Professional Documents

Culture Documents

Itr Ew 01a - Eng

Uploaded by

wassim nasriOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Itr Ew 01a - Eng

Uploaded by

wassim nasriCopyright:

Available Formats

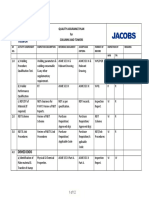

PROJECT Report No:

CLIENT

(Partner (Client Logo)

Logo) INSPECTION TEST REPORT Date:

Checks of Electrical Equipment

Ready for Precommissioning

Subcontractor: ITR-EW-01A

Reference QCP No: QCP phase:

Test Notification n°: Notification Date:

Equipment: ELECTRICAL EQUIPMENT Type: DRY POWER TRANSFORMER Equipment Tag:

Equipment Designation: System Tag:

Manufacturer: Model: P&ID No.:

Voltage Ratio: Nominal Frequency: Nominal Power:

Data Sheet No.: Drawing No.:

Checks Description C NC NA

Check the equipment, verifying the compliance with the project documentation in last revision: P&I D, drawings,

1.

specifications, standards, etc.

2. Check that the tag of the equipment is correct and appropriate.

3. Check that the equipment suitable for area classification.

4. Check that the enclosure - "ip rating" - correct as per specification.

5. Check that there are no damages/deformations.

6. Check that the internal and external painting is in satisfactory condition and does not need to be touched-up.

Check that the equipment is installed properly, in particular verify that:

Foundations/basement and joints are correct;

Position, level, orientation, verticality and horizontality are correct;

7. Sliding support and feet are free to move;

Number of the bolts, nuts and tie rods is correct;

Tightening of the bolts/tie rods is assured;

Grouting and levelling mortar is done in according to project specification.

Check that the earthing system is connected to earthing network and that the terminal on the equipment is well

8. tightened.

9. Check that all cables or bus-bars properly terminated, connected and supported.

10. Check that the terminal boxes in good condition (clean, dry, etc).

11. Check that the spare cable entry correctly plugged.

12. Check that internal free from dust, debris, etc.

13. Check that the copper grease applied to flange (ex-d enclosure).

14. Check the gasket and seals correctly installed and in good condition.

15. Check that the tap change mechanism operates satisfactorily.

16. Check that the neutral connections secure.

17. Check that padlocking facilities satisfactory.

18. Check the warning label (high voltage, high temperature, etc) properly installed.

19. Check that the equipment is complete of all accessories and instrumentation.

20. Check that insulators cleaned.

21. Check that the Bus-bars and/or cables terminal protection boxes well closed.

P.1/2 Mod. ITR-EW-01A/0

PROJECT Report No:

CLIENT

(Partner (Client Logo)

Logo) INSPECTION TEST REPORT Date:

Checks of Electrical Equipment

Ready for Precommissioning

Checks Description C NC NA

22. Check the accessories well fixed. Screws and nut not missed.

23. Check that the Rollers on rails chocked.

24. Check that the enclosures suitable against adverse weather conditions and sun correctly installed

25. Check that Eventual defects/abnormalities have been entered in the Project Punch List.

26. Check that the final documentation for QCP has been completed and signed off.

27. Check that all modifications have been highlighted on the “Master Copy” drawings (as built).

Insulation resistance

Test Voltage: Volt Test duration: min

HV – E

Between

L1-E L2-E L3-E L1-N L2-N L3-N L1-L2-L3-E N-E

IR (MΩ)

Remarks:

C = Conformance; NC = Non Conformance; NA = Not Applicable;

Conform

Test Instrument Used:

Not Conform – Report n°: Tag n°:

INSPECTORS SUBCONTRACTOR CONTRACTOR CLIENT AUTHORITY (if any)

Name:

Signature:

Date:

The information included in this document and any attachments are confidential and may also be privileged. Document and any attachments are property of ABB

SpA.: theirs reproduction, circulation and use without prior consent are forbidden.

P.2/2 Mod. ITR-EW-01A/0

You might also like

- Low Voltage Switchboard Inspection Test RecordDocument3 pagesLow Voltage Switchboard Inspection Test RecordAmyNo ratings yet

- QC-143 R2 Distribution Panel ChecklistDocument1 pageQC-143 R2 Distribution Panel ChecklistCamilo Jorquera100% (1)

- 26 1.itp ElectricalDocument1 page26 1.itp Electricalmee100% (1)

- Global Power Test Sdn. Bhd. Site Acceptance Test Report: Testing of 415V LV Switchgear PanelDocument10 pagesGlobal Power Test Sdn. Bhd. Site Acceptance Test Report: Testing of 415V LV Switchgear PanelTHULASI RAMNo ratings yet

- E&I QAP's - Submitted To Contractor HZADocument33 pagesE&I QAP's - Submitted To Contractor HZASuraj ShettyNo ratings yet

- Electrica QC Check ListDocument21 pagesElectrica QC Check Listmakana qc100% (1)

- Larsen & Toubro underground piping inspection planDocument4 pagesLarsen & Toubro underground piping inspection planBhavani PrasadNo ratings yet

- JX NIPPON Oil & Gas Low Voltage Cable ITRDocument2 pagesJX NIPPON Oil & Gas Low Voltage Cable ITRAmy100% (1)

- I&C Inspection and Test Plan - NWC Dhurma Pump Station, Pp11, Pp12, Pp13Document16 pagesI&C Inspection and Test Plan - NWC Dhurma Pump Station, Pp11, Pp12, Pp13Mohd Sami UddinNo ratings yet

- Installation of Fire & Gas Detectors (Flame - Toxic - Hydro Carbon) Check ListDocument1 pageInstallation of Fire & Gas Detectors (Flame - Toxic - Hydro Carbon) Check ListZulfequar R. Ali KhanNo ratings yet

- Epic For Upgradation of Ac Ups Units in Ngl3, Mesaieed: Result Checklist Description Remarks ItemDocument1 pageEpic For Upgradation of Ac Ups Units in Ngl3, Mesaieed: Result Checklist Description Remarks ItemmeeNo ratings yet

- Commissioning Standard Test FormatsDocument2 pagesCommissioning Standard Test FormatstajudeenNo ratings yet

- Inspection and Tests Plan: OPGW 60mm, 24coresDocument3 pagesInspection and Tests Plan: OPGW 60mm, 24coresErika Rafani WibowoNo ratings yet

- ITP For Flow MeterDocument4 pagesITP For Flow MeterSayee KrishnanNo ratings yet

- Form Motor Solo Run Interlock FuncDocument1 pageForm Motor Solo Run Interlock FuncImam HanafiNo ratings yet

- Switchgear Inspection Checklist: Section A - Customer DataDocument1 pageSwitchgear Inspection Checklist: Section A - Customer Data20082012No ratings yet

- Cable Tray InstallationDocument1 pageCable Tray InstallationNaeemNo ratings yet

- Portacabin Inspection ChecklistDocument2 pagesPortacabin Inspection ChecklistApm FoumilNo ratings yet

- NSC-400-CE-3220-ITP-02-A-Transmission Line Conductor - Stringing & InstallationDocument2 pagesNSC-400-CE-3220-ITP-02-A-Transmission Line Conductor - Stringing & InstallationElisco Pher SalmasanNo ratings yet

- Method Statement - Polarity TestDocument5 pagesMethod Statement - Polarity TestKhaled Badawy100% (1)

- Check ListDocument6 pagesCheck ListSikandar Khan0% (1)

- HFY3-3690-00-ELE-ITP-0001 - 0 ITP For Electrical Inspection and Test PlanDocument97 pagesHFY3-3690-00-ELE-ITP-0001 - 0 ITP For Electrical Inspection and Test PlanAmmar AlkindyNo ratings yet

- 04 - Material Receiving Inspection Procedure - Asf-Qc-Mri-001Document8 pages04 - Material Receiving Inspection Procedure - Asf-Qc-Mri-001Sherif YehiaNo ratings yet

- Inspection Test Plan (Itp) at Shop: Natural Gas Transportation Development Project - Siak RiauDocument10 pagesInspection Test Plan (Itp) at Shop: Natural Gas Transportation Development Project - Siak Riauanang_priNo ratings yet

- 1E-Motors Inspection ChecklistDocument1 page1E-Motors Inspection ChecklistAnonymous iiUUgwNo ratings yet

- Piping Fabrication Installation QCP On SiteDocument1 pagePiping Fabrication Installation QCP On SiteTarun PatelNo ratings yet

- Installation Check Sheet For Ahu FahuDocument2 pagesInstallation Check Sheet For Ahu FahuSamer AliNo ratings yet

- Inspection Amp Test Plan Itp Hvac Installation New Pump Station Ps 56a and Force Main To SWTP 9 JubailDocument28 pagesInspection Amp Test Plan Itp Hvac Installation New Pump Station Ps 56a and Force Main To SWTP 9 JubailBernardita QuintanaNo ratings yet

- Project: Samsun CCPP: Title: ITP of SwitchgearsDocument4 pagesProject: Samsun CCPP: Title: ITP of SwitchgearsUtku Can Kılıç100% (1)

- Epic For Upgradation of Ac Ups Units in Ngl3, Mesaieed: Test Description Insulation Resistance Test (IR)Document1 pageEpic For Upgradation of Ac Ups Units in Ngl3, Mesaieed: Test Description Insulation Resistance Test (IR)meeNo ratings yet

- Ohl TestDocument5 pagesOhl TestAnonymous ExWAN2xjFJNo ratings yet

- Checklist For Cable Try Fabrication and EractionDocument2 pagesChecklist For Cable Try Fabrication and Eractionnayum100% (1)

- Inspection Report For Installation of JB, Juncation BoxDocument1 pageInspection Report For Installation of JB, Juncation BoxnayumNo ratings yet

- Doha Petroleum Construction Co. LTD Inspection & Test Plan: ElectricalDocument1 pageDoha Petroleum Construction Co. LTD Inspection & Test Plan: ElectricalmeeNo ratings yet

- Itp Forabove Grade and Embedded Conduits Rev. 0Document6 pagesItp Forabove Grade and Embedded Conduits Rev. 0sartaj0% (1)

- Emergency Lights Inspection ChecklistDocument7 pagesEmergency Lights Inspection ChecklistDemmy Rose NugasNo ratings yet

- Epic For Upgradation of Ac Ups Units in Ngl3, Mesaieed: Multi Core Cable Test SheetDocument1 pageEpic For Upgradation of Ac Ups Units in Ngl3, Mesaieed: Multi Core Cable Test SheetmeeNo ratings yet

- Epic For Upgradation of Ac Ups Units in Ngl3, Mesaieed: Remarks Item Checklist Description ResultDocument1 pageEpic For Upgradation of Ac Ups Units in Ngl3, Mesaieed: Remarks Item Checklist Description ResultmeeNo ratings yet

- Function Checks Is Not Applicable For This Panel: Switchgear Functional TestDocument3 pagesFunction Checks Is Not Applicable For This Panel: Switchgear Functional Testeswaran005No ratings yet

- Epic For Upgradation of Ac Ups Units in Ngl3, MesaieedDocument1 pageEpic For Upgradation of Ac Ups Units in Ngl3, MesaieedmeeNo ratings yet

- Right Factorz Projects PVT LTD Checklist For Cable InstallationDocument9 pagesRight Factorz Projects PVT LTD Checklist For Cable InstallationRajesh RaghunathanNo ratings yet

- Welder Qualification Test - As Run Sheet: Weld Details Filler Shield Welding ParametersDocument1 pageWelder Qualification Test - As Run Sheet: Weld Details Filler Shield Welding ParametersGopalakrishnan GovindarajNo ratings yet

- Upgrading AC UPS Units in Qatar Gas ProjectDocument1 pageUpgrading AC UPS Units in Qatar Gas ProjectmeeNo ratings yet

- Epic For Upgradation of Ac Ups Units in Ngl3, Mesaieed: Title: Battery Installation ChecklistDocument1 pageEpic For Upgradation of Ac Ups Units in Ngl3, Mesaieed: Title: Battery Installation ChecklistmeeNo ratings yet

- 13 Fan Coil Unit: Location: - No.Document1 page13 Fan Coil Unit: Location: - No.JIJUNo ratings yet

- Insulation Test Report For Low Voltage Cables Free Ks4ibyDocument1 pageInsulation Test Report For Low Voltage Cables Free Ks4ibyJalal AlbadriNo ratings yet

- Work Method Statement For Erection in Loc Start D and End CDocument8 pagesWork Method Statement For Erection in Loc Start D and End CTwin Bulls0% (1)

- Inspection and Test Plan for Mars CS PackageDocument17 pagesInspection and Test Plan for Mars CS PackageMariah PearsonNo ratings yet

- KP-00+++-CQ712-B7907 - F01 - Rev.0 - MV Switchgear Installation Inspection Checklist1Document1 pageKP-00+++-CQ712-B7907 - F01 - Rev.0 - MV Switchgear Installation Inspection Checklist1Utku Can KılıçNo ratings yet

- Rsae-Frm-227 Inspection Check List For Motor Solo RunDocument1 pageRsae-Frm-227 Inspection Check List For Motor Solo RunkamilNo ratings yet

- Electrical Inspection and Test PlanDocument1 pageElectrical Inspection and Test PlanJames Pol JumarangNo ratings yet

- Contractor Quality Control Plan For Electrical Equipment InstallationDocument7 pagesContractor Quality Control Plan For Electrical Equipment Installationhasan_676489616No ratings yet

- Iwp Cable Tray Installation Checklist: Appendix - 9Document3 pagesIwp Cable Tray Installation Checklist: Appendix - 9dennykvg0% (1)

- KP-00+++-CQ712-B7907 - Rev.0 - ITP - MV Switchgear InstallationDocument1 pageKP-00+++-CQ712-B7907 - Rev.0 - ITP - MV Switchgear InstallationUtku Can KılıçNo ratings yet

- 2.8.2. Indicative QAP - ColumnsDocument12 pages2.8.2. Indicative QAP - ColumnsAshish Dhok0% (1)

- 00-GE-EQA-001 (Rev.a) Site Inspection and Test Plan For Electrical and I&C WorkDocument12 pages00-GE-EQA-001 (Rev.a) Site Inspection and Test Plan For Electrical and I&C WorkAbdul Mohid SheikhNo ratings yet

- Itr Ew 04a - EngDocument2 pagesItr Ew 04a - Engwassim nasriNo ratings yet

- Itr Ew 05a - EngDocument1 pageItr Ew 05a - Engwassim nasriNo ratings yet

- Itr Ew 07a - EngDocument1 pageItr Ew 07a - Engwassim nasriNo ratings yet

- E019 MV Breaker Function TestDocument10 pagesE019 MV Breaker Function TestMusab ShabbirNo ratings yet

- Itr Ew 04a - EngDocument2 pagesItr Ew 04a - Engwassim nasriNo ratings yet

- Ceri-Abb-Qua-0344 For Work Method Statement Steel Structure Painting & Repair Rev 000Document1 pageCeri-Abb-Qua-0344 For Work Method Statement Steel Structure Painting & Repair Rev 000wassim nasriNo ratings yet

- Fire Proofing Revised Procedure - C02Document47 pagesFire Proofing Revised Procedure - C02wassim nasriNo ratings yet

- Itr Ew 07a - EngDocument1 pageItr Ew 07a - Engwassim nasriNo ratings yet

- Itr Ew 05a - EngDocument1 pageItr Ew 05a - Engwassim nasriNo ratings yet

- Itr Ew 04a - EngDocument2 pagesItr Ew 04a - Engwassim nasriNo ratings yet

- Itr Ew 04a - EngDocument2 pagesItr Ew 04a - Engwassim nasriNo ratings yet

- Engineering Progress CommentedDocument5 pagesEngineering Progress Commentedwassim nasriNo ratings yet

- Overall Progress No.1 CommentedDocument1 pageOverall Progress No.1 Commentedwassim nasriNo ratings yet

- DIO - Final Form of UNINCORPORATED CONTRACT (Schedules) - REDACTED PDFDocument256 pagesDIO - Final Form of UNINCORPORATED CONTRACT (Schedules) - REDACTED PDFanisthabetNo ratings yet

- Progress No 1 Last Revision Commented and ApprovedDocument10 pagesProgress No 1 Last Revision Commented and Approvedwassim nasriNo ratings yet

- L4 22Document41 pagesL4 22wassim nasriNo ratings yet

- Technical Insulation Heavy Duty Wired MatDocument2 pagesTechnical Insulation Heavy Duty Wired Matwassim nasriNo ratings yet

- Cable Lugs & Connectors Price in US DollarDocument5 pagesCable Lugs & Connectors Price in US Dollarwassim nasriNo ratings yet

- Lifting Plan - Metering Building Shatering-27-08-2020 PDFDocument1 pageLifting Plan - Metering Building Shatering-27-08-2020 PDFSUHAIL S SIRAJUDEENNo ratings yet

- Bombas de Agua PaiDocument17 pagesBombas de Agua PaiEver Rivera50% (2)

- BSNL Complaint LetterDocument1 pageBSNL Complaint Lettershivi08No ratings yet

- Mud Logger Training Manual PDFDocument4 pagesMud Logger Training Manual PDFAnonymous oe5mdI0% (1)

- r5220104 Hydraulics and Hydraulic MachineryDocument1 pager5220104 Hydraulics and Hydraulic MachinerySaitheja SharmaNo ratings yet

- Syntizen Business ProfileDocument9 pagesSyntizen Business Profiledinesh1625No ratings yet

- CAT 01181 Catalogue POK Complete enDocument448 pagesCAT 01181 Catalogue POK Complete enIkhsan NurfajarNo ratings yet

- C++ Arrays - TutorialspointDocument3 pagesC++ Arrays - TutorialspointevilplueNo ratings yet

- Python Project #1: Guess The NumberDocument2 pagesPython Project #1: Guess The NumberMatt CarlbergNo ratings yet

- Ir-5075 - 5065 - 5055 - CD - Circuit Diagram PDFDocument107 pagesIr-5075 - 5065 - 5055 - CD - Circuit Diagram PDFregis.nx4100% (2)

- Essay Tik TokDocument6 pagesEssay Tik TokEzayffa HizfarNo ratings yet

- Zte Bts ManualDocument136 pagesZte Bts ManualDiwakar Mishra100% (2)

- Compro StarlinkDocument20 pagesCompro Starlinkjohan artajayaNo ratings yet

- Basics of Fire and Smoke Damper Installations - NFPADocument9 pagesBasics of Fire and Smoke Damper Installations - NFPAumerNo ratings yet

- A2: Asian Infrastructure Investment Bank - (Correct Alternative)Document28 pagesA2: Asian Infrastructure Investment Bank - (Correct Alternative)Patadi Iti Placement CellNo ratings yet

- Senr3193 Hydrostatic TransmissionDocument48 pagesSenr3193 Hydrostatic TransmissionMoicano P SánchezNo ratings yet

- FL - Fire Extinguishers - TycoDocument7 pagesFL - Fire Extinguishers - TycoNitin BuZzNo ratings yet

- Analisis SWOT Strategi Pengembangan Sekolah Unggul: January 2019Document12 pagesAnalisis SWOT Strategi Pengembangan Sekolah Unggul: January 2019Zulaikha FitriyantiNo ratings yet

- Be - Mechanical Engineering - Semester 4 - 2023 - February - Applied Thermodynamics at Pattern 2019Document2 pagesBe - Mechanical Engineering - Semester 4 - 2023 - February - Applied Thermodynamics at Pattern 2019loharjay772No ratings yet

- Cargo Aircraft Specifications GuideDocument18 pagesCargo Aircraft Specifications Guidearpitsingh06367% (3)

- Training Course BrochureDocument4 pagesTraining Course BrochureGodofredo PabloNo ratings yet

- Jf:Yo Dgqfnon) A) RF/ Dfwodnfo ( Xof) U X'G) GLLT Agfpg) : Wg'Iffsf B'O (Clws (T LXT ! HGF SD (RF/L LgndagDocument4 pagesJf:Yo Dgqfnon) A) RF/ Dfwodnfo ( Xof) U X'G) GLLT Agfpg) : Wg'Iffsf B'O (Clws (T LXT ! HGF SD (RF/L LgndagmadheshpostNo ratings yet

- Tadmor 2017 Modelling Simul. Mater. Sci. Eng. 25 071001Document4 pagesTadmor 2017 Modelling Simul. Mater. Sci. Eng. 25 071001Sandya KaranamNo ratings yet

- Test Case Parking Cost CalculatorDocument7 pagesTest Case Parking Cost CalculatorNevena KostadinovićNo ratings yet

- 300 011 782Document42 pages300 011 782राकेश कुमार सिंहNo ratings yet

- E-Choke Design UKDocument13 pagesE-Choke Design UKtehnotonNo ratings yet

- Precog's IEM Ranking List-7Document6 pagesPrecog's IEM Ranking List-7RubenNo ratings yet

- Rrepetitive Controller BasicDocument23 pagesRrepetitive Controller BasicSuranjana DasNo ratings yet

- A1 Principles of Teaching - Ans.KeyDocument11 pagesA1 Principles of Teaching - Ans.KeyJam Uly Gasty100% (2)

- Acceptance Criteria For Damaged PFP Info Sheet 12-2007Document9 pagesAcceptance Criteria For Damaged PFP Info Sheet 12-2007Richard HollidayNo ratings yet