Professional Documents

Culture Documents

Pushing The Envelope: High Accuracy and Productivity: Key in South African Engineering Projects

Pushing The Envelope: High Accuracy and Productivity: Key in South African Engineering Projects

Uploaded by

Marlon Velasquez0 ratings0% found this document useful (0 votes)

27 views2 pagesThe document discusses how Trimble technology, specifically the Trimble S8 Total Station, is playing a key role in ensuring high accuracy on two large infrastructure projects in South Africa - the construction of the new Green Point Stadium in Cape Town and the Gautrain Rapid Rail Link connecting Johannesburg, Pretoria, and Johannesburg International Airport. Julian Gray, the quality assurance surveyor for the stadium project, is using the Trimble S8 to check the positioning of structural elements like pylons to a tolerance of less than 2mm, and was able to survey over 1,800 workers and equipment on the small and busy construction site. On the Gautrain project, Gray verified the geometry and location of bridge piers for the pre

Original Description:

Original Title

Envelope

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document discusses how Trimble technology, specifically the Trimble S8 Total Station, is playing a key role in ensuring high accuracy on two large infrastructure projects in South Africa - the construction of the new Green Point Stadium in Cape Town and the Gautrain Rapid Rail Link connecting Johannesburg, Pretoria, and Johannesburg International Airport. Julian Gray, the quality assurance surveyor for the stadium project, is using the Trimble S8 to check the positioning of structural elements like pylons to a tolerance of less than 2mm, and was able to survey over 1,800 workers and equipment on the small and busy construction site. On the Gautrain project, Gray verified the geometry and location of bridge piers for the pre

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

27 views2 pagesPushing The Envelope: High Accuracy and Productivity: Key in South African Engineering Projects

Pushing The Envelope: High Accuracy and Productivity: Key in South African Engineering Projects

Uploaded by

Marlon VelasquezThe document discusses how Trimble technology, specifically the Trimble S8 Total Station, is playing a key role in ensuring high accuracy on two large infrastructure projects in South Africa - the construction of the new Green Point Stadium in Cape Town and the Gautrain Rapid Rail Link connecting Johannesburg, Pretoria, and Johannesburg International Airport. Julian Gray, the quality assurance surveyor for the stadium project, is using the Trimble S8 to check the positioning of structural elements like pylons to a tolerance of less than 2mm, and was able to survey over 1,800 workers and equipment on the small and busy construction site. On the Gautrain project, Gray verified the geometry and location of bridge piers for the pre

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Pushing the Envelope

High Accuracy and Productivity: Key in South African Engineering Projects

-22- Technology&more; 2008-2

G

rowth and investment in South Africas infra-

structure are providing new challenges and

opportunities for surveyors and engineers.

Trimble technology is playing a key role on two of the

countrys largest and most visible projects. In Cape

Town, construction is underway on the new Green

Point Stadium. Scheduled for completion in 2009, the

Stadium will host several matches in the 2010 FIFA

(International Federation of Football Associations)

World Cup soccer tournament. In Gauteng Province,

the new Gautrain Rapid Rail Link is the largest civil

engineering project ever undertaken in South Africa.

When completed, it will connect Johannesburg,

Pretoria, and the O.R. Tambo International Airport

with over 80 km (50 mi) of high-speed commuter

railways. Both projects are publicly funded and have

drawn widespread attention.

Rising to the challenge is Julian Gray, Geomatics

Engineer for GNA Geomatics in Cape Town. Gray

was appointed as the Quality Assurance Surveyor

for the Green Point Stadium, where hes responsible

for checking the 3D accuracy of the stadiums struc-

tural elements. With required tolerances of less than

2 mm (0.08 in), Gray knew he needed a high-precision

surveying system. He selected the Trimble S8 Total

Station.

The versatile Trimble S8 immediately proved its

worth. Using low-density scanning techniques, Gray

conducted precise surveys on the 72 external pylons

surrounding the stadium structure that will support

the stadium roof. Te stadium roof extends out over

the grandstands, and designers must have precise

data on the supporting pylons. Using custom software

he developed that works in conjunction with Trimble

Geomatics Ofce software, Gray was able to check

the location, size, shape and rotation of the pylon

structures. The software computed the anticipated

location of the tops of the fnished pylons and moni-

tored construction progress to ensure that each pylon

was built correctly.

The stadium is a difcult place to survey. It is a relatively

small site, about 350 m x 350 m (1150 ft x 1150 ft), and

extremely busy. Crammed into the location are 14 tower

cranes, more than 1,800 workers, dozens of machines,

and dense scafolding. Gray politely describes the proj-

ect as Very Instrument Unfriendly. In its frst few hours

on the project, a dollop of concrete falling from an over-

head bucket splattered the instrument. Since then, the

Trimble S8 has endured dust, sand, cement and water

without difculty. After months of severe treatment, it

continues to work well, according to Gray.

Throughout the project, Gray has used forced-centering techniques and Trimbles high-precision prisms and

targets. Te instrument is mounted on concrete pillars, and mini-prism control points are placed in permanent

mounts. Measured distances are usually in the range of 4060 m (130200 ft) and never longer than 100 m (330 ft).

With this approach, Gray stated that he obtains standard errors of observation that are even better than the

instruments published specifcations. Trimbles narrow-beam EDM technology provides an important beneft

on the project. It lets Gray measure through scafolding and narrow openings with speed and confdence.

The project recently reached the stage of placing embedded plates onto the tops of the pylons. Tis requires

the positioning of a large, complex plate onto each pylon table. Te table measures 4 m x 80 cm (13 ft x 31 in) and

is 50 m (160 ft) above the ground. Gray checked the work using the Trimble 360 prism in a specially manu-

factured prism mount as the target for the Trimble S8 AutoLock measurements. Gray is achieving accuracy of

better than 2 mm (0.08 in), and the work, he says, is proceeding to the satisfaction of all concerned.

In the second project, the trains of the Gautrain Rapid Rail Link will travel at over 160 kph (100 mph),

connecting three main terminals and seven intermediate stations. Gray was appointed to check the above-

ground structures with high precision and accuracy. A key part of his work was verifying the geometry and

location of all of the bridge piers.

Gautrains contractor had selected a pre-cast segment approach for constructing overhead viaducts. This is the

frst time this method has been used in South Africa, and its receiving a lot of attention. Te approach uses a

launching girder system to lift pre-cast concrete segments into place. The segments are locked together to form

the deck of the viaduct between the piers. Each segment is about 2.5 m long x 10.1 m wide (8.2 ft x 33 ft) and

weighs up to 55,000 kg (61 US tons). With spans between piers as long as 50 m (164 ft), the geometry of the pier

heads must be checked and confrmed before the frst segment can be placed. Te distance between pier heads

must be accurate to within 2 mm (0.08 in). Taking advantage of the Trimble S8 speed and precision performance,

Gray was able to check the all of the 3D elements of 36 piers on 4 separate viaducts in less than 5 days.

Gray has several uses for the Trimble S8 Total Station on the Gautrain project. Te instrument is used to check

the control points used by the project teams in setting out for construction. In the tunnels, Gray scanned

cross-sections, using the built-in laser pointer and Direct Refex EDM. And he has proposed to use the Trimble

S8 as a monitoring system to check for possible subsidence of viaduct piers. Some piers are difcult to access,

and the accuracy of the Trimble S8 will let the teams watch for any vertical settlement.

Julian Gray and both project teams are pleased. Te accuracy and versatility of the Trimble S8 plays a crucial

role in both projects. Te instrument is performing well under extremely adverse conditions, Gray says, and

the results are exceeding manufacturers specifcations. Gray says that the team has taken great satisfaction

in pushing the envelope with the Trimble S8. As a result, the project managers will be fnding more and more

uses for the Trimble S8 Total Station as a solution to their high-precision measurement needs

-23- Technology&more; 2008-2

You might also like

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Terence Reese - Begin Bridge With Reese (1979, Signet)Document148 pagesTerence Reese - Begin Bridge With Reese (1979, Signet)Lingofone100% (1)

- A Great UpheavalDocument22 pagesA Great UpheavalJake SpencerNo ratings yet

- International Truss SYSTEMS (Pty) LTD: Product CatalogueDocument34 pagesInternational Truss SYSTEMS (Pty) LTD: Product Catalogueansara89No ratings yet

- Two Over One in BridgeDocument28 pagesTwo Over One in BridgeMakis Politis100% (1)

- Diverless Removal of FPSO RisersDocument20 pagesDiverless Removal of FPSO RisersmatmarcantonioNo ratings yet

- Global Brochure PDFDocument16 pagesGlobal Brochure PDFElsa VelazquezNo ratings yet

- Trusses IV Composite and Raised Bottom Chord TrussesDocument18 pagesTrusses IV Composite and Raised Bottom Chord TrussesCristian Morar-BolbaNo ratings yet

- Bridge Inspection Manual Version 19Document145 pagesBridge Inspection Manual Version 19atac101100% (1)

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successFrom EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successRating: 4.5 out of 5 stars4.5/5 (3)

- For Dynapac Road Machinery: Leica Pavesmart 3DDocument4 pagesFor Dynapac Road Machinery: Leica Pavesmart 3DDonovan HarrellNo ratings yet

- Detail Design of Bridges and StructuresDocument61 pagesDetail Design of Bridges and StructuresEyoel Ashagre33% (3)

- Bridges Cable StayedDocument14 pagesBridges Cable StayedJaydeep BhawalNo ratings yet

- 012-MS For Wall Cladding, Roof Cladding & Life Line Installation PDFDocument16 pages012-MS For Wall Cladding, Roof Cladding & Life Line Installation PDFKöksal Patan91% (11)

- Construction & Project Management For Highway TunnelsDocument8 pagesConstruction & Project Management For Highway TunnelsShreedharNo ratings yet

- Marina Bay Sands HotelDocument26 pagesMarina Bay Sands HotelGilmar MazinhoroNo ratings yet

- GT Strudl BrochureDocument4 pagesGT Strudl BrochureRomeoSánchezNo ratings yet

- Jaguar Land Rover Case StudyDocument2 pagesJaguar Land Rover Case StudyRashi SinghNo ratings yet

- Mining Magazine - Design For LifeDocument8 pagesMining Magazine - Design For LifepaulogmelloNo ratings yet

- Panzerkrieg Revised RulesDocument14 pagesPanzerkrieg Revised Rulesspleenrippa17No ratings yet

- Demag Bottom BlockDocument22 pagesDemag Bottom BlockGer Gut100% (1)

- For G&Z Paving Equipment: Leica Pavesmart 3DDocument2 pagesFor G&Z Paving Equipment: Leica Pavesmart 3DDonovan HarrellNo ratings yet

- For Gomaco Equipment: Leica Pavesmart 3DDocument4 pagesFor Gomaco Equipment: Leica Pavesmart 3DDonovan HarrellNo ratings yet

- Moving A Capital City ForwardDocument3 pagesMoving A Capital City ForwardVictor Hugo FernandezNo ratings yet

- New Doha International Airport 022609Document3 pagesNew Doha International Airport 022609seema2112No ratings yet

- Brochure - PCS400 Paving Control SystemDocument6 pagesBrochure - PCS400 Paving Control SystemWJ Du ToitNo ratings yet

- Dragline and Drill Production Monitors: L. RaathsDocument6 pagesDragline and Drill Production Monitors: L. RaathsHari NairNo ratings yet

- 3.8.9.industry Case Study Rapid Prototype of Mountain Bike Frame SectionDocument11 pages3.8.9.industry Case Study Rapid Prototype of Mountain Bike Frame SectionritamendesNo ratings yet

- Gt3200 BrochureDocument12 pagesGt3200 Brochurerahmani bagherNo ratings yet

- GEOCOM Trimble 4D Control Software Geoespacial-Datasheet-01Document2 pagesGEOCOM Trimble 4D Control Software Geoespacial-Datasheet-01juan carlosNo ratings yet

- Sasol Synfuels Success StoryDocument3 pagesSasol Synfuels Success Storycool_rdNo ratings yet

- Datasheet: Trimble S3 Total StationDocument2 pagesDatasheet: Trimble S3 Total StationdjaaaamNo ratings yet

- UHQP5 Ko OXYPf 3 L FY65Document27 pagesUHQP5 Ko OXYPf 3 L FY65Revu GowdaNo ratings yet

- Petagma Pvt. Ltd. Technical ProposalDocument17 pagesPetagma Pvt. Ltd. Technical ProposalSatish GangarNo ratings yet

- Breakwater ConstructionDocument1 pageBreakwater Constructionbabu9595No ratings yet

- TruStories Monitoring LeicaGeoMoSDocument36 pagesTruStories Monitoring LeicaGeoMoSstat_istaNo ratings yet

- OTE Outotec MillMapper Eng LoresDocument4 pagesOTE Outotec MillMapper Eng LoresjadetorresNo ratings yet

- Revista Technology & More - Surveying and Mapping - 2008-1Document28 pagesRevista Technology & More - Surveying and Mapping - 2008-1Anibal LopezNo ratings yet

- OTE Outotec CrusherMapper Eng LoresDocument4 pagesOTE Outotec CrusherMapper Eng LoresjadetorresNo ratings yet

- Android 3 Axis Drilling MachineDocument76 pagesAndroid 3 Axis Drilling Machine1000kvNo ratings yet

- Prequalification 5-5-2021Document9 pagesPrequalification 5-5-2021Muhammed Gad Al-HaqqNo ratings yet

- GPS Drill NavigationDocument6 pagesGPS Drill NavigationAndy ObregonNo ratings yet

- Tritop Assemblyline enDocument9 pagesTritop Assemblyline enMiguel AngelNo ratings yet

- InsideGemcom Issue2 2012 FINALDocument0 pagesInsideGemcom Issue2 2012 FINALKenny CasillaNo ratings yet

- Investigations For Deducing Wall Thickness of Aluminium Shell Casting Using Three Dimensional PrintingDocument5 pagesInvestigations For Deducing Wall Thickness of Aluminium Shell Casting Using Three Dimensional PrintingR Moses KrupavaramNo ratings yet

- Spiral Bevel Gears Face Roughness Prediction ProduDocument20 pagesSpiral Bevel Gears Face Roughness Prediction ProduLucio MárquezNo ratings yet

- 6db5997c Rocky White Paper Predictive Optimization of Sag Mill Wear Using RockyDocument9 pages6db5997c Rocky White Paper Predictive Optimization of Sag Mill Wear Using Rockymatt_beutnerNo ratings yet

- Manufacturing of Helical Gears by Using Fused Deposite Modelling-An Additive Manufacturing ApproachDocument22 pagesManufacturing of Helical Gears by Using Fused Deposite Modelling-An Additive Manufacturing ApproachSri Nadh PadavalaNo ratings yet

- AUtomation in Construction IndustryDocument13 pagesAUtomation in Construction Industrydeekshith gowdaNo ratings yet

- Stockholm Precision Tools - Downhole Gyro - Surveying Systems and Borehole Survey InstrumentsDocument4 pagesStockholm Precision Tools - Downhole Gyro - Surveying Systems and Borehole Survey InstrumentsErika EliasonNo ratings yet

- TENGL Corporate Brochure FinalDocument12 pagesTENGL Corporate Brochure FinalRohit KaleNo ratings yet

- ATOS Compact Scan en RevADocument11 pagesATOS Compact Scan en RevAkoalaboiNo ratings yet

- Mining Software:: Overland Conveyors Gearless Drives IPCC SystemsDocument5 pagesMining Software:: Overland Conveyors Gearless Drives IPCC SystemsllllcesarllllNo ratings yet

- Utilities Capabilities Brochure 0210Document6 pagesUtilities Capabilities Brochure 0210azcompNo ratings yet

- Prosthetic Sockets Fabrication Using Rapid Prototyping TechnologyDocument7 pagesProsthetic Sockets Fabrication Using Rapid Prototyping TechnologyHaider NeamaNo ratings yet

- I-495/I-66 Interchange, VA: Project HighlightsDocument1 pageI-495/I-66 Interchange, VA: Project HighlightsMohd Razif SumairiNo ratings yet

- The Use of 3D Scanning in The Turbine Blade Industry.....Document1 pageThe Use of 3D Scanning in The Turbine Blade Industry.....MohanrajRajangamNo ratings yet

- Gps Trimble r8 CenaDocument3 pagesGps Trimble r8 CenaRobertNo ratings yet

- MX3D BridgeDocument7 pagesMX3D BridgeJanko Vukicevic100% (1)

- Datasheet: Trimble S6 Total StationDocument4 pagesDatasheet: Trimble S6 Total StationgombalamohNo ratings yet

- VÖGELE Pavers Build First Formula 1 Circuit Near New Delhi, IndiaDocument6 pagesVÖGELE Pavers Build First Formula 1 Circuit Near New Delhi, IndiaLucky ChopraNo ratings yet

- GeoMax General CatalogueDocument76 pagesGeoMax General Cataloguebbutros_317684077100% (1)

- Accepted Manuscript: Additive ManufacturingDocument53 pagesAccepted Manuscript: Additive ManufacturingAnkushNo ratings yet

- ROMER Absolute Arm BrochureDocument12 pagesROMER Absolute Arm BrochureArvat AlexandruNo ratings yet

- Geomatic Survey - Ramboll UK LimitedDocument7 pagesGeomatic Survey - Ramboll UK LimitedEndashaw DebruNo ratings yet

- Quickbird - A Milestone For High Resolution Mapping: January 2002Document10 pagesQuickbird - A Milestone For High Resolution Mapping: January 2002Ropafadzo MashingaidzeNo ratings yet

- Millimeter-Wave Receiver Concepts for 77 GHz Automotive Radar in Silicon-Germanium TechnologyFrom EverandMillimeter-Wave Receiver Concepts for 77 GHz Automotive Radar in Silicon-Germanium TechnologyNo ratings yet

- Apixaban VR Warfarina 3Document15 pagesApixaban VR Warfarina 3Marlon VelasquezNo ratings yet

- TAC - Trimble Aerial Camera: Nuno Vilaça - Regional Sales Manager June 2013Document4 pagesTAC - Trimble Aerial Camera: Nuno Vilaça - Regional Sales Manager June 2013Marlon VelasquezNo ratings yet

- Automatic, Large-Scale Monitoring: Cover StoryDocument2 pagesAutomatic, Large-Scale Monitoring: Cover StoryMarlon VelasquezNo ratings yet

- Datasheet TX5 ScannerDocument2 pagesDatasheet TX5 ScannerMarlon VelasquezNo ratings yet

- GameFAQs Darksiders II (PC) FAQ - Walkthrough by SokkusDocument170 pagesGameFAQs Darksiders II (PC) FAQ - Walkthrough by SokkusRidwan TannusNo ratings yet

- BB Lesson 11 HandoutDocument1 pageBB Lesson 11 HandoutAthanasios ChristogiannisNo ratings yet

- Advantages of Steel in Bridge ConstructionDocument5 pagesAdvantages of Steel in Bridge Constructionrashi1717No ratings yet

- Building Structures (ARC 2523) Project 1 Fettuccine Truss BridgeDocument21 pagesBuilding Structures (ARC 2523) Project 1 Fettuccine Truss BridgediyanahussainNo ratings yet

- Minibridge 02 - High-Card Points and TrumpsDocument6 pagesMinibridge 02 - High-Card Points and TrumpsAnirban NathNo ratings yet

- Composite Deck BridgesDocument59 pagesComposite Deck Bridgeskarpagajothimurugan100% (1)

- Recent Technology of Prestressed Concrete Bridges in Japan PDFDocument10 pagesRecent Technology of Prestressed Concrete Bridges in Japan PDFYuli Ana Fransisca SantanaNo ratings yet

- Curse of Strahd - Areas To ExploreDocument8 pagesCurse of Strahd - Areas To ExploreAliceNo ratings yet

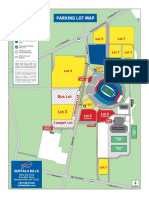

- NEF Parking PublicDocument1 pageNEF Parking PublicWGRZ-TVNo ratings yet

- Alter Bridge Lyrics Album: One Day Remains (2004)Document22 pagesAlter Bridge Lyrics Album: One Day Remains (2004)Iulian StamaNo ratings yet

- Executive Summary: Figure 1: Example of Illustrated ModelDocument10 pagesExecutive Summary: Figure 1: Example of Illustrated ModelArnie FarhanaNo ratings yet

- 4 Tension MemberDocument15 pages4 Tension Memberhari1008108No ratings yet

- Bernard Magee's Acol Bidding Quiz: Number One Hundred and Twenty-Nine September 2013Document48 pagesBernard Magee's Acol Bidding Quiz: Number One Hundred and Twenty-Nine September 2013rprafalNo ratings yet

- Jack Pesch Bicycle and Pedestrian Bridge (QLD)Document4 pagesJack Pesch Bicycle and Pedestrian Bridge (QLD)yyanan1118No ratings yet

- Dss - Question BankDocument10 pagesDss - Question Bankapi-306484475No ratings yet

- World Papercraft Buildings of The World Series England: (Section 1)Document3 pagesWorld Papercraft Buildings of The World Series England: (Section 1)GregNo ratings yet

- Building Construction IVDocument48 pagesBuilding Construction IVSajay PajarillagaNo ratings yet

- Wheat Stone Bridge-Unknown Electrical ResistanceDocument4 pagesWheat Stone Bridge-Unknown Electrical Resistancejosyulav100% (1)

- Fantoni NunesDocument44 pagesFantoni NunesTarpan Stefan AlexandruNo ratings yet

- Example in BridgesDocument9 pagesExample in BridgesturtlerexNo ratings yet

- Important Instructions Safety WorkspotDocument19 pagesImportant Instructions Safety WorkspotViswanadh Lvs KuchibhotlaNo ratings yet