Professional Documents

Culture Documents

Steca TR 0201 Instruction en

Uploaded by

daviko313Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Steca TR 0201 Instruction en

Uploaded by

daviko313Copyright:

Available Formats

SOLARTHERMIE - SOLAR THERMAL - SOLAR TRMICA- SOLAIRE THERMIQUE - SOLARE TERMICO

Installation and operating instructions

Temperature differential controller

2 inputs, 1 output

719.450 | Z03 | 07.49 | Subject to change due to technical improvements!

EN

These operating instructions are part of the product.

Read these operating instructions carefully before use.

Keep them over the entire lifetime of the product

and pass them on to any future owner or user of this product.

2

719.450 | 07.49

EN

Table of Contents

1 About this manual ..................... 3

1.1 Applicability .................................. 3

1.2 Users ............................................. 3

1.3 Description of symbols .................. 4

2 Safety .......................................... 5

2.1 Proper usage ................................. 5

2.2 Improper usage ............................. 5

2.3 Dangers during assembly and

commissioning .............................. 6

2.4 Detecting faults ............................. 7

2.5 Exclusion of liability ...................... 7

3 Description ................................. 9

3.1 Controller in the solar circuit ......... 9

3.2 Case overview ............................. 10

4 Installation ............................... 11

4.1 Opening / closing the case .......... 11

4.2 Assembly ..................................... 12

4.3 Electrical connection ................... 13

5 Display overview ...................... 17

6 Commissioning ........................ 18

7 Description of the controller

functions .................................. 19

7.1 Switch-on / switch-off

temperature difference ............... 19

7.2 Maximum storage tank

temperature ................................ 19

7.3 Maximum collector temperature ...20

7.4 Tube collector function (F1) ........ 20

7.5 Anti-freeze function (F2) ............. 21

8 Operation ................................. 22

8.1 Reading the temperature values .. 22

8.2 Setting the controller .................. 23

9 Maintenance ............................. 29

9.1 Fault causes ................................. 29

9.2 Testing the temperature sensors .. 33

10 Dismantling and disposal ........ 34

11 Legal Guarantee ....................... 35

12 Technical data ........................... 37

3

719.450| 07.49

EN

1 About this manual

1.1 Applicability

This manual describes the installation, commissioning,

operation, maintenance and dismantling of the temper-

ature differential controller for solar thermal energy sys-

tems. When installing the remaining components, e.g.

solar collectors, pump assemblies, storage tank, pumps

and switching valves, be sure to observe the appropriate

installation instructions provided by each manufacturer.

1.2 Users

Installation, commissioning, maintenance and disman-

tling of the controller may only be performed by trained

professional personnel. Before commissioning, the con-

troller must be professionally assembled and installed by

professional personnel in accordance with the applicable

regional and transregional regulations as well as the safety

instructions and general instructions within this installa-

tion and instruction manual. The professional personnel

must be familiar with this operation manual.

The controller is maintenance-free.

Use the controller only after first thoroughly reading and

understanding this instruction manual and the safety

instructions. Adhere to all safety instructions. In the

event of any ambiguities regarding the operation and

alteration of parameters or functions, consult profes-

sional personnel.

4

719.450 | 07.49

EN

1.3 Description of symbols

1.3.1 The structure of the warning notices

SIGNAL WORD

Type, source and consequences of the danger!

Measures for avoiding danger.

1.3.2 Danger levels in warning notices

Danger level Likelihood of

occurrence

Consequences

resulting from

non-compliance

DANGER

Imminent

threat of danger

Death, serious

bodily injury

WARNING

Possible

threat of danger

Death, serious

bodily injury

CAUTION

Possible

threat of danger

Minor

bodily injury

CAUTION Possible

threat of danger

Property damage

1.3.3 Notes

NOTE

Notes on easier and safer working habits.

Measures for easier and safer working habits.

5

719.450| 07.49

EN

1.3.4 Other symbols and markings

Symbol Meaning

Condition for action

Call to action

Result of action

List

Emphasis on

issue at hand

Emphasis on issue at hand

2 Safety

2.1 Proper usage

The temperature differential controller (below called

controller) may only be used for controlling solar ther-

mal systems within the permissible ambient conditions

(see chapter 12).

2.2 Improper usage

The controller must not be operated in the following

environments:

outdoors

in damp rooms

in rooms where highly flammable gas mixtures can

occur

in rooms in which the operation of electrical and

electronic components may cause dangers to arise

6

719.450 | 07.49

EN

2.3 Dangers during assembly and commis-

sioning

The following dangers exist during assembly / commis-

sioning of the controller and during operation (in case

of assembly errors):

Risk of death by electrocution

Risk of fire due to short-circuit

Damage to any of the constructional fire safety

measures present in the building due to incorrectly

installed cables

Damage to the controller and connected devices

due to improper ambient conditions, inappropriate

power supply and connecting prohibited devices or

faulty devices and incorrect assembly or installation

Therefore, all safety regulations apply when working

on the mains supply. Only electricians may perform

work that requires opening the controller (such as con-

nection work).

When laying cables, ensure that no damage occurs

to any of the constructional fire safety measures

present in the building.

Make sure that the permissible ambient condi-

tions at the installation site are not exceeded (see

chapter 12).

Be sure to comply with the specified degree of

protection.

Factory labels and markings may not be altered,

removed or rendered unreadable.

7

719.450| 07.49

EN

Before connecting the device, make sure that the

power supply matches the specifications on the

type plate.

Make sure that all devices which are connected to

the controller conform to the technical specifica-

tions of the controller.

Secure the device against unintentional commission-

ing.

All work on an open controller must be performed

with the mains supply disconnected.

Protect the controller against overloading and

short-circuiting.

2.4 Detecting faults

Check the display regularly.

In case of faults, isolate the cause (see chapter 9).

As soon as it becomes evident that safe operation

is no longer possible (e.g. visible damage), remove

the device from the mains supply immediately.

Have professional personnel remedy the fault.

2.5 Exclusion of liability

The manufacturer cannot monitor the compliance to

this manual as well as the conditions and methods dur-

ing the installation, operation, usage and maintenance

of the controller. Improper installation of the system

may result in damage to property and, as a result, in

bodily injury.

Therefore, we assume no responsibility and liability for

8

719.450 | 07.49

EN

loss, damage or costs which result from or are in any

way related to incorrect installation, improper opera-

tion, incorrect execution of installation work and incor-

rect usage and maintenance.

Similarly, we assume no responsibility for patent right

or other right infringements of third parties caused by

usage of this controller.

The manufacturer reserves the right to make changes

to the product, technical data or assembly and operat-

ing instructions without prior notice.

9

719.450| 07.49

EN

3 Description

3.1 Controller in the solar circuit

3.1.1 The purpose of the controller

The controller controls the pump in a solar thermal

system.

3.1.2 The structure of the solar circuit

Temperature differential controller

Storage

tank

Pump

Temperature sensor 1

(collector sensor)

Temperature sensor 2

(lower area of storage tank)

Collector

T1

T2

Solar circuit

10

719.450 | 07.49

EN

3.1.3 The function of the solar circuit

The controller constantly compares the temperatures

between the collector (T1) and the lower area of the

storage tank (T2) via temperature sensors. Once the

sun heats the collector and there is a temperature dif-

ference of 8 K (adjustable parameter) between the col-

lector and the storage tank, the pump is switched on.

The pump extracts the heat transfer fluid from the

lower cooler area of the storage tank and pumps it to

the collector. The heat transfer fluid in the collector is

heated by the sun and flows back to the storage tank.

The heat transfer fluid heats the domestic water via a

heat exchanger located in the storage tank.

3.2 Case overview

Automatic

On

Off

Operating buttons

Arrow up

SET button

Arrow down

Display

Display for controller operation

and system settings

Operating switch

The following modes of

operation can be selected:

- On

for commissioning

and testing for function

- Automatic

for automatic operation

- Off

to switch-off the pumps

Connections

grid, pump, temperature sensors

11

719.450| 07.49

EN

4 Installation

4.1 Opening / closing the case

DANGER

Risk of death by electrocution!

Remove the controller from the power supply before

opening the case.

Make sure that the power supply cannot be uninten-

tionally switched on.

Do not damage the case.

Only switch the power supply back on after the case

has been closed.

The top of the case will be fixed with two clips and one

screw on the lower case.

4.1.1 Opening the case

Loosen the screw and remove the upper case in an

upwards direction.

4.1.2 Closing the case

Place the upper case over the lower case at an

angle. Insert the clips in the pocket of the lower

case.

Pivot the upper case down and feed the operating

buttons through the matching holes.

Fasten the case tightly with the screw.

Clips

Operating

buttons

Upper case

Lower case

Screw

12

719.450 | 07.49

EN

4.2 Assembly

WARNING

Risk of electric shock and fire if assembled in a

damp environment!

Only assemble the controller in an area where the

degree of protection is sufficient.

4.2.1 Assembling the controller

CAUTION

Risk of injury and damage to the case when drill-

ing!

Do not use the case as a drilling template.

Choose a suitable installation site.

Drill the upper fastening hole.

Screw in the screw.

Remove the upper case.

Hang the case in the recess .

Mark the position of the lower fastening holes ,.

Remove the case again.

Drill the lower fastening holes.

Hang the case up again in the recess .

Screw the case firmly using the lower fastening

holes and .

Mount the upper case.

1

0

5

1

1

3

7

,

2

116

134

3 2

13

719.450| 07.49

EN

4.3 Electrical connection

WARNING

Risk of death by electrocution!

Remove the controller from the power supply before

opening the case.

Observe all guidelines and regulations of the local

electricity supplier.

NOTE

The device is to be connected to the grid by means

of a plug with grounding contact, or in the case of a

fixed electrical installation via a disconnection device

for complete disconnection in accordance with the

installation guidelines

4.3.1 Preparing the cable feed

Depending on the type of installation, the cables may

enter the device through the rear of the case or the

lower side of the case.

14

719.450 | 07.49

EN

Feeding the cable through the rear of the case

(diagram 1):

WARNING

Risk of electrical shock and fire due to cables com-

ing loose!

Install an external strain relief for the cables.

Remove the plastic flaps from the rear side of

the case using an appropriate tool.

Feeding the cable through the lower side of

the case (diagram 2):

WARNING

Risk of electrical shock and fire due to cables com-

ing loose!

Fasten the flexible cabling to the case using the

strain-relief clamps provided.

Cut the left and right plastic flaps using an appro-

priate tool and break them out of the case.

4.3.2 Connecting the cables

If a protective conductor is provided or required

for the pump, connect the protective conductor

to the terminal clamps of the controller. When

connecting the protective conductor, observe the

following points:

SET

6

Diagram 2: Cable feed from

below

SET

7

Diagram 1: Cable feed from

the rear

15

719.450| 07.49

EN

Make sure that the grounding contact is also

connected to the controller's mains supply side.

Each terminal may only be connected to a single

connecting wire (max 2.5 mm

2

).

The terminals are suitable for connection without

sleeves; stranded wires are to be twisted (1 twist

per 20 mm).

Only use the original temperature sensors (Pt1000)

that are approved for use with the controller.

Observe the following points:

The polarity of the sensor contacts is not important.

Do not lay sensor cables close to 230 volt or 400

volt cables (minimum separation 100 mm).

If inductive effects are expected, e.g. from heavy

current cables, overhead train cables, transformer

substations, radio and television devices, amateur

radio stations, microwave devices etc., then the

sensor cables must be adequately shielded.

Sensor cables may be extended to a maximum

length of 100 m.

When using extension cables, select the following

cable cross sections:

0.75 mm

2

up to 50 m long

1.5 mm

2

up to 100 m long

Connect the cables in accordance with the terminal

plan.

-

-

-

-

-

-

-

-

-

16

719.450 | 07.49

EN

L N N R1 T1 T2

4.3.3 Terminal plan

P

r

o

t

e

c

t

i

v

e

c

o

n

d

u

c

t

o

r

T

e

m

p

e

r

a

t

u

r

e

s

e

n

s

o

r

1

(

c

o

l

l

e

c

t

o

r

)

T

e

m

p

e

r

a

t

u

r

e

s

e

n

s

o

r

2

(

l

o

w

e

r

a

r

e

a

o

f

s

t

o

r

a

g

e

t

a

n

k

)

PE L1 N PE R1 N

G

r

i

d

2

3

0

V

~

(

o

p

t

i

o

n

a

l

1

1

5

V

~

)

P

u

m

p

2

3

0

V

~

(

o

p

t

i

o

n

a

l

1

1

5

V

~

)

4.3.4 Operation of the connecting terminals

NOTE

For any handling of the connecting terminal, only

adequate tools must be used. Any inadequate tool or

mechanical over-pressure will damage the terminal.

17

719.450| 07.49

EN

5 Display overview

1

Symbol for pump operation

2 Symbol for anti-frost function (see chapter 7.5)

3 Symbol max for maximum storage tank temperature and

maximum collector temperature (see chapter 7.2 and 7.3)

4

Display for temperature sensor, temperature readings and fault

symbols (see chapter 9.1), interruption, or "SYS" = system fault

(see chapter 9.1)

5

Temperature format [C / F] (see chapter 8.2.8)

1

2 3 5 4

88888

max

CF

18

719.450 | 07.49

EN

6 Commissioning

6.1 Testing the pump

CAUTION

Damage to pump caused by dry operation!

Make sure that the solar circuit is filled with heat

transfer fluid.

The controller case is closed.

All connections are properly made.

The solar energy system is filled.

Connect the mains supply.

To switch on the pump, set the operating switch to

the upper position (on).

on appears in the display. After approx. 3 sec-

onds on flashes in alternation with the display.

To switch off the pump, set the operating switch to

the lower position (oFF).

oFF appears in the display. After approx. 3 sec-

onds oFF flashes in alternation with the display.

CAUTION

The incorrect operating mode may cause the sys-

tem to shut down or impair proper functioning!

After testing the pump, always set the operating

switch to automatic operation.

On

Off

19

719.450| 07.49

EN

To set the controller in automatic operation, move

the operating switch to the middle position.

Auto is shown in the display for approx. 3

seconds.

7 Description of the controller

functions

7.1 Switch-on / switch-off

temperature difference

The controller constantly compares the temperatures

between the collector (T1) and the lower area of the

storage tank (T2). As soon as the temperature in the

collector (T1) is 8 K (adjustable in setup P2 [K]) higher

than the temperature in the storage tank (T2), and if

no safety limits prohibit the pump from operating, the

pump is switched on.

The following display appears:

The pump symbol is displayed

If the temperature difference falls below 4 K (adjust-

able in setup P3 [K]), the pump is switched off. The

pump symbol is no longer shown in the display.

7.2 Maximum storage tank temperature

The maximum storage temperature function is to pre-

vent the hot water tank from overheating. If the lower

area of the storage tank (T2) reaches the set maximum

Automatic

C

20

719.450 | 07.49

EN

storage tank temperature (factory setting of 60 C,

P1), charging is stopped. A temperature of 3 K below

the maximum storage tank temperature must first be

reached before charging can be resumed.

The following display appears:

The display flashes max

Note: The display only shows max when temperature

sensor T2 is also selected

7.3 Maximum collector temperature

During periods of high solar irradiance, the tempera-

ture (T1) of the heat transfer fluid can exceed 130 C.

The heat transfer fluid evaporates. In this case, the

pump is blocked for protection purposes until the

temperature drops below 127 C.

The following display appears:

The display flashes max

Note: The display only shows max when temperature

sensor T1 is also selected

7.4 Tube collector function (F1)

Due to its construction, the collector temperature (T1)

can only be inaccurately recorded with vacuum tube

collectors (in some cases there are no immersion sen-

sors; the sensor is outside the collector pipe). In these

cases, the solar circuit must be briefly activated at reg-

ular intervals to transmit the actual heat from the col-

lector pipe to the sensor (T1). If the tube collector func-

max

C

max

C

21

719.450| 07.49

EN

tion is activated, the controller automatically switches

the pump on every 30 minutes for 30 seconds.

7.5 Anti-freeze function (F2)

If the anti-freeze function is activated, the controller

switches the pump on as soon as the collector tem-

perature T1 falls below +5 C. The heat transfer fluid

is thus pumped through the collector and tries to pre-

vent refreezing. If the collector reaches a temperature

of +7 C, the pump is switched off again.

CAUTION

System can freeze despite the activated anti-freeze

function!

During a power outage (the anti-freeze function does

not operate).

During long-term periods of frost (due to restricted

water tank heat storage).

If collectors are mounted in locations exposed to wind.

It is recommended to generally use the heat carrier

fluid with antifreeze for Solar Plants.

Standard antifreeze liquid for solar energy systems also

contain an additional corrosion inhibitor.

The following display appears:

The anti-freeze symbol is displayed

C

22

719.450 | 07.49

EN

8 Operation

CAUTION

The incorrect operating mode may cause the sys-

tem to shut down or impair proper functioning!

Make sure that the operating switch is set to automatic

operation.

On the display you can see the temperature readings

of the individual temperature sensors. The controller

settings may be set in the settings menu.

8.1 Reading the temperature values

Select the temperature sensor using the

and

buttons (1=T1, 2=T2).

The selected temperature sensor and the current

measured temperature appear in the display.

C

C

Temperature sensor T1 display

with temperature reading from

collector and active pump

Temperature sensor T2 display

with temperature reading

from lower area of storage

tank and active pump

23

719.450| 07.49

EN

8.2 Setting the controller

8.2.1 Using the settings menu

To open the settings menu, press the

SET

button

for approx. 2 seconds.

Setting P1 "storage tank maximum temperature"

is displayed.

To switch to the next setting, press the

button.

To exit the settings menu, press the

button

again until the temperature sensor and tempera-

ture reading are shown again.

C

24

719.450 | 07.49

EN

8.2.2 Overview of menu settings

C

SET

C

Temperature reading (T1 or T2)

C

(hold down for 2 seconds)

P1: storage tank maximum

temperature

P2: switch-on temperature

difference

P3: switch-off temperature

difference

F1: tube collector function

F2: anti-freeze function

F3: temperature format (C / F)

Reset

25

719.450| 07.49

EN

8.2.3 Setting the storage tank maximum tem-

perature (P1)

DANGER

Risk of scalding due to storage tank temperature

of over 60 C!

Install a thermostatic mixer in the hot water pipe

and set to a maximum 60 C.

The P1 menu is open

Press the

SET

button for approx. 2 seconds until the

storage tank maximum temperature flashes.

Change the storage tank maximum temperature

using the

or

buttons.

To save the value, press the

SET

button.

8.2.4 Setting the switch-on temperature dif-

ference (P2)

The P2 menu is open

Press the

SET

button for approx. 2 seconds until the

switch-on temperature difference flashes.

Change the switch-on temperature difference using

the

or

buttons.

To save the value, press the

SET

button.

C

26

719.450 | 07.49

EN

8.2.5 Setting the switch-off temperature dif-

ference (P3)

The P3 menu is open

Press the

SET

button for approx. 2 seconds until the

switch-off temperature difference flashes.

Change the switch-off temperature difference using

the

or

buttons.

To save the value, press the

SET

button.

8.2.6 Activating the tube collector function

(F1)

NOTE

Incorrectly setting the controller can compromise the

efficiency of the solar energy system. Therefore, only

activate the tube collector function if the construction

of the collector does not allow its temperature to be

recorded immediately and/or accurately (in some cases

there are no immersion sensors; the sensor is outside

the collector pipe).

The F1 menu is open

Press the

SET

button for approx. 2 seconds until

either "oFF" or "on" flashes.

Toggle between "oFF" and "on" using the

or

buttons.

To save the setting, press the

SET

button.

27

719.450| 07.49

EN

8.2.7 Activating the anti-freeze function (F2)

CAUTION

System can freeze despite the activated anti-freeze

function!

During a power outage, the anti-freeze function does

not operate.

During long-term periods of frost (due to restricted

water tank heat storage).

If collectors are mounted in locations exposed to

wind.

If frost is expected for a long-term period of time,

only operate the system with heat transfer fluid.

For further information see chapter 7.5.

NOTE

Incorrectly setting the controller can compromise the

efficiency of the solar energy system.

Only activate the anti-freeze function for solar

energy systems that are not filled with anti-freeze.

The F2 menu is open

Press the

SET

button for approx. 2 seconds until

either "oFF" or "on" flashes.

Toggle between "oFF" and "on" using the

or

buttons.

To save the setting, press the

SET

button.

28

719.450 | 07.49

EN

8.2.8 Selecting the temperature format (F3)

The F3 menu is open

Press the

SET

button for approx. 2 seconds until

either "C" or "F" flashes.

Toggle between "C" and "F" using the

or

buttons.

To save the setting, press the

SET

button.

8.2.9 Reset

The reset function causes the controller to revert to its

factory settings, these are as follows:

P1 P2 P3 F1 F2 F3

60 8 4 oFF oFF C

The RESET menu is open

Press the

SET

button for approx. 5 seconds until

"RESET" flashes.

The controller reverts to its factory settings.

29

719.450| 07.49

EN

9 Maintenance

The controller was conceived for years of continuous

trouble-free operation. Nevertheless, faults may occur.

Maintenance may only be performed by professional

personnel.

In most cases, however, the fault does not lie with the

controller, but rather with the peripheral components.

The following description covers the most common

problems encountered with the controller.

Only send in the controller with a precise fault

description if none of the following faults are

present.

9.1 Fault causes

WARNING

Risk of death by electrocution!

Remove the controller from the power supply before

opening the case.

Controller does not appear to function at all.

Secondary symptoms Possible cause / remedy

The controller

display is blank.

No power supply is present

Have professional person-

nel check the fuse and the

supply cable.

30

719.450 | 07.49

EN

The pump, which is connected to the controller,

is not running, although its switch-on conditions

have been fulfilled.

Secondary

symptoms

Possible cause / remedy

The pump symbol

is shown in the

display.

The pump connecting cable

is not connected, inter-

rupted or the fuse in the

controller is burned out.

If necessary, have profes-

sional personnel replace

the fuse.

The pump symbol

is not shown in the

display.

Off is displayed in

alternation with

the temperature

reading

Operating switch is set to

Off

Set the operating switch

to automatic operation.

C

Pump symbol display

(example)

C

T1 temperature sensor

with temperature reading and

"off" display (example)

31

719.450| 07.49

EN

Short-circuit symbol and warning display appear.

Possible cause / remedy

Temperature sensor T1 or T2 or its supply cable is

short-circuited

Have professional personnel check the supply

cables of the temperature sensors and that they

are correctly connected to the controller.

Interruption symbol and warning signal appear.

Possible cause / remedy

Temperature sensor T1 or T2 or its supply cable is

interrupted

Have professional personnel check the supply

cables of the temperature sensors and that they

are correctly connected to the controller.

T1 temperature sensor

with short-circuit symbol and

warning sign (example)

T1 temperature sensor

with interruption symbol and

warning sign (example)

32

719.450 | 07.49

EN

"SYS" and the warning symbol flash in the control-

ler display.

Possible cause / remedy

SYS means there is a system error. This means that

despite the pump running, a temperature differ-

ence exceeding 80 K between the collector and the

storage tank was recorded.

The following causes are possible:

The pump is faulty or not correctly connected

The isolating valve in the solar circuit is closed

There is air in the solar circuit

Since a standard circulation pump cannot elimi-

nate air bubbles inside the piping system, the heat

transfer medium circuit comes to a standstill.

Have professional personnel check the solar

energy system to prevent damage.

Once the fault has been remedied, press any but-

ton to acknowledge the fault message.

SYS display

and warning sign (example)

33

719.450| 07.49

EN

9.2 Testing the temperature sensors

9.2.1 Safety

Only professional personnel may test the temperature

sensors.

9.2.2 Testing the resistance values

DANGER

Risk of death by electrocution!

Remove the controller from the power supply before

opening the case.

The temperature is recorded by resistance sensors.

These are Pt1000 temperature sensors. Depending on

the temperature, the resistance value also changes. A

potentially defective sensor can be checked using an

ohmmeter.

Measuring resistance values

Disconnect the corresponding temperature sensor

from the controller.

Measure the resistance value. The typical resistance

values, depending on the temperature, are listed in

the following table. Please note that small devia-

tions are permissible.

34

719.450 | 07.49

EN

Temperature sensor resistance values

Temperature [C] -30 -20 -10 0 10 20

Resistance [] 882 922 961 1000 1039 1078

Temperature [C] 30 40 50 60 70 80

Resistance [] 1117 1155 1194 1232 1271 1309

Temperature [C] 90 100 110 120 130 140

Resistance [] 1347 1385 1423 1461 1498 1536

Temperature [C] 150 160 170 180

Resistance [] 1573 1611 1648 1685

10 Dismantling and disposal

DANGER

Risk of death by electrocution!

Remove the controller from the power supply before

dismantling the controller.

To dismantle the controller, follow the assembly

instructions in the reverse order.

Dispose of the controller in accordance with the

regional regulations.

35

719.450| 07.49

EN

11 Legal Guarantee

In accordance with German statutory regulations,

there is a 2-year legal guarantee on this product for

the customer.

The seller will remove all manufacturing and mate-

rial faults that occur in the product during the legal

guarantee period and affect the correct functioning of

the product. Natural wear and tear does not constitute

a malfunction. Legal guarantee does not apply if the

fault can be attributed to third parties, unprofessional

installation or commissioning, incorrect or negligent

handling, improper transport, excessive loading, use of

improper equipment, faulty construction work, unsuit-

able construction location or improper operation or

use. Legal guarantee claims shall only be accepted if

notification of the fault is provided immediately after it

is discovered. Legal guarantee claims are to be directed

to the seller.

The seller must be informed before legal guarantee

claims are processed. For processing a legal guaran-

tee claim an exact fault description and the invoice

/ delivery note must be provided.

The seller can choose to fulfil the legal guarantee either

by repair or replacement. If the product can neither be

repaired nor replaced, or if this does not occur within a

suitable period in spite of the specification of an exten-

sion period in writing by the customer, the reduction in

36

719.450 | 07.49

EN

value caused by the fault shall be replaced, or, if this is

not sufficient taking the interests of the end customer

into consideration, the contract is cancelled.

Any further claims against the seller based on this legal

guarantee obligation, in particular claims for damages

due to lost profit, loss-of-use or indirect damages are

excluded, unless liability is obligatory by German law.

37

719.450| 07.49

EN

12 Technical data

Temperature differential controller

Operating voltage 230 V~ ( 15 %), 50 Hz

[optional 115 V ( 15 %), 60 Hz]

Own consumption 1 W

Inputs 2

temperature recording (Pt1000)

Output 1

1 x relay switched output

switching performance max. 800 W [230 V~]

Switch-on temperature difference 4 - 20 K (factory setting 8 K)

Switch-off temperature difference 2 - 18 K (factory setting 4 K)

Display LCD-display (48 segments)

Degree of protection IP 20/DIN 40050

Permitted ambient temperature 0 to +45 C

Installation wall-mounted

Weight 250 g

Case recyclable 3-piece plastic case

Dimensions L x W x H [mm] 137 x 134 x 38

Temperature sensors

2 x Pt1000

1.5 m silicone cable

(measuring range up to +230 C)

Fuse 4 A MT, 250 V or

T 4 A H 250 V (Littelfuse: 215004)

38

719.450 | 07.49

EN

39

719.450| 07.49

EN

719450

You might also like

- Millets: Future of Food & FarmingDocument16 pagesMillets: Future of Food & FarmingKIRAN100% (2)

- Toyota 21R, 22R, 22RC Engine Repair Manual (1980.08) (Pub No. 36056E)Document283 pagesToyota 21R, 22R, 22RC Engine Repair Manual (1980.08) (Pub No. 36056E)Master Xeoto100% (4)

- Icaro - Instruction ManualDocument10 pagesIcaro - Instruction ManualGoran PozderNo ratings yet

- Service Manual Af2035e PDFDocument273 pagesService Manual Af2035e PDFCristian BobaruNo ratings yet

- Get Started With Solar EnergyDocument76 pagesGet Started With Solar EnergySolar Nation100% (1)

- AirstageDocument76 pagesAirstagedaviko313No ratings yet

- Diametre Uzuale Tevi Si TubulaturiDocument3 pagesDiametre Uzuale Tevi Si TubulaturiSandra SirbescuNo ratings yet

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Catalogue of Industrial DehumidifierDocument8 pagesCatalogue of Industrial Dehumidifierdaviko313No ratings yet

- 15.910 Draft SyllabusDocument10 pages15.910 Draft SyllabusSaharNo ratings yet

- Kiswire General Purpose RopesDocument28 pagesKiswire General Purpose Ropesdaviko313No ratings yet

- Guide Line For Inspection of Overhead Crane StructureDocument43 pagesGuide Line For Inspection of Overhead Crane StructurePranoy Barua100% (1)

- BCA Solar PV GuideDocument36 pagesBCA Solar PV Guidecmms88No ratings yet

- Online Illuminati Brotherhood Registration Call On +27632807647 How To Join IlluminatiDocument5 pagesOnline Illuminati Brotherhood Registration Call On +27632807647 How To Join IlluminatinaseefNo ratings yet

- PFMEA Reference Card PDFDocument2 pagesPFMEA Reference Card PDFRajesh Yadav100% (5)

- Digest of Ganila Vs CADocument1 pageDigest of Ganila Vs CAJohn Lester LantinNo ratings yet

- FC-503-506 - Manual de Instalare PDFDocument72 pagesFC-503-506 - Manual de Instalare PDFliviupuNo ratings yet

- 300 UserDocument137 pages300 UserMiljan MirkovicNo ratings yet

- Elektromontazas ShemaDocument68 pagesElektromontazas ShemaDorin100% (1)

- GEA Cassette-Geko DF KSDocument64 pagesGEA Cassette-Geko DF KSCatalin FrincuNo ratings yet

- IS Vitorond 200 VD2 320-1080 KW PDFDocument32 pagesIS Vitorond 200 VD2 320-1080 KW PDFovidiuNo ratings yet

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- Dust Collector Controller BA4 BA16 User ManualDocument7 pagesDust Collector Controller BA4 BA16 User Manualramona.sabou918No ratings yet

- Convertizor de Frecventa Delta ManualDocument25 pagesConvertizor de Frecventa Delta ManualdanimihalcaNo ratings yet

- Cranes DEMAG CatalogueDocument160 pagesCranes DEMAG Cataloguelcorao100% (1)

- Cortizo (Unit 66 Unitized Façade) - 20-24283-3364-S (EN)Document1 pageCortizo (Unit 66 Unitized Façade) - 20-24283-3364-S (EN)safdNo ratings yet

- 999 CoduriDocument44 pages999 Codurighitza80No ratings yet

- SPF 3000TL LVM-ES User ManualDocument46 pagesSPF 3000TL LVM-ES User ManualFrozen TgrNo ratings yet

- Anexa 2 PTC11-2010Document2 pagesAnexa 2 PTC11-2010Magda ŞuliucNo ratings yet

- MR2118 Repeater PDFDocument4 pagesMR2118 Repeater PDFAnonymous CGk2roNo ratings yet

- SecoNET Tech 1-EnDocument71 pagesSecoNET Tech 1-EnGelu BordeaNo ratings yet

- EV CC N2 R134aDocument34 pagesEV CC N2 R134agenas7265No ratings yet

- KG 4266 230v - en - Rev1 2Document17 pagesKG 4266 230v - en - Rev1 2koniks519100% (1)

- Instructiuni Instalare, Utilizare Si Service, Cazane Otel 2 Drumuri 'Unical - Ellprex' (En)Document32 pagesInstructiuni Instalare, Utilizare Si Service, Cazane Otel 2 Drumuri 'Unical - Ellprex' (En)bsambNo ratings yet

- Moeller Datasheet EMR4 W500 1 D 290183Document4 pagesMoeller Datasheet EMR4 W500 1 D 290183Marcio RangellNo ratings yet

- XLR130 - XLR170: Electronic Controller For RefrigerationDocument19 pagesXLR130 - XLR170: Electronic Controller For RefrigerationgamunozdNo ratings yet

- Libretto G230 IngleseDocument52 pagesLibretto G230 IngleseMesara Kod KokijaNo ratings yet

- Seitron Beagle Instructions ManualDocument1 pageSeitron Beagle Instructions ManualAndrei MaresNo ratings yet

- Inverter 201 Ultra PFC ManualDocument44 pagesInverter 201 Ultra PFC ManualParadox UtopiaNo ratings yet

- Manual Utilizare Sistem Alarma Paradox Esprit 728ultDocument56 pagesManual Utilizare Sistem Alarma Paradox Esprit 728ultbadbatxNo ratings yet

- FTXC B - RXC B - 3P547757 1B - Installation Manual PDFDocument320 pagesFTXC B - RXC B - 3P547757 1B - Installation Manual PDFSandi CiureaNo ratings yet

- Digital Revolution Counter - RPMDocument2 pagesDigital Revolution Counter - RPMYonathan OrozcoNo ratings yet

- Gard Electric: Schema ElectronicaDocument3 pagesGard Electric: Schema ElectronicaFlorin MintaNo ratings yet

- Catalog CELPI CLEME ARMATURIDocument256 pagesCatalog CELPI CLEME ARMATURIgabrielcoman333No ratings yet

- Manual de Utilizare Sistem de Control AccesDocument16 pagesManual de Utilizare Sistem de Control AccesremussNo ratings yet

- Bizerba 1 406 204 Sys Manual PDFDocument62 pagesBizerba 1 406 204 Sys Manual PDFNikola PepurNo ratings yet

- Jumper: " Ver Tabela "Document1 pageJumper: " Ver Tabela "Gabriel de LimaNo ratings yet

- Certificat Conformitate Contact MagneticDocument1 pageCertificat Conformitate Contact MagneticCătălin MănăilăNo ratings yet

- Mi Ravas 1 Eu Rev 20150617Document21 pagesMi Ravas 1 Eu Rev 20150617Martin KnížekNo ratings yet

- Nokia Lightspan MF-2 DatasheetDocument3 pagesNokia Lightspan MF-2 Datasheetricho jullieNo ratings yet

- GSM Gate Control 1000 v3-13 Manual EN 10-03-2017Document16 pagesGSM Gate Control 1000 v3-13 Manual EN 10-03-2017manuel_lopescasa9273No ratings yet

- INS50 IPPBX Datasheet V2.0Document2 pagesINS50 IPPBX Datasheet V2.0Antonio PricopNo ratings yet

- Vdocuments - MX - SR HD 60364 6 PDF Wordpresscom A Cenelec HD 60364 1 D InformativeDocument2 pagesVdocuments - MX - SR HD 60364 6 PDF Wordpresscom A Cenelec HD 60364 1 D InformativeLucian BarboiNo ratings yet

- Equascanmasterrfhe 00480 en 0713Document2 pagesEquascanmasterrfhe 00480 en 0713CosminPodariuNo ratings yet

- Indesit Dea 601 Dea 602 Dea 603 Dea 700 Eos Alarm Table Error CodesDocument4 pagesIndesit Dea 601 Dea 602 Dea 603 Dea 700 Eos Alarm Table Error CodesЕвгений СафоновNo ratings yet

- Manual Centrala Termica WesternDocument100 pagesManual Centrala Termica WesternAndrei Filip Stefan100% (1)

- SEW MOVITRAC 31C ManualDocument65 pagesSEW MOVITRAC 31C ManualArun kumar100% (1)

- Steca TR 0301 Instruction EN PDFDocument38 pagesSteca TR 0301 Instruction EN PDFSanda RabontuNo ratings yet

- Steca PR Night Instruction enDocument18 pagesSteca PR Night Instruction enShane BaileyNo ratings yet

- Hamgam-System - Ir S Mp3500 4500 2Document488 pagesHamgam-System - Ir S Mp3500 4500 2Adnan RaufNo ratings yet

- SR208C PDFDocument35 pagesSR208C PDFAngel Pérez SantiagoNo ratings yet

- Steca TR 0603mc Instruction EN PDFDocument108 pagesSteca TR 0603mc Instruction EN PDFDaniela Si Ilinca BrancoveanuNo ratings yet

- S Af2035Document247 pagesS Af2035dieubimatNo ratings yet

- S Af2035Document254 pagesS Af2035liviumaraNo ratings yet

- Thermacare TC3001: Convective Warming UnitDocument32 pagesThermacare TC3001: Convective Warming UnitAhmadfakhroii AhmadfakroiiiNo ratings yet

- Calentador Gaymar Thermacare Manual ServicioDocument32 pagesCalentador Gaymar Thermacare Manual ServicioDiana PedrozaNo ratings yet

- SR868C6 Controller Manual PDFDocument16 pagesSR868C6 Controller Manual PDFUltisolar0% (1)

- Temperature Differential Controller: 5 Inputs, 2 OutputsDocument52 pagesTemperature Differential Controller: 5 Inputs, 2 OutputsAnonymous RCPxaonfvNo ratings yet

- Atr144 Rev eDocument88 pagesAtr144 Rev eDmitri NaumtsikNo ratings yet

- Operating Instructions: Temperature Differential ControllerDocument32 pagesOperating Instructions: Temperature Differential ControllerPlay FancourtNo ratings yet

- SP-C01 Safety InstructionsDocument18 pagesSP-C01 Safety InstructionsJose Luis SarmientoNo ratings yet

- Operating Instructions: Solar Charge ControllerDocument20 pagesOperating Instructions: Solar Charge ControllerilublessingNo ratings yet

- Mitsubishi Electric PAR-SL100A-E User Manual EngDocument17 pagesMitsubishi Electric PAR-SL100A-E User Manual EngИгорь ПавленкоNo ratings yet

- 1 enDocument32 pages1 endaviko313No ratings yet

- Simple Pressure VesselsDocument38 pagesSimple Pressure VesselsCristian BorcanescuNo ratings yet

- Tuv (LS600)Document3 pagesTuv (LS600)daviko313No ratings yet

- LeadSolar Gateway Superior v1.0Document173 pagesLeadSolar Gateway Superior v1.0daviko313No ratings yet

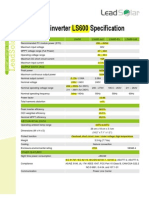

- Microinverter LS600 Specification: Input Data (DC) LS600 LS600-AU LS600-EU LS600-NADocument1 pageMicroinverter LS600 Specification: Input Data (DC) LS600 LS600-AU LS600-EU LS600-NAdaviko313No ratings yet

- ControlDampers CatalogDocument20 pagesControlDampers Catalogdaviko313100% (1)

- Chart Mobile Crane Kato 25tons0001Document3 pagesChart Mobile Crane Kato 25tons0001daviko313No ratings yet

- ControlDampers CatalogDocument20 pagesControlDampers Catalogdaviko313100% (1)

- Material Clarification Q345Document1 pageMaterial Clarification Q345daviko313No ratings yet

- Edm Aqtc W 4GBDocument24 pagesEdm Aqtc W 4GBdaviko313No ratings yet

- Column Speaker - T304Document2 pagesColumn Speaker - T304daviko313No ratings yet

- HVAC Accurate Load Calcs StrategyDocument47 pagesHVAC Accurate Load Calcs StrategySharon LambertNo ratings yet

- 4 THE OCCUPATIONAL SAFETY AND HEALTH ACT Amendment Fee For FCERTDocument2 pages4 THE OCCUPATIONAL SAFETY AND HEALTH ACT Amendment Fee For FCERTdaviko313No ratings yet

- ASHRAE Workshop Control WilliamYick Part 2Document48 pagesASHRAE Workshop Control WilliamYick Part 2daviko313No ratings yet

- 13Document11 pages13daviko313No ratings yet

- Sds-Bakim Kilavuzu enDocument24 pagesSds-Bakim Kilavuzu endaviko313No ratings yet

- Sds Eng PDFDocument8 pagesSds Eng PDFdaviko313No ratings yet

- Auto Parts & Accessories-EDMDocument110 pagesAuto Parts & Accessories-EDMdaviko313No ratings yet

- KTS ArDocument106 pagesKTS Ardaviko313No ratings yet

- VENT AXIA System CalculatorDocument38 pagesVENT AXIA System Calculatordaviko313No ratings yet

- Solar Energy OnDocument4 pagesSolar Energy Ondaviko313No ratings yet

- Solar Energy OnDocument4 pagesSolar Energy Ondaviko313No ratings yet

- Asme Pvho-2-2019Document61 pagesAsme Pvho-2-2019Vijay KumarNo ratings yet

- Add New Question (Download - PHP? SC Mecon&id 50911)Document9 pagesAdd New Question (Download - PHP? SC Mecon&id 50911)AnbarasanNo ratings yet

- Enabling Trade Report 2013, World Trade ForumDocument52 pagesEnabling Trade Report 2013, World Trade ForumNancy Islam100% (1)

- Latifi LAMY Catalog 2013 PDFDocument76 pagesLatifi LAMY Catalog 2013 PDFWang LinusNo ratings yet

- 25 - Marketing Channels - Value Networks.Document2 pages25 - Marketing Channels - Value Networks.zakavision100% (1)

- Document 20Document3 pagesDocument 20api-586815209No ratings yet

- Longley Rice PropagationDocument11 pagesLongley Rice Propagationy_m_algbaliNo ratings yet

- Unit 8 - Week 7: Assignment 7Document3 pagesUnit 8 - Week 7: Assignment 7Nitin MoreNo ratings yet

- 3D Archicad Training - Module 1Document3 pages3D Archicad Training - Module 1Brahmantia Iskandar MudaNo ratings yet

- ASTM A586-04aDocument6 pagesASTM A586-04aNadhiraNo ratings yet

- Ibm v3700 Storeage PDFDocument694 pagesIbm v3700 Storeage PDFJanakackvNo ratings yet

- 04.CNOOC Engages With Canadian Stakeholders PDFDocument14 pages04.CNOOC Engages With Canadian Stakeholders PDFAdilNo ratings yet

- Grade 5 Olympiad: Answer The QuestionsDocument14 pagesGrade 5 Olympiad: Answer The QuestionsVinieysha LoganathanNo ratings yet

- TC 9-237 Welding 1993Document680 pagesTC 9-237 Welding 1993enricoNo ratings yet

- 032017Document107 pages032017Aditya MakwanaNo ratings yet

- 3.1-7 Printer Deployment - Copy (Full Permission)Document18 pages3.1-7 Printer Deployment - Copy (Full Permission)Hanzel NietesNo ratings yet

- New York State - NclexDocument5 pagesNew York State - NclexBia KriaNo ratings yet

- Non-Hazardous Areas Adjustable Pressure Switch: 6900P - Piston SensorDocument2 pagesNon-Hazardous Areas Adjustable Pressure Switch: 6900P - Piston SensorDiana ArredondoNo ratings yet

- BSDC CCOE DRAWING FOR 2x6 KL R-1Document1 pageBSDC CCOE DRAWING FOR 2x6 KL R-1best viedosNo ratings yet

- Formula Retail and Large Controls Planning Department ReportDocument235 pagesFormula Retail and Large Controls Planning Department ReportMissionLocalNo ratings yet

- LG+32LX330C Ga LG5CBDocument55 pagesLG+32LX330C Ga LG5CBjampcarlosNo ratings yet

- Statics: Vector Mechanics For EngineersDocument25 pagesStatics: Vector Mechanics For EngineersProkopyo BalagbagNo ratings yet

- AMCHAM Press ReleaseDocument1 pageAMCHAM Press ReleaseAnonymous FnM14a0No ratings yet

- TX Open RS232 - 485 Module (TXI2.OPEN)Document8 pagesTX Open RS232 - 485 Module (TXI2.OPEN)harishupretiNo ratings yet