100%(6)100% found this document useful (6 votes) 5K views9 pagesCombined Cycle Gas Turbine.

REFERANCE.

CONCLUSION.

STATUS

ADVANTAGES & DISADVANTAGES.

VARIOUS FACTOR

VARIOUS TYPES

WORKING

BLOCK DIAGRAM&IT’S COMPONANTS.

Copyright

© Attribution Non-Commercial (BY-NC)

We take content rights seriously. If you suspect this is your content,

claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

- Introduction: Introduces the study objective for combined cycle power plant.

- Block Diagram: Presents the schematic diagram of a combined cycle power plant.

- Working of Combined Cycle Power Plant: Describes the operational workflow of a combined cycle power plant.

- Advantages & Disadvantages: Lists the benefits and drawbacks of using combined cycle power plants.

- Classification of Combined Cycle Power Plant: Explains the classification into open and closed cycle gas turbines.

- Site Selection for Combined Cycle Power Plant: Describes criteria for selecting a site for establishing a power plant.

- References: Provides links and titles of reference materials and sources consulted.

- Conclusion: Summarizes the advantages and flexibility of combined cycle power systems.

COMBINED CYCLE POWER PLANT

ENERGY SYSTEMS,

BY SHAILESH B. PATEL -090760111025

COMBINED CYCLE

POWER PLANT

CONTENTS

BLOCK DIAGRAM & IT’S COMPONANTS.

WORKING OF COMBINED CYCLE POWER PLANT.

ADVANTAGES & DISADVANTAGES.

CLASSIFICATION OF COMBINED CYCLE POWER PLANT.

SITE SELECTION COMBINED CYCLE POWER PLANT.

STATUS OF COMBINED CYCLE POWER PLANT IN INDIA.

CONCLUSION.

REFERANCE.

aggagaaaga

COMBINED CYCLE POWER PLANT

ENERGY SYSTEMS

SANKDASARIYA SHAILESH B.

ENRL NO-090760111025

‘SSASIT (E.C. DEPARTMENT)

SSASIT

| BYSHALESH PATE DEPARTMENT)�COMBINED CYCLE POWER PLANT

ENERGY SYSTEMS

BY SHAILESH B. PATEL -090760111025

IMBINED CYCLE POWER PLANT

@AIM:- TO STUDY ABOUT COMBINED CYCLE POWER PLANT.

Combined cycle is an electric generating technology that creates additional electri

from heat exiting gas turbines. The exhaust heat from the gas turbines is routed to a

conventional boiler or to a heat recovery steam generator for utilization by a steam

turbine in the production of electricity.

BLOCK DIAGRAM:-

GAS TURBINE COMBINED CYCLE fescrmcat svenTARoe

Power Plant System Schematic f jh

cone A

: ih i

GQicauene

©The schematic arrangement of a gas turbine power plant is shown in [Link] main

components of plants are given below:-

(i) Compressor

(ii)Regenerator

Combustion Chamber

(iv)Gas Turbine

(v)Alternator

(vi) Starting motor

ssasiT | BY SHAILESH B, PATEL(E.C. DEPARTMENT)�COMBINED CYCLE POWER PLANT

ENERGY SYSTEMS

BY SHAILESH B. PATEL -090760111025

\COMPRESSOR

©The compressor used in the plant is generally of rotatory [Link] air at atmospheric

pressure is drawn by the compressor via the filter which removes the dust from the

[Link] rotatory blades of the compressor push the air between stationary blades to

raise its [Link] air at high pressure is available at the output of the compressor.

(IDREGENERATOR

"A regenerator is a device which recovers heat from the the exhaust gases of the

[Link] exhaust is passed through the regenerator before wasting to atmosphere.A

regenerator consists of a nest of tubes contained in [Link] compressed air from the

compressor passes through the tubes on its way to the combustion [Link] this

way compressor is heated by the hot exhaust gases.

LII)COMBUSTION CHAMBER

©The air at high pressure from the compressor is led to the combustion chamber via

the [Link] the combustion chamber,heat is added to the air by burning oil. The

oil is injected through the burner into the chamber at high pressure ensure atomisation

of oil and its through mixing with [Link] result is that the chamber attains a very high

temperature(about 3000F).The combustion gases are suitably cooled to 1300F to 1500F

then delivered to gas turbine.

(IV)GAS TURBINE

©The products of combustion consisting of a mixture of gases at high temperature and

pressure are passed to the gas turbine. These gases in passing over the turbine blades

‘expand and thus do the mechanical [Link] temperature of the exhaust gases from

the turbine is about 900 F.

(V)ALTERNATOR,

©The gas turbine is coupled into the alternator. The alternator converts the mechanical

energy of the turbine into electrical energy. The output of the alternator is given to the

bus-bars through transformers, isolators and circuit breakers.

(VI) STARTING MOTOR

© Before starting the turbine,compressor has to be [Link] this purpose,an electric

motor is mounted on the same shaft as that of the [Link] motor is energised by

the [Link] the unit starts, a part of the mechanical power of the turbine drives

the compressor and there is no need of the motor now.

ssasiT | BY SHAILESH 8, PATEL. DEPARTMENT) [ER�COMBINED CYCLE POWER PLANT

ENERGY SYSTEMS

BY SHAILESH B. PATEL -090760111025

@WORKING OF COMBINED CYCLE POWER PLANT :-

Wiiater Purp

Ont

SH _ Heat Recover

‘Steam Generator

Gas Turbine

Electricity

Compressor

fae Air

©>First step is the same as the simple cycle gas turbine plant. Burning of gas, the thrust

rotating a gas turbine and the coupled generator produces Electricity. In the second

step the hot gases leaving the gas turbine passes into boiler to produce steam. This

boiler is called the ‘Heat Recovery Steam Generator (HRSG). The steam then rotates

the steam turbine and coupled generator to produce Electricity. The hot gases leave the

HRSG at around 140 degrees centigrade and are discharged into the atmosphere. The

steam condensing, and water recycling system is the same as in the steam power

plant.

“Roughly the steam turbine cycle produces one third of the power and gas turbine

cycle produces two thirds of the power output of the CCPP. Normally there will be two

generators, one driven by the gas turbine and one driven by the steam turbine. There

are also systems with one generator connected through a single shaft to both the gas

turbine and steam turbine.

"Even though this system is having the best efficiency, it has limitations. The gas

turbine can only use Natural gas or high grade oils like aviation or diesel fuel. Because

of this the combined cycle can be operated only in locations where these fuels are

available and cost effective.

"Developments for gasification of coal and use in the gas turbine are in advanced

stages. Once this is proven, Coal as the main fuel can also be used in the combined

cycle power plant.

ssasiT | BY SHAILESH B, PATEL(E.C. DEPARTMENT)�COMBINED CYCLE POWER PLANT

ENERGY SYSTEMS

BY SHAILESH B. PATEL -090760111025

@ADVANTAGES & DISADVANTAGES OF COMBINED CYCLE POWER PLANTS:-

ADVANTAGES:

eeeee

eeoe

*

Very high power-to-weight ratio, compared to reciprocating engines.

‘Smaller than most reciprocating engines of the same power rating.

Moves in one direction only, with far less vibration than a reciprocating engine.

Fewer moving parts than reciprocating engines.

Low operating pressures.

High operation speeds.

Low lubricating oil cost and consumption.

It is simple to design & construct compared to a Steam Power station, since no

boilers are required.

Much smaller compared to Steam Power station of same capacity.

Lower operating costs.

Less water used since there is no need for a condenser.

Maintenance charges are low

Can be started quickly

No stand-by losses.

‘© DISADVANTAGES:

Cost is much greater than for a similar-sized reciprocating engine since the

materials must be stronger and more heat resistant. Machining operations are

also more complex.

Usually less efficient than reciprocating engines, especially at idle.

Delayed response to changes in power settings.

Problem of starting. Compressor needs to be operating thus external source of

power is necessary.

Net output is low since greater power is used to drive compressor.

Overall efficiency of plant is low ~ 20% because of exhaust gases still containing

heat. only efficient in a Combined cycle configuration.

Temperature of combustion chamber is too high thus resulting in a lower life.

#CLASSIFICATION OF COMBINED CYCLE POWER PLANT:-

The gas turbine power plants which are used in electric power industry are classified

into two groups as per the cycle of operation

(a) Open cycle gas turbine.

(0) Closed cycle gas turbine.

SSASIT�‘OPEN CYCLE GAS TURBINE POWER PLANT:

Fue Suppyy

+

‘Compressor Tube Ef

; +

a Extaustto

oe Aimosphere

(OPEN OYCLE GAS TURBINE POWER PLANT

COMBINED CYCLE POWER PLANT

ENERGY SYSTEMS

BY SHAILESH B. PATEL -090760111025

=A simple open cycle gas turbine consists

of a compressor, combustion chamber and a

turbine as shown in [Link] compressor

takes in ambient air and raises its pressure

Heat is added to the air in combustion

chamber by burning the fuel and raises its

temperature.

The heated gases coming out of

combustion chamber are then passed to the

turbine where it expands doing mechanical

work. Part of the power developed by the

turbine is utilized in driving the compressor

and other accessories and remaining is used

for power generation. Since ambient air

enters into the compressor and gases

coming out of turbine are exhausted into the atmosphere, the working medium must be

replaced continuously. This type of cycle is known as open cycle gas turbine plant.

‘© CLOSED CYCLE GAS TURBINE POWER PLANT:

>In closed cycle gas turbine plant, the working fluid (air or any other suitable gas)

chambers Heat “TS uct Supt A Supply

Exchanger 4 ie wa

oS =>)

t ames Il

ee Water out

coming out from compressor is heated

a heater by an external source at

constant pressure. The high

temperature and high-pressure air

coming out from the external heater is,

passed through the gas turbine. The

fluid coming out from the turbine is

cooled to its original temperature in the

cooler using external cooling source

before passing to the compressor. The

working fluid is continuously used in the

system without its change of phase and

the required heat is given to the

working fluid in the heat exchanger.

The arrangement of the components of

the closed cycle gas turbine plant is

shown in [Link] types of cycle is

known as closed cycle gas turbine

power plant.

SSASIT

| BY SHAILESH B, PATEL(E.C. DEPARTMENT) [iq�COMBINED CYCLE POWER PLANT

ENERGY SYSTEMS

BY SHAILESH B. PATEL -090760111025

@SITE SELECTION FOR COMBINED CYCLE POWER PLANT:-

1)AVAILABILITY OF RAW MATERIAL:it is necessary to locate the plant as far as possible

near the natural gas sources to reduce the cost of transportation of fuel. If the plant is

located away from souces of fuel field it may create problems due to failure of

transportation system

2)NATURE OF THE LAND & ITS COST:The site selected should have high bearing

capacity of at least 10N/mm2 to withstand dead load of the plant. It would reduce the

cost of foundation of the plant.

3)LOAD CENTRE:-A power plant must be located near the load to which the power is

supplied. The location of power plant at C.G. of loads reduces the cost of transmission

lines & the losses occurring in it.

4)AVAILABILITY OF LABOUR:-Large men power is needed during the construction of

plant. therefore, labour should be available near the construction site at cheap cost.

5 )ACCESSIBILITY TO SITE:- The power plant should have rail and road transportation

facilities.

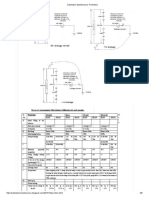

@STATUS OF COMBINED CYCLE POWER PLANT IN INDI

POWER PLANT NAME CAPACITY(MW) STATE

Godavari (Kakinada) Gas CCPP 208 ‘Andhra Pradesh

Lakwa Gas Turbine 120 Assam

Konaseema CCGT Gas 445 ‘Andhra Pradesh

Viljeswaran Gas CCT 272 Andhra Pradesh

GMMR Vernagiri Gas CCGT 389 ‘Andhra Pradesh

Samalkot/Peddapuram Gas CCGT 220 Andhra Pradesh

LANCO Kondapalli Gas CCGT 601 ‘Andhra Pradesh

GVK Jegurupadu Il Gas CCT 220 Andhra Pradesh

GVK Jegurupadu | Gas CCGT 235 ‘Andhra Pradesh

Gautami Gas CCGT 464 ‘Andhra Pradesh

Namrup Gas CCGT 1335 Assam

Kathalguri (Assam) Gas CCGT 291 Assam

Pragati Gas CCGT 330 Delhi

Indraprastha (Delhi) CCGT 282 Delhi

Vatwa Gas CCGT 100 Gujarat

Utran II CCGT Power Station 375 Gujarat

Utran | Gas CCGT 135 Gujarat�COMBINED CYCLE POWER PLANT

ENERGY SYSTEMS,

BY SHAILESH B. PATEL -090760111025

POWER PLANT NAME CAPACITY(MW) STATE

SUGEN (Torrent Power) CCT 1475 Gujarat

Paguthan Gas CCGT 655 Gujarat

Kawas Gas CCGT 644 Gujarat

Jhanor-Gandhar Gas CPP 648 Gujarat

Jamnagar RIL. Gas PP 300 Gujarat

Hazira RIL Gas CHP Plant 250 Gujarat

Hazira GSEG Gas CCGT 156.1 Gujarat

Hazira (Essar) Gas CCGT 515 Gujarat

Essar Hazira Gas CPP 32 Gujarat

Dhuvaran (GSECL) Gas CCT 219 Gujarat

Dhuvaran Oil GT Power Station 220 Gujarat

Bhandar (Essar Hazira) Gas CCGT 500 Gujarat

Vadodara Station Il (GIPCL) Gas CCGT 165 Gujrat

Vadodara Station | (GIPCL) Gas CCT 14s Gujarat

Faridabad NTPC Gas CCGT 430 Haryana

Pampore Gas Turbine 175 Jammu and Kashmir

Tanir Bavi Barge Gas CCPP 220 Kamataka

Kayamkulam (Rajiv Gandhi) Gas CCPP 360 Kerala

BSES Kochi Gas CCGT 167 Kerala

Uran Gas CCGT 912 Maharashtra

Trombay Gas CCGT 180 Maharashtra

South Bassein Gas PP 152 Maharashtra

Ratnagiri Ill (Dhabol) Gas CGT 740 Maharashtra

Ratnagiri ll (Ohabol) Gas CCGT 740 Maharashtra

Ratnagiri | (Dhabol) Gas CCGT 740 Maharashtra

Karaikal Gas CCGT 33 Puducherry

Ramgarh Gas CCGT 1138 Rajasthan

Dholpur Gas CCGT 330 Rajasthan

Anta Gas CCGT 413 Rajasthan

Sai Regency CCGT Power Plant 58 Tamil Nadu

Karuppur (APCL) CGT Power 198 Tamil Nadu

Valuthur (Perungulam) Gas CCGT 186.2 Tamil Nadu

Pillaiperumainallur Gas CCGT 3305 Tamil Nadu

Kuttalam Gas CCGT India 100 Tamil Nadu

Basin Bridge Gas Power Station 120 Tamil Nadu

Rokhia Gas Thermal Station "4 Tripura

Baramura Gas Thermal Station a Tripura

Agartala Gas Turbine Power Station 84 Tripura

Dadri Gas CCGT 817 Uttar Pradesh

Auraiya Gas CGT 652 Uttar Pradesh

‘Aonla Gas PP 100 Uttar Pradesh

ssasiT | BY SHAILESH 8, PATEL(E.. DEPARTMENT) EA�COMBINED CYCLE POWER PLANT

ENERGY SYSTEMS

BY SHAILESH B. PATEL -090760111025

@CONCLUSION:

Combine Cycle systems are efficient low cost systems that provides assurances of

performance and operating objectives. Combine Cycle systems can be customized to

the utility needs and preferences. They offer attractive economical reliable power

generation. Operating flexibility of Combine Cycle power generating warrant their

consideration for most power generation applications.

@REFERANCE :-

WWW, [Link]

WWW, [Link]

> [Link]

‘POWER PLANT ENGINEERING (NEW_AGE_INTERNATIONAL) BY A.K. RAJA & AMIT P.

SRIVASTAVA & MANISH DWIVEDI.

ssasiT | BY SHAILESH 8, PATEE.c, DEPARTMENT) EI