Professional Documents

Culture Documents

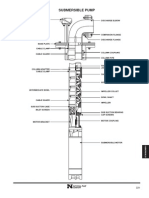

A Few Things About Pump

Uploaded by

abhilibra14Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A Few Things About Pump

Uploaded by

abhilibra14Copyright:

Available Formats

A few things about pump's piping system

There should be at least 10 diameters of pipe between the suction of the pump and

the frst elbow. This is especially critical in double-ended pump designs as the

turbulent inlet fow can cause shaft thrusting, and subsequent bearing problems. If

an elbow must be installed be sure it is in a plane at right angles to the pump shaft

to preent an uneen fow to both sides of a double suction impeller.

!ipe from the pump suction fange to the pipe rac", not the other way around.

#a"e sure eccentric reducers are not installed upside down at the pump

suction. The top of the reducer should go straight into the suction fange.

!iping should be arranged with as few bends as possible. If bends are

necessary use a long radius wheneer possible

If an e$pansion %oint is installed in the piping between the pump and the

nearest point of anchor in the piping, It should be noted that a force equal to

the area of the e$pansion %oint &which could be a lot larger than the normal

piping si'e( times the pressure in the piping will be transmitted to the pump

proper. !ipe couplings that do not proide an a$ially rigid connection hae the

same a)ect. If an e$pansion %oin or non-rigid coupling must be used, it is

recommended that a pipe anchor be installed between it and the pump.

*e aware that radial forces are being generated in the pump housing from

the pressure in the piping system acting on the olute area. The magnitude

and direction of the forces is dependent upon the piping arrangement along

with the areas and pressures inoled.

It is always a good idea to increase the si'e of the suction and discharge

pipes at the pump no''le in order to decrease the head loss from pipe

friction.

+uction piping should be at least one si'e larger than the suction fange at

the pump.

If increasers are used on the discharge side to increase the si'e of discharge

piping, they should be installed between the chec" ale and the pump.

*oth a chec" and gate ale should be installed in the discharge piping with

the chec" ale placed between the pump and the stop ale to protect the

pump from reerse fow and e$cessie bac" pressure. #anually operated

discharge ales that are hard to reach should hae some facility for quic"

closing. , sproc"et rim wheel and chain or a remotely operated motor are two

alternaties you might consider.

+uction piping must be "ept free of air lea"s.

The installation of chec" ales should be aoided in the suction piping

although they are often used to reduce the number of ales that hae to be

operated in switching between series and parallel pump operation.

, foot ale is often installed in the suction piping to aid priming. -o not

install them if the pump is operating against a high static head because

failure of the drier would allow liquid to rush bac" suddenly causing water

hammer. This is especially true for ertical turbine and submersible pumps

that are not designed for use with a foot ale.

.oot ales should be of the low loss fap type rather than the multiple spring

ariety and hae a clear passage for the liquid at least the same area as the

suction piping.

, hori'ontal suction line should hae a gradual rise or slope to the pump

suction.

/ast iron pumps should neer be proided with raised face fanges. If steel

suction or discharge piping is used, the pipe fanges should be of the fat face

type and not the raised face type. .ull-faced gas"ets must be used with cast

iron fanges.

The optimum control ale location is within fe feet &1,0 meters( of the

pump discharge to preent too much surging of fuid in the system when the

discharge is throttled.

The optimum pipe si'e will consider the installed cost of the pipe &the cost

increases with si'e( and the pump power requirements &the power required

increases with pipe friction(

o Try to limit the friction loss at design fow to 1-0 feet for each 100 feet

&1-1 meters for each 20 meters( of pipe(.

o To preent the settling of solids you need a minimum elocity of about

3 to 4 feet per second &1.0 to 1.0 meters per second(

o 5elocities of no more than 10 feet &2 meters( per second are

recommended in the suction side piping to preent abrasie wear.

You might also like

- Pump PipingDocument88 pagesPump Pipingmohamed abd eldayem100% (1)

- Practical Rules for the Management of a Locomotive Engine in the Station, on the Road, and in cases of AccidentFrom EverandPractical Rules for the Management of a Locomotive Engine in the Station, on the Road, and in cases of AccidentNo ratings yet

- Piping Recommendations For Pump PipingDocument3 pagesPiping Recommendations For Pump Pipingkapoorkunal26No ratings yet

- Oil and Gas Artificial Fluid Lifting TechniquesFrom EverandOil and Gas Artificial Fluid Lifting TechniquesRating: 5 out of 5 stars5/5 (1)

- Pump Piping and Valve InstallationDocument8 pagesPump Piping and Valve InstallationSinghNo ratings yet

- Steam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversFrom EverandSteam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversRating: 5 out of 5 stars5/5 (2)

- Pump & Air Compressor Piping Design RulesDocument24 pagesPump & Air Compressor Piping Design RulesDeven SutharNo ratings yet

- Conventional Pumping System GuidelinesDocument20 pagesConventional Pumping System GuidelinesT.N. Ramnauth Co LtdNo ratings yet

- Pipin StudyDocument81 pagesPipin StudyRaju NaiduNo ratings yet

- Piping Layout - Piping Guide - 2Document10 pagesPiping Layout - Piping Guide - 2s_baishyaNo ratings yet

- Pneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshFrom EverandPneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshNo ratings yet

- Considerations For Designing Piping Adjacent To A Centrifugal PumpDocument3 pagesConsiderations For Designing Piping Adjacent To A Centrifugal PumpbeqsNo ratings yet

- How to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesFrom EverandHow to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesRating: 5 out of 5 stars5/5 (1)

- Example Pumps PresentationDocument31 pagesExample Pumps PresentationsonpvmsNo ratings yet

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Centrifugal Pump InstallationDocument4 pagesCentrifugal Pump Installationjfisher2534No ratings yet

- General Guidelines of Pump Piping LayoutDocument8 pagesGeneral Guidelines of Pump Piping LayoutbainNo ratings yet

- Sump DesignDocument4 pagesSump DesignThiru AnanthNo ratings yet

- How To Do Pump Piping With Layout ExplainedDocument13 pagesHow To Do Pump Piping With Layout Explainedvenkat100% (1)

- Artificial Lift ModellingDocument35 pagesArtificial Lift Modellingvi7to8No ratings yet

- Bell and Gossett Sump DesignDocument8 pagesBell and Gossett Sump DesignVelpandian ManiNo ratings yet

- Pump document title under 40 charactersDocument32 pagesPump document title under 40 charactersKehinde Adebayo100% (1)

- Layout Arrangement For Centrifugal Pump PipingDocument20 pagesLayout Arrangement For Centrifugal Pump PipingKyaw Kyaw Aung50% (2)

- Centrifugal Pump Piping Design LayoutDocument21 pagesCentrifugal Pump Piping Design LayoutKavin KumarNo ratings yet

- Centrifugal Pump PipingDocument22 pagesCentrifugal Pump PipingBhupender Sharma100% (3)

- Pump Clinic 33Document8 pagesPump Clinic 33fnahas_bhNo ratings yet

- Piping and Pumping: Chemical Engineering and Materials Science Syracuse UniversityDocument54 pagesPiping and Pumping: Chemical Engineering and Materials Science Syracuse UniversityFaizal MuhainiNo ratings yet

- Tips For Layout1Document3 pagesTips For Layout1amitrai86No ratings yet

- Tray Column DesignDocument17 pagesTray Column DesignLaras Wuri D.100% (3)

- 5 431529563391000589Document1 page5 431529563391000589mNo ratings yet

- Plunger LiftDocument18 pagesPlunger LiftRizwan FaridNo ratings yet

- Piping Engineering - Piping SystemsDocument18 pagesPiping Engineering - Piping Systemskeiko davilaNo ratings yet

- Slurry Pipe DesignDocument2 pagesSlurry Pipe Designk_naseergNo ratings yet

- Reverse Circulation Pump PDFDocument4 pagesReverse Circulation Pump PDFthawdarNo ratings yet

- Piping DesignDocument9 pagesPiping DesignRahul ChavanNo ratings yet

- Penguin PSS Vertical Pump Operating Instructions & Spare Parts ManualDocument6 pagesPenguin PSS Vertical Pump Operating Instructions & Spare Parts Manualjoshua gomezNo ratings yet

- Pump Design by An IlDocument5 pagesPump Design by An IlANILNo ratings yet

- PIPING GUIDE How To Do Pump Piping With Layout Ex - 1579767576697 PDFDocument17 pagesPIPING GUIDE How To Do Pump Piping With Layout Ex - 1579767576697 PDFGiridhar Parab100% (1)

- Boiler Feed PumpsDocument25 pagesBoiler Feed PumpsEshan BhatNo ratings yet

- Pump Layout & PipingDocument91 pagesPump Layout & Pipingrahult19100% (5)

- Pump Clinic 43Document3 pagesPump Clinic 43fnahas_bhNo ratings yet

- Layout Arrangement For Centrifugal Pump PipingDocument30 pagesLayout Arrangement For Centrifugal Pump PipingAlderit BarajasNo ratings yet

- Hydraulic Institute StandardDocument2 pagesHydraulic Institute StandardCheerag100% (1)

- PT-104 Pumping Trap Installation and MaintenanceDocument12 pagesPT-104 Pumping Trap Installation and MaintenancevkumaranNo ratings yet

- Pumps Design and PerformanceDocument27 pagesPumps Design and PerformanceJefferson SmithNo ratings yet

- Lesson 7 SlidesDocument22 pagesLesson 7 SlidesBryan ScofieldNo ratings yet

- 2205GB Complete PitDocument2 pages2205GB Complete Pitvikas_ojha54706No ratings yet

- Sump Pit Design ConsiderationDocument8 pagesSump Pit Design ConsiderationkhalloudeeNo ratings yet

- SpecificationsDocument3 pagesSpecificationsajeesh_petrocilNo ratings yet

- Dosing PumpDocument10 pagesDosing PumpniceseshaNo ratings yet

- Piping Pump DesignDocument15 pagesPiping Pump DesignTON100% (1)

- Sucker Rod PumpingDocument27 pagesSucker Rod Pumpingzezo2011100% (4)

- Cavitations 1-3: The Mcnally InstituteDocument5 pagesCavitations 1-3: The Mcnally InstituteBaqirMuhammadNo ratings yet

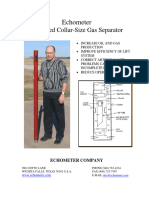

- Collar Size Gas Separator Brochure 20121203Document4 pagesCollar Size Gas Separator Brochure 20121203judsonlobNo ratings yet

- Percentage Wall Reduction Is The Most FrequentlyDocument4 pagesPercentage Wall Reduction Is The Most Frequentlysanketpavi21No ratings yet

- Bilge Ballast and SystemsDocument72 pagesBilge Ballast and SystemsRENGANATHAN P100% (7)

- Piping Codes & Standards - Piping GuideDocument8 pagesPiping Codes & Standards - Piping Guideabhilibra14No ratings yet

- Easy Control Valve SelectionDocument5 pagesEasy Control Valve SelectionhrtoroNo ratings yet

- Rudra Ashtakam by TulasidasDocument4 pagesRudra Ashtakam by TulasidasSaurabh MaheshwariNo ratings yet

- Pipie SizingDocument21 pagesPipie Sizingabhilibra14No ratings yet

- Flange Comparison PDFDocument1 pageFlange Comparison PDFabhilibra14No ratings yet

- AMIE Syllabus - Mechanical EngineeringDocument14 pagesAMIE Syllabus - Mechanical EngineeringAbhishek SharmaNo ratings yet

- Ac TreatmentDocument12 pagesAc Treatmentabhilibra14No ratings yet

- Fundamentals - ValvesDocument52 pagesFundamentals - Valvesapi-3808778100% (2)

- CVE 372 HYDROMECHANICS - 2 Flow in Closed Conduits 2 PDFDocument54 pagesCVE 372 HYDROMECHANICS - 2 Flow in Closed Conduits 2 PDFabhilibra14No ratings yet

- Fundamentals - ValvesDocument52 pagesFundamentals - Valvesapi-3808778100% (2)

- Boiler TreatmentDocument8 pagesBoiler Treatmentabhilibra14No ratings yet

- Resolution of ForcesDocument4 pagesResolution of Forcesabhilibra14No ratings yet

- Steam TablesDocument20 pagesSteam Tablesajitsamal456No ratings yet

- Petroleum GlossaryDocument32 pagesPetroleum Glossaryabhilibra14No ratings yet

- UopDocument2 pagesUopabhilibra14No ratings yet

- Visa Application FormDocument1 pageVisa Application Formabhilibra14No ratings yet

- Column PipingDocument7 pagesColumn Pipingabhilibra14No ratings yet

- Hanuman ChalisaDocument3 pagesHanuman ChalisaBidya Nath100% (2)

- Amie Study CircleDocument1 pageAmie Study Circleabhilibra14No ratings yet

- Piperack ConceptDocument2 pagesPiperack Conceptabhilibra14No ratings yet

- Pipie SizingDocument21 pagesPipie Sizingabhilibra14No ratings yet

- Centrifugal Pump SelectionDocument10 pagesCentrifugal Pump Selectionabhilibra14No ratings yet

- Flange ComparisonDocument1 pageFlange Comparisonabhilibra14No ratings yet

- Henry Foyles PrinciplesDocument11 pagesHenry Foyles PrinciplesPravinsinh AttardeNo ratings yet

- Abu Dhabi Government Information Security Policy SummaryDocument40 pagesAbu Dhabi Government Information Security Policy Summarymmh771100% (3)

- Final Technical - Signed OffDocument16 pagesFinal Technical - Signed OffMilan VujasićNo ratings yet

- Everything You Need to Know About Regenerative Air DryersDocument32 pagesEverything You Need to Know About Regenerative Air DryersPraveen RajNo ratings yet

- Flashing Routerboards With OpenWRT PDFDocument11 pagesFlashing Routerboards With OpenWRT PDFdamianuskrowinNo ratings yet

- Ribbon Blenders: and Other Horizontal MixersDocument8 pagesRibbon Blenders: and Other Horizontal MixersHằng NgaNo ratings yet

- 230-Ford-Ranger-Factory-Service-Repair-Manual-2011-to-2015 WSM PDFDocument1,257 pages230-Ford-Ranger-Factory-Service-Repair-Manual-2011-to-2015 WSM PDFH Dy100% (1)

- DiggerDocument21 pagesDiggerajgamesNo ratings yet

- USAT Online Brand Guidelines 2013Document39 pagesUSAT Online Brand Guidelines 2013Christopher Corgiat100% (1)

- EG Operating Instructions for Split Air ConditionersDocument62 pagesEG Operating Instructions for Split Air Conditionersf.simula50% (2)

- Viking: Product ManualDocument26 pagesViking: Product ManualCristian RobiconNo ratings yet

- Autosys commands guideDocument39 pagesAutosys commands guidesantosh_panditpurNo ratings yet

- Reinforcing Detailing of RCCDocument40 pagesReinforcing Detailing of RCCThamaraiselvan Ramadoss100% (1)

- CV Tool and Die MakerDocument3 pagesCV Tool and Die MakerMohammed AseerNo ratings yet

- Autofrettage in Pressure VesselsDocument28 pagesAutofrettage in Pressure Vesselssran1986No ratings yet

- BA 301 Final Exam QuestionsDocument14 pagesBA 301 Final Exam QuestionsJakeSimmonsNo ratings yet

- Ultrasonic Flow Detection: Miii-1Document10 pagesUltrasonic Flow Detection: Miii-1jishnusajiNo ratings yet

- Service Impacting Alarm ClassificationDocument15 pagesService Impacting Alarm ClassificationNaftaliNo ratings yet

- Case Ih Magnum Tractor Hydraulic Hose DiagramsDocument540 pagesCase Ih Magnum Tractor Hydraulic Hose DiagramsMega Polis100% (1)

- The Cybersecurity Guide For LeadersDocument24 pagesThe Cybersecurity Guide For LeadersMahmood AlyNo ratings yet

- Example 1Document13 pagesExample 1LeswNo ratings yet

- Volvo PentaDocument250 pagesVolvo Pentaweler13100% (2)

- Death of Crypto King Nikolai Mushegian Fuels Conspiracy TheoriesDocument15 pagesDeath of Crypto King Nikolai Mushegian Fuels Conspiracy Theorieshans hansenNo ratings yet

- AIRBAGS! Technical ManualDocument13 pagesAIRBAGS! Technical Manualhagar18No ratings yet

- Drill Pipe Flow Chart PDFDocument1 pageDrill Pipe Flow Chart PDFairlinemembershipNo ratings yet

- Eclectic IqDocument17 pagesEclectic IqriyanNo ratings yet

- DH Ipc Hdbw5541e Z5e Datasheet 20190620Document3 pagesDH Ipc Hdbw5541e Z5e Datasheet 20190620Ali KılıçkayaNo ratings yet

- Express Publishing Repetytorium-Test 3bDocument2 pagesExpress Publishing Repetytorium-Test 3bLena NowickaNo ratings yet

- Object Oriented Programming - Online NotesDocument66 pagesObject Oriented Programming - Online Notesvaibhav agarwalNo ratings yet

- Evolution of Cloud ComputingDocument3 pagesEvolution of Cloud ComputingVaishnavi ChockalingamNo ratings yet

- Exposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle Against DuPontFrom EverandExposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle Against DuPontRating: 4.5 out of 5 stars4.5/5 (18)

- The Rights of Nature: A Legal Revolution That Could Save the WorldFrom EverandThe Rights of Nature: A Legal Revolution That Could Save the WorldRating: 5 out of 5 stars5/5 (1)

- 3rd Grade Science: Life Sciences in Eco Systems | Textbook EditionFrom Everand3rd Grade Science: Life Sciences in Eco Systems | Textbook EditionNo ratings yet

- Desperate: An Epic Battle for Clean Water and Justice in AppalachiaFrom EverandDesperate: An Epic Battle for Clean Water and Justice in AppalachiaRating: 4 out of 5 stars4/5 (1)

- The Cyanide Canary: A True Story of InjusticeFrom EverandThe Cyanide Canary: A True Story of InjusticeRating: 4 out of 5 stars4/5 (51)

- Art of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionFrom EverandArt of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionRating: 3 out of 5 stars3/5 (1)

- Waste: One Woman’s Fight Against America’s Dirty SecretFrom EverandWaste: One Woman’s Fight Against America’s Dirty SecretRating: 5 out of 5 stars5/5 (1)

- Reduce, Reuse and Recycle : The Secret to Environmental Sustainability : Environment Textbooks | Children's Environment BooksFrom EverandReduce, Reuse and Recycle : The Secret to Environmental Sustainability : Environment Textbooks | Children's Environment BooksNo ratings yet

- Land Divided by Law: The Yakama Indian Nation as Environmental History, 1840-1933From EverandLand Divided by Law: The Yakama Indian Nation as Environmental History, 1840-1933No ratings yet

- Ecosystem Facts That You Should Know - The Forests Edition - Nature Picture Books | Children's Nature BooksFrom EverandEcosystem Facts That You Should Know - The Forests Edition - Nature Picture Books | Children's Nature BooksNo ratings yet

- Down to the Wire: Confronting Climate CollapseFrom EverandDown to the Wire: Confronting Climate CollapseRating: 4.5 out of 5 stars4.5/5 (8)

- Exposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle against DuPontFrom EverandExposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle against DuPontRating: 4.5 out of 5 stars4.5/5 (9)

- Arizona, Utah & New Mexico: A Guide to the State & National ParksFrom EverandArizona, Utah & New Mexico: A Guide to the State & National ParksRating: 4 out of 5 stars4/5 (1)

- Principles of direct and superior responsibility in international humanitarian lawFrom EverandPrinciples of direct and superior responsibility in international humanitarian lawNo ratings yet

- Environmental Education in Practice: Concepts and ApplicationsFrom EverandEnvironmental Education in Practice: Concepts and ApplicationsNo ratings yet

- The Intersection of Intellectual Property Law and the “Green” Movement: RIPL’s Green Issue 2010From EverandThe Intersection of Intellectual Property Law and the “Green” Movement: RIPL’s Green Issue 2010Rating: 5 out of 5 stars5/5 (2)