Professional Documents

Culture Documents

If Applicable: Certificate of Shop/Field Compliance

If Applicable: Certificate of Shop/Field Compliance

Uploaded by

manisami7036Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

If Applicable: Certificate of Shop/Field Compliance

If Applicable: Certificate of Shop/Field Compliance

Uploaded by

manisami7036Copyright:

Available Formats

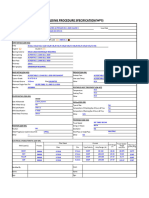

FORM U-1A MANUFACTURER'S DATA REPORT FOR PRESSURE VESSELS (Alternative Form for Single Chamber, Completely Shop

or Field Fabricated Vessels Only) As Required by the Provisions of the ASME Boiler and Pressure Vessel Code Rules, Section VIII, Division 1

1. Manufactured and certified by 2. Manufactured for 3. Location of installation 4. Type

(Horizontal or vertical, tank) (Manufacturers serial number) (CRN) (Name and address of Manufacturer) (Name and address of Purchaser) (Name and address) (Drawing number) (National Board number) (Year built)

5. The chemical and physical properties of all parts meet the requirements of material specifications of the ASME BOILER AND PRESSURE VESSEL CODE. The design, construction, and workmanship conform to ASME Rules, Section VIII, Division 1 to 6. Shell 7. Seams

[Addenda, if applicable (date)] (Material spec. number, grade) [Long. (welded, dbl., sngl., lap, butt)] (Nominal thickness) [R.T. (spot or full)] (Spec. no., grade) (Eff., %) (Code Case numbers) (Corr. allow.) (H.T. temp.) (Time, hr) (Inner diameter) [Girth (welded, dbl., sngl., lap, butt)] Year [Special service per UG-120(d)] [Length (overall)] [R.T. (spot or full)] (Eff., %) (No. of courses)

8. Heads: (a) Material

Location (Top, Bottom, Ends) Minimum Thickness

(b) Material

Knuckle Radius Elliptical Ratio Conical Apex Angle Hemispherical Radius

(Spec. no., grade)

Corrosion Allowance

Crown Radius

Flat Diameter

Side to Pressure (Convex or Concave)

(a) (b) If removable, bolts used (describe other fastenings) 9. MAWP

(Internal) (External) (Material spec. number, grade, size, number)

at max. temp.

(Internal)

(External)

. .

Min. design metal temp. Proof test .

at

. Hydro., pneu., or comb. test pressure

10. Nozzles, inspection, and safety valve openings:

Purpose (Inlet, Outlet, Drain etc.) No. Diameter or Size Type Material Nozzle Flange Nozzle Thickness Nom. Corr. Reinforcement Material Attachment Details Nozzle Flange Location (Insp. Open.)

11. Supports: Skirt

(Yes or no)

Lugs

(Number)

Legs

(Number)

Other

(Describe)

Attached

(Where and how)

12. Remarks: Manufacturers Partial Data Reports properly identified and signed by Commissioned Inspectors have been furnished for the following items of the report:

(Name of part, item number, Manufacturers name and identifying stamp)

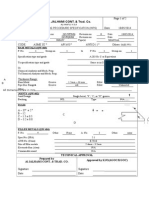

CERTIFICATE OF SHOP/FIELD COMPLIANCE We certify that the statements made in this report are correct and that all details of design, material, construction, and workmanship of this vessel conform to the ASME BOILER AND PRESSURE VESSEL CODE, Section VIII, Division 1. U Certificate of Authorization Number . expires Date Co. name

(Manufacturer)

Signed

(Representative)

CERTIFICATE OF SHOP/FIELD INSPECTION Vessel constructed by at . I, the undersigned, holding a valid commission issued by the National Board of Boiler and Pressure Vessel Inspectors and/or the State or Province of

and employed by have inspected the component described in this Manufacturer's Data Report on , and state that, to the best of my knowledge and belief, the Manufacturer has constructed this pressure vessel in accordance with ASME BOILER AND PRESSURE VESSEL CODE, Section VIII, Division 1. By signing this certificate neither the Inspector nor his/her employer makes any warranty, expressed or implied, concerning the pressure vessel described in this Manufacturer's Data Report. Furthermore, neither the Inspector nor his/her employer shall be liable in any manner for any personal injury or property damage or a loss of any kind arising from or connected with this inspection. Date

(07/10)

Signed

(Authorized Inspector)

Commissions

[National Board (incl. endorsements), State, Province, and number]

You might also like

- Asme BPVC - Ssc.i.ii.v.ix - Xiii-2023Document42 pagesAsme BPVC - Ssc.i.ii.v.ix - Xiii-2023mmendozagNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- EIL Procedure For Technical Audit - 5-1940-8020 Rev. 5Document26 pagesEIL Procedure For Technical Audit - 5-1940-8020 Rev. 5EILA545 QAQCNo ratings yet

- Surface Vehicle InformationDocument13 pagesSurface Vehicle InformationanupthattaNo ratings yet

- Working ITPDocument4 pagesWorking ITPStephen BoodooNo ratings yet

- Electrode Test Record E6010Document9 pagesElectrode Test Record E6010Veeraraghavan GuruNo ratings yet

- Mawp and MDMT Calculations PDFDocument5 pagesMawp and MDMT Calculations PDFobuse100% (7)

- Body Flanges On ShellsDocument2 pagesBody Flanges On ShellsPadmanabhan VenkateshNo ratings yet

- U1a - 735834Document2 pagesU1a - 735834Alex SimonNo ratings yet

- Overage, Shortage and Damage Voucher (OSDV)Document1 pageOverage, Shortage and Damage Voucher (OSDV)Yuzuan OthmanNo ratings yet

- Rolling ProcedureDocument6 pagesRolling ProcedureLuhur PrandikaNo ratings yet

- Saudi Aramco Typical Inspection PlanDocument12 pagesSaudi Aramco Typical Inspection Planspravin231No ratings yet

- Itp PSV, Dppu ImipDocument1 pageItp PSV, Dppu ImipHendra WidyantoroNo ratings yet

- Itp Ralgo HssDocument5 pagesItp Ralgo Hssmark quijlvoNo ratings yet

- Nde Plan: Joint Number / Parts Before PWHT After PWHT RT Paut UT MT PT PMI RT MTDocument2 pagesNde Plan: Joint Number / Parts Before PWHT After PWHT RT Paut UT MT PT PMI RT MTfizanlaminNo ratings yet

- 6001F Rev 07 Material, Fabrication and Installation StructureDocument83 pages6001F Rev 07 Material, Fabrication and Installation StructurePatrickioNo ratings yet

- EQUIPMENT: Tube Bundle For Shell &tube HX Titile: Inspection Test Plan Item: 6112-E-02Document6 pagesEQUIPMENT: Tube Bundle For Shell &tube HX Titile: Inspection Test Plan Item: 6112-E-02Khalilahmad KhatriNo ratings yet

- 0.hydro Test Package Index - 2Document13 pages0.hydro Test Package Index - 2VISHNUPRASAD ARAKKAL MOHANDASNo ratings yet

- ITP For Piping SystemsDocument6 pagesITP For Piping SystemssojeckNo ratings yet

- Tdoc 014 REV.01 - ITP FOR EXCAVATION & COMPACTION (ITP 002)Document1 pageTdoc 014 REV.01 - ITP FOR EXCAVATION & COMPACTION (ITP 002)mNo ratings yet

- Receiving Material Procedure CoverDocument1 pageReceiving Material Procedure Covergst ajahNo ratings yet

- 13427-01weekly QAQC ReportDocument1 page13427-01weekly QAQC ReportShyam SinghNo ratings yet

- MD1-0-T-030-05-00073 - ITP For Under Ground Piping PDFDocument8 pagesMD1-0-T-030-05-00073 - ITP For Under Ground Piping PDFTran KhuynhNo ratings yet

- Fit - Up and Visual Examination Report: Attachment Drawing Joint DetailDocument1 pageFit - Up and Visual Examination Report: Attachment Drawing Joint DetailMuhammad Fitransyah Syamsuar Putra100% (1)

- ITP Fuel Fillter (J-1001) Rev10+Document9 pagesITP Fuel Fillter (J-1001) Rev10+DjokoNo ratings yet

- WE1884 - ITP For Shop Fab. of Header Coils-120813Document4 pagesWE1884 - ITP For Shop Fab. of Header Coils-120813imran100% (1)

- AB-036386 Hardness Testing For Welding Procedure QualificationDocument1 pageAB-036386 Hardness Testing For Welding Procedure QualificationAmr MahmoudNo ratings yet

- Cold Tap Coating Report 2Document1 pageCold Tap Coating Report 2Jamal BakhtNo ratings yet

- SAIC-W-2077 Weld Joint Identification SystemDocument1 pageSAIC-W-2077 Weld Joint Identification Systemkarioke mohaNo ratings yet

- Golden Joint ChecklistDocument2 pagesGolden Joint ChecklistMohd Effiezool YaserNo ratings yet

- Editable AWS D1.1 WPSDocument2 pagesEditable AWS D1.1 WPSSheik Mohamed100% (1)

- Inspection and Test Plan: Page 1+0 of 7Document7 pagesInspection and Test Plan: Page 1+0 of 7Jamal Mohamed Rahamathullah100% (1)

- Activity Report Running WPS & PQRDocument3 pagesActivity Report Running WPS & PQRAndre Brama AlvariNo ratings yet

- THE THIRD PART INSPECTION FOR VALVES - OdtDocument8 pagesTHE THIRD PART INSPECTION FOR VALVES - OdtVelibor StokicNo ratings yet

- Package 2s E0001 - Jupiter DCR 30-10-2021Document96 pagesPackage 2s E0001 - Jupiter DCR 30-10-2021senthilNo ratings yet

- Saudi Aramco Inspection Checklist: Inspection of Structural Alignment During Erection SAIC-M-2007 30-Apr-13 MechDocument15 pagesSaudi Aramco Inspection Checklist: Inspection of Structural Alignment During Erection SAIC-M-2007 30-Apr-13 Mechpookkoya thangalNo ratings yet

- Welding Log DW-CWDocument12 pagesWelding Log DW-CWhasan shahriarNo ratings yet

- 1 SATIP-D-001-01 Pressure Vessel Installation-Rev 1 - 000Document3 pages1 SATIP-D-001-01 Pressure Vessel Installation-Rev 1 - 000j fNo ratings yet

- Siemens: 1200 MW DGEN Mega Power ProjectDocument4 pagesSiemens: 1200 MW DGEN Mega Power ProjectJuzer MadarwalaNo ratings yet

- Tata A2239 Qap Rev.00Document4 pagesTata A2239 Qap Rev.00PRASHANTNo ratings yet

- Coke Crusher - Lubrication Pumps Run in TestDocument26 pagesCoke Crusher - Lubrication Pumps Run in TestsayedNo ratings yet

- Interseal 670HDocument2 pagesInterseal 670Hmadmax_mfpNo ratings yet

- Double Pipe and Multitube IP 6-2-1 Hairpin Heat Exchangers: Section 1 - GeneralDocument7 pagesDouble Pipe and Multitube IP 6-2-1 Hairpin Heat Exchangers: Section 1 - Generalhcsharma1967No ratings yet

- Project:OLMTP Project No:16-PSS-002 Client:ZKB-RELIABLE: Daily Welding Inspection ReportDocument4 pagesProject:OLMTP Project No:16-PSS-002 Client:ZKB-RELIABLE: Daily Welding Inspection ReportEngr Saeed AnwarNo ratings yet

- G. Std. ITP For Pipeline Job PDFDocument4 pagesG. Std. ITP For Pipeline Job PDFAnonymous 4e7GNjzGW100% (1)

- Inspection of Test Plan Pressure Vessel: LOCATION: Isi Sesuai Lokasi Peralatan Akan Di InspeksiDocument3 pagesInspection of Test Plan Pressure Vessel: LOCATION: Isi Sesuai Lokasi Peralatan Akan Di Inspeksizvlcar nainNo ratings yet

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 pagesInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNo ratings yet

- ITP For Pipeline Repair Works - by Using Belzona Superwrap IIDocument4 pagesITP For Pipeline Repair Works - by Using Belzona Superwrap IIAhmedNo ratings yet

- CPVC ChecklistDocument1 pageCPVC Checklistchakravarthi kanugulaNo ratings yet

- 1.0 Scope: General Welding Standard For PipingDocument7 pages1.0 Scope: General Welding Standard For PipingandhucaosNo ratings yet

- QC-wps-06 Rev. 0 A283 GR.C Tank 130Document2 pagesQC-wps-06 Rev. 0 A283 GR.C Tank 130Richard PeriyanayagamNo ratings yet

- Precommissioning of Pipelines: Technical SpecificationDocument40 pagesPrecommissioning of Pipelines: Technical SpecificationLizeth RamirezNo ratings yet

- KP-00+++-CQ712-B7359-132kV Electrical Works (Switchyard Current and Voltage Transformer)Document3 pagesKP-00+++-CQ712-B7359-132kV Electrical Works (Switchyard Current and Voltage Transformer)Utku Can KılıçNo ratings yet

- TopCoreBelco 101 FCDocument9 pagesTopCoreBelco 101 FCCesar ArellanoNo ratings yet

- PF-0004-009-QA-955-0001 Rev D Code 1Document27 pagesPF-0004-009-QA-955-0001 Rev D Code 1Rıdvan UyarNo ratings yet

- NDE TABLE For HEADER BOX - R0 Modified With Type 1 Joint ofDocument9 pagesNDE TABLE For HEADER BOX - R0 Modified With Type 1 Joint ofrony16novNo ratings yet

- R0607-Cm-Itr-08-606 321a PDFDocument13 pagesR0607-Cm-Itr-08-606 321a PDFShelton S S SheltonNo ratings yet

- DBB BNCPP B M v29 0015 Revb IfaDocument6 pagesDBB BNCPP B M v29 0015 Revb IfaIzzadAfif1990No ratings yet

- FDA and 1935 2004 DoC General Food Contact Regulations BU HFH Rev 008Document15 pagesFDA and 1935 2004 DoC General Food Contact Regulations BU HFH Rev 008Gisela ViskaNo ratings yet

- 024 Itp For Grouting Works PDFDocument8 pages024 Itp For Grouting Works PDFHarshvardhan PathakNo ratings yet

- Form T-1B Manufacturer'S Data Report For Class 2 Transport Tanks As Required by The Provisions of The ASME Code Rules, Section XIIDocument1 pageForm T-1B Manufacturer'S Data Report For Class 2 Transport Tanks As Required by The Provisions of The ASME Code Rules, Section XIIEmma DNo ratings yet

- BPVC Viii-1 U-1a PDFDocument2 pagesBPVC Viii-1 U-1a PDFabdesselam00No ratings yet

- Form A-1P Manufacturer'S Data Report For Plate Heat Exchangers As Required by The Provisions of The ASME Code Rules, Section VIII, Division 2Document2 pagesForm A-1P Manufacturer'S Data Report For Plate Heat Exchangers As Required by The Provisions of The ASME Code Rules, Section VIII, Division 2Emma DNo ratings yet

- Alloying Elements and Their EffectsDocument5 pagesAlloying Elements and Their EffectsDimas Anugrah100% (2)

- Influence of PWHT To Steel Phase & PropertiesDocument6 pagesInfluence of PWHT To Steel Phase & PropertiesDimas AnugrahNo ratings yet

- Principles of DrawingDocument6 pagesPrinciples of DrawingSudesh Gubale BNo ratings yet

- Drain A Tank CalculationDocument743 pagesDrain A Tank CalculationDimas AnugrahNo ratings yet

- Pengantar NDT 2003Document27 pagesPengantar NDT 2003Dimas AnugrahNo ratings yet

- Quenched and Tempered Vacuum-Treated Carbon and Alloy Steel Forgings For Pressure VesselsDocument9 pagesQuenched and Tempered Vacuum-Treated Carbon and Alloy Steel Forgings For Pressure VesselssamehNo ratings yet

- U1a - 735834Document2 pagesU1a - 735834Alex SimonNo ratings yet

- GP 32-45Document13 pagesGP 32-45Diego100% (1)

- A263-12 Stainless Chromium Steel-Clad PlateDocument6 pagesA263-12 Stainless Chromium Steel-Clad PlatemehmetNo ratings yet

- Astm 455 PDFDocument2 pagesAstm 455 PDFJOSEPH REFUERZONo ratings yet

- Steel Castings Suitable For Pressure ServiceDocument6 pagesSteel Castings Suitable For Pressure ServiceRafael CossolinoNo ratings yet

- QW-450 Specimens: QW-451 Procedure Qualification Thickness Limits and Test SpecimensDocument1 pageQW-450 Specimens: QW-451 Procedure Qualification Thickness Limits and Test SpecimensBabar100% (2)

- Codeline Drawing 80S30 Non CodedDocument2 pagesCodeline Drawing 80S30 Non CodedLeandro AlvesNo ratings yet

- ASTM A240-A240M-05aDocument12 pagesASTM A240-A240M-05aNadhiraNo ratings yet

- ASME Standards Technology, LLC: New PublicationsDocument5 pagesASME Standards Technology, LLC: New PublicationsTrushar ParmarNo ratings yet

- I-2.54-E Penetrant Procedure RevizeDocument14 pagesI-2.54-E Penetrant Procedure RevizeMohanadNo ratings yet

- Asme SB 862 Astm b862 PDFDocument14 pagesAsme SB 862 Astm b862 PDFp v krishnakantNo ratings yet

- Summary of ASME BPVC Section VIII Div 1 (Part 1) - Welding & NDTDocument11 pagesSummary of ASME BPVC Section VIII Div 1 (Part 1) - Welding & NDTTin Aung KyiNo ratings yet

- Asme BPVC 2015 Section Viii Div 2 Annex 5-bDocument3 pagesAsme BPVC 2015 Section Viii Div 2 Annex 5-bsirsong1234No ratings yet

- Coe10508 PDFDocument25 pagesCoe10508 PDFcvg ertdNo ratings yet

- GSW-NG01017640-GEN-LA7303-00002 - Material Requisition For Pig Launcher and Receiver - D01Document22 pagesGSW-NG01017640-GEN-LA7303-00002 - Material Requisition For Pig Launcher and Receiver - D01Nnamdi Umezuruike100% (1)

- API 510 Exam May 2021Document30 pagesAPI 510 Exam May 2021Ahmed ShakirNo ratings yet

- ASME PTB-4-2013: Examples E4.5.1-E4.5.6 BPVC VIII-1 2013Document48 pagesASME PTB-4-2013: Examples E4.5.1-E4.5.6 BPVC VIII-1 2013ordenador90No ratings yet

- Pressure Vessel Design ASME Section VIII Divison1 and Division 2Document3 pagesPressure Vessel Design ASME Section VIII Divison1 and Division 2sammar_10No ratings yet

- Ipc - 2022 Design and Finite Element Analysis (Fea) of Bulkheads For A Pipe-Inpipe Flowline Application of Asme Boiler and Pressure Vessel CodeDocument6 pagesIpc - 2022 Design and Finite Element Analysis (Fea) of Bulkheads For A Pipe-Inpipe Flowline Application of Asme Boiler and Pressure Vessel CodeOswaldo MontenegroNo ratings yet

- TBE Clarification CCLPECDocument226 pagesTBE Clarification CCLPEClemuel bacsaNo ratings yet

- Certificado Liquidos PenetrantesDocument3 pagesCertificado Liquidos PenetrantesEnrique AntonioNo ratings yet

- Reactor Internals Design PDFDocument81 pagesReactor Internals Design PDFBest HopeNo ratings yet

- Batch Test Certificate: Page 1 of 2 Form No: F/QC/012/1 3 Rev: 05 /2022Document2 pagesBatch Test Certificate: Page 1 of 2 Form No: F/QC/012/1 3 Rev: 05 /2022gauravNo ratings yet

- Codes For Vessels/Heat ExchangersDocument23 pagesCodes For Vessels/Heat ExchangersChiheb KaanicheNo ratings yet

- PDFsam - B 395 - B 395M - 16Document12 pagesPDFsam - B 395 - B 395M - 16mike.jensen0581No ratings yet

- AE Standards 1309Document10 pagesAE Standards 1309vrapciudorianNo ratings yet

- 344.2 Visual Examination: Para. 344.7Document1 page344.2 Visual Examination: Para. 344.7NDTInstructorNo ratings yet