Professional Documents

Culture Documents

ASME Comparison

ASME Comparison

Uploaded by

Jaroslav KurucOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ASME Comparison

ASME Comparison

Uploaded by

Jaroslav KurucCopyright:

Available Formats

Comparison: ASME B31.1 to ASME B31.

A Comparison:

ASME B31.1 Power Piping

versus

ASME B31.3 Process Piping

Don Frikken, PE

BECHT ENGINEERING COMPANY, INC.

Topics Discussed

B31 History

Scopes

Organization of the Codes

Bases for Allowable Stresses

Piping Component Standards

Fluid Service Requirements

Material Requirements

Pressure Design

g

Flexibility Analysis

Fabrication and Installation

Inspection, Examination and Testing

BECHT ENGINEERING COMPANY, INC.

Comparison: ASME B31.1 to ASME B31.3

B31 History

In the mid

1800s, boiler

explosions were

occurring at the

rate of one

every four days

On April 27,

1865 the boiler

explosion on the

Sultana killed

1800 returning

civil war soldiers

From 1898 to 1903, more than 1200 people were killed

in the U.S. in 1900 separate boiler explosions. The

catastrophic explosion of a fire tube boiler in a factory

in Brockton, Massachusetts, in 1905 killed 58 people

BECHT ENGINEERING COMPANY, INC.

Introduction - 3

B31 History

ASME formed a committee to address the boiler

explosion problem - 1911

ASME Boiler and Pressure Vessel Code

(BPVC) was the first comprehensive standard

for the design, construction, inspection, and

testing of boilers and pressure vessels - 1915

American Standards Institute initiated a project

to develop a piping code - 1926

American Tentative Standard code for Pressure

Piping 1935

Separate sections were split off starting in 1955

BECHT ENGINEERING COMPANY, INC.

Introduction - 4

Comparison: ASME B31.1 to ASME B31.3

B31 Piping Codes

PIPELINE CODES

B31.4 Liquid Transportation Pipelines

B31.8 Gas Transportation Pipelines

B31.11 Slurry Transportation Pipelines

BECHT ENGINEERING COMPANY, INC.

Introduction - 5

B31 Piping Codes

PIPING CODES

B31.1 Power Piping

B31.3 Process Piping

B31.5 Refrigeration Piping

B31.9 Building Services Piping

BOTH

B31.12 Hydrogen

Piping and Pipelines

BECHT ENGINEERING COMPANY, INC.

Introduction - 6

Comparison: ASME B31.1 to ASME B31.3

B31 Piping Codes

Each Code provides a set of requirements

f obtaining

for

bt i i a safe,

f reliable

li bl and

d

economical installation.

The designer is cautioned that the Code

is not a design handbook; it does not

eliminate the need for the designer or for

competent engineering judgment.

BECHT ENGINEERING COMPANY, INC.

Introduction - 7

ASME Piping System Standards

BPE-1

BPE

1

Bioprocessing Equipment

PVHO-1 Pressure Vessels for Human

Occupancy

B&PV Code, Section III for Nuclear Power

Plants

BECHT ENGINEERING COMPANY, INC.

Introduction - 8

Comparison: ASME B31.1 to ASME B31.3

Other USA Piping System Standards

NFPA 13 Installation of Sprinkler Systems

sa a o o

of Private

a e Mains

a s

NFPA 24 Installation

NFPA 50 Bulk Oxygen Systems

NFPA 54 National Fuel Gas Code

CGA Handling of Anhydrous Ammonia (K61.1)

Chlorine Institute #6 Piping Systems for Chlorine

BECHT ENGINEERING COMPANY, INC.

Introduction - 9

B31.1 and B31.3 Scopes

Rules have been developed considering

piping

p

p g typically

yp

y found in

electric power generating

stations, industrial and

institutional plants,

geothermal heating

systems and central and

district heating and

cooling systems. (100.1)

ASME B31.1

petroleum refineries;

chemical,

pharmaceutical, textile,

paper, semiconductor,

and cryogenic plants; and

related processing plants

and terminals. (300.1)

ASME B31.3

BECHT ENGINEERING COMPANY, INC.

10

Comparison: ASME B31.1 to ASME B31.3

B31.1 and B31.3 Scopes

Power piping systems

include but are not

limited to

This Code applies for all

fluids, including:

(1) raw, intermediate,

i t

di t and

d

finished chemicals;

(2) petroleum products;

(3) gas, steam, air, and

water;

((4)) fluidized solids;;

(5) refrigerants; and

(6) cryogenic fluids.

steam

water

oil

gas

air

[100.1.2]

[300.1.1(b)]

BECHT ENGINEERING COMPANY, INC.

Whats Different in B31.1 -

11

Requirements

B31.1 provides requirements for types of B31.3 provides

piping

requirements for fluid

services

Boiler External

Category D (utility)

Blowoff and Blowdown

Category M (lethal)

Instrument, Control and Sample

Elevated Temperature

Spray Type Desuperheater

(creep range)

Pressure Relief

High Pressure (above

Flammable or Combustible Liquids

about 100 MPa)

Flammable Gases and Toxic Fluids

High

g Purity

y

Piping

Pi i for

f Corrosive

C

i Fluids

Fl id

Normal (Process)

Temporary

Severe Cyclic

Steam Trap

Conditions

Pump Suction and Discharge

District Distribution Systems

BECHT ENGINEERING COMPANY, INC.

Whats Different in B31.1 -

12

Comparison: ASME B31.1 to ASME B31.3

Organization of the Codes

I

II

III

IV

V

VI

Scope and Definitions

Design

g

Materials

Dimensional Requirements

Fabrication, Assembly, and Erection

Inspection, Examination and Testing

13

BECHT ENGINEERING COMPANY, INC.

Organization of the Codes

VII

Operation and

Maintenance

Appendices covering:

Nonmetallic Piping and

Piping Lined with

Nonmetals

Design of Safety Valve

I t ll ti

Installations

Corrosion Control

Restrained Underground

Piping

VII Nonmetallic Piping and

Piping Lined with

Nonmetals

VIII Piping for Category M

Fluid Service

IX High Pressure Piping

X High Purity Piping

Appendices covering:

Aluminum Alloy Flanges

Expansion Joints

BECHT ENGINEERING COMPANY, INC.

Whats Different in B31.1 -

14

Comparison: ASME B31.1 to ASME B31.3

Bases for Design Stresses

B31.1 The lowest of

B31.3 The lowest of

the specified minimum

tensile strength divided by

35

3.5

tensile strength at

temperature divided by 3.5

2/3 of specified minimum

yield strength

2/3 of yield strength at

temperature; except for

austenitic stainless steels,

90% of yield strength at

temperature

Creep strength criteria

BECHT ENGINEERING COMPANY, INC.

the specified minimum

tensile strength divided

by 3

tensile strength at

temperature divided by 3

2/3 of specified minimum

yield strength

2/3 of yield strength at

temperature; except for

austenitic stainless

steels, 90% of yield

strength at temperature

Creep strength criteria

Whats Different in B31.1 -

15

Bases for Design Stresses

ASTM A106 Grade B Carbon Steel (US Customary Units)

BECHT ENGINEERING COMPANY, INC.

16

Comparison: ASME B31.1 to ASME B31.3

Piping Component Standards

Standard

Components: Those

listed by standard

number in Table

126.1, which lists

material specifications

(ASTM) as well as

component standards

Nonstandard

Components: Those

not so listed.

Listed Components:

Those listed by

standard number in

Table 326.1 and

Appendix A

Unlisted Components:

Those not so listed.

BECHT ENGINEERING COMPANY, INC.

Whats Different in B31.1 -

17

Nonstandard/Unlisted Components

Can be used if they:

adherence to dimensional

standards of ANSI and

ASME is

i strongly

t

l

recommended when

practicable, and

Meet the pressure design

formulas and procedures

given in para. 104

[104 126

[104,

126.2]

2]

Can be used if they:

are checked for adequacy

of mechanical strength

under

d applicable

li bl

loadings, and

composition, mechanical

properties, method of

manufacture, and quality

control are comparable to

li t d components;

listed

t and

d

have pressuretemperature ratings that

conform with para. 304

[302.2.3, 326.1.2]

BECHT ENGINEERING COMPANY, INC.

Whats Different in B31.1 -

18

Comparison: ASME B31.1 to ASME B31.3

Selected Fluid Service Requirements

Furnace butt welded

pipe is not permitted

for flammable

flammable,

combustible or toxic

fluids

Soldered joints may

not be used for

flammable or toxic

fluids

Furnace butt welded

pipe is permitted only

for Category D fluid

service (utility)

Soldered joints may

be used only for

Category D fluid

service (utility)

BECHT ENGINEERING COMPANY, INC.

Whats Different in B31.1 -

19

Selected Fluid Service Requirements

Brazed joints may not

be used for flammable

or toxic fluids in fire

hazard areas

Threaded joint size

limited by temperature

and pressure; example

max. pressure NPS 3

(DN 80) joint

j i t is

i 400 psii

(2750 kPa)

Pipe thinner than STD

WT may not be thrdd

BECHT ENGINEERING COMPANY, INC.

Brazed joints are

permitted for fluids that

are flammable, toxic or

d

damaging

i tto h

human

tissue only if

safeguarded

NPS 1-1/2 (DN 40) and

smaller tapered joints

must be Sch 80 for

notch sensitive material

in Normal Service

Whats Different in B31.1 -

20

Comparison: ASME B31.1 to ASME B31.3

Material Requirements

Listed Material: a

material that conforms to

a specification in

Appendix A or to a

standard in Table 126.1

may be used (123.1.1)

Unlisted Material: a

material that is not so

listed mayy be used

under certain conditions

Listed Material: a

material that conforms to

a specification in

Appendix A or to a

standard in Table 326.1

may be used (323.1.1)

Unlisted Material: a

material that is not so

listed mayy be used

under certain conditions

(123.1.2)

Unknown Material: may

not be used (123.1.3)

(323.1.2)

Unknown Material: may

not be used (323.1.3)

BECHT ENGINEERING COMPANY, INC.

Whats Different in B31.1 -

21

Material Requirements

An unlisted material may be

used if (123.1.2)

It conforms to a published

specification covering

chemistry, mechanical

properties, etc.

Otherwise meets the

requirements of the Code

Allowable stresses are

determined in accordance

with Code bases, and

Qualified for serviceat

all temperatures

An unlisted material may be

used if (323.1.2)

It conforms to a published

specification covering

chemistry, mechanical

properties, etc.

Otherwise meets the

requirements of the Code

Allowable stresses are

determined in accordance

with Code bases, and

Qualified for serviceat

all temperatures (323.2.4)

BECHT ENGINEERING COMPANY, INC.

Whats Different in B31.1 -

22

Comparison: ASME B31.1 to ASME B31.3

Material Requirements

Materials for BEP

must be ASME B&PV

Code materials

Use at temperatures

above maximum in

the stress tables is

generally not

permitted

No rules for use at

temperatures below

-20F (-29C)

Use at temperatures

above maximum in

the stress tables is

generally permitted

Extensive rules for

use at temperatures

below -20F (-29C)

BECHT ENGINEERING COMPANY, INC.

Whats Different in B31.1 -

23

Cast Iron Fluid Service Limits

Gray Iron Generally limited

to 250 psi (1725

KPa) saturated

steam service

May not be used in flammable

service above 150 psi (1035 kPa)

Malleable Limited to 350

Iron

psi (2415 kPa)

and 450F

(230C)

Limited to -20F to 650F (-29C

to 343C)

Ductile

Iron

May not be used in other services

above

b

400 psii (2760 kP

kPa))

Generallyy limited Generallyy limited to temperature

p

to temperature range of -20F to 650F (-29C to

of 450F (232C) 343C) and B16.42 ratings

and B16.42

ratings

BECHT ENGINEERING COMPANY, INC.

24

Comparison: ASME B31.1 to ASME B31.3

Pressure Design

The rules for pressure design are essentially

the same in B31.1 and B31.3, but they are

not identical.

BECHT ENGINEERING COMPANY, INC.

25

Design Pressure & Temperature

allowance for pressure and temperature

variation: The Codes allow the design pressure to

be set below the most severe coincident pressure

and temperature for the following variations:

Can exceed allowable by

20% for no more than 1

hr/event and no more

than 80 hr/year

Can exceed allowable by

15% for no more than 8

hr/event and nor more

than 800 hr/year

Can exceed allowable by

33% for no more than 10

hr/event and no more

than 100 hr/year

Can exceed allowable by

20% for no more than 50

hr/event and nor more

than 500 hr/year

BECHT ENGINEERING COMPANY, INC.

26

Comparison: ASME B31.1 to ASME B31.3

Flexibility Analysis

Acceptance Criteria for Sustained Loads

Dead Loads

SL Sh[W]

SL Sh[W]

Wind

SL 1.2Sh

SL 1.33Sh(Ec),

Earthquake

or

or

Water Hammer

SL 1.15Sh

SL 0.90SytX(Ec)

Live Loads

BECHT ENGINEERING COMPANY, INC.

Whats Different in B31.1 -

27

Flexibility Analysis

Acceptance Criteria for Displacement Loads

SE SA = f [1.25(S

[1 25(Sc + Sh) SL]

Max. value of f is 1.0

Use single Stress

Intensification Factor

Max. value of f is 1.2

Use in-plane and outof-plane Stress

Intensification Factors

Provides SIFs for

buttwelds, tapered

transitions & reducers

BECHT ENGINEERING COMPANY, INC.

Whats Different in B31.1 -

28

Comparison: ASME B31.1 to ASME B31.3

Fabrication

Welder & brazer qualification and bending &

forming requirements are very similar but

not identical

Preheating and post weld heat treatment

requirements are different, for example

B31.1 requires preheating to 200F (95C) or

post weld heat treatment for carbon steel with

thickness less than or equal to 3/4 in

in. (19

(19.0

0 mm)

B31.3 requires neither preheating nor post weld

heat treatment for the same thickness range

BECHT ENGINEERING COMPANY, INC.

29

Installation

Bolts must be

Bolts may be one

threaded trough

thread short of a

the nut

full nut

Threaded joints

Threaded joints

that are intended to

that are intended to

be seal welded

be seal welded

should be made up

shall be made up

without any thread

without any thread

compound.

compound.

BECHT ENGINEERING COMPANY, INC.

30

Comparison: ASME B31.1 to ASME B31.3

Inspection and Examination

Authorized inspector

required for boiler

external piping

piping, ASME

B&PV Code, Section I

Does not include the

concept of random

with progressive

examination either

100% or none

Owners Inspector is

required to verify

examination and

testing was done

correctly

Does include the

concept of random

with progressive

examination, e.g. 5%

random RT

BECHT ENGINEERING COMPANY, INC.

Whats Different in B31.1 -

31

Examination

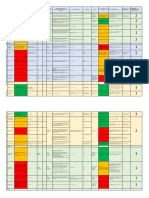

Examination required by Table 136.4:

Visual plus

Over 750F (400C)

For NPS 2 (DN 50), MP/LP

For NPS > 2 (DN > 50), 100%

radiography

Over 1025 psig (70

b ) and

bar)

d 350 tto

750F (175 to 400C)

Visual plus

F wallll thi

For

thickness

k

(19

mm), 100% radiography

All Others

Visual only

BECHT ENGINEERING COMPANY, INC.

32

Comparison: ASME B31.1 to ASME B31.3

Examination

Examination required by para. 341:

CategoryD(utility)

g y (

y)

VisualOnlyy

Normal(Process)

Visualplus5%radiography

CategoryM(lethal)

Visualplus20%radiography

ElevatedTemperature

(creep range)

(creeprange)

Visualplus5%radiography

100% LP/MP of fillet welds

100%LP/MPoffilletwelds

HighPressure(above

about100MPa)

Visualplus100%RT

BECHT ENGINEERING COMPANY, INC.

33

Leak Testing

BEP requires hydrotest in

accordance with ASME

B&PV Code, Section I

Non BEP requires

hydrotest or, at the

owners option,

pneumatic, sensitive leak

or initial service leak

testing

g

Insulated systems may

be tested by fluid loss

over time method

Category D Fluid Service

may be initial service leak

tested

All other fluid services

require hydrostatic or

pneumatic testing

Category M Fluid Service

requires a sensitive leak

test in addition to the

hydrostatic or pneumatic

test

BECHT ENGINEERING COMPANY, INC.

34

Comparison: ASME B31.1 to ASME B31.3

Leak Testing

Hydrostatic test is at 1.5

times design pressure

Pneumatic test is at 1.2

to 1.5 times design

pressure

Hydrostatic test pressure

must be held a minimum

of 10 minutes,

minutes and then

may be reduced to

design pressure for leak

examination period

Hydrostatic test is at 1.5

times design pressure

corrected for temperature

Pneumatic test is at 1.1

to 1.33 times design

pressure

Hydrostatic test pressure

must be held a minimum

of 10 minutes,

minutes and may

not be reduced for leak

examination period

BECHT ENGINEERING COMPANY, INC.

35

You might also like

- Asme b31.3 Training SeminarDocument382 pagesAsme b31.3 Training Seminarglazetm96% (45)

- Asme B31.3Document69 pagesAsme B31.39440864459100% (4)

- Asme b31.8 Comp Iso 13623Document7 pagesAsme b31.8 Comp Iso 13623tss13723100% (2)

- Asme B31.9Document86 pagesAsme B31.9mrivera100% (5)

- Asme ViiiDocument88 pagesAsme ViiiAnonymous jtbdj73W100% (15)

- Asme B36.10M-2018 PDFDocument36 pagesAsme B36.10M-2018 PDFCarlosIkeda100% (4)

- Fire Hydrant System Design Installation Commisioning and TestingDocument5 pagesFire Hydrant System Design Installation Commisioning and Testingjaianit89No ratings yet

- ABSA PipingDocument1 pageABSA Pipingcorreen100% (1)

- 4.1 Rerating Piping and Pressure Vessels: Major Piping Inspection CodesDocument23 pages4.1 Rerating Piping and Pressure Vessels: Major Piping Inspection CodesriysallNo ratings yet

- API 582 The Welding Solution PDFDocument21 pagesAPI 582 The Welding Solution PDFRemmy Torres Vega75% (8)

- ASME B31.3 Process Piping Course Training Material PDFDocument385 pagesASME B31.3 Process Piping Course Training Material PDFriswandi50% (4)

- qst30 g5Document4 pagesqst30 g5Muhammed Ali NoureddeenNo ratings yet

- 4.-QA-QC-Plan-job Desc Field PDFDocument12 pages4.-QA-QC-Plan-job Desc Field PDFAli HajirassoulihaNo ratings yet

- OPERATING MANUAL Biomass BoilerDocument23 pagesOPERATING MANUAL Biomass BoilerCORPORACION VENMATCO100% (1)

- ASME B 31 SimplifiedDocument6 pagesASME B 31 Simplifiedramundt50% (2)

- Whats Different in B31.1 PDFDocument30 pagesWhats Different in B31.1 PDFhirenkumar patel100% (2)

- Wall Thickness Calculation As Per ASME B31.3Document2 pagesWall Thickness Calculation As Per ASME B31.3Meena Rezkallah100% (4)

- B31.3 Process Piping Course - 16 Category M Fluid Service PDFDocument8 pagesB31.3 Process Piping Course - 16 Category M Fluid Service PDFRomner CordovaNo ratings yet

- Ower Iping: Charles Becht IVDocument52 pagesOwer Iping: Charles Becht IVmiguel medina100% (1)

- ASMEDocument3 pagesASMErajesh100% (2)

- Different Asme b31.1 b31.3 b31.8Document15 pagesDifferent Asme b31.1 b31.3 b31.8Wilson Chavez BasantesNo ratings yet

- PFI - ES - 48 - 2008 - Random ExaminationsDocument5 pagesPFI - ES - 48 - 2008 - Random Examinationsespluisjavier100% (1)

- Welcome To: Training Program On ASME Sec. VIII Div. 1Document120 pagesWelcome To: Training Program On ASME Sec. VIII Div. 1Wilson Wilfredo Yucra Paco100% (1)

- Pipes. Wall Thickness Calculation According ASME B31.3Document86 pagesPipes. Wall Thickness Calculation According ASME B31.3Jeannie Tatiana Pérez Sánchez100% (4)

- Fluid Service CategoriesDocument5 pagesFluid Service CategoriesKodali Naveen Kumar100% (1)

- Piping Inspection ProcedureDocument8 pagesPiping Inspection Proceduremohd as shahiddin jafriNo ratings yet

- ASME PCC-2-2015 Repair of PressureDocument1 pageASME PCC-2-2015 Repair of PressureJohn17% (6)

- Engieering Standard - Piping SpecificationDocument10 pagesEngieering Standard - Piping SpecificationDinesh MohanNo ratings yet

- 2654 - Pipe Wall Thickness Calculation As Per ASME B31.3Document20 pages2654 - Pipe Wall Thickness Calculation As Per ASME B31.3Sridhar Vijayan100% (3)

- Spiral Wound GasketsDocument7 pagesSpiral Wound GasketsYap HSNo ratings yet

- Asme B16.21 (2005) PDFDocument22 pagesAsme B16.21 (2005) PDFLevi Porter100% (1)

- ASME 2 Related Post Construction Codes and StandardsDocument38 pagesASME 2 Related Post Construction Codes and StandardsInstech Premier Sdn BhdNo ratings yet

- Flanges ASME B16.47Document18 pagesFlanges ASME B16.47Saifulla Baig67% (3)

- WPS SummaryDocument33 pagesWPS SummaryMidhun K ChandraboseNo ratings yet

- Pfi Es-24Document10 pagesPfi Es-24kingstonNo ratings yet

- Flange Inspection - Part1Document5 pagesFlange Inspection - Part1safwanNo ratings yet

- PipeDocument47 pagesPipemohanNo ratings yet

- Specification For Carbon Steel Forgings, For Piping ApplicationsDocument8 pagesSpecification For Carbon Steel Forgings, For Piping Applicationsedisson_barrera100% (1)

- Problems With B16.5 and B16.47 Flange StandardsDocument1 pageProblems With B16.5 and B16.47 Flange StandardsManohar SeetharamNo ratings yet

- ASME B31.1 Power PipingDocument1 pageASME B31.1 Power Pipingslxanto25% (4)

- ASME Sec VIII - AwarenessDocument33 pagesASME Sec VIII - AwarenessNirmal100% (4)

- ASME B31.4 Pipeline Transportation Systems For Liquid HydrocarbonsDocument1 pageASME B31.4 Pipeline Transportation Systems For Liquid HydrocarbonsAmrit Sarkar100% (1)

- Asme IxDocument132 pagesAsme IxAhmed Shaban Kotb100% (1)

- ASME B31.1 Vs B31.3 Vs B31.8Document9 pagesASME B31.1 Vs B31.3 Vs B31.8Nguyen Anh Tung67% (3)

- Asme 16.9Document58 pagesAsme 16.9kampit100% (2)

- History b16 34Document5 pagesHistory b16 34qazi12100% (1)

- Calculator ASME B31 4Document11 pagesCalculator ASME B31 4Sameera RanasingheNo ratings yet

- MAWP CalculationDocument2 pagesMAWP CalculationMuhammad Zeeshan Wasi60% (5)

- Electric-Fusion-Welded Steel Pipe For Atmospheric and Lower TemperaturesDocument7 pagesElectric-Fusion-Welded Steel Pipe For Atmospheric and Lower Temperaturesrgi178No ratings yet

- Code Comparison ASME B31.1 Vs B31.3 Vs B31.8Document27 pagesCode Comparison ASME B31.1 Vs B31.3 Vs B31.8khaireddinNo ratings yet

- b31.1 InterpretationsDocument265 pagesb31.1 Interpretationsahmedbeaet100% (1)

- Ansi-Asme B16.47 A (MSS SP 44)Document6 pagesAnsi-Asme B16.47 A (MSS SP 44)arferrafNo ratings yet

- Piping ComponentsDocument26 pagesPiping ComponentsVarun Patel100% (1)

- PipingDocument28 pagesPipingSalim ChohanNo ratings yet

- 02 Samss 012 PDFDocument10 pages02 Samss 012 PDFnadeem shaikhNo ratings yet

- SS Weld SpecificationDocument39 pagesSS Weld SpecificationmurugesanNo ratings yet

- ASME P-Numbers PDFDocument1 pageASME P-Numbers PDFFahri Risfa ZulfiNo ratings yet

- ASME B31.1 InterpretationsDocument223 pagesASME B31.1 InterpretationsETNo ratings yet

- Process Piping DetailsDocument21 pagesProcess Piping DetailsMuhammed SulfeekNo ratings yet

- ASME B31.3 Vs B31.12Document25 pagesASME B31.3 Vs B31.12bagulrahul2023No ratings yet

- Piping CodesDocument32 pagesPiping CodesPrashant IngoleNo ratings yet

- Appendix ADocument6 pagesAppendix ALocus Jhun MichaelNo ratings yet

- Appx A Pipe SpecDocument57 pagesAppx A Pipe Specomveer singhNo ratings yet

- Section 23 11 25 Facility Gas PipingDocument10 pagesSection 23 11 25 Facility Gas PipingNiong DavidNo ratings yet

- B31.3 Process Piping Course - Supplement BECHTDocument55 pagesB31.3 Process Piping Course - Supplement BECHTJonah TravisNo ratings yet

- MEP Works OverviewDocument14 pagesMEP Works OverviewMuhammed Ali Noureddeen60% (10)

- ASME B31 - 1 Power PipingDocument52 pagesASME B31 - 1 Power PipingLuís SantanaNo ratings yet

- Basic WeldingDocument40 pagesBasic WeldingVishnu Vardhan . C100% (9)

- API 650 Part 2 - 2001 Welded Tanks-2Document15 pagesAPI 650 Part 2 - 2001 Welded Tanks-2Hassan Ali SadiqNo ratings yet

- Bar / Wire Wrapped Steel Cylinder Pipes With Mortar Lining and Coating (Including Specials) - SpecificationDocument22 pagesBar / Wire Wrapped Steel Cylinder Pipes With Mortar Lining and Coating (Including Specials) - SpecificationPratik KharmateNo ratings yet

- Steam Boiler - Hydrostatic Test in Steam BoilerDocument2 pagesSteam Boiler - Hydrostatic Test in Steam BoilerRoland NicolasNo ratings yet

- Inspection Procedure For ContractDocument24 pagesInspection Procedure For ContractVijaya PatilNo ratings yet

- Pressure Vessels IP 5-1-1: ScopeDocument14 pagesPressure Vessels IP 5-1-1: Scopeandrés morantes100% (1)

- QM 30 - Pressure Vessels Questions (JGM Comments Incorp)Document3 pagesQM 30 - Pressure Vessels Questions (JGM Comments Incorp)mohamed elmasry100% (1)

- Hydrostatic Test ProcedureDocument2 pagesHydrostatic Test ProcedureAlan AtienzaNo ratings yet

- Spec. For Pressure Testing of ErDocument9 pagesSpec. For Pressure Testing of ErASHISH GORDENo ratings yet

- 01-SAMSS-043 2018 ASTM Carbon Steel and Low Alloy Pipes For On-Plot ApplicationsDocument18 pages01-SAMSS-043 2018 ASTM Carbon Steel and Low Alloy Pipes For On-Plot ApplicationsWHWEN100% (1)

- SB 135Document4 pagesSB 135AnilNo ratings yet

- Saudi Aramco Inspection Checklist: Field Hydrostatic Testing of Isolation Valves SAIC-L-2042 25-May-05 MechDocument3 pagesSaudi Aramco Inspection Checklist: Field Hydrostatic Testing of Isolation Valves SAIC-L-2042 25-May-05 MechHamidNo ratings yet

- SB - 622 PDFDocument10 pagesSB - 622 PDFSamir ChaudharyNo ratings yet

- Dec 09Document55 pagesDec 09c_nghia100% (1)

- ASMEDocument77 pagesASMEJitendra BhosaleNo ratings yet

- Working Sheet For Tank 108 Assessment 080222Document4 pagesWorking Sheet For Tank 108 Assessment 080222Aycan GürbüzNo ratings yet

- 32 Samss 017Document11 pages32 Samss 017naruto256No ratings yet

- 4) บจ.การ์เดียน อินดัสทรีย์ ระยองDocument8 pages4) บจ.การ์เดียน อินดัสทรีย์ ระยองsierthinNo ratings yet

- Khaled Saeed CVDocument9 pagesKhaled Saeed CVkhsaeedNo ratings yet

- P105576-IC-IDF-204 - Rev01Document10 pagesP105576-IC-IDF-204 - Rev01bmanojkumar16No ratings yet

- Saes L 650Document14 pagesSaes L 650Shawn LeoNo ratings yet

- Compress EvaluateDocument23 pagesCompress EvaluateVishalDhiman100% (1)

- Safety Instruction SheetDocument32 pagesSafety Instruction SheetAdamuNo ratings yet

- Addendum To Method Statement For Installation of Plumbing System 1. Hydrostatic Pressure Test of Water Services PipingDocument4 pagesAddendum To Method Statement For Installation of Plumbing System 1. Hydrostatic Pressure Test of Water Services PipingSIBINNo ratings yet

- Asme Questions and Answers Part - IvDocument4 pagesAsme Questions and Answers Part - IvAshwani Dogra100% (1)

- 2018proceedings Davis Food TruckDocument17 pages2018proceedings Davis Food TruckMohamad Iqbal HanfiNo ratings yet

- Storage Tanks PresentationDocument107 pagesStorage Tanks Presentationsinner123100% (12)

- Hydrotest ProcedureDocument8 pagesHydrotest ProcedureSiti NurbayanahNo ratings yet