Professional Documents

Culture Documents

Pressure Control Calculation Title

Uploaded by

Wira D. BayuwegaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pressure Control Calculation Title

Uploaded by

Wira D. BayuwegaCopyright:

Available Formats

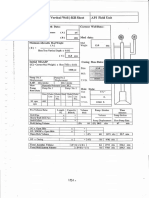

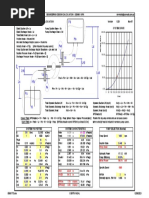

Pressure Control Calculation for Vertical Well

--------------- Driller Method --------------- CSIP−DPSIP

1. Draw the Well !!!

...ft

ρk =ρml −

( 0 . 052×h k )

...ft

Pk =0 . 052×ρk ×h k

...ft

Pk

IDCAS ...ft Pressure Gradient of Kick= =0 .052×ρk

hk

...ft

6. Initial & Final Circulating Pressure

ICP=DPSIP+Ploss

ODDP ...ft

IDDP ρmb

FCP=P loss

ρml

ODDC ...ft

IDDC

...ft

DOH 7. Pumping Time

...ft

Strokekick out timekick out

Strokemb-bit timemb-bit

2. Capacity & Volume Each Section

Strokebit-surface timebit-surface

CDP VDP

Total Stroke total time

CDC VDC Volume Drill String

Volume

COH-DC VOH-DC Stroke=

Volume t=

bbl bbl stroke

COH-DP VOH-DP ×

Volume Annulus stroke stroke menit

CCAS-DP VCAS-DP

8. Total Time to Kill the Well

3. Formation Pressure

t tot =t kick out +t make new mud +t mb@surface−bit +t mb@bit−annulus

Pf =DPSIP + ( 0. 052× ρml×D )

9. Pressure Decrease that encountered while new mud

4. Kill Mud Density

circulated from surface to bit

DPSIP

ρmb =ρml + +T ICP−FCP

Atau

0 .052×D m arg in Pstand pipe =ICP−

( t mb−bit

×t i

)

Pf ICP−FCP

ρmb = +T

0. 052×D m arg in

Pstand pipe =ICP−

( stokemb−bit

×stroke i

)

lb

T m argin =

(

YP dalam

100 ft 2 ) 10. Pressure @surface of casing @Certain Depth

1

11. 7 ( Diameter OH −Outer Diameter Drillstring ) A A 2 0 . 052×ρml ×Pf ×hk ×Z surf ×T surf

5. Kick Properties

Psurf = +

2 4

+

[ T b ×Z b ] 2

Volume Kick A=DPSIP−P k + ( 0. 052×ρml× X )

hk =

C OH− DC

11. Maximum Volume Increase of Kick @Surface

Volume Kick

hk = ×cos I

C OH− DC

s@kt! t@nR!p@da / 12204051 / Petroleum Engineering - Bandung Institute of Technology Page 1 of 7

P surf − A

V ks =Ca

( 0 . 052×ρ ml ) Ca=C CAS-DP

dimana nilai Psurf & A X = 0 (berada di permukaan)

s@kt! t@nR!p@da / 12204051 / Petroleum Engineering - Bandung Institute of Technology Page 2 of 7

n

--------- Batch/Wait and Weight Method

∑ ρmti ρmt 1 + ρmt 2 + ρmt 3 +. ..+ ρ mtn

--------- ρmt = i=1 =

***Procedure 1st – 6th as the same as Driller Method

n n

Densitas mud lama tidak diperhitungkan, jadi mulai

7. Pumping Time dari mud transisi pertama sampai dengan mud baru.

Strokemb-bit timemb-bit

Strokebit-surface timebit-surface 7. Pumping Time

Total Stroke total time

Strokemb-bit timemb-bit

Volume

Stroke=

Volume t= Strokebit-surface timebit-surface

bbl bbl stroke

× Total Stroke total time

stroke stroke menit

Volume

Stroke=

Volume t=

8. Total Time to Kill the Well bbl bbl stroke

×

stroke stroke menit

t tot =t make new mud +tmb @surface−bit +t mb @bit−annulus

8. Total Time to Kill the Well

9. Pressure Decrease Equation that encountered while

t tot =t t +t mb@ surface−bit +t mb@ bit−annulus

new mud circulated from surface to bit

(sama dengan Driller Method) ( ρmb− ρml )

t t =t x

v mud increase

10. Pressure @surface of casing @Certain Depth

t x =interval waktu penambahan mud transisi

1

A A 0 . 052×ρmb ×Pf ×hk ×Z surf ×T surf

2

Psurf = +

2 4

+

[ T b ×Z b ] 2

v mud increase =r ate kenaikan densitas

9. Pressure Decrease Equation that encountered while

A=( 0 . 052 ( ρmb −ρml ) hml )−Pk + Pf −( 0 .052×ρmb ×D )

new mud circulated from surface to bit

+ ( 0 . 052× ρmb× X )

ICP−FCP

V

hml = drill string

Pstand pipe =ICP−

(( v

)

ρmb −ρml mud increase )

CCAS−DP ; hml=tinggi mud lama

10. Pressure @surface of casing @Certain Depth

@annulus,@surface

1

A A 2 0 . 052×ρmb ×Pf ×hk ×Z surf ×T surf

11. Maximum Volume Increase of Kick @Surface

Psurf = +

2 4

+

[ T b ×Z b ] 2

P surf − A

V ks =Ca

( 0 . 052×ρ mb ) Ca=C CAS-DP A=( 0 . 052 ( ρmb− ρ ml ) hml )+ ( 0 . 052 ( ρmb− ρ mt ) h mt )

dimana nilai Psurf & A X = 0 (berada di permukaan) −Pk + P f −( 0. 052× ρmb×D ) + ( 0 . 052×ρmb ×X )

--------------- Concurrent Method ---------------

***Procedure 1st – 6th as the same as Driller Method

V drill string V mt

hml = hmt =

CCAS−DP ;

CCAS−DP ;

4+.Average Mud Transition

V mt =t mt×. . .b /m

11. Maximum Volume Increase of Kick @Surface

s@kt! t@nR!p@da / 12204051 / Petroleum Engineering - Bandung Institute of Technology Page 3 of 7

P surf − A

V ks =Ca

( 0 . 052×ρ mb ) Ca=C CAS-DP

dimana nilai Psurf & A X = 0 (berada di permukaan)

s@kt! t@nR!p@da / 12204051 / Petroleum Engineering - Bandung Institute of Technology Page 4 of 7

--------------- Volumetric Method --------------- Kick dari bawah-atas (open hole)

***Procedure 1st – 2th as the same as Driller Method

0 .052×ρml

m=

3. Height of Kick

C OH

Vk 0 .052×ρml

hk = m=

COH Kick dari bawah-atas (casing)

CCAS

4. Formation Pressure Kick keluar disertai pemasukan Lumpur penambah

Vk

(

Pf =CSIP+ 0 . 052×ρml × D−

( C OH )) + Pk

m=−

0 . 052×ρmp

C CAS

Vk

(

Pf =CSIP+ 0 . 052×ρml × D−

( COH )) 9. Pumping Time

kick gas Strokemb-bit timemb-bit

5. Kill Mud Density Strokebit-surface timebit-surface

Total Stroke total time

CSIP+ P k ρ ×V k

ρmb =ρml + (

0 . 052×D

− ml

D×COH )(

+T m argin

) Stroke=

Volume t=

bbl

Volume

stroke

bbl ×

lb stroke stroke menit

T m argin =

(

YP dalam

100 ft 2 )

11. 7 ( Diameter OH −Outer Diameter DP ) 10. Total Time to Kill the Well

μ=θ 600−θ300 t tot =t k +t lumpur penambah +t mb@surface−bit +t mb@bit−annulus

0 . 052×ρ ml×D

YP=2 θ300 −θ600 t k=

v CSIP

6. Densitas Mud Penambah

tk = waktu kick sampai ke surface

( ρmb ×D )−( ρml ( D−hk ) ) vCSIP = kecepatan kenaikan CSIP (psi/jam psi/min)

ρmp =

hk

Vk

atau t lumpur penmbah=

bbl

menit atau

V ks

ρmp =

( (

( ρmb ×D )− ρml D− C

CAS

)) V ks

hk =

bbl

7. Initial & Final Circulating Pressure menit

ρmb

FCP=P loss 11. Pump Pressure Decrease

ρml

Jika menggunakan Lumpur lama dulu

sirkulasi dimulai dengan lumpur lama

ICP=Ploss

sirkulasi dimulai dengan lumpur baru ICP−FCP

ICP=FCP

ΔP pump =

( t pipe

ti

)

8. Koefisien arah/Gradient grafik tekanan (psi/bbl)

Jika langsung menggunakan Lumpur baru tidak

terjadi penurunan tekanan karena sejak awal

pemompaan sudah sebesar FCP

s@kt! t@nR!p@da / 12204051 / Petroleum Engineering - Bandung Institute of Technology Page 5 of 7

12. Pressure @surface of casing @Certain Depth 13. Maximum Volume Increase of Kick @surface

1

A A 2 0 . 052×ρml ×Pf ×hk ×Z surf ×T surf P surf − A

Psurf = +

2 4

+

[ T b ×Z b ] 2

V ks =Ca

( 0 . 052×ρ ml ) Ca=C CAS

A=CSIP−( 0 . 052×ρ ml×h k ) + ( 0 .052×ρml× X )

------------------ Formation Evaluation ------------------

1. Tentukan d-eksponent pada setiap kedalaman

ROP

d eks=

log

[ 60 RPM ] ROP=(ft /hr )

12WOB WOB=( lbs)

log

[ 106 d bit ] d bit =(in)

2. Tentukan d-correction pada setiap kedalaman

ρmn ρmn =normal mud density

d corr =d eks

ρma ρma =actual mud density

9

d corr =d eks

Densitas normal berupa air asin ρma

8 .33

d corr =d eks

Densitas normal berupa air tawar ρma

3. Plot titik-titik d-correction vs Depth

4. Regresi titik-titik d-corr vs Depth dan diperoleh persamaan garis berupa persamaan d-normal.

d norm =( m×Depth )+b , yang diregresi yang sesuai dengan trend normal/kecenderungannya.

5. Tentukan d-norm dengan menggunakan persamaan garis di atas untuk setiap Depth.

d norm

EMW=Gn

6. EWM d corr

d norm d norm

EMW=9 EMW=8. 33

d corr atau d corr

d norm

d overlay =ρnormal

7. Overlay EMW

d norm d norm

d overlay =9 d overlay =8 . 33

misal overlay 11 11 atau 11

s@kt! t@nR!p@da / 12204051 / Petroleum Engineering - Bandung Institute of Technology Page 6 of 7

8. Plot d-overlay vs Depth

θ 2−θ1

BUR= ×100=. .. . .. .o /100 ft

MD 2 −MD1

180

R= =. . .. .. . ft

π×BUR

TVD=R ( sin θ2 −sin θ1 )=. .. . .. ft TVD

180

... ..o =. . .... . radian× =. . .... o

π

π

W= ( OD 2 −ID 2 ) ×SGbesi ×62 . 4

4×144 SG = 7.8

W ×4×144

√

ID= OD 2 −

( π ×SG besi×62 . 4 )

s@kt! t@nR!p@da / 12204051 / Petroleum Engineering - Bandung Institute of Technology Page 7 of 7

You might also like

- Compressor efficiency calcs < 40 charsDocument2 pagesCompressor efficiency calcs < 40 charsAhmed HassanNo ratings yet

- HORIZNTLDocument9 pagesHORIZNTLGourav RanaNo ratings yet

- Section 5B Rheology & HydraulicsDocument10 pagesSection 5B Rheology & HydraulicsLazharNo ratings yet

- Compressors Efficiency Calculations5Document11 pagesCompressors Efficiency Calculations5Ahmed HassanNo ratings yet

- Surface BOP Kill SheetDocument12 pagesSurface BOP Kill Sheetzouke2002No ratings yet

- Subsea Kill Sheet - Blank - With Visual AidDocument3 pagesSubsea Kill Sheet - Blank - With Visual Aidmsu6383No ratings yet

- Cracking Moment Calculation for Reinforced Concrete BeamDocument8 pagesCracking Moment Calculation for Reinforced Concrete BeamalexanderNo ratings yet

- SHEAR CONNECTION (Plate Washer and Tab Checks)Document5 pagesSHEAR CONNECTION (Plate Washer and Tab Checks)katar kumarNo ratings yet

- PADEYE DESIGN CALCULATIONDocument1 pagePADEYE DESIGN CALCULATIONNasrul AdliNo ratings yet

- Surface Vertical Well: Kili Bop) FieldDocument1 pageSurface Vertical Well: Kili Bop) FieldandrewNo ratings yet

- CH 02Document7 pagesCH 02hedayatullahNo ratings yet

- Kill Sheet Surface BOP DataDocument1 pageKill Sheet Surface BOP DataandrewNo ratings yet

- International Well Control Forum Surface BOP Kill Sheet - Deviated Well (S.I. Units)Document3 pagesInternational Well Control Forum Surface BOP Kill Sheet - Deviated Well (S.I. Units)Kenaouia Bahaa100% (1)

- Surface BOP Kill Sheet - Vertical Well (Metric/BarDocument2 pagesSurface BOP Kill Sheet - Vertical Well (Metric/BarMelnapsterDsouzaNo ratings yet

- Hydraulic Pump Efficiency GuideDocument20 pagesHydraulic Pump Efficiency GuidehellfireNo ratings yet

- Padeye design calculationDocument1 pagePadeye design calculationNasrul AdliNo ratings yet

- International Well Control Forum Subsea BOP Kill Sheet - Deviated Well (Metric/Bar)Document3 pagesInternational Well Control Forum Subsea BOP Kill Sheet - Deviated Well (Metric/Bar)Tg TarroNo ratings yet

- Img 0111 PDFDocument1 pageImg 0111 PDFandrewNo ratings yet

- K Sidpp - 'I" L: Initial:Lfic RDocument1 pageK Sidpp - 'I" L: Initial:Lfic RandrewNo ratings yet

- Radar principles and parameters for airborne synthetic aperture radar systemsDocument6 pagesRadar principles and parameters for airborne synthetic aperture radar systemsMatthew ListroNo ratings yet

- Well Control Kill Sheet: (A) Well Data (C) Calculation (E) Drillpipe Pressure ScheduleDocument4 pagesWell Control Kill Sheet: (A) Well Data (C) Calculation (E) Drillpipe Pressure SchedulezhaoNo ratings yet

- Assignment 1 Kill SheetDocument4 pagesAssignment 1 Kill SheetPrateekNo ratings yet

- Alpu: Ts-Bah CT + (Y - T (H-Tos) AsDocument3 pagesAlpu: Ts-Bah CT + (Y - T (H-Tos) AsShivansh SinghNo ratings yet

- 14b-Kill Sheet PreparationDocument10 pages14b-Kill Sheet PreparationLorenaStămulescuNo ratings yet

- Useful Formulas and CalculationsDocument8 pagesUseful Formulas and CalculationsAnonymous 4ADs7sW8No ratings yet

- Img 0120Document1 pageImg 0120andrewNo ratings yet

- Retaining WallDocument3 pagesRetaining WallkbnoblezadaNo ratings yet

- Air Receivers Volume CalculationDocument83 pagesAir Receivers Volume CalculationAnonymous yt4t6XjgScNo ratings yet

- Greene Street Shade Shear Connection DesignDocument6 pagesGreene Street Shade Shear Connection DesignNagender KumarNo ratings yet

- Kill SheetDocument2 pagesKill SheetAzhar GulzarNo ratings yet

- Assignment-2 Kill SheetDocument13 pagesAssignment-2 Kill SheetPrateekNo ratings yet

- Lington Revision PackageDocument25 pagesLington Revision PackageNagenderNo ratings yet

- Design and Analysis of Fins with Realistic Boundary Conditions for Maximum BenefitsDocument34 pagesDesign and Analysis of Fins with Realistic Boundary Conditions for Maximum Benefitssantiago alonso perilla lozanoNo ratings yet

- International Well Control Forum Surface BOP Kill Sheet - Vertical Well (S.I. Units)Document2 pagesInternational Well Control Forum Surface BOP Kill Sheet - Vertical Well (S.I. Units)roshanpateliaNo ratings yet

- Well control worksheet drillers methodDocument1 pageWell control worksheet drillers methodTriana Priyo SunjoyoNo ratings yet

- Engineering Design Calculation - Dennis Kirk Single Stage Centrifugal Pump Calculation (Clean Water Use) System CurveDocument1 pageEngineering Design Calculation - Dennis Kirk Single Stage Centrifugal Pump Calculation (Clean Water Use) System Curvebuntimehta007No ratings yet

- Air receiver volume and compressor flow rate calculationDocument86 pagesAir receiver volume and compressor flow rate calculationyoyoNo ratings yet

- Subsea BOP Stack Operations SI - Deviated Well Kill SheetDocument3 pagesSubsea BOP Stack Operations SI - Deviated Well Kill SheetWell ControlNo ratings yet

- Kill Sheet VerticalDocument2 pagesKill Sheet Verticalpogc.spd13aNo ratings yet

- Equations & Conversions: The Following Equations and Conversions Will Be Given As Part of ExamsDocument1 pageEquations & Conversions: The Following Equations and Conversions Will Be Given As Part of ExamsTruong NguyenNo ratings yet

- Plate Girder Design Summary in 40 CharactersDocument22 pagesPlate Girder Design Summary in 40 CharactersBang OchimNo ratings yet

- Air Receivers Volume CalculationDocument86 pagesAir Receivers Volume CalculationHgagselim SelimNo ratings yet

- Surface BOP Kill Sheet Provides Critical Well Control DataDocument2 pagesSurface BOP Kill Sheet Provides Critical Well Control Datarafiullah353No ratings yet

- Process Control Design ProjectDocument4 pagesProcess Control Design Projectds2228No ratings yet

- Book 3Document6 pagesBook 3Sasikumar Jothi100% (1)

- Air Receivers Volume CalculationDocument86 pagesAir Receivers Volume CalculationTuesou MachereNo ratings yet

- Fórmulas Fresamento PolegadasDocument1 pageFórmulas Fresamento PolegadasJunior GuedesNo ratings yet

- Radiation characteristics of AntennasDocument4 pagesRadiation characteristics of AntennasMatthew ListroNo ratings yet

- STRESSING CALCULATIONS - Malbogon BridgeDocument1 pageSTRESSING CALCULATIONS - Malbogon BridgeRay Vincent Agorita FriasNo ratings yet

- Mechanistic Rate Decline Analysis in Shale Gas ReservoirsDocument31 pagesMechanistic Rate Decline Analysis in Shale Gas ReservoirsLibya TripoliNo ratings yet

- Ilker Drilling ProgrammeDocument71 pagesIlker Drilling Programmerıdvan duranNo ratings yet

- HVACR Formulas and SymbolsDocument46 pagesHVACR Formulas and SymbolsatiqNo ratings yet

- Cascading Knapsack Inequalities - Hidden Structures in Some Inventory-Production-Distribution ProblemsDocument20 pagesCascading Knapsack Inequalities - Hidden Structures in Some Inventory-Production-Distribution ProblemsManuelRamosNo ratings yet

- assdDocument12 pagesassdjoe leeNo ratings yet

- Air Receivers Volume CalculationDocument83 pagesAir Receivers Volume CalculationsudarwantoNo ratings yet

- International Well Control Forum Subsea BOP Kill Sheet - Vertical Well (Metric/Bar)Document2 pagesInternational Well Control Forum Subsea BOP Kill Sheet - Vertical Well (Metric/Bar)Vassilios KelessidisNo ratings yet

- Solution Manual for an Introduction to Equilibrium ThermodynamicsFrom EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsNo ratings yet

- Construction checklist for GI trunking installationDocument1 pageConstruction checklist for GI trunking installationMAZHALAI SELVANNo ratings yet

- Boq ChandigarhDocument2 pagesBoq ChandigarhVinay PantNo ratings yet

- Building RepairsDocument8 pagesBuilding RepairsRenuka ChalikwarNo ratings yet

- Coiled Tubing Gauge Carrier DatasheetDocument2 pagesCoiled Tubing Gauge Carrier Datasheetu2006262918No ratings yet

- 5V/-12V/-15V or Adjustable, High-Efficiency, Low I Inverting DC-to-DC ControllersDocument16 pages5V/-12V/-15V or Adjustable, High-Efficiency, Low I Inverting DC-to-DC ControllersManikanta Sai KumarNo ratings yet

- Computaion IntelligentDocument624 pagesComputaion IntelligentThaiHuynhNgocNo ratings yet

- Simulation Engineer - Drives SystemsDocument2 pagesSimulation Engineer - Drives Systemsdipraj kadlagNo ratings yet

- C617 PDFDocument6 pagesC617 PDFJaime Montelongo GarcíaNo ratings yet

- PFM-42-0 Document ReviewDocument9 pagesPFM-42-0 Document ReviewSIVAKUMAR NATARAJANNo ratings yet

- VIEWIT: Computation of Seen Areas, Slope, and Aspect For Land-Use PlanningDocument67 pagesVIEWIT: Computation of Seen Areas, Slope, and Aspect For Land-Use PlanningPACIFIC SOUTHWEST RESEARCH STATION REPORTNo ratings yet

- Aplications of Engine RoomDocument10 pagesAplications of Engine Roomady.sabauNo ratings yet

- Summative Test New NormalDocument1 pageSummative Test New NormalElron KarlNo ratings yet

- Usb Flash Drive Hidden Camera and Audio Recorder Manual Web ReducedDocument2 pagesUsb Flash Drive Hidden Camera and Audio Recorder Manual Web ReducedtatonyNo ratings yet

- TFFT Blow Out Procedures 1Document13 pagesTFFT Blow Out Procedures 1Nathaniel E. Barrios FuentesNo ratings yet

- SpecsDocument309 pagesSpecsNarendra GoudNo ratings yet

- VENUS e CatalogueDocument38 pagesVENUS e CatalogueGanesh BabuNo ratings yet

- Jetking Rajajinagar MinDocument7 pagesJetking Rajajinagar MinNeha ShekarNo ratings yet

- CFD LectureDocument19 pagesCFD LectureRobi Afrizal100% (1)

- Loadings and Sign Convention SummaryDocument9 pagesLoadings and Sign Convention SummaryGovindan KrishnamoorthybashyamNo ratings yet

- Compaction Factor TestDocument3 pagesCompaction Factor TestNitisha Rathore100% (5)

- Modern AC Land Drilling Rig PosterDocument1 pageModern AC Land Drilling Rig Posterjavierlozano10No ratings yet

- Design of Tank and Tubes - TransformersDocument6 pagesDesign of Tank and Tubes - TransformersAJAY KOSHY PS 18-20No ratings yet

- Medium and Long-Term Strategic Skills List (MLTSSL) : So Who Is Bravo Migration?Document1 pageMedium and Long-Term Strategic Skills List (MLTSSL) : So Who Is Bravo Migration?OsniSoiNo ratings yet

- Paint Brushes RollersDocument9 pagesPaint Brushes RollersDevender SharmaNo ratings yet

- Curriculum Vitae: Working ExperienceDocument2 pagesCurriculum Vitae: Working ExperienceSiti AjiraNo ratings yet

- 2.0 Intro To Hydraulics, Pneumatics & PLC's Notes PDFDocument22 pages2.0 Intro To Hydraulics, Pneumatics & PLC's Notes PDFDannyNo ratings yet

- Boeing 737NG 800 900 BBJ2 BBJ3Normal Flow ChecklistDocument2 pagesBoeing 737NG 800 900 BBJ2 BBJ3Normal Flow ChecklistМая Маркова100% (1)

- Eview: Retentive Aids in Maxillofacial Prosthodontics - A ReviewDocument5 pagesEview: Retentive Aids in Maxillofacial Prosthodontics - A ReviewjoephinNo ratings yet

- 222Document5 pages222sumanNo ratings yet

- FLLTDocument34 pagesFLLTShyam SNo ratings yet