Professional Documents

Culture Documents

Airier Bio Mass 2 MW Example

Uploaded by

Trisha GallagherCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Airier Bio Mass 2 MW Example

Uploaded by

Trisha GallagherCopyright:

Available Formats

Credentials & Technology

A PRESENTATION

WHO ARE WE

We are a leading player in the clean-tech

energy

We have been leading innovation in clean-

tech energy for over a decade

We have pioneered the wind ventilator in India

We have partnered with the biggest names in

Indian industry

WHERE DO WE SEE OURSELVES

To be the most trusted renewable energy brand

across markets, offering innovative, zero

emission products, profiting & benefiting the

company , customers , employees &

community at large.

WHAT DO WE DO

We are pioneers and innovators

in wind

solar

and bio-mass energy.

HOW WE DO IT

With our spirit of non-conventional

entrepreneurship and clear processes enable us

to think smarter & move faster to offer

superior renewable energy solutions.

WHY WE DO IT

Because we believe in change for good for

the individual, the organization, the customer,

industry & the planet.

CHANGE FOR GOOD

From conventional fossil fuels to

Airier Bio-Mass Fuel

WHY CHANGE FOR GOOD

Because fossil fuels like diesel and coal is fast

dwindling

They cause immense environmental damage

They are expensive to extract

Power produced from fossil fuels costs almost

twice of fuels produced from bio mass

WHY CHANGE FOR GOOD

The power situation in India is near critical

The power shortage is likely to get worse

The cost of conventional power is likely to see

an upward trend

Power distribution in India is likely to become

more inefficient in the future with poor

infrastructure

CHANGE FOR GOOD

To a decentralised power and energy system

To captive power plants run on Bio Mass

To run in parallel with the existing centralised

grid systems

To become energy independent

To become eco-friendly and reduce carbon

emission

2 MW Bio Mass Power Plant

A PRESENTATION

HOW DOES IT WORK

Bamboo is cut to size and dried to be fed into

the reactor

The solid bio mass inside the reactor converts

to a gaseous fuel having a composition of:

CO : 20 1 %

H

2

: 20 1 %

CH

4

: 3 1 %

CO

2

: 12 1 %

N

2

: Balance

Average lower heating value : 4.8 0.2 MJ / kg

Avg. density of producer gas : 1.095kg / Nm

3

( at 0

0

C &

760 mmHg)

HOW DOES IT WORK

This gaseous fuel contains dust and tar

particulates which is cleaned using water by

coolers and scrubbers

Moisture traps are used to remove the moisture

Gas is further filtered through a sawdust and

fabric filter

The clean gas emerges out as per the engine

requirements

HOW DOES IT WORK

This gas is connected to the Engine by a

pipeline

The engine is connected to an alternator for

production of electricity

Power from the alternator is fed to the grid

through panels which sync with the grid

FUEL FOR 2 MW BIO MASS

POWER PLANT

Bamboo is to be used with moisture

content below 12%-15%

FUEL REQUIREMENT FOR 2 MW

BIO MASS

POWER PLANT

45-55 Tonne/Day for 24 Hr operation

Bio mass of density 300-400 Kg/m3

2 3.5 in Dia and 3-3.5 in length

CHANGE FOR GOOD

To Airier Bio-Mass Power Plant

Save Money. Save The Future.

AIRIER BIO-MASS POWER

PLANT

During continuous operation, all filtration

equipments have standby for cleaning

purposes

All pumps have standby in case of failure

Oxygen levels monitored using Oxygen

monitors for any ingress of Oxygen into the

system

AIRIER BIO-MASS POWER

PLANT

Compatible with Diesel Generator Sets

Good quality of gas

Minimal maintenance for engine

AIRIER BIO-MASS POWER

PLANT

Stringent quality control

Quality standards

Reduced installation time

AIRIER 2 MW BIO MASS

PLANT

Gasifier Size: 4 x 550 Kg/Hr

Specific fuel consumption is 1.15 Kg/Kwh

(appx.)

Continuous operation for 24 Hrs with

allowance for breakdown maintenance

2MW BIO-MASS

POWER PLANT

Schematic Drawing

Stage 1

Stage 3 Stage 2 Stage 4 Stage 5

Processing

Chopping

Briquetting

Dehydration

Drying

Gasification

Gas cleaning

Boiler/Furnace/k

iln

Turbine

Engine

Biomass

Harvesting

Complete Gasification Process

2MW BIO-MASS

POWER PLANT

General Description

Materials of construction

IS 2062 for Reactor, flanges & fine filter

SS316L for cyclone, reactor air nozzles, outlet pipe &

reactor bottom plate

SS304 for all other components

Laser cut of materials in SS304, SS316L & flanges in

IS2062

Reactor top cover is a hinged cover (manually operated) &

provided with a biomass feeding hopper of cap 175kg

Wet removal of ash & charcoal separation at collection

sump

Reactor air nozzle closing using pneumatic air cylinder

based with solenoid operation

Temperature sensor at reactor outlet, cooler outlet,

scrubber outlet & downstream of Mist eliminator

Gasifier cooling towers 3x100TR with induced draft

Solenoid activated valves in ash & charcoal discharge

waterline

Cooling water pump 4+2

Gas suction blowers Static pressure 1250 mmwcand flow

rate of 1775 m3/hr each

Structural's: 2 level for all equipments with provision of

platform for service & refill

Pressure transducer for reactor pressure drop measurement

& operation of Screw conveyer in parallel with timed

operation of conveyer

Skip charger 2x160kg for each reactor

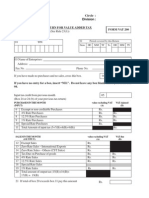

ECONOMICS

Power & Heat purchase agreement

Rs. 6.50/ unit for 12 hrs/Day

Rs. 4 / unit for remaining 12 Hrs

Heat- Rs. 2/Kw @ 8 hrs/day

Assumptions

55 Tonne of fuel per day is available @

Rs.3/Kg

Plant is connected to the grid

Charcoal is sold at Rs. 20/Kg

600 Kw of thermal energy is continuously

utilized

Approximate project cost Rs. 16,00,00,000

Expenditure: Plant running expenses (Per day) Rs. / Day

Input fuel/ Day 165000

(55 Tonnes @ Rs.3000/Tonne)

Processing 27500

(Appx. Rs. 0.50/Kg)

Generation/Labor Charges 15000

(30 members @ Rs.10,000 each per month)

Maintenance 10000

(Engine & Gasifier Maintenance)

Water treatment charges 5000

Dryer charges 10000

Others 10000

Total running cost per day Rs. 2,42,500

Income Rs/ Day

Power1 (Rs. 6.50/Kwh) 128000

Power2 ( Rs. 4/Kwh) 78720

(Considering 18% power for gasifier operation)

Heat 28800

(Rs.2/Kw @ 600 Kw)

Charcoal 66000

(6% of fuel input @ Rs.20/Kg)

Carbon Credits @ Rs.0.70/Unit 33600

335120

Profit/Day Rs.92,620

Appx. ROI 5 Years

OUR RELATIONSHIPS

L&T

L&T ECC

Toyota

Volvo

Asahi Glass

THANK YOU

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Safed MusliDocument1 pageSafed MusliTrisha GallagherNo ratings yet

- Main Physical Characteristics of ContainersDocument1 pageMain Physical Characteristics of ContainersTrisha GallagherNo ratings yet

- Vat Monthly ReturnDocument2 pagesVat Monthly ReturnJayadeep VuppalaNo ratings yet

- Pre-Fabricated Building - Mahadev ProfilesDocument50 pagesPre-Fabricated Building - Mahadev ProfilesTrisha GallagherNo ratings yet

- Vuda ApprovalDocument4 pagesVuda ApprovalTrisha GallagherNo ratings yet

- Vat Monthly ReturnDocument2 pagesVat Monthly ReturnJayadeep VuppalaNo ratings yet

- Kurnool To Wada Thane MHDocument5 pagesKurnool To Wada Thane MHTrisha GallagherNo ratings yet

- India Sol Brochure 2014Document12 pagesIndia Sol Brochure 2014Trisha GallagherNo ratings yet

- Syndicate Bank Contact ListDocument3 pagesSyndicate Bank Contact ListTrisha GallagherNo ratings yet

- Dalmia Cement FactoryDocument2 pagesDalmia Cement FactoryTrisha GallagherNo ratings yet

- Elecon Range of ProductsDocument12 pagesElecon Range of ProductsTrisha GallagherNo ratings yet

- Oci ChartDocument4 pagesOci ChartrayaproluNo ratings yet

- Zerodha FormDocument2 pagesZerodha FormTrisha GallagherNo ratings yet

- Biomass Pelleting PDFDocument6 pagesBiomass Pelleting PDFbanapte59100% (1)

- How Solar Inverters Work With Solar PanelsDocument13 pagesHow Solar Inverters Work With Solar Panelsglobalrevolution100% (2)

- Bank Holidays 2014 Andhra PradeshDocument1 pageBank Holidays 2014 Andhra PradeshTrisha GallagherNo ratings yet

- 249 GB PM30Document2 pages249 GB PM30Trisha GallagherNo ratings yet

- Memorendum of Understanding-STEVIADocument3 pagesMemorendum of Understanding-STEVIATrisha GallagherNo ratings yet

- New NHB GuidelinesDocument101 pagesNew NHB Guidelinesblue13No ratings yet

- APCPDCLDocument13 pagesAPCPDCLTrisha GallagherNo ratings yet

- Polyhouse Etc Schemes - Gujarat FirstDocument32 pagesPolyhouse Etc Schemes - Gujarat FirstJaideep Vasant SolankiNo ratings yet

- BioMass ResearchDocument3 pagesBioMass ResearchTrisha GallagherNo ratings yet

- SteviaDocument7 pagesSteviaKapal SelamNo ratings yet

- 16 June 2010 GuidelinesDocument26 pages16 June 2010 GuidelinesgkmandalNo ratings yet

- Navaratna MalikaDocument18 pagesNavaratna MalikaTrisha GallagherNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- ICATSD2016 Fulltext TemplateDocument3 pagesICATSD2016 Fulltext TemplatekhalyjNo ratings yet

- PollutionDocument3 pagesPollutionThekhanNo ratings yet

- Energy Efficiency Existing Ship Index (Eexi) : Regulatory DebriefDocument8 pagesEnergy Efficiency Existing Ship Index (Eexi) : Regulatory DebriefSalomonlcNo ratings yet

- Damar ResinDocument3 pagesDamar ResinKukuh Satrio WibowoNo ratings yet

- Town of Seabrook NH Building PermitDocument4 pagesTown of Seabrook NH Building PermitKevin McGinleyNo ratings yet

- Pollution Prevention and Abatement Handbook WORLD BANK GROUP Effective JulyDocument5 pagesPollution Prevention and Abatement Handbook WORLD BANK GROUP Effective JulyEdgarvitNo ratings yet

- 1 s2.0 S2468203917300912 Main PDFDocument7 pages1 s2.0 S2468203917300912 Main PDFBonaventure NzeyimanaNo ratings yet

- Importance Water Quality ControlDocument10 pagesImportance Water Quality ControlYS YSNo ratings yet

- Meliadine Brine Project DescriptionDocument22 pagesMeliadine Brine Project DescriptionNunatsiaqNewsNo ratings yet

- Green Tech Industries (India) Pvt. LTD., EXE SUM-EnGDocument7 pagesGreen Tech Industries (India) Pvt. LTD., EXE SUM-EnGkalyanm203515No ratings yet

- Energy AssessmentDocument2 pagesEnergy Assessmentapi-342299656No ratings yet

- Performance of Waste Stabilization Ponds in Bhutan Experience PDFDocument16 pagesPerformance of Waste Stabilization Ponds in Bhutan Experience PDFsherub_pNo ratings yet

- Sewage Collection and Transport Management & Wastewater TreatmentDocument22 pagesSewage Collection and Transport Management & Wastewater TreatmentRotich VincentNo ratings yet

- Outline Construction Method StatementDocument15 pagesOutline Construction Method Statementtsuak100% (2)

- Environmental Guidelines For DevelopingDocument18 pagesEnvironmental Guidelines For DevelopingJarrod100% (1)

- The Seven Environmental PrinciplesDocument12 pagesThe Seven Environmental PrinciplesAngela VillamorNo ratings yet

- Externalities and Public Goods: Prepared byDocument35 pagesExternalities and Public Goods: Prepared byAnik RoyNo ratings yet

- Project Child Labour ShakespeareDocument78 pagesProject Child Labour ShakespeareSuman KarNo ratings yet

- T68 Q1681 EIAReportDocument449 pagesT68 Q1681 EIAReportDeepika RajpootNo ratings yet

- Water Maze Delta-3000a 1Document2 pagesWater Maze Delta-3000a 1Marcelita AraujoNo ratings yet

- CDP Jaitwara EnglishDocument376 pagesCDP Jaitwara EnglishCity Development Plan Madhya PradeshNo ratings yet

- Working Paper Takht Bhai Bypass Road MardanDocument3 pagesWorking Paper Takht Bhai Bypass Road MardanEngr AhmadNo ratings yet

- Resume With Cover Letter For OnlineDocument5 pagesResume With Cover Letter For OnlineSandesh PawarNo ratings yet

- Environmental SanitationDocument2 pagesEnvironmental SanitationAngelica GraceNo ratings yet

- VA1 DEC 00100 M M1D PHL 8202 - RevD PDFDocument42 pagesVA1 DEC 00100 M M1D PHL 8202 - RevD PDFAnonymous JtYvKt5XENo ratings yet

- Tceq Water SamplesDocument2 pagesTceq Water SamplesColorado County CitizenNo ratings yet

- Use of Amine Reclaimer WasteDocument10 pagesUse of Amine Reclaimer WasteGopi Kiran NNo ratings yet

- Marine Painting HandbookDocument212 pagesMarine Painting HandbookVallabh Vishwanath Desai100% (3)

- Material PArticulado en AerotransporteDocument406 pagesMaterial PArticulado en AerotransporteJubert Julio AlarcónNo ratings yet

- Gap AnalysisDocument12 pagesGap AnalysisAshok SharmaNo ratings yet