Professional Documents

Culture Documents

DC generator commutator design

Uploaded by

Marko Antonio MccoyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DC generator commutator design

Uploaded by

Marko Antonio MccoyCopyright:

Available Formats

POLYTECHNIC UNIVERSITY OF THE PHILIPPINES

College of Engineering

Electrical Engineering Department

ELECTRICAL MACHINE DESIGN

Design 2: Commutating Poles for DC Generator

Submitted by

PAUIG, MARK ANTHONY C.

BSEE V-3

Submitted to

ENGR. LIBRADO S. GESALTA

Instructor

June ___ , 2014

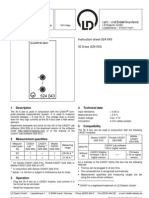

===== PART 2 : Commutator & Brushes ======== ===================== ====================

40 Diameter of Commutator D

c

26.632 in.

41 Average volts per turn of armature winding 28.24 V

42 Number of turns between bars 1

43 Total number of commutator bars 77

44 Bar pitch 1.087 in.

45 Width of copper bar 1.057 in.

46 Radial depth of bar 2.77 in.

47 Current density at brush contact surface

b

40 amps/in.

2

39.97 amps/in.

2

48 Contact area per brush set 48.76 in.

2

48.8 in.

2

49 Brush arc 1 in.

50 Axial brush length per set 48.8 in.

51 Number of brushes per set 78.08

52 Axial length of commutator L

c

53.3 in

53 Brush-contact drop 2.3 V

54 Brush-contact loss 17,942.56 Watts

55 Brush-friction loss 27,689.79 Watts

56 Total brush loss 45,632.35 Watts

57 Drawing to scale giving leading dimensions of

armature and commutator

9.73 in.

PART 2 :

Item 40: Diameter of Commutator

D

c

= (40.024 2) + 6.62 D

c

= 26.632 in.

This is 66.54% of the core diameter and makes the peripheral velocity

=0.6654 14,145.65

=9412.516 fpm

Items 41 to 43: Number of Commutator Bars

Average volts per turn

E

average

/turn = ___240___ E

average

/turn = 28.24V

136 16

Number of turns between bars

One (1)

Number of Commutator bars

(

) = (4/2 39) 1

*It is desirable to use 77 commutator bars to improve the commutation and to be more suitable and narrower.

Items 44 and 45: Width of Commutator Segments

Bar pitch

Bar pitch =

Bar pitch = 26.632 _ Bar pitch = 1.087 in.

77

Width of copper bar

*using 0.03 in mica insulation

Width

Cu

= Bar pitch - 0.03 = 1.087 0.03 Width

Cu

= 1.057 in.

Item 46: Radial Depth of Segment

Radial depth of bar

h =

+ 15 / 15

h = _26.632 + 15_ h = 2.77 in.

15

Items 47 to 51: Dimensions of Brushes

Current density at brush contact surface

*assume 40 A as preliminary value

b

= 40 amps/ in.

2

Contact area per brush set

_8 975.139 _ 48.76 in.

2

4 40

Brush Arc (Circumferential Width) 1 inch

Axial brush length per set 48.76 in.

Number of brushes per set

Actual area per brush set 48.8 in.

2

*from Art. 34 the usual width of brush is something between the limits of 5/8 in and 1 in, and as a further check on the

desirabledimensions, the width should not exceed one-tenth of the pole pitch referred to the commutator surface.Thus , use a brush of 5/8

in. width

No. of brushes per set = 48.8 / 0.625 = 78.08 Brushes

The Current Density will be slightly decreased to,

40(48.76/48.8)= 39.97 amps/ in.

2

Item 52: Length of Commutator

Axial length of commutator

*In addition to the 48.8 in. which must be provided for the four 5/8 in. Carbon Brushes, the Axial Length for the Commutator face must

allow the following:

a.) Brush Holder and Clearances = 5/2 in.

b.) Staggering of (+) and (-) brushes = 5/8 in.

c.) End clearance for brushes =1 in.

d.) End play =3/8 in.

L

c

= 48.8 + 2.5 +0.625 + 1 + 0.375 L

c

= 53.3 in.

Item 53: Brush-contact Drop

*Brush contact drop for hard carbon at about 40 amps/ in.

2

is 2.085 volts. Allowing the 10% of roughness, chipping and irregularities, this

drop will be about 2.3 volts. *2.3 V

Item 54 to 56: Brush Losses

Brush contact loss

Loss

Brush contact

= Brush contact drop P

= 2.3 8 975.139 Loss

Brush contact

= 17,942.56 Watts

Brush contact friction

*For Peripheral speed greater than 4,000 fpm use c=0.25 for hard carbon; P= 2

W

f

=( c PAN D

c

746)/12 33,000

W

f

= _0.25 2 (48.8 8 ) 26.632 900 746 _ W

f

= 27,689.79 Watts

12 33000

Total brush loss

Loss

TOTAL

= 17,942.56 +27,689.79 Loss

TOTAL

=45,632.35 Watts

Item 57: Drawing to scale giving leading dimensions of armature and commutator

Shaft Diameter = 0.84

= 0.84

= 9.73 in.

You might also like

- Earthing CalculationDocument14 pagesEarthing CalculationNatarajan Ramakrishnan100% (18)

- Bus Bar CalculationDocument8 pagesBus Bar CalculationSubhash ChekkaNo ratings yet

- 110 Waveform Generator Projects for the Home ConstructorFrom Everand110 Waveform Generator Projects for the Home ConstructorRating: 4 out of 5 stars4/5 (1)

- End Plate ConnectionDocument10 pagesEnd Plate ConnectionMohamed Tahar Allagui100% (1)

- Podcast Show Notes Template 1: Summary & Bullet Points: ExampleDocument3 pagesPodcast Show Notes Template 1: Summary & Bullet Points: ExampleMarko Antonio MccoyNo ratings yet

- Short Circuit Force CalculationDocument11 pagesShort Circuit Force CalculationAchint Kumar100% (2)

- Earthing Design Calculation: Project: Document No. DateDocument9 pagesEarthing Design Calculation: Project: Document No. Dateboopathy1705100% (1)

- Philippine People's Budget 2014 (English)Document62 pagesPhilippine People's Budget 2014 (English)Facebook.com/OscarFranklinTanNo ratings yet

- DC Machine Design Problem With SolutionDocument36 pagesDC Machine Design Problem With Solutionlvb123No ratings yet

- Cold Formed Steel Channel Section DesignDocument62 pagesCold Formed Steel Channel Section DesignNishan GajurelNo ratings yet

- Designed By: Submitted ToDocument46 pagesDesigned By: Submitted To106 MOMENUL ISLAM KHAN 17No ratings yet

- Design of Steel Batten Column: Grid ID K4 1.0 Sectional PropertiesDocument7 pagesDesign of Steel Batten Column: Grid ID K4 1.0 Sectional PropertiesBijay ThapaNo ratings yet

- Tuturial DIY Honda Odometer ReprogrammingDocument32 pagesTuturial DIY Honda Odometer Reprogrammingnicolas brizzioNo ratings yet

- Design and calculations of an electric motorDocument38 pagesDesign and calculations of an electric motorHalley Mayer TorresNo ratings yet

- Differential Forms on Electromagnetic NetworksFrom EverandDifferential Forms on Electromagnetic NetworksRating: 4 out of 5 stars4/5 (1)

- Tutorial Problems AlternatorDocument5 pagesTutorial Problems AlternatorMarko Antonio Mccoy0% (3)

- Column Reinforcement Design: Uex UeyDocument15 pagesColumn Reinforcement Design: Uex Ueyswargadwari consultancyNo ratings yet

- Column To Beam Connection Check (EP-01)Document3 pagesColumn To Beam Connection Check (EP-01)Md. Mahmudle HassanNo ratings yet

- Busbar Current Rating and BPI Cantilever Calculation(Equation No. 30, IEEE 605Document45 pagesBusbar Current Rating and BPI Cantilever Calculation(Equation No. 30, IEEE 605annuvyas100% (1)

- Three Phase Induction Motors: Output Equation of Induction MotorDocument7 pagesThree Phase Induction Motors: Output Equation of Induction MotoraaparumugamNo ratings yet

- Keiilf: Training ManualDocument53 pagesKeiilf: Training ManualGary GouveiaNo ratings yet

- Sonosite Echo Machine Model MicromaxxDocument100 pagesSonosite Echo Machine Model MicromaxxAakshiRajputNo ratings yet

- CAL-00-P-0005 Rev 0 Vessel SizingDocument10 pagesCAL-00-P-0005 Rev 0 Vessel SizingSyed Zaki HaiderNo ratings yet

- Burner CalculationDocument9 pagesBurner CalculationAbul QasimNo ratings yet

- End Plate Moment Connection DesignDocument16 pagesEnd Plate Moment Connection DesignAbdul HameedNo ratings yet

- Electrical Machine Design: Design 1: DC Generator Armature DesignDocument8 pagesElectrical Machine Design: Design 1: DC Generator Armature DesignMarvin DacayanNo ratings yet

- Chapter.3 Design of Commutator and BrushesDocument10 pagesChapter.3 Design of Commutator and BrushesFernando Rmz100% (1)

- Mckoi Design ArmatureDocument11 pagesMckoi Design ArmatureMarko Antonio MccoyNo ratings yet

- ComputationDocument13 pagesComputationLester MuscaNo ratings yet

- 10-RF Electronics Kikkert Ch7 RFFiltersPart2Document27 pages10-RF Electronics Kikkert Ch7 RFFiltersPart2AliOucharNo ratings yet

- New Era University: EE 572 Electrical Machine Design "Design I-A"Document21 pagesNew Era University: EE 572 Electrical Machine Design "Design I-A"DanixNo ratings yet

- Machine Design of Stepper MotorsDocument12 pagesMachine Design of Stepper Motorsabhrajit ghoshNo ratings yet

- Design of Commutator and BrushesDocument10 pagesDesign of Commutator and BrushesshashikumarNo ratings yet

- Design of Commutator and BrushesDocument5 pagesDesign of Commutator and BrushesSam AndersonNo ratings yet

- Connections 1 - Ch.2,3 Summarized Exercise Solutions (150-153)Document5 pagesConnections 1 - Ch.2,3 Summarized Exercise Solutions (150-153)travis8zimmermannNo ratings yet

- St2 Qust PaperDocument3 pagesSt2 Qust PaperDILJA KNo ratings yet

- Certificate: Sandipan Mishra Kaustav BhadarDocument47 pagesCertificate: Sandipan Mishra Kaustav BhadarSanmoy DattaNo ratings yet

- 50 Kva Distibution Transformer DesignDocument9 pages50 Kva Distibution Transformer Designjera garcia100% (1)

- Design of Electrical Apparatus - Question PaperDocument12 pagesDesign of Electrical Apparatus - Question PaperVIGNESH T ANo ratings yet

- EEE8155 Design and Analysis of Electrical Machines and DrivesDocument13 pagesEEE8155 Design and Analysis of Electrical Machines and DrivesstephenNo ratings yet

- DC effect on inductanceDocument4 pagesDC effect on inductanceAndrei LeleaNo ratings yet

- 50 Kva Distibution Transformer DesignDocument11 pages50 Kva Distibution Transformer DesignJemal MusaNo ratings yet

- Design Calculation of Current Transformer and Voltage TransformerDocument21 pagesDesign Calculation of Current Transformer and Voltage TransformerMoe Thant OoNo ratings yet

- Design of Electrical Apparatus Solved ProblemsDocument14 pagesDesign of Electrical Apparatus Solved ProblemsRichard RegidorNo ratings yet

- Electrical Machine Design Project for 440kW GeneratorDocument8 pagesElectrical Machine Design Project for 440kW GeneratorArvin TorrenteNo ratings yet

- 5-hp Motor Design SpecsDocument7 pages5-hp Motor Design SpecsNoykols GRncNo ratings yet

- Unit 2 Two Marks1Document3 pagesUnit 2 Two Marks1SafjrocnNo ratings yet

- Machine Design Lab ReportDocument57 pagesMachine Design Lab Reportkarabo kwataNo ratings yet

- Connections 3Document72 pagesConnections 3jrobert123321No ratings yet

- Objective:: Voltage Per Turn: EDocument19 pagesObjective:: Voltage Per Turn: EMohammed Rubayet Sharif100% (1)

- Design of Distribution TransformerDocument8 pagesDesign of Distribution Transformerprincedo marcelloNo ratings yet

- Unit IiDocument27 pagesUnit IiThomas NigilNo ratings yet

- JEROME M. GUETA QUIZ 3 - Advance Steel DesignDocument105 pagesJEROME M. GUETA QUIZ 3 - Advance Steel DesignJerome M. GuetaNo ratings yet

- Design of Electrical Apparatus Solved ProblemsDocument15 pagesDesign of Electrical Apparatus Solved ProblemsnandhakumarmeNo ratings yet

- Design of a submerged slide gate structureDocument11 pagesDesign of a submerged slide gate structurealiNo ratings yet

- Microstrip Patch Antenna With Inclined Slot For Dual-Band OperationDocument4 pagesMicrostrip Patch Antenna With Inclined Slot For Dual-Band Operationsandeepkumararya_eceNo ratings yet

- Microwave Tomasi Questions and AnswersDocument4 pagesMicrowave Tomasi Questions and AnswersGegra DueNo ratings yet

- Wideband Dual Posts Waveguide Band Pass FilterDocument7 pagesWideband Dual Posts Waveguide Band Pass FilterAmador Garcia IIINo ratings yet

- Compact full Ku-band triplexer with improved E-plane power dividerDocument13 pagesCompact full Ku-band triplexer with improved E-plane power dividerBukNo ratings yet

- EMDq - Question Bank - Jul 2019Document18 pagesEMDq - Question Bank - Jul 2019madhu balan0% (1)

- AC Generator Stator Design ReportDocument18 pagesAC Generator Stator Design ReportEngelie Mae ColloNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityPalak AriwalaNo ratings yet

- Electricity in Fish Research and Management: Theory and PracticeFrom EverandElectricity in Fish Research and Management: Theory and PracticeNo ratings yet

- Reverberation Chambers: Theory and Applications to EMC and Antenna MeasurementsFrom EverandReverberation Chambers: Theory and Applications to EMC and Antenna MeasurementsNo ratings yet

- Reaction PaperDocument1 pageReaction PaperMarko Antonio MccoyNo ratings yet

- Its More Sun in The PhilsDocument16 pagesIts More Sun in The PhilsMarko Antonio MccoyNo ratings yet

- Cistern Tank Water Level Monitoring Date Time Level RemarksDocument1 pageCistern Tank Water Level Monitoring Date Time Level RemarksMarko Antonio MccoyNo ratings yet

- Research KunwariDocument9 pagesResearch KunwariMarko Antonio MccoyNo ratings yet

- Transmission ConsiderationDocument23 pagesTransmission ConsiderationMarko Antonio MccoyNo ratings yet

- Standard Tuning-RunDocument8 pagesStandard Tuning-RunMarko Antonio MccoyNo ratings yet

- Kiss The RainDocument2 pagesKiss The RainAristo KurniawanNo ratings yet

- ExamDocument1 pageExamMarko Antonio MccoyNo ratings yet

- Transmission Line DesignDocument12 pagesTransmission Line DesignGeEs AnggaNo ratings yet

- Transmission ConsiderationDocument23 pagesTransmission ConsiderationMarko Antonio MccoyNo ratings yet

- 4Document15 pages4Marko Antonio MccoyNo ratings yet

- DC generator commutator designDocument4 pagesDC generator commutator designMarko Antonio MccoyNo ratings yet

- DC generator commutator designDocument4 pagesDC generator commutator designMarko Antonio MccoyNo ratings yet

- Recto's 'Free Wifi in Metro Manila' Bill (SB2232)Document4 pagesRecto's 'Free Wifi in Metro Manila' Bill (SB2232)Jojo MaligNo ratings yet

- Alternator ReviewerDocument7 pagesAlternator ReviewerMarko Antonio MccoyNo ratings yet

- Alternator ProblemsDocument2 pagesAlternator ProblemsMarko Antonio MccoyNo ratings yet

- BEEE - LAB Manual-Intro - Part 2Document6 pagesBEEE - LAB Manual-Intro - Part 2Anant UpadhiyayNo ratings yet

- 4001 ManualDocument31 pages4001 ManualSantiago Fernandez MorenoNo ratings yet

- Basic Electrical MCQ Online TestDocument9 pagesBasic Electrical MCQ Online Testsumanta.kundu318020No ratings yet

- CS-205 Completely-in-the-Canal Wireless Earphone: Main Feature of CS-205Document6 pagesCS-205 Completely-in-the-Canal Wireless Earphone: Main Feature of CS-205burdujaviorelNo ratings yet

- AMU - List of M.Tech. / B.Tech. Computer / Electronics & MCA 2022 BatchDocument6 pagesAMU - List of M.Tech. / B.Tech. Computer / Electronics & MCA 2022 BatchManish SharmaNo ratings yet

- Networks 512 PrepDocument12 pagesNetworks 512 PrepseepanetselaneNo ratings yet

- Water Power Technologies Office 2017 Hydropower Market ReportDocument8 pagesWater Power Technologies Office 2017 Hydropower Market Reporthimiko togaNo ratings yet

- JCLP SpliTech2019 FinalDocument19 pagesJCLP SpliTech2019 FinalRemigild PeterNo ratings yet

- MeocDocument10 pagesMeocGeneric nameNo ratings yet

- XLM35 DS T140088en eDocument2 pagesXLM35 DS T140088en eStefanos BokiNo ratings yet

- 30 AboxDocument1 page30 AboxHoàng YếnNo ratings yet

- Room Air Conditioner Service ManualDocument28 pagesRoom Air Conditioner Service ManualFlorian LeordeanuNo ratings yet

- Led TV: Service ManualDocument75 pagesLed TV: Service ManualIulius-virgil DogaruNo ratings yet

- Talking Board: 80 December 1981 U.K. 65 PDocument76 pagesTalking Board: 80 December 1981 U.K. 65 PWagner SilvaNo ratings yet

- UNIT-3 Image Enhancement in Frequency DomainDocument66 pagesUNIT-3 Image Enhancement in Frequency DomainYatish ChutaniNo ratings yet

- Week 2 Assignment SolutionDocument2 pagesWeek 2 Assignment SolutionAdhi SuruliNo ratings yet

- Single Cycle ProcessorDocument23 pagesSingle Cycle ProcessorLý 1 1619No ratings yet

- A5e32081626 002 AbDocument186 pagesA5e32081626 002 AbOscarJavierVillarVargasNo ratings yet

- Lecture Lossy DielectricsDocument15 pagesLecture Lossy DielectricsBill WhiteNo ratings yet

- Ant DS y (B) 4506 0115Document1 pageAnt DS y (B) 4506 0115SentaNo ratings yet

- FMECA Paper2Document7 pagesFMECA Paper2malcom rajNo ratings yet

- Emb Lab Manual FinalDocument142 pagesEmb Lab Manual FinalSatheesh Kumar100% (1)

- Voltage Influence On Typical Protection and Controls ForDocument22 pagesVoltage Influence On Typical Protection and Controls ForM Kumar MarimuthuNo ratings yet

- PSS 46th EditionDocument96 pagesPSS 46th EditionMUHAMMAD USAMANo ratings yet

- Audio, Video and Media Module: Transducers, EQ and FiltersDocument16 pagesAudio, Video and Media Module: Transducers, EQ and FiltersIsmail MusharafNo ratings yet

- Coupling Circuit Design For PLCDocument5 pagesCoupling Circuit Design For PLCzafarbajwaNo ratings yet

- 2114 SramDocument4 pages2114 SramKarloz IbarraNo ratings yet