Professional Documents

Culture Documents

ABB Smart Transformer

Uploaded by

steven9747Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ABB Smart Transformer

Uploaded by

steven9747Copyright:

Available Formats

Smart Transformers

Inocencio Solteiro, Transformer Service, Global M&S Manager, Technology Days South Africa, May 8-9 2013

Agenda

Definition and specifications

Smart Grid

Needs from transformer owners

Smart Transformer

e-Accessories

Sensors

Platform

Models

Applications and examples

Take away

ABB Group

May 20, 2013 | Slide 2

Features and requirements of Smart Transformer

Features of Smart Grids

Demand

vs

Supply

Reliability

Efficiency

Sustainability

ABB Group

May 20, 2013 | Slide 3

Transformer requirements to fulfill Smart Grid functions

Smart Grid Functions

Smart Transformers Spec.

Cooling Control tuned to

load profil

Energy flow

Power Quality

Network

Stability

Continuity

Voltage Regulation

Reliability

Fault prediction - detection

Energy efficiency

Environment

Asset

Management

Condition Assessment

Communication

ABB Group

May 20, 2013 | Slide 4

Transformer owner challenges today

Reliability & Availability

Society highly dependent on reliable energy supply

Integration of renewable energy sources

Overload

Increased energy consumption, new consumption patterns

(electrical cars)

Maintenance planning

Optimize maintenance costs and reduce downtime

Life extension

Ageing infrastructure plan / postpone replacements

Company image

Strong focus on reliability

Knowing the condition of the unit allows informed decisions

ABB Group

May 20, 2013 | Slide 5

Commissioning

Transformer

Operation

TBM TBCM

Corrective

Maintenance

Major Work On-

site or in

Workshop

Ok

Interpretation

Apply Special Tests and/or Intensive

Monitoring (if needed)

Normal?

Yes

No

Major work Minor work

Technical &

Economic

Evaluation

Refurbish

or Repair

Scrap &

Replace

End of Life

OLCM

Condition Assessment

Maintenance Strategy (TBM, CBM, RCM)

Tests & Checks

CBM

TBCM =Time Based

Condition Monitoring

CBM = Condition Based

Maintenance

OLCM = On-Line Condition

Monitoring

TBM = Time Based

Maintenance

CIGRE Brochure 445 Feb

2011 Guide for Transformer

Maintenance WG A2.34

Asset management and maintenance planning

ABB Group

May 20, 2013 | Slide 6

Moving from diagnosis to On-Line Monitoring

Monitoring (transformer is on-line)

Detection of latent defect / Evaluation

Trends analysis & Overall supervision /Control

Transf.

in service

No action

Maintenance

needed

Normal Operation

100% 10% 5%

5% 90%

yes No

No yes

Is it a serious

problem?

Abnormal Operation

Diagnostic (transformer is off-line)

Precise analyze / Quantification Status

Risk assessment

Is the operation

normal?

ABB Group

May 20, 2013 | Slide 7

ABB Smart Transformers

ABB Group

May 20, 2013 | Slide 8

Protection & Smart Accessories

COMEM e-Accessories

Buchholz relay

Over-pressure relay

Oil level indicator

Temperature sensors

Self Dehydrating Breather

All devices equipped with

Modbus and 4-20 mA

or PT100 output

ABB Group

May 20, 2013 | Slide 9

Sensors

Sensors to catch the prime failure modes

Top transformer failures from Doble statistics

43% winding insulation

19% bushings

16% tap changers

Pollution, dust & debris affecting

bushings & cooling systems

Cooling System inefficiency

Blocking or Wedging

ABB Group

May 20, 2013 | Slide 10

Sensors

Monitored parameters

Load, Voltage

Temperatures:

Top oil and Bottom oil

Ambient

(Hot Spot with Fiber Optic)

Gas in oil:

Composed gas

Multi-gas (DGA)

Moisture

Bushing

Tan Delta and Capacitance

OLTC:

Position, Temperature, Contact wear

(Partial Discharge)

ABB Group

May 20, 2013 | Slide 11

New sensors

Bushing monitoring

Novel technology

Can measure changes in capacitance and Tan on the same phase of different

transformers, traditional technology compare three different phases (voltage

unbalanced)

No need for cable between transformers: Very tight time synchronization of

measurements using GPS clock

Strengths

Detect latent defect earlier

Achieves very high accuracy: similar to offline measurement

Noise can be better filtered out (Parallel units see same voltage)

ABB Group

May 20, 2013 | Slide 13

TEC platform key benefits

User friendly web interface no additional

software needed on users computer

Based on a microprocessor and Modular

design, possible to add the sensors that the

customer requests with additional hardware

Very strong mechanical stability and

temperature endurance => Long lifespan

Reliable and proven technology

(longest serving unit has >10 years in the

field)

Compact and easy to install

Support for standard communication

protocols, including IEC 61850 (certified by

SGCC)

ABB Group

May 20, 2013 | Slide 15

Web Interface - dual language support

10 translations available

ABB Group

May 20, 2013 | Slide 16

Web Interface - graphs with data

Easy overview of remotely downloaded historical data

ABB Group

May 20, 2013 | Slide 17

Information VS Data

Top oil 57C Bottom oil 42C Ambient sun 21C Ambient shadow 17C Hot-spot HV 65C Hot-spot LV 67C Load 50%

Peak load 51% OLTC pos 5L OLTC temp 52C Operations 23654 Time to contact exchange 2545 days Operations to

contact exchange 256675 Days to contact exchange 456days Operations to service 53670 Coolers 23 Cooler1 236h Cooler2

240h Cooler3 230h

O

v

e

r

l

o

a

d

c

a

p

a

c

i

t

y

1

4

7

%

A

g

e

i

n

g

r

a

t

e

0

.

0

2

%

A

g

e

i

n

g

2

5

6

8

7

h

M

o

i

s

t

u

r

e

i

n

o

i

l

2

p

p

m

H

y

d

r

o

g

e

n

3

2

p

p

m

SCADA system

or only computer

DNP3, IEC 61850 or other protocols

PC with web browser

remote or in station

Diagrams

Overload forecasts

Diagrams

Diagnoses

Overview

Event log

Historical data

Prediction

Dry contacts to SCADA

system

Monitoring cabinet

OLTC IED

Bushing IED

DGA IED

Partial

Discharge IED

ABB Group

May 20, 2013 | Slide 18

TEC

How TEC Models can support ?

Examples of actionable information provided by TEC

Gas in oil, trend and analysis

Temperature trends and balance

OLTC usage pattern

Overloadability / Hotspot forecast

Bubbling Temp.

Anticipated coolers start

OLTC maintenance forecast

Cooler runtime & bank rotation

Moisture in solid insulation

Transformer insulation ageing

Gas in oil, trend and analysis

Annual status report

Operation

Maintenance

Asset Manager

ABB Group

May 20, 2013 | Slide 19

On-Line Monitoring

From raw data to actionable information

Most of the utilities/industries report us the following:

ABB solutions: Asset Health Center:

Merge off-line and on-line data from several transformers

and substations

Health/Reliability Index: Intelligent models to assess overall

condition of each unit

Dashboards: Fleet overview with drilldown capabailities for

each stake holder

Massive amount of data

Limited resources and time to look at and draw conclusions

No compatibility between system from different vendors

Need advises to take actions while existing systems provide

mainly data

Need for centralized information with access through web

browsers

Need for migration service / upgrade

Several stake holders: Managements / Asset Management /

Maintainance

ABB Group

May 20, 2013 | Slide 20

Smart Transformer

Applications and examples

ABB Group

May 20, 2013 | Slide 21

Increasing reliability and availability

Source (CIGRE):

Catastrophic failures reduced from 0.7% down to 0.3%

ABB Group

May 20, 2013 | Slide 22

Securing availability / Avoiding failure

Hydro Power Plant to keep supplying key customer

Preventive actions requested by the customer

Condition Assessment on one strategic 40MVA Transformer

Condition Assessment results

Advanced paper degradation (High moisture and acidity)

Recommendations

Oil treatment / filtration and drying

Purchase a new unit

Monitoring of the transformer until its replacement

Do not switch off the unit (risk of free water)

Monitoring with remote supervision

Allowed to supply needed energy during peak season (supply of a sky

resort in winter)

Keep the sick transformer running during 9 more months until replacement

Avoid penalty

ABB Group

May 20, 2013 | Slide 23

Planning maintenance

Latent failure detected by monitoring

Increase of dissolved

gasses due to an increase

of oil temperature while

constant load

The monitoring system

allowed ABB experts to

detect the blocking of a

OFWF heat exchanger

(mineral buildup)

ABB Group

May 20, 2013 | Slide 24

Summary

On-Line Monitoring can support asset owners who need

more real time information to:

Avoid unexpected failures (reliability)

Plan maintenance (availability)

Maximize utilization of assets (loading/life extension)

Plan investments (financials)

etc

ABB Smart Transformer philosophy is to:

Use as few sensors as possible and proven technology to

increase the robustness of the system

Provide as much information as possible from these sensors

using intelligent models

ABB Group

May 20, 2013 | Slide 27

You might also like

- Bulk vs. condenser bushingsDocument11 pagesBulk vs. condenser bushingsKarthik SriramakavachamNo ratings yet

- The Technology of Instrument Transformers: Current and Voltage Measurement and Insulation SystemsFrom EverandThe Technology of Instrument Transformers: Current and Voltage Measurement and Insulation SystemsNo ratings yet

- Station Protection - Power Transformer Protection GuideDocument91 pagesStation Protection - Power Transformer Protection GuideSakthi MuruganNo ratings yet

- Creating and Using Meaningful Asset Health Indices - 15 FebDocument44 pagesCreating and Using Meaningful Asset Health Indices - 15 Febleonard williamsNo ratings yet

- Kabeldon HV Presentation-2016 IDDocument63 pagesKabeldon HV Presentation-2016 IDsajuaanalsaNo ratings yet

- Transformer Fleet Management - AB Mar 2022 (AltaNova)Document58 pagesTransformer Fleet Management - AB Mar 2022 (AltaNova)danilo MendozaNo ratings yet

- Understanding Offline Testing and Condition Monitoring Results From BushingDocument51 pagesUnderstanding Offline Testing and Condition Monitoring Results From Bushingcarlos patrick100% (1)

- Modulos Hibridos Siemens PDFDocument12 pagesModulos Hibridos Siemens PDFgueilor perezNo ratings yet

- CB Testing SCOPE Compatibility ModeDocument58 pagesCB Testing SCOPE Compatibility ModeVepty whoops100% (1)

- VIZIMAX - CIGRE Toronto - Using A Controlled Switching Device For A Power Transformer PDFDocument8 pagesVIZIMAX - CIGRE Toronto - Using A Controlled Switching Device For A Power Transformer PDFgeorge_cpp2No ratings yet

- Transformer Life CycleDocument53 pagesTransformer Life CycleTaher El NoamanNo ratings yet

- Paper 9.5 - H DingDocument22 pagesPaper 9.5 - H Dingmarg1972No ratings yet

- S1-3-Possibility of 400kV Auto Transformer With Neutral Tappings-Satyam Dewangan-TBEA - R1Document5 pagesS1-3-Possibility of 400kV Auto Transformer With Neutral Tappings-Satyam Dewangan-TBEA - R1MallikarjunNo ratings yet

- Testing of TransformersDocument28 pagesTesting of Transformersnaveendevi13100% (1)

- Current Transformers For GIS SWG Type ELK - 1VLM000628 Rev.3, en 2017.08.28Document12 pagesCurrent Transformers For GIS SWG Type ELK - 1VLM000628 Rev.3, en 2017.08.28Binode sarkarNo ratings yet

- PLCC Technology for Power Line CommunicationDocument24 pagesPLCC Technology for Power Line CommunicationNeelakandan MasilamaniNo ratings yet

- Est118150 Da Bac 1 - SLD.0.3 1 PDFDocument36 pagesEst118150 Da Bac 1 - SLD.0.3 1 PDFThiên LýNo ratings yet

- VSC Course Lecture2Document27 pagesVSC Course Lecture2eng7senNo ratings yet

- HVDC Transmission and FACTS Devices LectureDocument22 pagesHVDC Transmission and FACTS Devices LectureKiran KunchamNo ratings yet

- En SmartDGA ManualDocument114 pagesEn SmartDGA ManualbaoHVLABNo ratings yet

- Bushing Power Factor Training PPTDocument44 pagesBushing Power Factor Training PPTMiguel Zuñiga100% (1)

- 24/30 MVA Transformer SpecsDocument1 page24/30 MVA Transformer Specsram krishnanNo ratings yet

- Invited Speaker - Vitor Sokolov PDFDocument21 pagesInvited Speaker - Vitor Sokolov PDFAndar ApriadiNo ratings yet

- Application ItsDocument26 pagesApplication ItsDarko PanduricNo ratings yet

- Novel Techniques for Power Transformer DiagnosticsDocument64 pagesNovel Techniques for Power Transformer DiagnosticsWilmer CubasNo ratings yet

- CT CVTDocument56 pagesCT CVTGuru Mishra100% (1)

- Knowledge Is Power: Bushing Testing for TransformersDocument30 pagesKnowledge Is Power: Bushing Testing for TransformersmwasahaNo ratings yet

- Troubles & Failures Report: Doble Engineering CompanyDocument28 pagesTroubles & Failures Report: Doble Engineering CompanyCarlos PlmNo ratings yet

- Impact of Oil Parameters On ReliabilityDocument59 pagesImpact of Oil Parameters On Reliabilitytaufiqishak09No ratings yet

- Understanding Circuit Breakers: Basic ConceptsDocument24 pagesUnderstanding Circuit Breakers: Basic Conceptsdanh17100% (1)

- Testing and Diagnostics of Medium- and High-Voltage Instrument TransformersDocument7 pagesTesting and Diagnostics of Medium- and High-Voltage Instrument TransformersRaúl Choque SandovalNo ratings yet

- Development of Optical Instrument TransformersDocument155 pagesDevelopment of Optical Instrument TransformersMohamad FuadNo ratings yet

- Application of Fuzzy Support Vector Machine For Determining The Health Index of The Insulation System of In-Service Power Transformers - AshkezariDocument9 pagesApplication of Fuzzy Support Vector Machine For Determining The Health Index of The Insulation System of In-Service Power Transformers - AshkezariMartua MarioNo ratings yet

- Vietnam GIS Day SlidesDocument45 pagesVietnam GIS Day SlidesGia Toàn LêNo ratings yet

- 25.insulation Testing M4000Document86 pages25.insulation Testing M4000rashid rahmanNo ratings yet

- HV Outdoor CVTDocument6 pagesHV Outdoor CVTReji KurianNo ratings yet

- COMEM Solutions For Higher Transformer Lifetime:: - Self Dehydrating Breather SDB - Combined Resin Silicone CRS BushingDocument20 pagesCOMEM Solutions For Higher Transformer Lifetime:: - Self Dehydrating Breather SDB - Combined Resin Silicone CRS BushingPablo Narváez B.No ratings yet

- BIIT-05 Future Bushing Technology WilliamsDocument5 pagesBIIT-05 Future Bushing Technology WilliamsAbdellah AbdouNo ratings yet

- Different Ways To Mount Travel TransducerDocument14 pagesDifferent Ways To Mount Travel TransducerIsa SolakNo ratings yet

- Alstom Technical FlyerDocument2 pagesAlstom Technical Flyerram_kisna007No ratings yet

- S1-5-Reducing Transformer Mass and Dimensions - S Ryder-DobleDocument9 pagesS1-5-Reducing Transformer Mass and Dimensions - S Ryder-DobleMallikarjunNo ratings yet

- RIP (Resin Impregnated Paper) Bushing For EHV Class Power TransformerDocument3 pagesRIP (Resin Impregnated Paper) Bushing For EHV Class Power TransformerBaSant KohliNo ratings yet

- TRNG-6 Potential TransformerDocument37 pagesTRNG-6 Potential TransformerbaoHVLABNo ratings yet

- Equipment Labeling: Arc Flash & Shock Hazards: Zarheer Jooma and Hugh HoaglandDocument44 pagesEquipment Labeling: Arc Flash & Shock Hazards: Zarheer Jooma and Hugh HoaglandJlynnManaloNo ratings yet

- 3-Ph Induction MotorDocument246 pages3-Ph Induction MotorAn00pgadzillaNo ratings yet

- BBB M, M, KLKLKL JJKDocument16 pagesBBB M, M, KLKLKL JJKEngr Irfan AkhtarNo ratings yet

- Doble - Acceptance and Maintenance Testing For Medium-Voltage Electrical Power CablesDocument23 pagesDoble - Acceptance and Maintenance Testing For Medium-Voltage Electrical Power CablessulemankhalidNo ratings yet

- Auto Transformer Energy Conversion 6Document38 pagesAuto Transformer Energy Conversion 6Katari Sreenu100% (1)

- Doble Conference Transformer Testing ProceduresDocument150 pagesDoble Conference Transformer Testing ProceduresGlenys MuñozNo ratings yet

- 80-85 Standards Relevant To Transformers - P. RamachandranDocument6 pages80-85 Standards Relevant To Transformers - P. RamachandranAnderson Jair Velandia PiraquiveNo ratings yet

- Health Indexing of TransformerDocument35 pagesHealth Indexing of TransformerSamanway BeraNo ratings yet

- F10 Taps in Auto Transformers SlidesDocument42 pagesF10 Taps in Auto Transformers Slidesverma210100% (1)

- COM600Document51 pagesCOM600castrojpNo ratings yet

- Transformer Health Indices and Probability of Failure: Cigre Gotf Cleveland, Ohio, USA October 2017Document22 pagesTransformer Health Indices and Probability of Failure: Cigre Gotf Cleveland, Ohio, USA October 2017Abhishek GuddadNo ratings yet

- International Tutorials & Colloquium On Latest Trends and Innovations OnDocument12 pagesInternational Tutorials & Colloquium On Latest Trends and Innovations OnAradhana RayNo ratings yet

- Application Guide StroomtransformatorenDocument127 pagesApplication Guide StroomtransformatorenJemal MusaNo ratings yet

- ABB OLGA UGM 2009 - Flow Assurance Applications in An Integrated Operations FrameworkDocument23 pagesABB OLGA UGM 2009 - Flow Assurance Applications in An Integrated Operations Frameworksondung4verNo ratings yet

- Study and Analysis of Systems For Monitoring in Power SubstationsDocument3 pagesStudy and Analysis of Systems For Monitoring in Power SubstationsIsrael DanielNo ratings yet

- Landfill Gas Operation ManualDocument266 pagesLandfill Gas Operation Manualshtou2No ratings yet

- Transformer StudyDocument256 pagesTransformer StudysulemankhalidNo ratings yet

- A Guide To Transformer Oil Analysis: BY I.A.R. GRAY Transformer Chemistry ServicesDocument12 pagesA Guide To Transformer Oil Analysis: BY I.A.R. GRAY Transformer Chemistry ServicesAnonymous OCDJg17Z100% (1)

- A Guide To Transformer Oil Analysis: BY I.A.R. GRAY Transformer Chemistry ServicesDocument12 pagesA Guide To Transformer Oil Analysis: BY I.A.R. GRAY Transformer Chemistry ServicesAnonymous OCDJg17Z100% (1)

- Fist3 30Document87 pagesFist3 30flegias100% (1)

- Letter of Credit GuideDocument50 pagesLetter of Credit GuideMohamed Naji100% (5)

- Heat Radiation From FlaresDocument90 pagesHeat Radiation From FlaresAman Goel100% (3)

- Heat Radiation From FlaresDocument90 pagesHeat Radiation From FlaresAman Goel100% (3)

- Chemical ResistanceDocument12 pagesChemical ResistancegusunNo ratings yet

- C 4Document12 pagesC 4steven9747No ratings yet

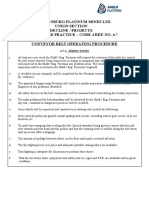

- 4.7 Conveyor Belt Operating ProcedureDocument3 pages4.7 Conveyor Belt Operating Procedurejohnson OlubiNo ratings yet

- Store Layout & ArchitectureDocument76 pagesStore Layout & ArchitectureGyan Singh100% (1)

- 2014 Brochure EN FERMENTECDocument18 pages2014 Brochure EN FERMENTECP RAJAVELUNo ratings yet

- SCHLENKER Katalog 2022 EN - WEBDocument136 pagesSCHLENKER Katalog 2022 EN - WEBhosseinNo ratings yet

- MGT1211 - Development of Product and Services For Global MarketDocument9 pagesMGT1211 - Development of Product and Services For Global MarketShagufta Karim DinaniNo ratings yet

- Lawaan Cemetery Part 2Document17 pagesLawaan Cemetery Part 2Mark Joseph ArellanoNo ratings yet

- EpicorSLS10 MigrateGuide SQL 10.2.100.505100Document219 pagesEpicorSLS10 MigrateGuide SQL 10.2.100.505100Marianne Hernandez MendietaNo ratings yet

- Mobile QA Tester ResumeDocument4 pagesMobile QA Tester ResumeJitendra kumarNo ratings yet

- The Evolution of Cyber Espionage - Jessica BourquinDocument0 pagesThe Evolution of Cyber Espionage - Jessica BourquinVivek KhareNo ratings yet

- Instruction Manual: SpecificationsDocument16 pagesInstruction Manual: SpecificationsJorge L. ContrerasNo ratings yet

- New Route CardDocument3 pagesNew Route CardVenkat ChakriNo ratings yet

- Airbus Vs BoeingDocument8 pagesAirbus Vs BoeingPrajwal Rajiv ShettyNo ratings yet

- Igus Energy Chain CatalogDocument1,385 pagesIgus Energy Chain CatalogigusukNo ratings yet

- Sample Paper 6Document7 pagesSample Paper 6kchiranjeeviNo ratings yet

- Bajaj PULSUR 220 DTS - OkokDocument75 pagesBajaj PULSUR 220 DTS - OkokSubramanya DgNo ratings yet

- Discharge Nozzle 360º Fedrxxx: DescriptionDocument2 pagesDischarge Nozzle 360º Fedrxxx: Descriptionhatem hbibiNo ratings yet

- Report FinalDocument80 pagesReport Finalnitishbhardwaj123No ratings yet

- DB Cylinder Pressure Sensor enDocument2 pagesDB Cylinder Pressure Sensor enjulien17No ratings yet

- Designsolutions 2010springDocument68 pagesDesignsolutions 2010springjkarpitskiyNo ratings yet

- Maintenance Technician Job OpeningDocument1 pageMaintenance Technician Job OpeningRizky NafandyNo ratings yet

- 7.0 Call Back ServiceDocument2 pages7.0 Call Back ServiceSreenath S KallaaraNo ratings yet

- Catalog E EslonValve ManualOperationDocument72 pagesCatalog E EslonValve ManualOperationAnonymous ItzBhUGoiNo ratings yet

- Mohamed Badr CVDocument2 pagesMohamed Badr CVMohamed BadrNo ratings yet

- Sanitary Napkin Vending MachineDocument11 pagesSanitary Napkin Vending Machineshobanraj1995No ratings yet

- Benefits of Cycling: Lessons from Top Cycling NationsDocument42 pagesBenefits of Cycling: Lessons from Top Cycling NationsZuniAsihNo ratings yet

- Problem Set Ee8205 PDFDocument4 pagesProblem Set Ee8205 PDFksajjNo ratings yet

- Asad's Profile - Asda SAP-SD & MMDocument6 pagesAsad's Profile - Asda SAP-SD & MMTechneto TonicNo ratings yet

- IRender NXT For SketchUp Rendering - RenderPlusDocument6 pagesIRender NXT For SketchUp Rendering - RenderPlusRender PlusNo ratings yet

- Exercise - Quality ToolsDocument10 pagesExercise - Quality ToolsĐức TrungNo ratings yet