Professional Documents

Culture Documents

CAL-00-P-0005 Rev 0 Vessel Sizing

Uploaded by

Syed Zaki HaiderCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CAL-00-P-0005 Rev 0 Vessel Sizing

Uploaded by

Syed Zaki HaiderCopyright:

Available Formats

CAL-00-P-0004 Rev A - Vessel Sizing

Contents

1. Summary.................................................................................................................. 3

2. Objective .................................................................................................................. 3

3. Method..................................................................................................................... 3

4. Inputs/Assumptions .................................................................................................. 4

5. Calculations .............................................................................................................. 4

5.1 Design Cases .................................................................................................... 4

5.2 Candles Required .............................................................................................. 5

5.3 Tubes Required................................................................................................. 6

5.4 Candle / Tube Configuration .............................................................................. 7

5.5 Vessel Diameter................................................................................................ 8

5.6 Vessel Length ................................................................................................... 8

5.7 Length / Diameter Ratio .................................................................................... 9

5.8 Nozzle Sizings ................................................................................................... 9

6 Results ................................................................................................................... 10

List of Tables

Table 1 – Summary........................................................................................................... 3

Table 2 – Design Cases ..................................................................................................... 4

Table 3 – Candle Surface Area ........................................................................................... 5

Table 4 – Required Candle Surface Area............................................................................. 5

Table 5 – Candles Required ............................................................................................... 5

Table 6 – Tube Flow ......................................................................................................... 6

Table 7 – Tubes Required.................................................................................................. 6

Table 8 – Comparison of Candles / Tubes Required............................................................. 7

Table 9 – Gas Nozzle Sizing ............................................................................................. 10

Table 10 – Summary of Results ....................................................................................... 10

List of Figures

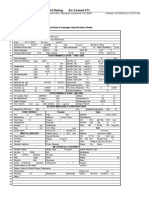

Figure 1 – Candle Configuration ......................................................................................... 7

S:\Projects\…\CAL-00-P-0005 Rev 0 - Filter Page 2 of 10

V-1003 Sizing.doc

CAL-00-P-0004 Rev A - Vessel Sizing

1. Summary

This calculation determines the dimensions, number of filter candles and nozzle sizes of

vessel V-1003A/B/C. This vessel is a horizontal two-stage filter separator.

All calculations are based on parameters taken from Mass and Energy Balances (DS-00-P-

0002.01 Rev C and DS-00-P-0002.02 Rev C). Number of filter candles required has been

given an allowance of 25%. The tan-to-tan vessel length consists of filtering and demisting

compartments. Minimum nozzle sizes have been calculated such that the maximum ρV2 is

less than 3750 kg/ms2 for the feed and gas. A summary of results is shown below in Table 1.

Nominal bore sizes shown correspond to Schedule 80 pipe.

Table 1 – Summary

Parameter

Design Case

Phase 1 10,140 Am3/h (105 MMSCFD)

Phase 2 19,610 Am3/h (50 MMSCFD)

Number of Filter Candles Required 117

Candle Configuration Triangular

Vessel diameter 2.03 m

Vessel length

Tan-to-tan 3.54 m

Filter Compartment 2.54 m

Demisting Compartment 1.00 m

Length / Diameter Ratio 1.7

Minimum Nozzle Sizing

Gas Nozzle 432 (Schedule 80, N.B. 20”)

Feed nozzle 432 (Schedule 80, N.B. 20”)

Liquid nozzle (Schedule 80, N.B. 2”)

2. Objective

The objective of this calculation is to determine vessel dimensions of V-1003A/B. Number of

filter candles, candle configuration, vessel diameter, vessel length and nozzle sizes will be

considered.

3. Method

• Determine design cases.

• Determine number of candles required.

• Determine number of tubes required.

• Candle configuration.

• Vessel diameter calculation.

• Vessel length calculation.

• Length / diameter ratio.

• Nozzle sizing calculation.

S:\Projects\…\CAL-00-P-0005 Rev 0 - Filter Page 3 of 10

V-1003 Sizing.doc

CAL-00-P-0004 Rev A - Vessel Sizing

4. Inputs/Assumptions

• Assume horizontal two-stage filter separator. The two stages are filtering (remove

dust and coalesce fine mist) and demisting (remove coalesced liquid droplets).

• Filter candles with an outer diameter of 4”, inner diameter of 3” and length of 36” or

72”.

• The maximum gas velocity into the filter part of the candles is 0.10 m/s to allow for

proper coalescing.

• The maximum flow per filter tube is based upon an allowable ρGv2G,tube ≤ 1000.

• An additional 25% allowance for number of candles and filter tubes will be

calculated.

• Filter candles will be arranged in a triangular configuration within the vessel.

• The space between filter candles on each row and down each column is equivalent to

the outer diameter of one filter candle.

• A distance of 0.05 m will be allowed between the filter candles and the vessel wall.

• In the filter compartment, the length of the outlet tube is 1.4 times the feed nozzle

inner diameter.

• There is no demisting device in this vessel. Fine vapour particles will be removed in

the compressor suction scrubbers, V-1000 A/B/C during Phase 1 and V-2000 A/B/C

during Phase 2.

• The demisting compartment may be assumed to be 1 m long.

• The minimum nozzle diameter is based upon an allowable ρGv2G,nozzle ≤ 3750.

• For this calculation the gas and feed nozzle sizes are the same.

• Liquid nozzles are assumed to be of 2” nominal bore.

5. Calculations

5.1 Design Cases

The design cases for Phase 1 and 2 are shown below in Table 2. These values are taken from

the Mass and Energy Balances DS-00-P-0002.01 Rev C and DS-00-P-0002.02 Rev C.

Table 2 – Design Cases

Gas Flow

Phase Standard Actual

(MMSCFD) (std.m3/hr) (act.m3/hr)

1 104.9 123,788 10,140

2 49.9 58,837 19,610

S:\Projects\…\CAL-00-P-0005 Rev 0 - Filter Page 4 of 10

V-1003 Sizing.doc

CAL-00-P-0004 Rev A - Vessel Sizing

5.2 Candles Required

Filter candles typically have an outer diameter of 4”, inner diameter of 3” and length of 36” or

72”. Candle surface area is calculated using the equation:

2

πd o L

Surface Area =

4

The results are shown below in Table 3.

Table 3 – Candle Surface Area

Inner Diameter Outer Diameter Length Surface Area per Candle

(di, inch) (do, inch) (L, inch) (in2) (m2)

3 4 36 452 0.292

3 4 72 905 0.584

Required candle surface area is dependent on Actual Flow passing through the filter.

Required candle surface area is calculated using the equation:

Actual Flow Rate

Required Candle Surface Area =

Allowable Velocity

Where:

• Allowable velocity over the candles (vG,candle) is assumed to be 0.10 m/s.

The results are shown below in Table 4.

Table 4 – Required Candle Surface Area

Phase Actual Flow Velocity Required Candle Surface Area

(m3/s) (m/s) (m2)

1 2.8 0.10 28

2 5.4 0.10 54

Since Phase 2 requires the greatest candle surface area, the number of candles required will

be based on Phase 2 requirements. Number of candles required is calculated using the

equation:

Required Surface Area

Number of Candles =

Surface Area per Candle

The results are shown below in Table 5.

Table 5 – Candles Required

Number of .Candles

Candle Length Number of Candles

(25% margin)

36" 187 233

72" 93 117

A 25% margin is allowed for number of candles required.

S:\Projects\…\CAL-00-P-0005 Rev 0 - Filter Page 5 of 10

V-1003 Sizing.doc

CAL-00-P-0004 Rev A - Vessel Sizing

5.3 Tubes Required

The maximum flow per filter tube is based upon an allowable ρGv2G,tube ≤ 1000.

• “To avoid atomisation of the coalesced droplets in the outlet tubes of the candles:

ρGv2G,tube ≤ 1000

vG,tube. is the gas velocity inside the outlet tubes.

Density values were taken from the Mass and Energy Balances DS-00-P-0002.01 Rev C and

DS-00-P-0002.02 Rev C. vG,tube is calculated using the equation:

ρ G v 2G,tube

v G,tube =

ρG

Flow per filter tube is calculated using the equation:

πd i2 v G,tube

Flow per filter tube =

4

The results are shown below in Table 6.

Table 6 – Tube Flow

Phase ρGv2G,tube ρG vG,tube Flow per Filter Tube

(kg/ms2) (kg/m3) (m/s) (m3/s)

1 1000 10.183 9.91 0.045

2 1000 2.516 19.94 0.091

The number of tubes required is calculated using the equation:

Actual Flow Rate

Number of Tubes =

Flow per Filter Tube

The results are shown below in Table 7.

Table 7 – Tubes Required

Phase Number of Filter Tubes Number of Filter Tubes

(25% margin)

1 62 78

2 60 75

A 25% margin is allowed for number of tubes required.

S:\Projects\…\CAL-00-P-0005 Rev 0 - Filter Page 6 of 10

V-1003 Sizing.doc

CAL-00-P-0004 Rev A - Vessel Sizing

5.4 Candle / Tube Configuration

Comparison of the calculated number of candles (Section 5.2, vG,candle criterion) and number

of filter tubes required (Section 5.3, ρGv2G,tube criterion) is shown below in Table 8.

Table 8 – Comparison of Candles / Tubes Required

Criterion 36" 72" Phase 1 Phase 2

candle candle tube tube

1 233 117

2 78 75

As Criterion 1 results in the greater number of candles, results from its calculation shall be

used. 72” candles will be used in the calculation since a large number of candles are required.

The candle configuration is shown below in Figure 1. The space between filter candles on

each row and down each column is equivalent to the outer diameter of one filter candle.

Thus, the configuration is 19 filter candles wide and 19 filter candles high.

Figure 1 – Candle Configuration

S:\Projects\…\CAL-00-P-0005 Rev 0 - Filter Page 7 of 10

V-1003 Sizing.doc

CAL-00-P-0004 Rev A - Vessel Sizing

5.5 Vessel Diameter

The diameter of a filter candle row is given by:

Diameter of Filter Candle Row = Number of Filter Candles x d o

= 19 x 4"

= 1.93m

A distance of 0.05 m will be allowed between the filter candles and the vessel wall.

The inner diameter of the vessel is given by:

Vessel Internal Diameter = Diameter of Filter Candle Row + 2(0.05 m)

= 1.93 + 0.1

D = 2.03 m

5.6 Vessel Length

The length of each filter candle is 72” (1.83 m).

The length of the outlet tube is 1.4d1, where d1 is the feed nozzle inner diameter (Refer to

Section 5.8).

d1 = 20"

= 0.508 m

Length of Outlet Tube = 1.4d1

= 1.4 x 0.508 m

= 0.711 m

The length of the filter compartment is:

Length Coalescer Compartment = Length Filter Candle + Length Outlet Tube

= 1.83 + 0.711

= 2.54 m

The length of the demisting compartment is arbitrarily assigned as 1 m. There is no demisting

device in this vessel as removal of fine vapours will be performed at the compressor suction

scrubbers, V-1000 A/B/C during Phase 1 and V-2000 A/B/C during Phase 2.

The length of the vessel is:

Length Vessel = Length Coalescer Compartment + Length Demisting Compartment

= 2.54 + 1.00

= 3.54 m

S:\Projects\…\CAL-00-P-0005 Rev 0 - Filter Page 8 of 10

V-1003 Sizing.doc

CAL-00-P-0004 Rev A - Vessel Sizing

5.7 Length / Diameter Ratio

The length on diameter ratio is given by:

Length 3.54

=

Diameter 2.03

= 1.7

5.8 Nozzle Sizings

The limiting criteria on gas and feed nozzle sizing is:

ρGv2G,nozzle ≤ 3750

Gas Nozzle

The gas parameters are taken to be the same as the feed parameters for the purposes of this

calculation.

An example calculation for Phase 1 gas nozzle is shown below.

• Maximum allowable ρV2 = 3750 kg/ms2.

• Gas velocity,

ρV 2

V=

ρ

3750

=

10.183

= 19.19 m

s

Q

• A=

V

and

πD 2

A=

4

so

4Q

D=

πV

m3 h

4 x 10,140 x

= h 3600s

m

π x 19.19

s

= 432mm

• This minimum I.D. corresponds to a nominal bore of 20” for Schedule 80 pipe.

S:\Projects\…\CAL-00-P-0005 Rev 0 - Filter Page 9 of 10

V-1003 Sizing.doc

CAL-00-P-0004 Rev A - Vessel Sizing

Results for gas nozzle sizings for Phase 1 and 2 are shown below in Table 9.

Table 9 – Gas Nozzle Sizing

Phase 1 Phase 2

Maximum allowable ρV2 (kg/ms2) 3750 3750

ρg (kg/m3) 10.183 2.516

Fluid velocity, V (m/s) 19.19 38.61

Gas flow rate, Q (m3/h) 10,140 19,610

Minimum diameter, I.D. (mm) 432 424

Schedule 80 80

Nominal Bore 20 20

Feed Nozzles

The feed nozzles will be the same as the gas nozzles since they utilise the same parameters.

Liquid Nozzles

The liquid nozzles may be assumed to be 2” nominal bore.

6 Results

A summary of the pertinent results is shown below in Table 10.

Table 10 – Summary of Results

Parameter

Design Case

Phase 1 10,140 Am3/h

Phase 2 19,610 Am3/h

Number of Filter Candles Required 117

Candle Configuration Triangular

Vessel diameter 2.03 m

Vessel length

Tan-to-tan 3.54 m

Filter Compartment 2.54 m

Demisting Compartment 1.00 m

Length / Diameter Ratio 1.7

Minimum Nozzle Sizing

Gas Nozzle 432 (Schedule 80, N.B. 20”)

Feed nozzle 432 (Schedule 80, N.B. 20”)

Liquid nozzle (Schedule 80, N.B. 2”)

S:\Projects\…\CAL-00-P-0005 Rev 0 - Filter Page 10 of 10

V-1003 Sizing.doc

You might also like

- Petro-Refining Guidance June-1985 PDFDocument246 pagesPetro-Refining Guidance June-1985 PDFdalila_agueroNo ratings yet

- Technical Specification - LT (DP Based)Document4 pagesTechnical Specification - LT (DP Based)ManodipPatilNo ratings yet

- Steam Boilers VeloaDocument96 pagesSteam Boilers VeloaSteve WanNo ratings yet

- Milton Roy CatalogueDocument5 pagesMilton Roy CatalogueAnil KumarNo ratings yet

- SCPF-PETW-LIS-P-01001 - Rev0 - Utility Consumption List - CPFDocument3 pagesSCPF-PETW-LIS-P-01001 - Rev0 - Utility Consumption List - CPFSEGUNNo ratings yet

- Distillation Column Tray Selection & Sizing - 1 - Separation TechnologiesDocument18 pagesDistillation Column Tray Selection & Sizing - 1 - Separation TechnologiesOmesh Borole100% (1)

- VCTDS-01061 Sizing of Tank Blanketing System-EnDocument3 pagesVCTDS-01061 Sizing of Tank Blanketing System-EnvipinNo ratings yet

- GT-DWC White-Paper Naphtha-Splitters 9.23.16Document11 pagesGT-DWC White-Paper Naphtha-Splitters 9.23.16Qadir JafarofffNo ratings yet

- Line Sizing ProcessDocument13 pagesLine Sizing ProcessEngr Theyji0% (1)

- Choosing A Line Size and Wall ThicknessDocument29 pagesChoosing A Line Size and Wall ThicknessAndhy Arya EkaputraNo ratings yet

- 541-PC-1002 Utility Consumption Summary1Document3 pages541-PC-1002 Utility Consumption Summary1svnaik14No ratings yet

- Establishing Control Valve Trim Flow VelocityDocument11 pagesEstablishing Control Valve Trim Flow VelocityakhileshkuniyilNo ratings yet

- Minimum Submergence Required For Vortex Breaker - Industrial Professionals - Cheresources - Com CommunityDocument7 pagesMinimum Submergence Required For Vortex Breaker - Industrial Professionals - Cheresources - Com CommunitySHINo ratings yet

- Lecture 2+3 Pipeway EnggDocument61 pagesLecture 2+3 Pipeway EnggJaveria SheikhNo ratings yet

- Glycol Dehydration Unit English LetterDocument4 pagesGlycol Dehydration Unit English LetterRaulCamachoNo ratings yet

- HCP-8000-PL-Z-3322 P3 S22 Maintenance & Inspection of MobileDocument10 pagesHCP-8000-PL-Z-3322 P3 S22 Maintenance & Inspection of MobileeryNo ratings yet

- Process Basis of DesigneDocument14 pagesProcess Basis of Designeamini_mohiNo ratings yet

- Engineering Group: Kuwait Oil Company (K.S.C.)Document14 pagesEngineering Group: Kuwait Oil Company (K.S.C.)Aravindan Ganesh KumarNo ratings yet

- Specify Three-Phase SeparatorsDocument12 pagesSpecify Three-Phase SeparatorsRobert MontoyaNo ratings yet

- 6.1 Working Principle of Equipment:: 6.2.1 Steady State Heat TransferDocument35 pages6.1 Working Principle of Equipment:: 6.2.1 Steady State Heat TransferAthar IqbalNo ratings yet

- NGL SeparationDocument6 pagesNGL SeparationhoustonmathNo ratings yet

- KIRK Sep-Calc SoftwareDocument4 pagesKIRK Sep-Calc Softwaredhl_tuNo ratings yet

- Tank relief designDocument12 pagesTank relief designsachinumaryeNo ratings yet

- Norsok Standard Process SystemsDocument131 pagesNorsok Standard Process SystemsJohnNo ratings yet

- Pressure Relief Valve Spec SheetDocument1 pagePressure Relief Valve Spec Sheetanamaria ursuNo ratings yet

- Flare Systems-Conclusion Safety, Noise, and Emissions Elements Round Out Flare GuidelinesDocument7 pagesFlare Systems-Conclusion Safety, Noise, and Emissions Elements Round Out Flare GuidelinesRebekah SchmidtNo ratings yet

- Porous Sparger SizingDocument4 pagesPorous Sparger Sizingprav.saradaNo ratings yet

- Vortex-Breaking PDFDocument7 pagesVortex-Breaking PDFZeroRecoNo ratings yet

- PSV D-103Document24 pagesPSV D-103DIANTORONo ratings yet

- Optimize Flare System DesignDocument8 pagesOptimize Flare System DesignVinothrajaNo ratings yet

- PEPA3-11-MS-03-DS-005 - Tank Mechanical Datasheet For Tangki Prioritas 2 (Tambun SP) Rev ADocument30 pagesPEPA3-11-MS-03-DS-005 - Tank Mechanical Datasheet For Tangki Prioritas 2 (Tambun SP) Rev ARokan PipelineNo ratings yet

- Gas Dehydration (ENGINEERING DESIGN GUIDELINE)Document23 pagesGas Dehydration (ENGINEERING DESIGN GUIDELINE)Tu Dang TrongNo ratings yet

- Alarm & ESD Set Point-R01Document5 pagesAlarm & ESD Set Point-R01Hossein Zohdi RadNo ratings yet

- Norsok Standard P-001: Edition 5, Sep. 2006Document26 pagesNorsok Standard P-001: Edition 5, Sep. 2006Đào_hải_10No ratings yet

- General Abbreviations and Piping Symbols GuideDocument1 pageGeneral Abbreviations and Piping Symbols GuideĐỗ Thiện100% (1)

- Diseño de ProcesoDocument9 pagesDiseño de ProcesotinocamargoNo ratings yet

- Designing Biogas Systems: A Technical GuideDocument7 pagesDesigning Biogas Systems: A Technical GuideMunish VashisthaNo ratings yet

- A8ij 300 25 BD 0006 - 1Document34 pagesA8ij 300 25 BD 0006 - 1becpavanNo ratings yet

- Condensate Stabilization Design BasisDocument22 pagesCondensate Stabilization Design BasisMuhammad.SaimNo ratings yet

- Aspen Exchanger Design and Rating Sheet for Forced Draft Air Cooled Heat ExchangerDocument1 pageAspen Exchanger Design and Rating Sheet for Forced Draft Air Cooled Heat ExchangerHafidzAliyufaNo ratings yet

- Pumps Final TeDocument48 pagesPumps Final Tegharsallah mounaNo ratings yet

- O&Msec2 Heat & Material BalanceDocument8 pagesO&Msec2 Heat & Material Balanceugun87No ratings yet

- PRESSURISEDDocument17 pagesPRESSURISEDrahigi8656No ratings yet

- Ario Damar - Sriwijaya Oil & Gas Development: Document No. CT-F17795-TE2-31-E-002-001Document5 pagesArio Damar - Sriwijaya Oil & Gas Development: Document No. CT-F17795-TE2-31-E-002-001idilfitriNo ratings yet

- Nioec SP 47 27Document29 pagesNioec SP 47 27sgh1355No ratings yet

- Simulation of Liquefied Petroleum Gas LPG Producti PDFDocument7 pagesSimulation of Liquefied Petroleum Gas LPG Producti PDFfarshadNo ratings yet

- Linan Dehydration UnitDocument49 pagesLinan Dehydration UnitAndrew ArNo ratings yet

- REBOILER CALCULATION GUIDEDocument12 pagesREBOILER CALCULATION GUIDESabba CabbaNo ratings yet

- Tank BlankettingDocument6 pagesTank BlankettingBaskar KannaiahNo ratings yet

- Choke Valve SizingDocument8 pagesChoke Valve SizingreninbabaskiNo ratings yet

- Thermosyphon Reboiler (Horizontal) GPSADocument6 pagesThermosyphon Reboiler (Horizontal) GPSAsyamsudin2006No ratings yet

- SMR Hydrogen Generators-Technologies and Producers 2009Document28 pagesSMR Hydrogen Generators-Technologies and Producers 2009Zoran JuricNo ratings yet

- To-HQ-02-037 Rev 00 Philosophy For Piping Design - OnshoreDocument41 pagesTo-HQ-02-037 Rev 00 Philosophy For Piping Design - OnshoreBassem BalghouthiNo ratings yet

- Air&gas-Design Pr.29576Document18 pagesAir&gas-Design Pr.29576JKKNo ratings yet

- Dhamra LNG Terminal Pvt. Ltd. (DLTPL)Document11 pagesDhamra LNG Terminal Pvt. Ltd. (DLTPL)balajikrishnanNo ratings yet

- DJM-MBA-PCS-CA-018 LPG On-Spec Storage REV-BDocument3 pagesDJM-MBA-PCS-CA-018 LPG On-Spec Storage REV-BDIANTORONo ratings yet

- Burner CalculationDocument6 pagesBurner CalculationAbul QasimNo ratings yet

- Burner CalculationDocument9 pagesBurner CalculationAbul QasimNo ratings yet

- FM (Practical) PDFDocument44 pagesFM (Practical) PDFPrathmesh BakkarNo ratings yet

- CAL-00-P-0003 Rev 0 - Line SizingDocument91 pagesCAL-00-P-0003 Rev 0 - Line SizingSyed Zaki HaiderNo ratings yet

- CAL-00-P-0009 Rev A Compressed Air SystemDocument13 pagesCAL-00-P-0009 Rev A Compressed Air SystemSyed Zaki HaiderNo ratings yet

- CAL-00-P-0006 Rev 0 - V-5702 SizingDocument11 pagesCAL-00-P-0006 Rev 0 - V-5702 SizingSyed Zaki HaiderNo ratings yet

- Commissioing and Start-Up Schedule2Document12 pagesCommissioing and Start-Up Schedule2Syed Zaki HaiderNo ratings yet

- Calculation of Actual Contaminated Firewater Volume: K T Q VDocument5 pagesCalculation of Actual Contaminated Firewater Volume: K T Q Vankur2061No ratings yet

- CALCULATION SHEET FOR THREE-PHASE SEPARATOR WEIR ARRANGEMENTDocument44 pagesCALCULATION SHEET FOR THREE-PHASE SEPARATOR WEIR ARRANGEMENTSyed Zaki HaiderNo ratings yet

- CALCULATION SHEET FOR THREE-PHASE SEPARATOR WEIR ARRANGEMENTDocument44 pagesCALCULATION SHEET FOR THREE-PHASE SEPARATOR WEIR ARRANGEMENTSyed Zaki HaiderNo ratings yet

- FEED STUDY FOR MEPL CONDENSATE & LPG TRANSPORTATIONDocument29 pagesFEED STUDY FOR MEPL CONDENSATE & LPG TRANSPORTATIONSyed Zaki HaiderNo ratings yet

- Calculation of Actual Contaminated Firewater Volume: K T Q VDocument5 pagesCalculation of Actual Contaminated Firewater Volume: K T Q Vankur2061No ratings yet

- Installation Manual - OrificeDocument15 pagesInstallation Manual - OrificeNithyANo ratings yet

- Supply Chain Lessons From Alexander The GreatDocument7 pagesSupply Chain Lessons From Alexander The GreatSyed Zaki Haider100% (1)

- Supply Chain Lessons From Alexander The GreatDocument7 pagesSupply Chain Lessons From Alexander The GreatSyed Zaki Haider100% (1)

- CHEM 18 PROBLEM SET CHEMICAL THERMODYNAMICS AND EQUILIBRIUMDocument4 pagesCHEM 18 PROBLEM SET CHEMICAL THERMODYNAMICS AND EQUILIBRIUMDaniel Jann CotiaNo ratings yet

- Nano EmulsionDocument52 pagesNano EmulsionAbdul NadeemNo ratings yet

- Solidification ShrinkageDocument4 pagesSolidification ShrinkagesubavlNo ratings yet

- Organic Reactions 28 (1982) eDocument266 pagesOrganic Reactions 28 (1982) eRobNo ratings yet

- Booklet 2 Topic 1Document61 pagesBooklet 2 Topic 1Sarah Al ObaidanNo ratings yet

- Math 6 Unit 8 Volume of Solids and LiquidsDocument1 pageMath 6 Unit 8 Volume of Solids and LiquidsRobi AkmalNo ratings yet

- CarbonicAnhydrases Manuscript withDOIDocument11 pagesCarbonicAnhydrases Manuscript withDOIFadhil MiftahulNo ratings yet

- Mech-HT 15.0 WS05 SolenoidDocument16 pagesMech-HT 15.0 WS05 SolenoidAndres Felipe Salas VillalvaNo ratings yet

- Controlling Wax Deposition Presence Hydrates-01!25!10Document85 pagesControlling Wax Deposition Presence Hydrates-01!25!10wjawichNo ratings yet

- Marine PurifierDocument30 pagesMarine PurifierJayDelosSantos100% (1)

- Recyclingand Reuseof TextileDocument47 pagesRecyclingand Reuseof TextileRey100% (1)

- Selective Bromination With Copper (I1) Bromide - King - JOC 29 (1964)Document3 pagesSelective Bromination With Copper (I1) Bromide - King - JOC 29 (1964)dextroenantiomerNo ratings yet

- Experiment 3: Sublimation and Melting Point DeterminationDocument4 pagesExperiment 3: Sublimation and Melting Point Determinationjane de leonNo ratings yet

- KapilDocument69 pagesKapilPraveen SrivastavaNo ratings yet

- Clay Mineral Cements in SandstonesDocument3 pagesClay Mineral Cements in Sandstonesandrea.cipagautaNo ratings yet

- Collected By: Prof: Abdul Samad Mechanical Engineering Department. 2017Document19 pagesCollected By: Prof: Abdul Samad Mechanical Engineering Department. 2017Ans ahmedNo ratings yet

- CO Capture by Absorption With Potassium CarbonateDocument23 pagesCO Capture by Absorption With Potassium CarbonatekumarNo ratings yet

- TOC Application HandbookDocument79 pagesTOC Application Handbookmregalopez3647100% (1)

- PESSAT-Chemistry-Model-PaperDocument12 pagesPESSAT-Chemistry-Model-PaperpullagalkNo ratings yet

- Investigation of Failures of 230KV Copper Conductor BushingsDocument15 pagesInvestigation of Failures of 230KV Copper Conductor BushingscalripkenNo ratings yet

- Cyclones ExerciseDocument4 pagesCyclones ExerciseValeria cNo ratings yet

- Paper 4 Jun 2001 PhysicsDocument2 pagesPaper 4 Jun 2001 Physicssolarixe100% (1)

- Hygroscopic and Nonhygroscopic MaterialDocument9 pagesHygroscopic and Nonhygroscopic Materialiresa_nuratNo ratings yet

- Ganoderma laccase optimizationDocument9 pagesGanoderma laccase optimizationRajeshKumarNo ratings yet

- Characteristics - Requirements of Fibre Forming Polymers - Online Textile AcademyDocument1 pageCharacteristics - Requirements of Fibre Forming Polymers - Online Textile AcademyRAFIAHAMMEDNo ratings yet

- Project Carburizing Lupu Stefan EnglezaDocument5 pagesProject Carburizing Lupu Stefan EnglezaStefan LupuNo ratings yet

- Ultrasonic Gas Flowmeters For Permanent Installation in Hazardous AreasDocument31 pagesUltrasonic Gas Flowmeters For Permanent Installation in Hazardous AreasrudrakrNo ratings yet

- Thermal Analysis Choosing The Right BaselineDocument24 pagesThermal Analysis Choosing The Right BaselineHung NGUYENNo ratings yet

- LP2 SCI-12 MICROBIO LABORATORY-fINALDocument21 pagesLP2 SCI-12 MICROBIO LABORATORY-fINALJOHNERROL CARCELLARNo ratings yet

- Determination of Core Sample Absolute Permeability Using Gas Permeameter and Liquid Fluid Practicum ReportDocument17 pagesDetermination of Core Sample Absolute Permeability Using Gas Permeameter and Liquid Fluid Practicum ReportAqsal IlhamNo ratings yet