Professional Documents

Culture Documents

Itr Ew 04a - Eng

Uploaded by

wassim nasriOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Itr Ew 04a - Eng

Uploaded by

wassim nasriCopyright:

Available Formats

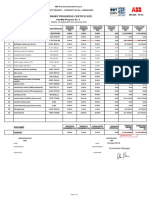

PROJECT Report No:

CLIENT

(Partner (Client Logo)

Logo) INSPECTION TEST REPORT Date:

Checks of Electrical Equipment

Ready for Precommissioning

Subcontractor: ITR-EW-04A

Reference QCP No: QCP phase:

Test Notification n°: Notification Date:

Equipment: ELECTRICAL EQUIPMENT Type: LV SWITCHBOARD Equipment Tag:

Equipment Designation: System Tag:

Manufacturer: Model: P&ID No.:

Voltage Ratio: Nominal Frequency: Nominal Power:

Data Sheet No.: Drawing No.:

Checks Description C NC NA

Check the equipment, verifying the compliance with the project documentation in last revision: P&I D, drawings,

1. specifications, standards, etc.

2. Check that the tag of the equipment is correct and appropriate.

3. Check that the equipment is complete of all accessories and instrumentation.

4. Check the elevation and planarity of switchgear basement and panel fixation.

5. Check installation and fixing of all internals are according to construction drawings.

6. Check the correct mechanical functioning of switchgear components, in particular breakers and isolators.

Check the installation and connection of all ancillaries (voltage and current transformers, dischargers on incoming

7.

lines, etc.).

Check the power connection of the switchgear (the Mechanical Completion certificates of all cables/Bus-ducts are

8.

filled-in and signed).

Check the tightness of bolts by means of a suitable torque wrench on each one of the connecting joints of the bus-

9.

bars.

Check the completeness and integrity of the switchboard Bus-bars (including insulating coating) and relevant isolated

10.

supports.

Check the auxiliary connections of the switchboard (the Mechanical Completion certificates of all auxiliary cables are

11.

filled-in and signed).

12. Check that there are no damages/deformations.

13. Check that the internal and external painting is in satisfactory condition and does not need to be touched-up.

14. Check that the internal and external cleaning is in satisfactory.

15. Check the opening and closing of all compartment/drawer doors. The keys of all locks are available.

Check the cable entries (they shall be sealed as described in design drawings, all openings foreseen for future uses

16.

are properly plugged).

Check that the earthing system is connected to earthing network and that the terminal on the equipment is well

17.

tightened.

18. Measure the insulation resistance of current transformers (see next page).

19. Check that Eventual defects/abnormalities have been entered in the Project Punch List.

20. Check that the final documentation for QCP has been completed and signed off.

21. Check that all modifications have been highlighted on the “Master Copy” drawings (as built).

P.1/2 Mod. ITR-EW-04A/0

PROJECT Report No:

CLIENT

(Partner (Client Logo)

Logo) INSPECTION TEST REPORT Date:

Checks of Electrical Equipment

Ready for Precommissioning

22. Measure insulation resistance of bus-bars. Ambient Temperature: …....ºC

Insulation Resistance of bus-bars (Ohm)

Bus-bars Deviation

UΣT,V,W VΣT,U,W WΣT,U,V

I

II

III

IV

Note: The insulation resistance of bus-bars is measured by means of a Megger applying a voltage ……..…..Vcc for one minute. All other bus-bars

shall be short-circuited and connected to Plant earthing network.

Remarks:

C = Conformance; NC = Non Conformance; NA = Not Applicable;

Conform

Test Instrument Used:

Not Conform – Report n°: Tag n°:

INSPECTORS SUBCONTRACTOR CONTRACTOR CLIENT AUTHORITY (if any)

Name:

Signature:

Date:

The information included in this document and any attachments are confidential and may also be privileged. Document and any attachments are property of ABB

SpA.: theirs reproduction, circulation and use without prior consent are forbidden.

P.2/2 Mod. ITR-EW-04A/0

You might also like

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 3.5 out of 5 stars3.5/5 (3)

- Itr Ew 01a - EngDocument2 pagesItr Ew 01a - Engwassim nasriNo ratings yet

- Itr Ew 07a - EngDocument1 pageItr Ew 07a - Engwassim nasriNo ratings yet

- Itr Ew 05a - EngDocument1 pageItr Ew 05a - Engwassim nasriNo ratings yet

- Current TransformerDocument12 pagesCurrent TransformerSyed AbbasNo ratings yet

- Surge Arrestor Commissioning ChecklistDocument7 pagesSurge Arrestor Commissioning ChecklistSyed Abbas100% (1)

- E019 MV Breaker Function TestDocument10 pagesE019 MV Breaker Function TestMusab ShabbirNo ratings yet

- Box Up All Lighting CircuitDocument2 pagesBox Up All Lighting CircuitHafiz YunusNo ratings yet

- Itr Ew 03b HV MV SwitchboardDocument6 pagesItr Ew 03b HV MV SwitchboardmatrengNo ratings yet

- 04.1 - Test Format For MV Switchgear (PCT-01)Document2 pages04.1 - Test Format For MV Switchgear (PCT-01)Gajendran SriramNo ratings yet

- CL-NG-6460-002-023 Checklist For CT Rev01Document5 pagesCL-NG-6460-002-023 Checklist For CT Rev01sachin francisNo ratings yet

- Potential TransformerDocument8 pagesPotential TransformerSyed AbbasNo ratings yet

- Check List For Pre Commissioning of MV SwitchgearDocument2 pagesCheck List For Pre Commissioning of MV Switchgeararuna100% (9)

- Electrical ConduitingDocument1 pageElectrical ConduitingGabriel GabeNo ratings yet

- QC-143 R2 Distribution Panel ChecklistDocument1 pageQC-143 R2 Distribution Panel ChecklistCamilo Jorquera100% (1)

- Low Voltage Switchboard Inspection Test RecordDocument3 pagesLow Voltage Switchboard Inspection Test RecordAmyNo ratings yet

- E 001B1 MotorDocument2 pagesE 001B1 MotorBhihi RajaNo ratings yet

- 9 LorDocument2 pages9 LorThameemul BuhariNo ratings yet

- Standard Check List: NTPC TelanganaDocument4 pagesStandard Check List: NTPC TelanganaVikrant DeshmukhNo ratings yet

- ElectroMechanical Completion-INTRINSICALLY SAFE (IS) - System Check ListDocument2 pagesElectroMechanical Completion-INTRINSICALLY SAFE (IS) - System Check Listhuseyinyuksel1903No ratings yet

- Electrica QC Check ListDocument21 pagesElectrica QC Check Listmakana qc100% (1)

- Checklist For Commissioning of CCTV SystemDocument2 pagesChecklist For Commissioning of CCTV Systemnsadnan70% (10)

- Sheet 1 of 1 Rev 1 Equipment Grounding Installation and Connection ChecklistDocument1 pageSheet 1 of 1 Rev 1 Equipment Grounding Installation and Connection ChecklistnayumNo ratings yet

- Auxiliary Contactors Test FormatDocument1 pageAuxiliary Contactors Test FormatHumayun Ahsan100% (1)

- ElectroMechanical Completion-PRE INSTALLATION-INSTRUMENT INSPECTIONDocument1 pageElectroMechanical Completion-PRE INSTALLATION-INSTRUMENT INSPECTIONhuseyinyuksel1903No ratings yet

- IGCC-OPM-QUA-FMT-0105 Rev.0 - FLOODLIGHT-ROAD AND COLUMN MOUNTED LIGHTING INSTALLATIONDocument2 pagesIGCC-OPM-QUA-FMT-0105 Rev.0 - FLOODLIGHT-ROAD AND COLUMN MOUNTED LIGHTING INSTALLATIONAhmedNo ratings yet

- Checklist For T&C of CCTV SystemDocument2 pagesChecklist For T&C of CCTV Systemsheb_khaleelNo ratings yet

- Construction Check Sheet Control & Relay Panel E-025A: ElectricalDocument1 pageConstruction Check Sheet Control & Relay Panel E-025A: ElectricalhrimklimNo ratings yet

- Sheath Test FormatDocument5 pagesSheath Test FormatAhmed FaragNo ratings yet

- Epcc MBC Pilot Plant Skid For Tgast-Electrical & Instrumentation WorksDocument11 pagesEpcc MBC Pilot Plant Skid For Tgast-Electrical & Instrumentation Workssaffririzal4237No ratings yet

- SEC-EOA Site Test ReportDocument9 pagesSEC-EOA Site Test ReportmaheshknmNo ratings yet

- Inspection and Test Program: Fabrication / In-Process InspectionDocument10 pagesInspection and Test Program: Fabrication / In-Process InspectionGLEDSONNo ratings yet

- Oper Epc NGRDocument3 pagesOper Epc NGRarief bayuNo ratings yet

- Dammam Housing 115/13.8KV Substation #1 Site Test ReportDocument1 pageDammam Housing 115/13.8KV Substation #1 Site Test ReportjayabalNo ratings yet

- LG Energy Test. RM3Document5 pagesLG Energy Test. RM3salmanNo ratings yet

- Epic For Upgradation of Ac Ups Units in Ngl3, Mesaieed: Title: Ups Installation ChecklistDocument1 pageEpic For Upgradation of Ac Ups Units in Ngl3, Mesaieed: Title: Ups Installation ChecklistmeeNo ratings yet

- MDB Commissioning ChecklistDocument3 pagesMDB Commissioning ChecklistifranNo ratings yet

- Report For Routine Verification (Routine Test Report) : Power Switchgear and Controlgear AssemblyDocument3 pagesReport For Routine Verification (Routine Test Report) : Power Switchgear and Controlgear AssemblywaqarNo ratings yet

- Surge ArresterDocument3 pagesSurge Arresterوليد موسىNo ratings yet

- Binh Nguyen Solar Power Plant Electrical System ITPDocument184 pagesBinh Nguyen Solar Power Plant Electrical System ITPbinhnguyen dmtNo ratings yet

- Itr FoDocument6 pagesItr Fomasmus208No ratings yet

- ITR-A E Gas Turbine GeneratorDocument1 pageITR-A E Gas Turbine GeneratorMomo ItachiNo ratings yet

- Instrument Commissioning Checklist PDFDocument9 pagesInstrument Commissioning Checklist PDFBrijesh Srivastav100% (1)

- Instrumentation Switch ChecklistDocument9 pagesInstrumentation Switch ChecklistIñaki EseberriNo ratings yet

- Instrument Check List PDFDocument9 pagesInstrument Check List PDFIgor PaivaNo ratings yet

- 639-2017 - Forms (ITP)Document9 pages639-2017 - Forms (ITP)george stanley paceteNo ratings yet

- Instrumentation Switch ChecklistDocument9 pagesInstrumentation Switch ChecklistAli Mukhtar ShigriNo ratings yet

- Instrumentation Loop ChecklistDocument9 pagesInstrumentation Loop ChecklistHarold David Gil MuñozNo ratings yet

- Instrumentation Switch ChecklistDocument9 pagesInstrumentation Switch Checklistgeorge stanley paceteNo ratings yet

- Instrument Check List PDFDocument9 pagesInstrument Check List PDFBrijesh Srivastav100% (1)

- Pre-Post Energization ListDocument1 pagePre-Post Energization ListnomuNo ratings yet

- Inspection and Test Plan: Fabrication / In-Process InspectionDocument17 pagesInspection and Test Plan: Fabrication / In-Process InspectionGLEDSON100% (1)

- 5.avr Relay Tapcon260Document9 pages5.avr Relay Tapcon260jayabalNo ratings yet

- Instrument Check List: CJX00 - MiscellaneousDocument2 pagesInstrument Check List: CJX00 - MiscellaneousogyriskyNo ratings yet

- Site Test Report Ng-Sa Name of Substation: Dammam Housing 115/13.8KV Substation # 1Document21 pagesSite Test Report Ng-Sa Name of Substation: Dammam Housing 115/13.8KV Substation # 1Jayabal GnanaprakasamNo ratings yet

- Bus Duct Installation ChecklistDocument3 pagesBus Duct Installation ChecklistgaladrialNo ratings yet

- DISCONNECT&GROUNDING SWITCHEsDocument5 pagesDISCONNECT&GROUNDING SWITCHEsShady NasrNo ratings yet

- Periodic Inspection Report For An Electrical Installation: A. Details of The ClientDocument6 pagesPeriodic Inspection Report For An Electrical Installation: A. Details of The ClientAzizul KhanNo ratings yet

- Alfanar Co.: Site Test Report Sec-Eoa Name of Substation: Dammam Housing 115/13.8KV Substation # 1Document7 pagesAlfanar Co.: Site Test Report Sec-Eoa Name of Substation: Dammam Housing 115/13.8KV Substation # 1Jayabal GnanaprakasamNo ratings yet

- Ceri-Abb-Qua-0344 For Work Method Statement Steel Structure Painting & Repair Rev 000Document1 pageCeri-Abb-Qua-0344 For Work Method Statement Steel Structure Painting & Repair Rev 000wassim nasriNo ratings yet

- Fire Proofing Revised Procedure - C02Document47 pagesFire Proofing Revised Procedure - C02wassim nasriNo ratings yet

- Itr Ew 04a - EngDocument2 pagesItr Ew 04a - Engwassim nasriNo ratings yet

- Itr Ew 04a - EngDocument2 pagesItr Ew 04a - Engwassim nasriNo ratings yet

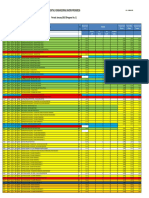

- Overall Progress No.1 CommentedDocument1 pageOverall Progress No.1 Commentedwassim nasriNo ratings yet

- L4 22Document41 pagesL4 22wassim nasriNo ratings yet

- Progress No 1 Last Revision Commented and ApprovedDocument10 pagesProgress No 1 Last Revision Commented and Approvedwassim nasriNo ratings yet

- Engineering Progress CommentedDocument5 pagesEngineering Progress Commentedwassim nasriNo ratings yet

- Cable Lugs & Connectors Price in US DollarDocument5 pagesCable Lugs & Connectors Price in US Dollarwassim nasriNo ratings yet

- Technical Insulation Heavy Duty Wired MatDocument2 pagesTechnical Insulation Heavy Duty Wired Matwassim nasriNo ratings yet

- DIO - Final Form of UNINCORPORATED CONTRACT (Schedules) - REDACTED PDFDocument256 pagesDIO - Final Form of UNINCORPORATED CONTRACT (Schedules) - REDACTED PDFanisthabetNo ratings yet

- Rewiring & Special Duty Capabalities, SiteDocument18 pagesRewiring & Special Duty Capabalities, SiteMAHESH VNo ratings yet

- SL Light Series OverviewDocument63 pagesSL Light Series OverviewMuresan AdrianNo ratings yet

- Method Statement For Installation and Testing of Control CablesDocument17 pagesMethod Statement For Installation and Testing of Control CablesJohn ArvieNo ratings yet

- UT511 Insulation Tester User ManualDocument30 pagesUT511 Insulation Tester User ManualEynar Camilo DavidNo ratings yet

- OHLDocument106 pagesOHLvaithy1990No ratings yet

- Isolators/Grounding Switches Data Sheets 110 KV Ab SwitchesDocument10 pagesIsolators/Grounding Switches Data Sheets 110 KV Ab SwitchesAnonymous MDkp0hnb3lNo ratings yet

- GL-01-EHS-019 Guidelines On Electrical SafetyDocument12 pagesGL-01-EHS-019 Guidelines On Electrical SafetyClarabelle Mae Dela RosaNo ratings yet

- Technical Data Sheet - 250kva TransformersDocument2 pagesTechnical Data Sheet - 250kva TransformerspavanNo ratings yet

- Electrical Safety: Assignment No. 10Document21 pagesElectrical Safety: Assignment No. 10waqashabib100% (1)

- Testing of InsulatorDocument15 pagesTesting of Insulatorela81No ratings yet

- High Voltage Engineering: Causes of Over Voltage in Power SystemDocument8 pagesHigh Voltage Engineering: Causes of Over Voltage in Power SystemMohammed Sabeel KinggNo ratings yet

- Prisma Plus and IEC 61439-1-2Document8 pagesPrisma Plus and IEC 61439-1-2FrancisautomacaoNo ratings yet

- HV cable test report summaryDocument2 pagesHV cable test report summarymahesh thoreNo ratings yet

- Transformer Bushings PDFDocument28 pagesTransformer Bushings PDFSaravananSelvarajNo ratings yet

- Designation Codes for Harmonized CablesDocument7 pagesDesignation Codes for Harmonized Cablesvinayak.khorate2707No ratings yet

- Govt. of India - Central Electricity Authority - MOMDocument188 pagesGovt. of India - Central Electricity Authority - MOMChandrakant ChandanNo ratings yet

- PDP42V18HADocument77 pagesPDP42V18HAbobju14No ratings yet

- NF C33-042 2013 - AnchoringDocument16 pagesNF C33-042 2013 - AnchoringPalani Jayaraman100% (1)

- Technical Specs for Instrument CablesDocument24 pagesTechnical Specs for Instrument CableskarimNo ratings yet

- Sheehan 06 PDFDocument8 pagesSheehan 06 PDFpalani.djpNo ratings yet

- List Price W.E.F. 13th June, 2020: (Higher Current Carrying Capacity)Document8 pagesList Price W.E.F. 13th June, 2020: (Higher Current Carrying Capacity)raviNo ratings yet

- Sony Dsrl-A700 Level 2Document118 pagesSony Dsrl-A700 Level 2nikola1660No ratings yet

- Manual Simoreg DC MasterDocument616 pagesManual Simoreg DC MasterThiago MouttinhoNo ratings yet

- Power System Analysis 1Document4 pagesPower System Analysis 1John Louie NocheNo ratings yet

- CONDUCTORSDocument79 pagesCONDUCTORSniloNo ratings yet

- S Aaa Cab Inst MV (Rev.0 2015)Document19 pagesS Aaa Cab Inst MV (Rev.0 2015)AAK AlAinNo ratings yet

- Tesla Transformer Based 500 KV Pulser For Low Emittance Test Stand at Paul Scherrer InstituteDocument6 pagesTesla Transformer Based 500 KV Pulser For Low Emittance Test Stand at Paul Scherrer InstituteSushant ChhotrayNo ratings yet

- Paris, L - Influence of Air Gap Characteristics On Line-To-Ground Switching Surge StrengthDocument12 pagesParis, L - Influence of Air Gap Characteristics On Line-To-Ground Switching Surge Strengthrogeriojuruaia100% (1)

- Interpretation of Sweep Frequency Response AnalysiDocument8 pagesInterpretation of Sweep Frequency Response AnalysiRyan JohnNo ratings yet

- Combined Searchable Employer Requirement)Document389 pagesCombined Searchable Employer Requirement)Ahmad ButtNo ratings yet