Professional Documents

Culture Documents

Steel Work Inspection Report

Uploaded by

Ahmad HasnanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Steel Work Inspection Report

Uploaded by

Ahmad HasnanCopyright:

Available Formats

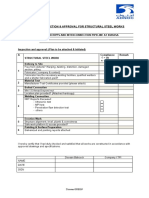

RECORD OF INSPECTION & APPROVAL FOR STRUCTURAL STEEL WORKS

Project Ref. No.:

Project Title:

Inspection and approval: (Plan to be attached & initiated)

A

STRUCTURAL STEEL WORK

Compliance

= ok

x = Not ok

Delivery to Site

Free from defects? Warping, twisting, distortion, damaged

section, pitting

Fabricator ( company & contact)

Fabricator has the necessary welding facilities, qualified welders

and a shelter fabrication yard?

Structural Steel

Grade of Steel

Hot rolled / cold-formed (please circle)

Cutting & Steel section dimension (D x B X L)

Thickness (Flange & Web)

Steel markings provided

Stiffener plates as per drawing?

Material Test ( BC1:2008 Design Guide on Use of alternative steel

Materials to BS 5950 )

Class of certified steel: Class 1 / 2 (please circle)

Factory production Control Certificates provided (please attach)

Manufacturer Test Certificates provided (please attach)

If Class 2 certified steel materials used:

a) Please indicate the type & country of origin:

b) Comply to material testing required by BC1 (App. B)? (please

submit report )

c) Frequency of material testing comply to BS EN10025-2:2004?

(please attach)

Any non-certified Steel used? (country of origin)

If so, what action has been taken? Rejected / Highlighted to QP

for follow up (pls circle)

Independent strength tests by certified ISO tester/ ITA (please

submit report)

Is the laboratory accredited by SAC-SINGLAS?

Form SSS steel structures- edited 10/2/09

Y/N

Remark

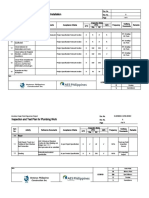

Bolted Connection

Bolt grade & type conform to BS4190

Bolts dimension (diameter x length)

Washer grade & type

Connection joints/splice joints constructed as per drawings

Bolts tightened to correct torque

Min 1.5 thread beyond nut

Any defects? (eg Tilted bolts / holes enlarged by torch cutting)

What is the remedy action (Attached report)?

Y/N

Embedment length and arrangement of holding down bolts

Location plan provided? (Attached hardcopy)

5

Welding Connection

Size & length of weld according to approved plan & specifications

Welding electrode strength comply with BS639

Weld surface clean & free from dust, rust & scales

Qualified welder & certificate provided

Any welding defects? (eg Undercuts, pits, surface cracks, lack of

fusion) What is the remedy action (Attached report)?

Y/N

Welding test (%) :

- Ultrasonic test

- MPI test

- Radiographic test

- Penetration flaw detection test

- others

Location plan provided

For welding test failures, any remedial action taken?

6

Erection Work

PE design & Certificate of Supervision for temporary structure,

support bracings tie backs are submitted

Structure alignment, level, plumb & correctness

Erection sequence is in accordance to PE design

Safe work platform & access provided?

Form SSS steel structures- edited 10/2/09

Y/N

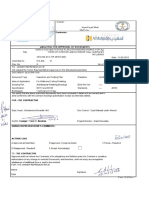

Painting & Surface Preparation

Steel area thoroughly cleaned, scraped, wire-brushed/sand

blasted, free from rust & scale before printing?

Galvanized steel hot dipped to SS117 requirements?

Galvanized steel / Surface painted to QPs specifications?

Corrosion and Fire Protection

Specifications and thickness of material according to approved

plan and specifications

Protection such as coatings and fire protection coatings be evenly

applied and no damages to the coatings.

I hereby certify that I had duly checked and satisfied that all works are constructed in accordance with

approved drawings and specifications.

________________________________________

Name & Signature of Builder's site representatives

Date: _______________

Approve/ Disapprove

__________________________________

Name & Signature of Resident Engineer

/ Resident Technical Officer

Date: _______________

Form SSS steel structures- edited 10/2/09

You might also like

- Structural Steel Fabrication ChecklistDocument1 pageStructural Steel Fabrication ChecklistHoque Anamul82% (11)

- Structural Steel Inspection ReportDocument2 pagesStructural Steel Inspection ReportAnnaNo ratings yet

- Structural Steel Inspection Report01Document2 pagesStructural Steel Inspection Report01JM PerezNo ratings yet

- Structural Steel Inspection Report01Document1 pageStructural Steel Inspection Report01JobJob100% (1)

- Structural Steel Inspection ReportDocument2 pagesStructural Steel Inspection Reportsj_scribd84% (38)

- Steel ChecklistDocument2 pagesSteel ChecklistBruce Weathers100% (8)

- Structural Steel Checklist 17Document2 pagesStructural Steel Checklist 17mgb2010hotmailcomNo ratings yet

- Steel Structure Fabrication Inspection ReportDocument1 pageSteel Structure Fabrication Inspection ReportFerhan Dikilitaş86% (14)

- Structural Steel Erection ChecklistDocument3 pagesStructural Steel Erection ChecklistRini ButarbutarNo ratings yet

- Fabrication & Erection of Steel Works ChecklistDocument1 pageFabrication & Erection of Steel Works ChecklisttaghlubNo ratings yet

- ITP - Fabrication of Structural SteelDocument2 pagesITP - Fabrication of Structural Steelsahad100% (6)

- Steel Structure Checklist: Items to InspectDocument1 pageSteel Structure Checklist: Items to InspectbambaeeroNo ratings yet

- Itp For Fabrication Steel Structure of Warehouse and WorkshopDocument6 pagesItp For Fabrication Steel Structure of Warehouse and WorkshopPhong Do100% (1)

- HOSSAINDocument2 pagesHOSSAINHoque AnamulNo ratings yet

- Steel Fabrication Method StatementDocument12 pagesSteel Fabrication Method Statementvolcanox1288% (59)

- Steel Erection ChecklistDocument2 pagesSteel Erection Checklistkfctco100% (3)

- Structural Steel ErectionDocument8 pagesStructural Steel Erectionbratishkaity100% (1)

- Method Statement For Steel Structure & Erection PDFDocument16 pagesMethod Statement For Steel Structure & Erection PDFDomie Neil Bucag Salas83% (24)

- Checklist For Rebar (Columns, Neck Columns and Plinth Wall) : QA/QC RequirementsDocument1 pageChecklist For Rebar (Columns, Neck Columns and Plinth Wall) : QA/QC Requirementsmanoj100% (1)

- Fabrication Division QMDDocument11 pagesFabrication Division QMDRakesh RanjanNo ratings yet

- Structural Steel Work Check ListDocument1 pageStructural Steel Work Check ListAhmad Bilal100% (1)

- Method Statement For Cold GalvanizationDocument1 pageMethod Statement For Cold GalvanizationsaravanakumarpalaniNo ratings yet

- Check List of Steel Structure ErectionDocument1 pageCheck List of Steel Structure ErectionUtku Can Kılıç50% (2)

- ITP Check List For Metal Deck InstallationDocument2 pagesITP Check List For Metal Deck InstallationLeo PascualNo ratings yet

- Method Statement of Steel FabricationDocument15 pagesMethod Statement of Steel Fabricationjohney290% (10)

- Precast Building ChecklistDocument4 pagesPrecast Building ChecklistSasala Raju100% (1)

- Jabali Project Steel Structure ErectionDocument26 pagesJabali Project Steel Structure ErectionNick LawNo ratings yet

- Material Inspection Report (Steel) FormDocument1 pageMaterial Inspection Report (Steel) Formfoxeylady80% (15)

- Inspection Test Plan ITP Painting WorksDocument4 pagesInspection Test Plan ITP Painting WorksMichael AntipuestoNo ratings yet

- Anchor Bolt ProcedureDocument7 pagesAnchor Bolt ProcedureAthanasius Kurniawan Prasetyo Adi100% (1)

- CHECKLIST FOR PLASTER PREPARATIONDocument1 pageCHECKLIST FOR PLASTER PREPARATIONMani AppaNo ratings yet

- Method Statement For Steel ErectionDocument15 pagesMethod Statement For Steel Erectionstrikersam95% (20)

- Erection Quality ChecklistsDocument22 pagesErection Quality ChecklistsdaxNo ratings yet

- Field Welding Inspection Checklist: Wisconsin Department of TransportationDocument1 pageField Welding Inspection Checklist: Wisconsin Department of Transportationandreafaith biatingoNo ratings yet

- Steel Structures Installation Procedure and Method StatementDocument6 pagesSteel Structures Installation Procedure and Method StatementOussama Sissaoui100% (1)

- Method Statement No: 04 Fabrication and Installation of Steel Structure SUPPORT (SPS-B065-099) FOR 52-K0624Document9 pagesMethod Statement No: 04 Fabrication and Installation of Steel Structure SUPPORT (SPS-B065-099) FOR 52-K0624Azel Bumagat94% (18)

- Inspection & Test Plan For DrywallDocument2 pagesInspection & Test Plan For Drywallexia1992100% (1)

- Structural Steel Inspection Report Record Number: Date: Project Number: Project Name: Unit/Area: System: Work Package Number: Building: Description: Reference Document No. Rev. No. RemarksDocument2 pagesStructural Steel Inspection Report Record Number: Date: Project Number: Project Name: Unit/Area: System: Work Package Number: Building: Description: Reference Document No. Rev. No. Remarkscherif yahyaoui100% (1)

- ITP For Drywall & Furring Wall InstallationDocument2 pagesITP For Drywall & Furring Wall Installationexia1992100% (1)

- Quality Control Procedure Strcture-SSDocument16 pagesQuality Control Procedure Strcture-SSKamran AliNo ratings yet

- Erection and Painting of Steel StructureDocument11 pagesErection and Painting of Steel StructureomarcadNo ratings yet

- Barkat Infraprojects: Checklist Fabrication / Fixing of Structural SteelDocument1 pageBarkat Infraprojects: Checklist Fabrication / Fixing of Structural SteelZahid SayyedNo ratings yet

- Marriot Grand Ballroom Concrete Works: Project Title: Contract Package No. 02Document9 pagesMarriot Grand Ballroom Concrete Works: Project Title: Contract Package No. 02Imho TepNo ratings yet

- Structural Steel Painting Inspection ChecklistDocument3 pagesStructural Steel Painting Inspection Checklistajit karandikar78% (9)

- Painting Checklist Daily QaDocument2 pagesPainting Checklist Daily QaJaun Viviers100% (2)

- Inspection and Test Plan For Seel StructureDocument3 pagesInspection and Test Plan For Seel StructureChris McNairNo ratings yet

- Itp PlasteringDocument7 pagesItp PlasteringJervino RuahNo ratings yet

- Steel Checklist AuditDocument2 pagesSteel Checklist AuditsandipNo ratings yet

- Steel Structures Erection Method Statement-DraftDocument43 pagesSteel Structures Erection Method Statement-DraftMahmoud Fakhereddin100% (1)

- Itp For Steel Structure Erection (Content) Rev.1Document3 pagesItp For Steel Structure Erection (Content) Rev.1Anonymous nLMJGu100% (5)

- AASHTHO Road DesignDocument7 pagesAASHTHO Road DesignDilbert ScottNo ratings yet

- Vproject Rzzef. Nvo.: V Title:: (Bc1:2008 Design Guide On Use of Alternative Steel Materials To Bs 5950)Document3 pagesVproject Rzzef. Nvo.: V Title:: (Bc1:2008 Design Guide On Use of Alternative Steel Materials To Bs 5950)dweko1No ratings yet

- Structural Steel WorkDocument4 pagesStructural Steel WorkNick LawNo ratings yet

- Division 5 5000Document10 pagesDivision 5 5000Luis Gabriel BautistaNo ratings yet

- GratingsDocument3 pagesGratingssaurabhsubhuNo ratings yet

- Uniform General Conditions For Construction Contracts, State of Texas, 2010 (UGC) - ConstructionDocument13 pagesUniform General Conditions For Construction Contracts, State of Texas, 2010 (UGC) - ConstructionTaher AmmarNo ratings yet

- ST Structural Steel FramingDocument45 pagesST Structural Steel Framingwookie1977100% (1)

- Specifications:: 1 Project Site Information & Intent of SpecificationDocument8 pagesSpecifications:: 1 Project Site Information & Intent of Specificationardee pashamylaramNo ratings yet

- SECTION 051200 Structural Steel Part 1 - GeneralDocument8 pagesSECTION 051200 Structural Steel Part 1 - GeneralBrijithNo ratings yet

- 3.2 Standard1Document1 page3.2 Standard1Thi PhamNo ratings yet

- PLTG 45MW - Equipment ComparisonDocument32 pagesPLTG 45MW - Equipment ComparisonAhmad HasnanNo ratings yet

- 3phase Single Line DiagramDocument1 page3phase Single Line DiagramAhmad Hasnan100% (1)

- Infrastruktur: Jurnal Teknik SipilDocument8 pagesInfrastruktur: Jurnal Teknik SipilAhmad HasnanNo ratings yet

- Pressure Vessel ITP Rev 0Document21 pagesPressure Vessel ITP Rev 0Ahmad HasnanNo ratings yet

- Aplikasi CFD MultiphaseDocument7 pagesAplikasi CFD MultiphaseAhmad HasnanNo ratings yet

- 2 - Electrical Energy Audit PDFDocument10 pages2 - Electrical Energy Audit PDFPrachi BhaveNo ratings yet

- Max Torque, Gammax (N-MM) Max Speed, Wmax (RPM, Rad/sec) Torque Speed Slope Constant, K WincDocument9 pagesMax Torque, Gammax (N-MM) Max Speed, Wmax (RPM, Rad/sec) Torque Speed Slope Constant, K WincAhmad HasnanNo ratings yet

- PFD PipelineDocument1 pagePFD PipelineAhmad HasnanNo ratings yet

- Site Inspection ReportDocument45 pagesSite Inspection ReportAhmad HasnanNo ratings yet