Professional Documents

Culture Documents

The Automation - The Following Figure Shows Some of The Basic Categories of Control System Problems

Uploaded by

imdebarshiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Automation - The Following Figure Shows Some of The Basic Categories of Control System Problems

Uploaded by

imdebarshiCopyright:

Available Formats

INTRODUCTION

Industrial Automation is the use of Control Systems to control Industrial Machinery and Processes, reducing the need for human intervention. If we compare a job being done by human and by Automation, the physical part of the job is replaced by use of a Machine, whereas the mental capabilities of the human are replaced with the automation.

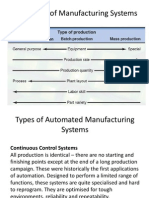

The following figure shows some of the basic categories of control system problems.

CONTROL

CONTINUOUS NON-LINEAR e.g MARC, FUZZY CONDITIONAL e.g -- PID

DISCRETE

LINEAR

SEQUENTIAL

TEMPORAL LOGIC BOOLEAN e.g -- TIMERS

EVENT BASED EXPERT SYSTEM e.g -- COUNTERS

FIG. CONTROL DICHOTOMY

Continuous - The values to be controlled change smoothly. e.g. the speed of a car. Logical / Discrete - The value to be controlled are easily described as on-off. e.g. the car motor is on-off. NOTE: all systems are continuous but they can be treated as logical for simplicity, and When it is done, that always happens! For example, when the power is turned on, the press closes!

Linear - Can be described with a simple differential equation. This is the preferred starting point for simplicity, and a common approximation for real world problems. e.g. A car can be driving around a track and can pass same the same spot at a constant velocity. But, the longer the car runs, the mass decreases, and it travels faster, but requires less gas, etc. Basically, the math gets tougher, and the problem becomes non-linear. and We are driving the perfect car with no friction, with no drag, and can predict how it will work perfectly. Non-Linear - Not Linear. This is how the world works and the mathematics become much more complex. e.g. As rocket approaches sun, gravity increases, so control must change. Sequential - A logical controller that will keep track of time and previous events. The difference between these control systems can be emphasized by considering simple elevator. An elevator is a car that travels between floors, stopping at precise heights. There are certain logical constraints used for safety and convenience. The points below emphasize different types of control problems in the elevator. Logical: 1. The elevator must move towards a floor when a button is pushed. 2. The elevator must open a door when it is at a floor. 3. It must have the door closed before it moves,etc. Linear: 1. If the desired position changes to a new value, accelerate quickly towards the new position. 2. As the elevator approaches the correct position, slow down.

Non-linear: 1. 2. 3. 4. Accelerate slowly to start. Decelerate as you approach the final position. Allow faster motion while moving. Compensate for cable stretch, and changing spring constant, etc.

Logical and sequential control is preferred for system design. These systems are more stable, and often lower cost. Most continuous systems can be controlled logically. But, some times we will encounter a system that must be controlled continuously. When this occurs the control system design becomes more demanding. When improperly controlled,continuous systems may be unstable and become dangerous. When a system is well behaved it is said to be self regulating. These systems dont need to be closely monitored, and we use open loop control. An open loop controller will set a desired position for a system, but no sensors are used to verify the position. When a system must be constantly monitored and the control output adjusted we say it is closed loop. A cruise control in a car is an excellent example. This will monitor the actual speed of a car, and adjust the speed to meet a set target speed. Many control technologies are available for control. Early control systems relied upon mechanisms and electronics to build controlled. Most modern controllers use a computer to achieve control. The most flexible of these controllers is the PLC (Programmable Logic Controller). Control engineering has evolved over time. In the past humans were the main method for controlling a system. More recently electricity has been used for control and early electrical control was based on relays. These relays allow power to be switched on and off without a mechanical switch. It is common to use relays to make simple logical

control decisions. The development of low cost computer has brought the most recent revolution,the Programmable Logic Controller (PLC). The advent of the PLC began in the 1970s, and has become the most common choice for manufacturing controls. PLCs have been gaining popularity on the factory floor and will probably remain predominant for some time to come. Most of this is because of the advantages they offer. Cost effective for controlling complex systems. Flexible and can be reapplied to control other systems quickly and easily. Computational abilities allow more sophisticated control. Trouble shooting aids make programming easier and reduce downtime. Reliable components make these likely to operate for years before failure.

You might also like

- EE2253 NotesDocument124 pagesEE2253 NotesSiva Kathikeyan100% (1)

- EE2253 - Control Systems PDFDocument124 pagesEE2253 - Control Systems PDFaduveyNo ratings yet

- Bottle Filling Station Using PLC AutomationDocument4 pagesBottle Filling Station Using PLC AutomationL Deepanti PunjabanNo ratings yet

- FlexFactory Users Manual 29164188AADocument552 pagesFlexFactory Users Manual 29164188AAAshish GowandeNo ratings yet

- Hotel Management System FinalDocument23 pagesHotel Management System Finalranahamid007100% (2)

- Introduction To PLCDocument13 pagesIntroduction To PLCdimasNo ratings yet

- IntroductionDocument4 pagesIntroductionafainurNo ratings yet

- Control SystemDocument3 pagesControl SystemsryunkNo ratings yet

- Subject - Mechatronics: Summer - 2018 SolutionDocument31 pagesSubject - Mechatronics: Summer - 2018 SolutionFaheem TirmiziNo ratings yet

- Process Control SystemDocument9 pagesProcess Control SystemTrung KiênNo ratings yet

- Systems and Control 1Document6 pagesSystems and Control 1stephendixNo ratings yet

- Automatic Control: Open Loop Control Systems: A System in Which The Output Has No Effect On The Control Action IsDocument11 pagesAutomatic Control: Open Loop Control Systems: A System in Which The Output Has No Effect On The Control Action IsmjoNo ratings yet

- Chapter 1Document178 pagesChapter 1Hugo GandaraNo ratings yet

- PLC Handbook - FinaleDocument85 pagesPLC Handbook - FinalesaravanaNo ratings yet

- Introduction To Programmable Logic ControllersRev2Document43 pagesIntroduction To Programmable Logic ControllersRev2apelokayaNo ratings yet

- What Is Automation?: - Automatic Assembly MachinesDocument24 pagesWhat Is Automation?: - Automatic Assembly MachinesNazmul AhsanNo ratings yet

- RTbook Chapter 1Document16 pagesRTbook Chapter 1Bilal ShahidNo ratings yet

- Close & Open Loop SystemDocument6 pagesClose & Open Loop SystemAdonis NicolasNo ratings yet

- Control System NOTESDocument9 pagesControl System NOTESSTUDENTS OF DOE CUSATNo ratings yet

- Omron PLC StudyDocument99 pagesOmron PLC StudyferoztechitNo ratings yet

- Submitted by DaDocument3 pagesSubmitted by DaDagii MuleNo ratings yet

- Nov 162845Document6 pagesNov 162845hassanaagibNo ratings yet

- PC Based Industrial Automation With AVR Atmega 16 - Project ReportDocument33 pagesPC Based Industrial Automation With AVR Atmega 16 - Project ReportRobo IndiaNo ratings yet

- CSC Unit 1Document22 pagesCSC Unit 1aviitharu2472No ratings yet

- Control System (Closed Loop and Open Loop)Document10 pagesControl System (Closed Loop and Open Loop)Fhyras Ayatullah100% (1)

- CS Lecture Notes Units 1 2 3Document88 pagesCS Lecture Notes Units 1 2 3sushinkNo ratings yet

- Chapter 2 How Organizations Use ICT 1Document27 pagesChapter 2 How Organizations Use ICT 1Arpan JhaNo ratings yet

- Jahid 1Document24 pagesJahid 1Nazmul AhsanNo ratings yet

- Control EngineeringDocument21 pagesControl EngineeringNor AshimyNo ratings yet

- Automation Ch04Document20 pagesAutomation Ch04Junaid SayedNo ratings yet

- Automation PDFDocument20 pagesAutomation PDFsudhir raiNo ratings yet

- Automation Ch04Document20 pagesAutomation Ch04PeerBuxNo ratings yet

- Automation Ch04Document20 pagesAutomation Ch04Junaid SayedNo ratings yet

- PLC - Automation and Sensor PDFDocument20 pagesPLC - Automation and Sensor PDFsudhir raiNo ratings yet

- Automation Ch04Document20 pagesAutomation Ch04musharrfNo ratings yet

- EE2253 - Control SystemsDocument124 pagesEE2253 - Control SystemsrameshsmeNo ratings yet

- LogixPro CISE 313 Automation Devices and Electronics Lab ManualDocument36 pagesLogixPro CISE 313 Automation Devices and Electronics Lab ManualHelder NascimentoNo ratings yet

- Design of Five Floors Elevator With SCADA System Based On S7200 PLCDocument6 pagesDesign of Five Floors Elevator With SCADA System Based On S7200 PLCothmanNo ratings yet

- Automatic Bottle Filling and Capping Control SystemDocument41 pagesAutomatic Bottle Filling and Capping Control SystemoscarNo ratings yet

- Control Systems: Moyasar Al-TatariDocument12 pagesControl Systems: Moyasar Al-Tatarisusu1996No ratings yet

- 1 IntroDocument5 pages1 IntroTrâm TrầnNo ratings yet

- Control SystemDocument55 pagesControl SystemEr Rajdeep SahaNo ratings yet

- 1 Mechatronics - Control - DevicesDocument40 pages1 Mechatronics - Control - DevicesAdrian GCNo ratings yet

- First Autopilots: Sperry CorporationDocument10 pagesFirst Autopilots: Sperry Corporationpooja0100No ratings yet

- Control Systems - NotesDocument61 pagesControl Systems - NotesNarasimha Murthy YayavaramNo ratings yet

- Ipc (Group-5) : Sr. No Name En. NoDocument15 pagesIpc (Group-5) : Sr. No Name En. Noian jheferNo ratings yet

- Automated Manufacturing SystemsDocument25 pagesAutomated Manufacturing SystemsSoto KunNo ratings yet

- Automatic Bottle Filling and Capping Control SystemDocument41 pagesAutomatic Bottle Filling and Capping Control Systemmahderina_218241157100% (12)

- Presentation ON Programmble Logical Device (PLC) AT Automation SystemDocument24 pagesPresentation ON Programmble Logical Device (PLC) AT Automation SystemChandni MehtaNo ratings yet

- Lesson No. 1 LectureDocument98 pagesLesson No. 1 Lecturezen anastacioNo ratings yet

- Understanding PID Control, Part 7 - Important PID ConceptsDocument5 pagesUnderstanding PID Control, Part 7 - Important PID ConceptsFirman Wahyu NugrohoNo ratings yet

- Unit No - II: Block Diagram RepresentationDocument56 pagesUnit No - II: Block Diagram RepresentationNamrta DeokateNo ratings yet

- 1.introduction Control SystemDocument21 pages1.introduction Control SystemhilminroziNo ratings yet

- Control EngineeringDocument7 pagesControl Engineeringuet158No ratings yet

- Design & Control of An Elevator Control System Using PLC: April 2017Document6 pagesDesign & Control of An Elevator Control System Using PLC: April 2017othmanNo ratings yet

- Ass 1 AnswerDocument8 pagesAss 1 AnswerChala BalchaNo ratings yet

- Aparent ProjectDocument14 pagesAparent ProjectbernabasNo ratings yet

- Classification of Control SystemsDocument6 pagesClassification of Control Systemssandesh kelamNo ratings yet

- Automotive Electronic Diagnostics (Course 2)From EverandAutomotive Electronic Diagnostics (Course 2)Rating: 4 out of 5 stars4/5 (2)

- ECONOMICS WBCS 2015 Mains PDFDocument14 pagesECONOMICS WBCS 2015 Mains PDFimdebarshiNo ratings yet

- HIST Mains 2015Document9 pagesHIST Mains 2015imdebarshiNo ratings yet

- ECONOMICS WBCS 2015 Mains PDFDocument14 pagesECONOMICS WBCS 2015 Mains PDFimdebarshiNo ratings yet

- Wbcs Prelims 2016 Answer Key AADocument15 pagesWbcs Prelims 2016 Answer Key AAimdebarshiNo ratings yet

- Reading Comprehension ExercisesDocument26 pagesReading Comprehension ExercisesimdebarshiNo ratings yet

- Data Interpretation ExercisesDocument42 pagesData Interpretation ExercisesimdebarshiNo ratings yet

- Issue 11 (Low Res)Document52 pagesIssue 11 (Low Res)imdebarshiNo ratings yet

- Govnow V1 I1 Lowres PDF'sDocument39 pagesGovnow V1 I1 Lowres PDF'simdebarshiNo ratings yet

- Issue 14 (Low Res)Document52 pagesIssue 14 (Low Res)imdebarshiNo ratings yet

- Kurukshetra - English January 2012Document50 pagesKurukshetra - English January 2012imdebarshiNo ratings yet

- Operator Overloading & Dunder Methods - Python Tutorials For Absolute Beginners in Hindi #67Document3 pagesOperator Overloading & Dunder Methods - Python Tutorials For Absolute Beginners in Hindi #67Anonymous AZNo ratings yet

- MatthewPan ResumeDocument1 pageMatthewPan ResumeTiago CaladoNo ratings yet

- CPU-bound Programs, On The Other Hand, Use Their Entire Quantum Without Performing Any Blocking I/ODocument12 pagesCPU-bound Programs, On The Other Hand, Use Their Entire Quantum Without Performing Any Blocking I/ONguyen Dang Dung (K15 HL)No ratings yet

- PIIMSDocument2 pagesPIIMSShalk GNo ratings yet

- Experiment 06: Study of Process Control-I: Mesbah Ahmad Lecturer Department of Chemical Engineering, BUETDocument18 pagesExperiment 06: Study of Process Control-I: Mesbah Ahmad Lecturer Department of Chemical Engineering, BUETMd Abid AfridiNo ratings yet

- ISO/IEC 25010: Functional SuitabilityDocument5 pagesISO/IEC 25010: Functional SuitabilityRaymond RamirezNo ratings yet

- CpE Laws - Professional Practice - Module 04Document17 pagesCpE Laws - Professional Practice - Module 04Joel ManacmulNo ratings yet

- CC103 Mod2Document4 pagesCC103 Mod2Vincent SiaronNo ratings yet

- Institute of Space Technology: Submitted byDocument12 pagesInstitute of Space Technology: Submitted byMesum IrfaniNo ratings yet

- Tutorial VB Project AnalyzeDocument44 pagesTutorial VB Project AnalyzeFaisal BashirNo ratings yet

- GAMP 5 and The Supplier: Leveraging Supplier Advantage Out of ComplianceDocument19 pagesGAMP 5 and The Supplier: Leveraging Supplier Advantage Out of ComplianceMaheshNo ratings yet

- 1.5 Systems Software End of Topic QuizDocument12 pages1.5 Systems Software End of Topic QuizA popopNo ratings yet

- A3chart SFIA 5 enDocument1 pageA3chart SFIA 5 enrobanderson72No ratings yet

- Jackson System DevelopmentDocument18 pagesJackson System DevelopmentArun SaxenaNo ratings yet

- Learn PythonDocument2 pagesLearn PythonDilshad HussainNo ratings yet

- Closure, Currying and IIFE in JavaScript - DEV Community ? ?? ? PDFDocument1 pageClosure, Currying and IIFE in JavaScript - DEV Community ? ?? ? PDFbebofayezNo ratings yet

- WizGear BrochureDocument5 pagesWizGear BrochureabNo ratings yet

- Interview Questions For Software TestersDocument41 pagesInterview Questions For Software Testersapi-3719303100% (1)

- "Cocomo Ii: Model For Estimating Software Cost": Honors Credit Contract Kapil B. VyasDocument10 pages"Cocomo Ii: Model For Estimating Software Cost": Honors Credit Contract Kapil B. Vyaskbv2842No ratings yet

- Shalaka Potdar CV MumbaiDocument2 pagesShalaka Potdar CV Mumbaiapi-3800762No ratings yet

- MES3053 - Chap5 Blackbox TestingDocument71 pagesMES3053 - Chap5 Blackbox TestingEeiouNo ratings yet

- 00a CIS EWP Projects Plan CheckListDocument7 pages00a CIS EWP Projects Plan CheckListCarlos EspinosaNo ratings yet

- BAPI - It Is Nothing, But A FM Which Is Used To Load The Data Into SAP System. The Data May Be From TheDocument2 pagesBAPI - It Is Nothing, But A FM Which Is Used To Load The Data Into SAP System. The Data May Be From ThejovanaNo ratings yet

- English QSM11 - 3578079431Document217 pagesEnglish QSM11 - 3578079431sharef18No ratings yet

- EP - EngineDocument4 pagesEP - EngineAkhmad HasimNo ratings yet

- Engine P222LE SDocument2 pagesEngine P222LE SFederico BabichNo ratings yet

- Test Universe v3 10 ClientServer Booklet ENUDocument12 pagesTest Universe v3 10 ClientServer Booklet ENUUdomsak ThanatkhaNo ratings yet

- Warehousing LiteratureDocument41 pagesWarehousing LiteraturePredragNo ratings yet