Professional Documents

Culture Documents

Scaffold Safety Checklist

Uploaded by

89simbuOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Scaffold Safety Checklist

Uploaded by

89simbuCopyright:

Available Formats

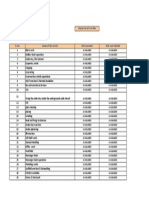

Scaffold safety checklist

Date Prepared:_________________________ Project Name/No.______________________

By:_______________________ Location:__________________

Check the box if the statement is true.

HAZARD IDENTIFICATION

The company has a written Injury and Illness Prevention Program (IIPP) that meets all Cal/OSHA requirements. It includes identification of potential scaffold safety hazards on the site, regular inspections, accident investigation, and correction of hazardous conditions. [1509]

PERMIT

A Cal/OSHA permit has been obtained for erection or dismantling of any scaffold or falsework more than 3 stories (36 feet) high. [341(a)(2) and (a)(3)]

USE OF SCAFFOLDS

No scaffolds are necessary on this job because all of the following are true: (1) the work is of a limited nature and short duration; (2) the fall distance is less than 15 feet; (3) adequate risk control exists; and (4) the work is under competent supervision. [1637(a)]

No scaffolds are necessary on this job because all of the following are true: (1) the work is of short duration; (2) the work is on joists or similar members; and (3) the joists are centered 2 feet or closer with planking at least 12" wide. [1637(a)]

Scaffolds are used. There is no permanent/solid construction at least 20" wide to stand on, and the work can't be done safely from ladders. [1637(a)]

THE QUALIFIED PERSON

Scaffolds are erected and dismantled under the supervision of a qualified person. [1637(k)(1)]

The qualified person has a certificate of competence in scaffold erection, dismantling, and use, issued by a trade association or state approved apprenticeship program. [1637(k)(1)] Or the qualified person has been identified by the company based on other experience or training, and is familiar with the operations to be performed and the hazards involved. [1504]

Name of qualified person:_____________________________

Scaffolds are tagged to show that the qualified person has met his or her responsibilities.

PROHIBITED SCAFFOLDS

No lean-to or jack scaffolds. [1637(j)] No shore scaffolds. [1637(j)] No nailed brackets. [1637(j)] No loose tile, brick, or blocks used in place of a scaffold. [1637(j)] No stilts. [1637(j)]

DESIGN OF THE SCAFFOLD

Any wooden pole scaffold over 60 feet is designed by a registered civil engineer. [1643] Any tube and coupler scaffold over 125 feet is designed by a registered civil engineer. [1644(b)(5)] Any tubular welded frame scaffold over 125 feet is designated by a registered civil engineer. [1644(c)(7)] If an engineer designed the scaffold, the drawings are on site during the erection of the scaffold. [1637(k)(2)] Single or tiered horse scaffolds are not over 10 feet high. [1647(e)(1)]

MATERIALS AND PLANKING

The scaffold uses stress grade lumber (or metal such as aluminum if structural integrity is maintained). [1637(b)] The wood is not cracked, warped, knotted, or defective. [1637(d)] All lumber is visually inspected for defects before and during use. No defective lumber is used. [1637(h)] The planking is at least 2" x 10" scaffold grade plank. [1637(f)(1)] The 2" x 10" spans no more than 10 feet if the working load is 25 pounds per square foot (light trades). It spans no more than 8 feet if the load is 50 psf (medium trades), or 7 feet for 75 psf (heavy trades). [1637(f)(2)]

Manufactured planks longer than 10 feet are labeled with their maximum load. [1637(f)(3)] The platforms are planked solid, except open area under the back railing. [1640(b)(5)(A) and 1644(a)(7)] Planks dont overhang their support by more than 18 inches un less access is prevented by a barrier. [1637(g)] Metal is not rusted or corroded. Nails are not smaller than 8-penny. [1637(i)(4)] Bolts are of a size and in sufficient number at each connection to develop the designed strength of the scaffold. [1637(r) and Plate B-31 in Appendix]

EXTENSION PLANKING:

Has 5 fingers on each side and is at least 1" x 2-1/8" select straight-grained Douglas fir or equivalent. [1637(e)(1)] Is not longer than 12 feet, with overlap between the 2 halves not less than 1/8 the length of the extended planking. A substantial stop is provided to maintain this overlap. [1637(e)(2)] Is not used as a platform on ladder-jack, suspended, or other unstable scaffolds. [1637(e)(4)]

ERECTION AND DISMANTLING OF THE SCAFFOLD

Each level is maintained plumb. Scaffolds are built from the bottom up and dismantled from the top down. [1637(k)(3) and (4)] The scaffold is secured to the structure during erection. Ties to the structure are installed as soon as the scaffold is completed to each tie-in area. [1637(k)(3)] The scaffold is secured to the structure during dismantling. Ties are removed only as the work progresses downward, unless other methods are used to prevent the scaffold from falling over. [1637(k)(4)] The Scaffold is secured to the structure during dismantling. Ties are removed only as the work progresses downward, unless other methods are used to prevent the scaffold from falling over. [1637(k)(4)] When dismantling, structural members are not removed below the level being dismantled. [1637(k)(5)] If platforms are sloped, the slope is no more than 2 feet vertical to 10 feet horizontal. Platforms are also secured so they cant slip from supports. [1637(o)] When a platform turns a corner, planks are laid so as to avoid tipping. [1637(t)]

INTEGRITY OF SCAFFOLD

Braces, uprights, or supports are not removed unless other members of equivalent strength are substituted. [1637(l)] The scaffold is not overloaded. [1637(m)] Planks are capable of sustaining the load. [1637(f)(4)] The scaffold is tied off and secure. [1637(c)]

ACCESS

There are safe, unblocked means of access to all scaffold platforms (such as a ladder, walkway, or stairs). [1637(n)(1)] Ladders or stairways are located so as not to make the scaffold unstable. [1637(n)(2)] If a ladder is used for access, it is securely attached to the scaffold and extends at least 3 feet above the platform level. [1637(n)(2)(A)]

GUARDRAILS

There are top rails, between 42" and 45" high, for all open sides and ends that are 7 feet high or more. Rails are constructed of 2" x 4", double 1" x 4", or equivalent. [1620(a) and (c)] There are midrails halfway between the work platform and the guardrail. Midrails are constructed of at least 1" x 6" or equivalent. [1620(a) and (c)]

There are vertical posts spaced at 8 foot intervals or closer. Posts are constructed of 2" x 4" or equivalent. [1620(b)] Guardrails will withstand at least 13 pounds per linear foot. [1620(f)] There are toeboards at least 4 inches high on all open sides and ends of platforms if there are workers below. If material is piled high, there are also panels or screens. [1621(b) and (c)]

You might also like

- Basic Scaffolding Questions AnswersDocument11 pagesBasic Scaffolding Questions AnswersSomu Mahadevan89% (27)

- Fixed Access Ladders: Engineering Data Sheet 2-04 - Ministry of LabourDocument7 pagesFixed Access Ladders: Engineering Data Sheet 2-04 - Ministry of LabourEd CortesNo ratings yet

- Chemical Industries in MumbaiDocument2 pagesChemical Industries in Mumbai89simbu75% (4)

- Ladders Engineering Data Sheet Ontario - 2014Document5 pagesLadders Engineering Data Sheet Ontario - 2014Eric0% (1)

- OSHA Regulations 1926 Subpart L ScaffoldsDocument34 pagesOSHA Regulations 1926 Subpart L ScaffoldsfiercecatNo ratings yet

- Method Statement For Scaffolding Erection - Docx R3Document14 pagesMethod Statement For Scaffolding Erection - Docx R3magramya100% (1)

- Basic Scaffolding Knowledge QuestionsDocument11 pagesBasic Scaffolding Knowledge QuestionsHSE INTECHNo ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- ASME B 31.3 2016 Process PipingDocument30 pagesASME B 31.3 2016 Process Pipingr.devendran25% (4)

- Esstd0202scjp Pip Pnfj8000Document71 pagesEsstd0202scjp Pip Pnfj8000Engr Tahir UL HaqNo ratings yet

- Enesti Study PlansDocument6 pagesEnesti Study PlansCooperante AnonimoNo ratings yet

- Design Technology HL Paper 1Document22 pagesDesign Technology HL Paper 1zerleneNo ratings yet

- Scaffolds ChecklistDocument6 pagesScaffolds ChecklistYuli RahmawatiNo ratings yet

- Factories Works Act - Building Structural Excavation Work - RegsDocument9 pagesFactories Works Act - Building Structural Excavation Work - Regschrissy zee1No ratings yet

- OSHA 1926 Subpart R - Steel ErectionDocument30 pagesOSHA 1926 Subpart R - Steel Erectionferrero68100% (1)

- 06 ScaffoldingDocument4 pages06 ScaffoldingRosli Bin Abdul ShukorNo ratings yet

- Notes On ScaffoldDocument50 pagesNotes On ScaffoldSunil Boyz-uNo ratings yet

- SOLAS Embarkation LadderDocument10 pagesSOLAS Embarkation LadderDinoNo ratings yet

- DerrickDocument17 pagesDerrickNigin Parambath100% (4)

- Sccafolding Safety+ DM Code of ConstructionDocument11 pagesSccafolding Safety+ DM Code of ConstructionGodwin0% (1)

- Ada Ramp 4.8 Ramps: 4.8.1 GeneralDocument4 pagesAda Ramp 4.8 Ramps: 4.8.1 GeneralDeepak SahNo ratings yet

- 1926.1053 - Ladders. - Occupational Safety and Health AdministrationDocument9 pages1926.1053 - Ladders. - Occupational Safety and Health AdministrationAdnan QuaziNo ratings yet

- OSHA LADDER RegulationsDocument10 pagesOSHA LADDER Regulationsthe_dehumanizerNo ratings yet

- Part Number: - Part Title: - Subpart: - Subpart Title: - Standard Number: - TitleDocument1 pagePart Number: - Part Title: - Subpart: - Subpart Title: - Standard Number: - TitleDuy HaNo ratings yet

- Scaffolding 1Document50 pagesScaffolding 1jmichailNo ratings yet

- 603 Stairways and LaddersDocument40 pages603 Stairways and LaddersAhmed BoraeyNo ratings yet

- Calculation Note: Armadillo 500RDocument27 pagesCalculation Note: Armadillo 500RMacNo ratings yet

- LaddersDocument11 pagesLaddersNaveen ReddyNo ratings yet

- Insert Name of Company: Procedure For Safe Use of Ladders, Step-Ladders and TrestlesDocument5 pagesInsert Name of Company: Procedure For Safe Use of Ladders, Step-Ladders and TrestlesVenkatNo ratings yet

- 8 Scaffolding SafetyDocument12 pages8 Scaffolding SafetygbogboiweNo ratings yet

- Ladder Self Inspection ChecklistDocument3 pagesLadder Self Inspection ChecklistRajkumsr VNo ratings yet

- Use of Ladders StandardDocument9 pagesUse of Ladders StandardYavannaNo ratings yet

- Osha Standard LadderDocument7 pagesOsha Standard LadderDhineshNo ratings yet

- Stairways LaddersDocument33 pagesStairways LaddersWander Anthony Capellán CordonesNo ratings yet

- Scaffold Inspection Form - MasterDocument4 pagesScaffold Inspection Form - Mastermichael100% (1)

- Scaffolding - Pump Jack LadderDocument33 pagesScaffolding - Pump Jack LadderAther SeemabNo ratings yet

- Scaffolding Procedure CA 3913Document8 pagesScaffolding Procedure CA 3913Mohamed RizwanNo ratings yet

- Scaffoliding Training R1Document69 pagesScaffoliding Training R1Farrukh AhmedNo ratings yet

- Osha Spiral Staircase Req.Document5 pagesOsha Spiral Staircase Req.njkasdncjkdNo ratings yet

- Scaffolding OSHA 1Document50 pagesScaffolding OSHA 1in123No ratings yet

- Pump Jack/Ladder Jack Scaffold Photo Compliance GuideDocument33 pagesPump Jack/Ladder Jack Scaffold Photo Compliance GuideDharmendra RajanNo ratings yet

- Pump Jack/Ladder Jack Scaffold Photo Compliance GuideDocument33 pagesPump Jack/Ladder Jack Scaffold Photo Compliance GuideMahendra ShuklaNo ratings yet

- Osha 1956.502Document10 pagesOsha 1956.502DURANLEENo ratings yet

- DCP Manual K100 Models OCT2007Document36 pagesDCP Manual K100 Models OCT2007arypauloNo ratings yet

- Artista Columns ManualDocument24 pagesArtista Columns ManualsotirisNo ratings yet

- Scaffolding Work ProcedureDocument6 pagesScaffolding Work ProcedureMuhammad Shiraz KhalidNo ratings yet

- What Are The Highlights of The Scaffolding Standard?: Andy HamonanganDocument12 pagesWhat Are The Highlights of The Scaffolding Standard?: Andy Hamonanganandy hamonangan0% (1)

- Temporary StructuresDocument50 pagesTemporary StructuresAntonio Jose De Jesus0% (1)

- Regulations of Sf.Document28 pagesRegulations of Sf.shakeelNo ratings yet

- Scaffolding Safetyاوشا انكلشDocument14 pagesScaffolding Safetyاوشا انكلشtwingoNo ratings yet

- Flat SlabDocument16 pagesFlat SlabAbdul Hadhi100% (2)

- ScaffoldingDocument11 pagesScaffoldingEmil ShaqiraNo ratings yet

- ScafDocument15 pagesScafPila BilalNo ratings yet

- Design of FootingsDocument102 pagesDesign of FootingsTBCACCOUNTs100% (1)

- Scaffolds, Ladders and Other Working Surfaces: Subpart EDocument47 pagesScaffolds, Ladders and Other Working Surfaces: Subpart EAju ajuNo ratings yet

- Example Site Specific Erection PlanDocument3 pagesExample Site Specific Erection PlanQi ZengNo ratings yet

- Guardrails, Handrails and Covers For Construction: Name of School: Date of InspectionDocument4 pagesGuardrails, Handrails and Covers For Construction: Name of School: Date of InspectionJEORJENo ratings yet

- Berkeley Requirements - Decks, Porches and StairsDocument3 pagesBerkeley Requirements - Decks, Porches and StairsbassigwNo ratings yet

- Marquee Installation HandbookDocument56 pagesMarquee Installation HandbookShengrong YeeNo ratings yet

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- MRAPs: Main Resistant Ambush Protected VehiclesFrom EverandMRAPs: Main Resistant Ambush Protected VehiclesRating: 5 out of 5 stars5/5 (1)

- Reinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionFrom EverandReinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionNo ratings yet

- 02 INSP 0002 BackHoe CheckDocument1 page02 INSP 0002 BackHoe Check89simbu100% (1)

- Rig Down Checklist: S.No Description of Activity Observation RemarksDocument2 pagesRig Down Checklist: S.No Description of Activity Observation Remarks89simbuNo ratings yet

- Rigging Up Checklist: Rig ModelDocument2 pagesRigging Up Checklist: Rig Model89simbuNo ratings yet

- Daily ChecklistDocument2 pagesDaily Checklist89simbuNo ratings yet

- Safety Alert WeldingDocument3 pagesSafety Alert Welding89simbuNo ratings yet

- List of DGMS FormsDocument2 pagesList of DGMS Forms89simbuNo ratings yet

- Safety Alert WeldingDocument3 pagesSafety Alert Welding89simbuNo ratings yet

- Invalid HTTP Request HeaderDocument1 pageInvalid HTTP Request Header89simbuNo ratings yet

- Fundamental Principles of Occupational Health and SafetyDocument159 pagesFundamental Principles of Occupational Health and SafetyRehan HassanNo ratings yet

- Handbook On Electrical SafetyDocument72 pagesHandbook On Electrical Safetybimalbk100% (1)

- Reliability of Safety Systems and Probabilistic Risk AssessmentDocument6 pagesReliability of Safety Systems and Probabilistic Risk Assessment89simbuNo ratings yet

- EarthingDocument63 pagesEarthingLiMe GrEenNo ratings yet

- Documentation For K.A. Nizami Centre For Islamic Stiduies at AMUDocument12 pagesDocumentation For K.A. Nizami Centre For Islamic Stiduies at AMUferozfaruqiNo ratings yet

- 54450b13e6c55 Dutypoint Dosing Pots DetailsDocument2 pages54450b13e6c55 Dutypoint Dosing Pots DetailsMohammed KhaledNo ratings yet

- Opening of Bids Dorm 2, Ph1Document3 pagesOpening of Bids Dorm 2, Ph1Laurie Carr LandichoNo ratings yet

- Brochure UCL ENG 2018Document12 pagesBrochure UCL ENG 2018ashumishra007No ratings yet

- Applications of Bismaleimides ConfirmDocument2 pagesApplications of Bismaleimides ConfirmsggdgdNo ratings yet

- Maps - Useful Phrases (Updated) (2021)Document2 pagesMaps - Useful Phrases (Updated) (2021)Vy Đặng ThảoNo ratings yet

- Visual Inspection of Seamless PipesDocument20 pagesVisual Inspection of Seamless PipesFasil Paruvanath100% (2)

- ASME B36.19M-2004 (R2010) - UnlockDocument14 pagesASME B36.19M-2004 (R2010) - UnlockadprimNo ratings yet

- Technicalupdate ColdWeldingPolymersDocument63 pagesTechnicalupdate ColdWeldingPolymersChris TeohNo ratings yet

- Kem Microconcrete - NDocument2 pagesKem Microconcrete - NIrfan BiradarNo ratings yet

- The Influence of Construction Side Effects On ExisDocument19 pagesThe Influence of Construction Side Effects On ExisJose Leo MissionNo ratings yet

- Workplace Inspection Checklist TemplateDocument5 pagesWorkplace Inspection Checklist Templatemyo lwinNo ratings yet

- 23Cr Infrastructure TNPADocument15 pages23Cr Infrastructure TNPAHarul Ganesh S BNo ratings yet

- V5329A TWDocument4 pagesV5329A TWS M NaveedNo ratings yet

- 27 Jul 2018 Tenders Bids of Pakistan by Maven PKDocument162 pages27 Jul 2018 Tenders Bids of Pakistan by Maven PKMaven PKNo ratings yet

- Tube-To-Tube Sheet Joint RequirementsDocument2 pagesTube-To-Tube Sheet Joint RequirementsWaqas WaqasNo ratings yet

- Dynamic Study of Step Back and Set Back Building: ResearchDocument7 pagesDynamic Study of Step Back and Set Back Building: ResearchSristi GuptaNo ratings yet

- Weekly Progress Report No 9 (SSO)Document95 pagesWeekly Progress Report No 9 (SSO)JohnnyNo ratings yet

- PreviewpdfDocument214 pagesPreviewpdfViviana MoraNo ratings yet

- Internal Forces in A Beam: Shear ForceDocument52 pagesInternal Forces in A Beam: Shear ForceCho Wing SoNo ratings yet

- Seismic Behavior of Concrete Filled Steel TubeDocument3 pagesSeismic Behavior of Concrete Filled Steel TubeForsythe LearningNo ratings yet

- Urban Design Proposal For Ramkund, AnkleshwarDocument4 pagesUrban Design Proposal For Ramkund, AnkleshwarHimakshi Tarde100% (1)

- Clean Room Wall FinishDocument6 pagesClean Room Wall FinishjoannakahlNo ratings yet

- Lift Maintenance Outcome GuidebookDocument44 pagesLift Maintenance Outcome GuidebookKayeyera LawrenceNo ratings yet

- Manual Batch Records Mix Design ExcelDocument2 pagesManual Batch Records Mix Design ExcelIswantoNo ratings yet