller - KSBDocument6 pagesImpeller - KSBEd0% (1)

- Sulzer Centrifugal Pumps - Basic OperationDocument26 pagesSulzer Centrifugal Pumps - Basic OperationMarcelo PerettiNo ratings yet

- NPSH Calculation Spreadsheet With Sample Looses Values in MetersDocument11 pagesNPSH Calculation Spreadsheet With Sample Looses Values in Meterserjainrachit50% (2)

- Blow-Down Procedure For Marine Boilers PDFDocument7 pagesBlow-Down Procedure For Marine Boilers PDFRejoGevargheseRajanNo ratings yet

- Plant Air SystemDocument7 pagesPlant Air SystemAnuj ShahiNo ratings yet

- Selection of Pumps For Process IndustriesDocument6 pagesSelection of Pumps For Process IndustriesgermankrebsNo ratings yet

- Grundfos Submersible Pumps Data BookDocument100 pagesGrundfos Submersible Pumps Data BookonspsnonsNo ratings yet

- B&W HRSG OverviewDocument8 pagesB&W HRSG OverviewAnonymous xaayU9b9GNo ratings yet

- Acrylic Acid and Derivatives: Ullmann's Encyclopedia of Industrial ChemistryDocument18 pagesAcrylic Acid and Derivatives: Ullmann's Encyclopedia of Industrial ChemistryNoman Abu-FarhaNo ratings yet

- Method of Heat Exchanger Sizing (Kern Method)Document11 pagesMethod of Heat Exchanger Sizing (Kern Method)Hani Kirmani80% (5)

- Pump FundamentalsDocument127 pagesPump FundamentalsSheik Mohd50% (2)

- What's Correct For My Application A Centrifugal or Reciprocating Compressor PDFDocument10 pagesWhat's Correct For My Application A Centrifugal or Reciprocating Compressor PDFRapee PuaksungnoenNo ratings yet

- ALARKO CirculationPump PDFDocument8 pagesALARKO CirculationPump PDFAlienshowNo ratings yet

- SQ - 4.7 - Pumps (Table Format)Document5 pagesSQ - 4.7 - Pumps (Table Format)Amitav MishraNo ratings yet

- Transfer Pump BrochureDocument12 pagesTransfer Pump BrochureRafert RamNo ratings yet

- Grundfos SP SubmersibleDocument108 pagesGrundfos SP SubmersiblemitualvesNo ratings yet

- SV80-100 Eng Data1-1996Document9 pagesSV80-100 Eng Data1-1996Bala Krishnan NataNo ratings yet

- Calculation For Suction Specific SpeedDocument2 pagesCalculation For Suction Specific SpeedAnam FatimaNo ratings yet

- 21 5 1710Document31 pages21 5 1710Ton PhichitNo ratings yet

- PumpsDocument32 pagesPumpsAngela Paul PeterNo ratings yet

- 29 CarburetionDocument48 pages29 CarburetionABNo ratings yet

- 0304Document14 pages0304Hair Samayoa BrionesNo ratings yet

- Vessel VolumesDocument72 pagesVessel VolumeskanchanabalajiNo ratings yet

- Sulphuric Acid HandbookDocument268 pagesSulphuric Acid HandbooklemeitNo ratings yet

- Gasifiers DatabaseDocument44 pagesGasifiers DatabaseNoman Abu-FarhaNo ratings yet

- Nominalmonthlycountryexchangerates 1Document121 pagesNominalmonthlycountryexchangerates 1Noman Abu-FarhaNo ratings yet

- 4T16 Project Execution Plan Checklist v4-0Document2 pages4T16 Project Execution Plan Checklist v4-0Noman Abu-Farha100% (1)

- Steam Turbines: Prof. Osama El MasryDocument13 pagesSteam Turbines: Prof. Osama El MasryNoman Abu-Farha100% (1)

- Cost EstimationDocument12 pagesCost EstimationNoman Abu-FarhaNo ratings yet

- Piping Considerations - Maximum Fluid Velocity: Friction LossDocument1 pagePiping Considerations - Maximum Fluid Velocity: Friction LossNoman Abu-FarhaNo ratings yet

- FlangesDocument7 pagesFlangesNoman Abu-FarhaNo ratings yet

- Kich Glitch Inlet NozzleDocument2 pagesKich Glitch Inlet NozzleNoman Abu-FarhaNo ratings yet

- Two Phase Flow RegimeDocument8 pagesTwo Phase Flow RegimeNoman Abu-FarhaNo ratings yet

- Gallons Pounds ConversionDocument17 pagesGallons Pounds ConversionNoman Abu-FarhaNo ratings yet

- Assignment 2Document2 pagesAssignment 2Faiz TaimuriNo ratings yet

- Rotary Screw Compressor Units: MODELS: RXF-12 Through RXF-101Document56 pagesRotary Screw Compressor Units: MODELS: RXF-12 Through RXF-101Miguel SoteloNo ratings yet

- Data For Experiment No. 10 Application of Bernoulli Principle in Pipe SystemsDocument1 pageData For Experiment No. 10 Application of Bernoulli Principle in Pipe SystemsPoochi DougNo ratings yet

- CarburetorDocument19 pagesCarburetorSelazinap LptNo ratings yet

- OkloDocument4 pagesOkloSHH 1018No ratings yet

- r05 412410 - Alternative Energy Sources For AutomobilesDocument4 pagesr05 412410 - Alternative Energy Sources For AutomobilesSRINIVASA RAO GANTANo ratings yet

- CyrogenicDocument4 pagesCyrogenicBayu SaputraNo ratings yet

- Modelling Flexible Power Demand and Supply in The EU Power System: Soft-Linking Between JRC-EU-TIMES and The Open-Source Dispa-SET ModelDocument13 pagesModelling Flexible Power Demand and Supply in The EU Power System: Soft-Linking Between JRC-EU-TIMES and The Open-Source Dispa-SET ModelAlex GNo ratings yet

- Renewable Energy: Keum Soo Jeon, Jun Ik Jeong, Jae-Kyung Pan, Ki-Wahn RyuDocument10 pagesRenewable Energy: Keum Soo Jeon, Jun Ik Jeong, Jae-Kyung Pan, Ki-Wahn Ryuhasybi abiNo ratings yet

- x4 - On-Load Boiler Cleaning With SteamDocument21 pagesx4 - On-Load Boiler Cleaning With SteamKan ChoraNo ratings yet

- SFFECO Fire PumpDocument17 pagesSFFECO Fire PumpAnjamul Hoque AnandaNo ratings yet

- PompaDocument71 pagesPompa3C10Iqbal Miftachul FalahNo ratings yet

- QGD55 75风冷外形图Document1 pageQGD55 75风冷外形图RUN GONo ratings yet

- An Introduction To Jet Propulsion (Mme 4071 PPT-1)Document20 pagesAn Introduction To Jet Propulsion (Mme 4071 PPT-1)Peter GeorgeNo ratings yet

- Interio 22 IngDocument45 pagesInterio 22 IngMalik RonaldoNo ratings yet

- Comparison FM Vs ATEX Flow Chart PDFDocument1 pageComparison FM Vs ATEX Flow Chart PDFGoogool YNo ratings yet

- Taller 2Document5 pagesTaller 2Lina Marcela Ariza LopezNo ratings yet

- Smokjet: RZ - Smokjet - 0105 - Ifr - Uk - Indd 1Document14 pagesSmokjet: RZ - Smokjet - 0105 - Ifr - Uk - Indd 1PiotrekBzdręgaNo ratings yet

- Kathmandu University Dhulikhel Kavre: Term Paper AboutDocument4 pagesKathmandu University Dhulikhel Kavre: Term Paper AboutAayusha BhattaraiNo ratings yet

- Colibri StorkDocument4 pagesColibri Storkbruce1312No ratings yet

- Resume-Selcio PaulinaDocument2 pagesResume-Selcio PaulinaSélcio PaulinaNo ratings yet

- Blocking Diode and Bypass Diode For Solar PanelsDocument8 pagesBlocking Diode and Bypass Diode For Solar Panelsvihan shahNo ratings yet