Professional Documents

Culture Documents

IRT For CP System

Uploaded by

Anonymous i3lI9MOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IRT For CP System

Uploaded by

Anonymous i3lI9MCopyright:

Available Formats

1 I . H H .

2 A . R H X

3 R

.

RW W

X

4 R . RW W X

5 R

.

R R

X

6 R . RW W X

7 R

.

R R

X

8 R

.

RW W

X

9 R

.

R R

X

10 R

.

R R

X

11 R

.

RW W

X

12 R . R R X

Visual inspection for dimension, net weight, type of support (mounting details), mechanical

defects like surface cracks, cavities,shrinkages, excessive flash,sharp or other surface

projections, laminations, cold laps and surface slag etc.

RT check of anode- For casting quality or destructive test on one anode per delivery to

check above items.

Destructive test of two anodes per 15T of manufacturing for checking bonding between

inserts and anode (NACE RP 0387 & RP 0492)

4. Inspection by Vendor / Subvendor

IRT for Cathodic Protection System

1. Inspection by ONGC/CA

Inspection Category: C

Location and number of anodes installed on structure.(To be checked in fabrication yard)

Welding ,Cleaning and blasting of all inserts before casting

Routine tests on anodes- For example continuity check and resistance check between

core/inserts and anode (I.e. less that 0.10 Ohm resistance) etc.

2. Inspection by ONGC / Third Party Inspection Agency (TPI of Company)

3. Inspection by Afcons / Afcons appointed TPI

Pre-Inspection Meeting:

Approval of QA Plan / Inspection & Test Plan (ITP) from vendor.

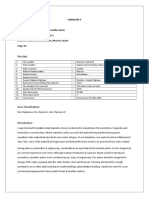

Project: HRD Process Platform Inspection Requirement Table (Indicative)

A

C

T

I

V

I

T

I

E

S

N

o

Item:

Galvanic CP system (sacrificial anodes)

IRT No. 00812-200-IRT-2410-01 Rev. 0

Location and number of monitoring and reference anodes installed (To be checked in

fabrication yard)

5. Certificate / Data to be submitted

STAGES OF INSPECTION INVOLVED.

Monitoring and Reference anodes (Set)

Alloy material composition of sacrificial anode - Mg, Zn, or Al (Two samples from each cast

at the beginning and end of casting)

Test for Electrochemical efficiency (Electrochemical value of the anode material in

amperehour per kg- weight loss method -4 days test ) as per DNV RP B401 Appendix A

and ASTM D 1141 and its potential w.r.t. Ag/Ag cl reference electrode under site conditions.

Sacrificial Anodes

Client: ONGCL

Monitoring Panel

Type test certification of panel for ingress protection and area classification

4. Inspection by Vendor / Subvendor

IRT for Cathodic Protection System

1. Inspection by ONGC/CA

Inspection Category: C

2. Inspection by ONGC / Third Party Inspection Agency (TPI of Company)

3. Inspection by Afcons / Afcons appointed TPI

Project: HRD Process Platform Inspection Requirement Table (Indicative)

A

C

T

I

V

I

T

I

E

S

N

o

Item:

IRT No. 00812-200-IRT-2410-01 Rev. 0

5. Certificate / Data to be submitted

STAGES OF INSPECTION INVOLVED.

Client: ONGCL

13 R

.

RW W

X

14 R

.

RW W

X

15 R

.

R R

X

16 R . R R X

17 R . R R X

18 R

.

W W X

19 R . H H X

X-Submission of Supporting Documents.

Rw-Random Witness.(10%)

TPI-Third Party Inspection Agency appointed by Afcons.

TPI of Company- Inspection AgencyAppointed by Client (ONGC).

CA- Certification Agency Appointed by ONGC.

CAT-B: Category B: Equipments classified under "B" category are considered sub critical for the

performance of the facilities and thus these equipment attract final inspection and certification before

despatch by various parties involved.

CAT-C: Category C: Items under this will be inspected by Afcons / Afcons appointed TPI.

Note 1: Categorisation for Inspection.

CAT-A: Category A: Equipments classified under "A" category are considered critical for the performance of the

facilities and thus these equipment involves stagewise inspection and certification by various parties involved.

A-Approval

I-Information

NOTES:

Potential measurement between anode and reference electrode/anode. (Closed circuit

potential) in site.

Current out put measurement mA/m^2)- between anode and monitoring electrode/anodes

in site.

Eletrical cables continuity check ( In Fabrication yard).

W-Witness

R-Review

Legend:

H-Hold

Other Requirements:

Review of final documentation to spec. requirements

Final package Inspection for completeness during/after packaging-tagging, preservation,

packing including spares.

TPI release note.

Wiring, function check of components (switches), mounting details, dimension, instumens

range and calibration (Ammeter, voltmeter etc.) as required per drawings/spec.

4. Inspection by Vendor / Subvendor

IRT for Cathodic Protection System

1. Inspection by ONGC/CA

Inspection Category: C

2. Inspection by ONGC / Third Party Inspection Agency (TPI of Company)

3. Inspection by Afcons / Afcons appointed TPI

Project: HRD Process Platform Inspection Requirement Table (Indicative)

A

C

T

I

V

I

T

I

E

S

N

o

Item:

IRT No. 00812-200-IRT-2410-01 Rev. 0

5. Certificate / Data to be submitted

STAGES OF INSPECTION INVOLVED.

Client: ONGCL

ONGC / CA

Note 2: Inspection and Certification by COMPANY / CA ; TPI / CONTRACTOR does not take away the responsibilities of the

vendor to supply a product conforming to the Purchase Order / Specification requirements.

CAT- BULK: Category BULK: Items under this category shall be inspected by Afcons/TPI (RINA) and issue the

releae note.Afcons/TPI (RINA) shall endorse all QC documents as " Reviewed and Accepted ''

Date:

Name:

Signature:

Note 3: If there is involvement of AI (Authrised Inspector) it shall be the responsibility of vendor to arrange for the same. TPI /

CA shall not replace AI. Cost towards AI fees is deemed to be included in the quoted price for such equipment.

Note 4: This IRT is issued for the purpose of RFQ / Enquiry only and is subject to approval by CA / COMPANY.

Afcons / TPI (RINA)

Note 5: This IRT is for guidance and will be replaced by formal ITP / QAP to be submitted by the Vendors for Approval, based

on complete Engineering.Inspection will be based on approved vendor ITP / QAP and Project Technical Specifications.

You might also like

- Column Condenser ITP inspection planDocument2 pagesColumn Condenser ITP inspection planAshish DhokNo ratings yet

- Alstom IRDocument4 pagesAlstom IRkasi reddyNo ratings yet

- Inspection and Test Program: Fabrication / In-Process InspectionDocument10 pagesInspection and Test Program: Fabrication / In-Process InspectionGLEDSONNo ratings yet

- Field Itp For Piping Work Samur Project Rev-5 (23 April 2013)Document28 pagesField Itp For Piping Work Samur Project Rev-5 (23 April 2013)Echik KiciNo ratings yet

- QA/QC Instrumentation QuestionsDocument5 pagesQA/QC Instrumentation Questionsengrrahman3135100% (3)

- Instrumentation Inspection and Quality Control InterviewDocument3 pagesInstrumentation Inspection and Quality Control InterviewzhangyiliNo ratings yet

- What Is: Electrical QuestionaireDocument19 pagesWhat Is: Electrical QuestionaireDanish H100% (8)

- R05323 P 001a X009 0042 PDFDocument464 pagesR05323 P 001a X009 0042 PDFcquibajoNo ratings yet

- Inspection Report: Page 1 of 2 Vendor P.O. NODocument3 pagesInspection Report: Page 1 of 2 Vendor P.O. NOsudipta dasNo ratings yet

- 22 66 KV LA R4 Jan 11 PDFDocument17 pages22 66 KV LA R4 Jan 11 PDFDin CuyNo ratings yet

- Item Inspected: CBLT-TPI-00F-186-12623Document16 pagesItem Inspected: CBLT-TPI-00F-186-12623Zulfadli RaniNo ratings yet

- Experience Base - QA/QC StandardsDocument41 pagesExperience Base - QA/QC StandardsRaheel Jibran100% (5)

- Itp For SSDP Project Rev CDocument9 pagesItp For SSDP Project Rev CRachel FloresNo ratings yet

- Base Line SurveyDocument10 pagesBase Line Surveycisar0007No ratings yet

- Sub 011 Submittal Package - 16158 Variable Frequency Drives-1Document460 pagesSub 011 Submittal Package - 16158 Variable Frequency Drives-1Thangarajan NagarajanNo ratings yet

- Itr Ew 01a - EngDocument2 pagesItr Ew 01a - Engwassim nasriNo ratings yet

- SATIP-X-400-01 Rev 5Document3 pagesSATIP-X-400-01 Rev 5aamirapiNo ratings yet

- MCC and Switchboard Inspection PlanDocument3 pagesMCC and Switchboard Inspection PlanBob Kmn0% (1)

- Itr Ew 04a - EngDocument2 pagesItr Ew 04a - Engwassim nasriNo ratings yet

- SATR-J-6912 Rev 0 PDFDocument4 pagesSATR-J-6912 Rev 0 PDFAdel KlkNo ratings yet

- Itr Ew 07a - EngDocument1 pageItr Ew 07a - Engwassim nasriNo ratings yet

- Iso Work InstructionsDocument115 pagesIso Work InstructionsEkondroNo ratings yet

- ITP For MCC - HV - LV-switchgear Boards-PaneDocument2 pagesITP For MCC - HV - LV-switchgear Boards-Panerodel100% (1)

- CT Testing LTDocument25 pagesCT Testing LTVijaya Kumar100% (1)

- Itp Installation of Fiber Optic CablesDocument4 pagesItp Installation of Fiber Optic Cablesqasim078100% (2)

- General QuestionnaireDocument9 pagesGeneral Questionnairehemant1284No ratings yet

- Coskovic Branimir Etfos 2017 Zavrs SveucDocument2 pagesCoskovic Branimir Etfos 2017 Zavrs SveucsffvghjNo ratings yet

- Installation of Fiber Optic Cables ITPDocument5 pagesInstallation of Fiber Optic Cables ITPVasilica Barbarasa50% (4)

- NSC-400-CE-3220-ITP-02-A-Transmission Line Conductor - Stringing & InstallationDocument2 pagesNSC-400-CE-3220-ITP-02-A-Transmission Line Conductor - Stringing & InstallationElisco Pher SalmasanNo ratings yet

- Inspection Report: Page 1 of 2 Vendor P.O. NODocument4 pagesInspection Report: Page 1 of 2 Vendor P.O. NOsudipta dasNo ratings yet

- B-7-005 MR Induction Bends Rev A1Document19 pagesB-7-005 MR Induction Bends Rev A1Advis100% (3)

- FQPDocument9 pagesFQPtushar647No ratings yet

- ITP Fire FightingDocument2 pagesITP Fire FightingDiar Azzis S100% (1)

- 7 - 220 - 132 - 220 - KV - NCT - 2147Document20 pages7 - 220 - 132 - 220 - KV - NCT - 2147Sheraz azamNo ratings yet

- Guidance Inspection Crane RuiDocument34 pagesGuidance Inspection Crane RuiRonniNo ratings yet

- Lafarge Quality Control PlanDocument64 pagesLafarge Quality Control Planmanu_giteNo ratings yet

- Inspection and Test Plan: Fabrication / In-Process InspectionDocument17 pagesInspection and Test Plan: Fabrication / In-Process InspectionGLEDSON100% (1)

- D002 (I&C) Instrument and Calibration Procedure For Turbine & Boiler AreaDocument38 pagesD002 (I&C) Instrument and Calibration Procedure For Turbine & Boiler AreaSurya Darma100% (1)

- WPS - Smaw - 2Document6 pagesWPS - Smaw - 2Harkesh RajputNo ratings yet

- Inspection & Testing of Elastic Rail Clips PDFDocument5 pagesInspection & Testing of Elastic Rail Clips PDFfiemsabyasachi0% (1)

- ETP Inspection and Test Plan for LPG Terminal ProjectDocument2 pagesETP Inspection and Test Plan for LPG Terminal ProjectClaudio PataniaNo ratings yet

- ECTDocument17 pagesECTvikramNo ratings yet

- Itr Ew 05a - EngDocument1 pageItr Ew 05a - Engwassim nasriNo ratings yet

- Saudi Aramco Test Report: Final Inspection/Re-Instatement Punch ListDocument17 pagesSaudi Aramco Test Report: Final Inspection/Re-Instatement Punch ListnadeemNo ratings yet

- CV Aravind API InspectorDocument12 pagesCV Aravind API Inspectorநான் மகான் அல்லNo ratings yet

- Yanbu Industrial City, KSA: Itp For Hvac (Heating Ventilation and Air Conditioning) System InstallationDocument5 pagesYanbu Industrial City, KSA: Itp For Hvac (Heating Ventilation and Air Conditioning) System InstallationAmair Cool88% (8)

- Jawad+Ahsan + ResumeDocument3 pagesJawad+Ahsan + ResumeAndiappan PillaiNo ratings yet

- PTC19022100601S-LD01 Test ReportDocument103 pagesPTC19022100601S-LD01 Test ReportSumit SinhaNo ratings yet

- Inspection and Test Plan for Mars CS PackageDocument17 pagesInspection and Test Plan for Mars CS PackageMariah PearsonNo ratings yet

- Daily QAQC Check SheetsDocument1 pageDaily QAQC Check Sheetsfhairuz.wahidNo ratings yet

- Commissioning Procedure EngrDocument11 pagesCommissioning Procedure EngrkumarNo ratings yet

- Control and Relay Panel Technical SpecificationsDocument71 pagesControl and Relay Panel Technical Specificationsgohilnarendra100% (1)

- Is 16205 24 PMDocument6 pagesIs 16205 24 PMR.HarishNo ratings yet

- Dots For Engineering Industries: Test Stump Recertification Document Package SN (D-N-RFL-1635)Document13 pagesDots For Engineering Industries: Test Stump Recertification Document Package SN (D-N-RFL-1635)Moustafa AshrafNo ratings yet

- BSEE Production Inspection HandbookDocument71 pagesBSEE Production Inspection HandbookStephanie Burns AyersNo ratings yet

- CL-NG-6460-002-023 Checklist For CT Rev01Document5 pagesCL-NG-6460-002-023 Checklist For CT Rev01sachin francisNo ratings yet

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Emergency Response NumbersDocument1 pageEmergency Response NumbersAnonymous i3lI9MNo ratings yet

- OpTransactionHistory11 11 2018Document3 pagesOpTransactionHistory11 11 2018Anonymous i3lI9MNo ratings yet

- KalikaDocument11 pagesKalikaAnonymous i3lI9MNo ratings yet

- Areas For Improvement - Lessons Learnt From Test PileDocument10 pagesAreas For Improvement - Lessons Learnt From Test PileAnonymous i3lI9MNo ratings yet

- New India Assurance policy schedule for Hull Machinery InsuranceDocument3 pagesNew India Assurance policy schedule for Hull Machinery InsuranceAnonymous i3lI9MNo ratings yet

- KM 180 - Class & Loadline 12.3.18Document5 pagesKM 180 - Class & Loadline 12.3.18Anonymous i3lI9MNo ratings yet

- Certificate Varad IIDocument1 pageCertificate Varad IIAnonymous i3lI9MNo ratings yet

- Recent Trends in Technologies in Sewerage System: March 2012Document25 pagesRecent Trends in Technologies in Sewerage System: March 2012Anonymous i3lI9MNo ratings yet

- New Doc 2018-11-03 16.59.46 PDFDocument4 pagesNew Doc 2018-11-03 16.59.46 PDFAnonymous i3lI9MNo ratings yet

- Kalika PDFDocument11 pagesKalika PDFAnonymous i3lI9MNo ratings yet

- OpTransactionHistory11 11 2018Document3 pagesOpTransactionHistory11 11 2018Anonymous i3lI9MNo ratings yet

- Donotworry 01Document1 pageDonotworry 01Anonymous i3lI9MNo ratings yet

- Certificate GaribdasDocument1 pageCertificate GaribdasAnonymous i3lI9MNo ratings yet

- Evaluation Statement For Zero PDDocument2 pagesEvaluation Statement For Zero PDAnonymous i3lI9MNo ratings yet

- Intact Stability Booklet for Pontoon ESSEM-IIDocument92 pagesIntact Stability Booklet for Pontoon ESSEM-IIAnonymous i3lI9MNo ratings yet

- Insurance D.B Essem-IIIDocument2 pagesInsurance D.B Essem-IIIAnonymous i3lI9MNo ratings yet

- Certificate Akash IDocument1 pageCertificate Akash IAnonymous i3lI9MNo ratings yet

- Garibdas Marine Hull PolicyDocument3 pagesGaribdas Marine Hull PolicyAnonymous i3lI9MNo ratings yet

- Akash I HCLDocument1 pageAkash I HCLAnonymous i3lI9MNo ratings yet

- 5S Principle of HousekeepingDocument1 page5S Principle of HousekeepingAnonymous i3lI9MNo ratings yet

- Outstanding Issues: Project ControlDocument36 pagesOutstanding Issues: Project ControlAnonymous i3lI9MNo ratings yet

- 5S Principle of HousekeepingDocument20 pages5S Principle of HousekeepingAnonymous i3lI9MNo ratings yet

- New Doc 2019-02-06 16.38.36Document6 pagesNew Doc 2019-02-06 16.38.36Anonymous i3lI9MNo ratings yet

- குங்குமம் டாக்டர் 1-15 மார்ச் 19 PDFDocument84 pagesகுங்குமம் டாக்டர் 1-15 மார்ச் 19 PDFAnonymous i3lI9MNo ratings yet

- HSE Code for SubcontractorsDocument2 pagesHSE Code for SubcontractorsAnonymous i3lI9M0% (1)

- E-Tckt C Stephenson Feb 10 2019Document1 pageE-Tckt C Stephenson Feb 10 2019Anonymous i3lI9MNo ratings yet

- Hindu Delhi 02.03.19 PDFDocument20 pagesHindu Delhi 02.03.19 PDFAnonymous i3lI9MNo ratings yet

- Journallist 1 PDFDocument400 pagesJournallist 1 PDFRajasekar PichaimuthuNo ratings yet

- KamdhenuDocument5 pagesKamdhenuAnonymous i3lI9MNo ratings yet

- Donotworry 01Document1 pageDonotworry 01Anonymous i3lI9MNo ratings yet

- Cwi QuestionsDocument6 pagesCwi QuestionsGokul Thangam75% (4)

- Fallout 1 ManualDocument124 pagesFallout 1 ManualDave100% (1)

- Ferhat ErdalDocument22 pagesFerhat ErdalsaifoaNo ratings yet

- MCQ 140Document14 pagesMCQ 140Aawez AkhterNo ratings yet

- Wa500-6 Sen00236-04d PDFDocument1,705 pagesWa500-6 Sen00236-04d PDFanggie100% (4)

- Brakes & Clutches: Formulas and Applications for Friction DevicesDocument16 pagesBrakes & Clutches: Formulas and Applications for Friction DevicesNeil RubsNo ratings yet

- Folio SainsDocument15 pagesFolio SainsMohammad Afifi Rohman80% (5)

- Apocalyptic Rhetoric KritikDocument31 pagesApocalyptic Rhetoric KritikMilkdelishNo ratings yet

- DC Machine Theory and Transformer PrinciplesDocument32 pagesDC Machine Theory and Transformer PrinciplesPolireddi Gopala KrishnaNo ratings yet

- Q 1000Document24 pagesQ 1000Fredy Vázquez VelázquezNo ratings yet

- FAI Services Overview SHORTDocument58 pagesFAI Services Overview SHORTMariela CarrilloNo ratings yet

- Syllabus of Diploma in Electrical EngineeringDocument17 pagesSyllabus of Diploma in Electrical EngineeringJoson Chan100% (1)

- (Geoffrey Lawrence, Kristen Lyons, Tabatha Walling (BookFi) PDFDocument321 pages(Geoffrey Lawrence, Kristen Lyons, Tabatha Walling (BookFi) PDFIManNo ratings yet

- 6-Achs SPMT 210.12.4 G4 6-Axle SPMT 210.12.4 G4: Scheuerle-Fahrzeugfabrik GMBHDocument22 pages6-Achs SPMT 210.12.4 G4 6-Axle SPMT 210.12.4 G4: Scheuerle-Fahrzeugfabrik GMBHsrikanthc8550% (2)

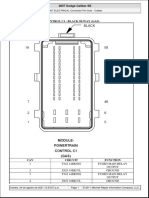

- Caliber Modulo PCM PinoutDocument7 pagesCaliber Modulo PCM PinoutManuel Suarez100% (3)

- Survey of Tea Vendors 01Document2 pagesSurvey of Tea Vendors 01Sandeep SinghNo ratings yet

- 4,5. Transformers (1 Phase & 3 Phase)Document48 pages4,5. Transformers (1 Phase & 3 Phase)nakkasrinuNo ratings yet

- Current Transformer - Electrical Notes & ArticlesDocument47 pagesCurrent Transformer - Electrical Notes & Articlesnomy158100% (1)

- Scope of Work Doc-Fire Hydrant SystemDocument2 pagesScope of Work Doc-Fire Hydrant SystemMauliNo ratings yet

- India's Former President APJ Abdul Kalam on Leadership, Knowledge and Managing FailureDocument14 pagesIndia's Former President APJ Abdul Kalam on Leadership, Knowledge and Managing FailureHarsh TiwariNo ratings yet

- 568100Document2 pages568100Talha TariqNo ratings yet

- OMM 00023 Maintenance Guide JDocument49 pagesOMM 00023 Maintenance Guide Jkenedi74100% (2)

- Budget of Lesson Science 9Document14 pagesBudget of Lesson Science 9Hezl Valerie ArzadonNo ratings yet

- 262 Controlled Switching of HVAC Circuit Breaker PDFDocument34 pages262 Controlled Switching of HVAC Circuit Breaker PDFepriNo ratings yet

- CH 3 Gas Refrigeration CycleDocument20 pagesCH 3 Gas Refrigeration CycleMeleseNo ratings yet

- HKBEAMDocument0 pagesHKBEAMTse Lam ChanNo ratings yet

- Pressure MeasurementDocument19 pagesPressure MeasurementShadmanSakiefHridoyNo ratings yet

- SGP Chapter-1Document81 pagesSGP Chapter-1Shashank ReddyNo ratings yet

- RP Manuale D'uso e Manutenzione - CAVALLINO CE PDFDocument24 pagesRP Manuale D'uso e Manutenzione - CAVALLINO CE PDFMiraNo ratings yet

- Boundary Layer ThicknessDocument23 pagesBoundary Layer ThicknessPridhar ThiagarajanNo ratings yet