Professional Documents

Culture Documents

Pile Instalation Methods 2

Uploaded by

Bright MuzaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pile Instalation Methods 2

Uploaded by

Bright MuzaCopyright:

Available Formats

PILE INSTALATION METHODS

8.1 Introduction

The installation process and method of installations are equally important

factors as of the design process of pile foundations. In this section we will

discuss the two main types of pile installation methods; installation by pile

hammer and boring by mechanical auger.

In order to avoid damages to the piles, during design, installation Methods

and installation equipment should be carefully selected.

If installation is to be carried out using pile-hammer, then the following

factors should be taken in to consideration

the si!e and the weight of the pile

the driving resistance which has to be overcome to achieve

the design penetration

the available space and head room on the site

the availability of cranes and

the noise restrictions which may be in force in the locality.

8.2 Pile driving method !di"l#cement "ile$

Methods of pile driving can be categorised as follows

". #ropping weight

$. %&plosion

'. (ibration

). *acking +restricted to micro-pilling,

-. *etting

8.2.1 Drop hammers

. hammer with appro&imately the weight of the pile is raised a suitable

height in a guide and released to strike the pile head. This is a simple form

of hammer used in con/unction with light frames and test piling, where it

may be uneconomical to bring a steam boiler or compressor on to a site to

drive very limited number of piles.

There are two main types of drop hammers

0ingle-acting steam or compressed-air hammers

#ouble-acting pile hammers

". 0ingle-acting steam or compressed-air comprise a massive weight

in the form of a cylinder +see fig.1-",. 0team or compressed air

admitted to the cylinder raises it up the fi&ed piston rod. .t the top of

the stroke, or at a lesser height which can be controlled by the

operator, the steam is cut off and the cylinder falls freely on the pile

helmet.

$. #ouble-acting pile hammers can be driven by steam or compressed

air. . pilling frame is not required with this type of hammer which can

be attached to the top of the pile by leg-guides, the pile being guided

by a timber framework. 2hen used with a pile frame, back guides

are bolted to the hammer to engage with leaders, and only short leg-

guides are used to prevent the hammer from moving relatively to the

top of the pile. #ouble-acting hammers are used mainly for sheet

pile driving.

Figure 8-1 Pile driving using hammer

8.2.2 Diesel hammers

.lso classified as single and double-acting, in operation, the diesel hammer

employs a ram which is raised by e&plosion at the base of a cylinder.

.lternatively, in the case of double-acting diesel hammer, a vacuum is

created in a separate annular chamber as the ram moves upward, and

assists in the return of the ram, almost doubling the output of the hammer

over the single-acting type. In favourable ground conditions, the diesel

hammer provide an efficient pile driving capacity, but they are not effective

for all types of ground.

8.2.3 Pile driving by vibrating

(ibratory hammers are usually electrically powered or hydraulically

powered and consists of contra-rotating eccentric masses within a housing

attaching to the pile head. The amplitude of the vibration is sufficient to

break down the skin friction on the sides of the pile. (ibratory methods are

best suited to sandy or gravelly soil.

%etting to aid the penetration of piles in to sand or sandy gravel, water

/etting may be employed. 3owever, the method has very limited effect in

firm to stiff clays or any soil containing much coarse gravel, cobbles, or

boulders.

8.& 'oring method ! non(di"l#cement "ile$

8.3.1 Continuous Flight Auger (CFA)

.n equipment comprises of a mobile base carrier fitted with a hollow-

stemmed flight auger which is rotated into the ground to required depth of

pilling. To form the pile, concrete is placed through the flight auger as it is

withdrawn from the ground. The auger is fitted with protective cap on the

outlet at the base of the central tube and is rotated into the ground by the

top mounted rotary hydraulic motor which runs on a carrier attached to the

mast. 4n reaching the required depth, highly workable concrete is pumped

through the hollow stem of the auger, and under the pressure of the

concrete the protective cap is detached. 2hile rotating the auger in the

same direction as during the boring stage, the spoil is e&pelled vertically as

the auger is withdrawn and the pile is formed by filling with concrete. In this

process, it is important that rotation of the auger and flow of concrete is

matched that collapse of sides of the hole above concrete on lower flight of

auger is avoided. This may lead to voids in filled with soil in concrete.

The method is especially effective on soft ground and enables to install a

variety of bored piles of various diameters that are able to penetrate a

multitude of soil conditions. 0till, for successful operation of rotary auger

the soil must be reasonably free of tree roots, cobbles, and boulders, and it

must be self-supporting.

#uring operation little soil is brought upwards by the auger that lateral

stresses is maintained in the soil and voiding or e&cessive loosening of the

soil minimise. 3owever, if the rotation of the auger and the advance of the

auger is not matched, resulting in removal of soil during drilling-possibly

leading to collapse of the side of the hole.

5igure 1-$ 65. 7rocess

8.3.2 nderreaming

. special feature of auger bored piles which is sometimes used to enable

to e&ploit the bearing capacity of suitable strata by providing an enlarged

base. The soil has to be capable of standing open unsupported to employ

this technique. 0tiff and to hard clays, such as the 8ondon clay, are ideal.

In its closed position, the underreaming tool is fitted inside the straight

section of a pile shaft, and then e&panded at the bottom of the pile to

produce the underream shown in fig. 1-'.9ormally, after installation and

before concrete is casted, a man carrying cage is lowered and the shaft

and the underream of the pile is inspected.

5igure 1 -' a,hydraulic rotary drilling equipment b, 6.5.., c,undrreaming tool

open position

8.3.3 C.!.D.P

5igure 1-), 6ontinuous helical displacement piles a short, hollow tapered

steel former complete with a larger diameter helical flange, the bullet head

is fi&ed to a hallow drill pipe which is connected to a high torque rotary

head running up and down the mast of a special rig. . hollow cylindrical

steel shaft sealed at the lower end by a one-way valve and fitted with

triangular steel fins is pressed into the ground by a hydraulic ram. There

are no vibrations.

#isplaced soil is compacted in front and around the shaft. 4nce it reaches

the a suitably resistant stratum the shaft is rotated. The triangular fins

either side of its leading edge carve out a conical base cavity. .t the same

time concrete is pumped down the centre of the shat and through the one-

way valve. :otation of the fins is calculated so that as soil is pushed away

from the pile base it is simultaneously replaced by in-flowing concrete.

:ates of push, rotation and concrete in/ection are all controlled by an

onboard computer. Torque on the shaft is also measured by the computer.

2hen torque levels reach a constant low value the base in formed. The

inventors claim that the system can install a; typical pile in "$ minute. .

typical <m long pile with an 1==mm diameter base and '-=mm shaft

founded on moderately dense gravel beneath soft overlaying soils can

achieve an ultimate capacity of over $==t. The pile is suitable for

embankments, hard standing supports and floor slabs, where you have a

soft silty layer over a gravel strata.

5igure 1 -) 6.3.#.7.

Back to Top

Copyright of the material in this suite of web pages belongs to the authors.

Last updated: May 13 1!!!.

LOAD TEST ON PILES

).1 Introduction

7ile load test are usually carried out that one or some of the following

reasons are fulfilled

To obtain back-figured soil data that will enable other piles to

be designed.

To confirm pile lengths and hence contract costs before the

client is committed to over all /ob costs.

To counter-check results from geotechnical and pile driving

formulae

To determine the load-settlement behaviour of a pile,

especially in the region of the anticipated working load that

the data can be used in prediction of group settlement.

To verify structural soundness of the pile.

Tet lo#ding There are four types of test loading

compression test

uplift test

lateral-load test

torsion-load test

the most common types of test loading procedures are 6onstant rate of

penetration +6:7, test and the maintained load test +M8T,.

".1.1 C#P ($onstant rate o% penetration)

In the 6:7 +constant rate of penetration, method, test pile is /acked into

the soil, the load being ad/usted to give constant rate of downward

movement to the pile. This is maintained until point of failure is reached.

5ailure of the pile is defined in to two ways that as the load at which the

pile continues to move downward without further increase in load, or

according to the >0, the load which the penetration reaches a value equal to

one-tenth of the diameter of the pile at the base.

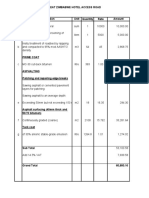

5ig.?-$, In the cases of where compression tests are being carried out,

the following methods are usually employed to apply the load or

downward force on the pile

. platform is constructed on the head of the pile on which a mass of

heavy material, termed @kentledge@ is placed. 4r a bridge, carried on

temporary supports, is constructed over the test pile and loaded with

kentledge. The ram of a hydraulic /ack, placed on the pile head, bears on

a cross-head beneath the bridge beams, so that a total reaction equal to

the weight of the bridge and its load may be obtained.

".1.2 &'() the maintained in$rement load test

5ig.?-", the maintained increment load test, kentledge or ad/acent tension

piles or soil anchors are used to provide a reaction for the test load

applied by /acking+s, placed over the pile being tested. The load is

increased in definite steps, and is sustained at each level of loading until

all settlements has either stop or does not e&ceed a specified amount of in

a certain given period of time.

5igure ?-" test load arrangement using kentledge

5igure ?-$ test being carried out

Back to Top

You might also like

- Methods of Piles InstallationDocument5 pagesMethods of Piles InstallationAsif KhanNo ratings yet

- Rock Blasting - A Practical Treatise On The Means Employed In Blasting Rocks For Industrial PurposesFrom EverandRock Blasting - A Practical Treatise On The Means Employed In Blasting Rocks For Industrial PurposesNo ratings yet

- STATIC LOAD TEST - การทดสอบการรับน้ำหนักของเสาเข็มDocument11 pagesSTATIC LOAD TEST - การทดสอบการรับน้ำหนักของเสาเข็มWilrutstien WilrutstienNo ratings yet

- Ultra-High Capacity Micropiles, Drilled Displacement Steel Piles & Expanded Base PilesDocument1 pageUltra-High Capacity Micropiles, Drilled Displacement Steel Piles & Expanded Base PilesAnonymous JZFSB3D0% (1)

- CBR TestDocument4 pagesCBR TestAtish Kumar100% (1)

- Specification For Pile EmbankmentDocument5 pagesSpecification For Pile EmbankmentamirriyyahNo ratings yet

- SW Juntas CwsDocument5 pagesSW Juntas CwsflylilaNo ratings yet

- A Lecture Notes 2012 Dda2132 CHP 3b Pile TestDocument13 pagesA Lecture Notes 2012 Dda2132 CHP 3b Pile Testmkpasha55mpNo ratings yet

- Plant & Guide Wall ConstructionDocument10 pagesPlant & Guide Wall ConstructionAnonymous S7Cq7ZDgPNo ratings yet

- Rapid Load Testing of Foundation Piles in Barcelona:: IssueDocument5 pagesRapid Load Testing of Foundation Piles in Barcelona:: IssuebozarromegustaNo ratings yet

- Static Pile Load Test - (Kuliah-3)Document4 pagesStatic Pile Load Test - (Kuliah-3)banuardiNo ratings yet

- Method Statement of Crossing Box CulvertDocument2 pagesMethod Statement of Crossing Box CulvertNur EmalinNo ratings yet

- Method Statement For Sheet PilingDocument8 pagesMethod Statement For Sheet PilingAbdul Muneer PalapraNo ratings yet

- Method Statement For Bored Pile at RB 012, Temoh - Sg. Lesong (CH 226.000)Document11 pagesMethod Statement For Bored Pile at RB 012, Temoh - Sg. Lesong (CH 226.000)MAYMODERN STEEL100% (1)

- Boiling or Heaving in CofferdamsDocument2 pagesBoiling or Heaving in Cofferdamsslawek780303No ratings yet

- A Parametric Study of Wall Deflections in Deep Excavations With The Installation of Cross Walls PDFDocument11 pagesA Parametric Study of Wall Deflections in Deep Excavations With The Installation of Cross Walls PDFAhmed ArafaNo ratings yet

- PT. PAKUBUMI SEMESTA Bored Piling MethodDocument19 pagesPT. PAKUBUMI SEMESTA Bored Piling MethodjimdabrondNo ratings yet

- Yjack - Ms 20170211 - BD For Bp600mm Wl2827kn Tl5654knDocument56 pagesYjack - Ms 20170211 - BD For Bp600mm Wl2827kn Tl5654knKS Lee100% (1)

- Rock Bolting MethodologyDocument4 pagesRock Bolting Methodologykavi rajNo ratings yet

- Performance of Bored Piles Constructed Using Polymer Fluids: Lessons From European ExperienceDocument9 pagesPerformance of Bored Piles Constructed Using Polymer Fluids: Lessons From European ExperiencesandycastleNo ratings yet

- Load Testing SetupDocument23 pagesLoad Testing SetupWalid TahhanNo ratings yet

- Standard Penetration TestDocument21 pagesStandard Penetration TestVenkatesh ThumatiNo ratings yet

- Bored PilingDocument3 pagesBored PilingAdonis AlabiNo ratings yet

- Mackintosh Probe TestDocument11 pagesMackintosh Probe Testmoneesha sriNo ratings yet

- Check Dams SE-4: Description and PurposeDocument5 pagesCheck Dams SE-4: Description and PurposeAziz Khan KakarNo ratings yet

- Method Statement For Installation of Soil Nails With For Slope StabilizationDocument11 pagesMethod Statement For Installation of Soil Nails With For Slope StabilizationDelon Yau100% (2)

- Install Horizontal Drainage DrainsDocument3 pagesInstall Horizontal Drainage DrainsTaqiuddin MJNo ratings yet

- Termination Criteria of Piles Subjected To Axial Loading To Is StandardsDocument15 pagesTermination Criteria of Piles Subjected To Axial Loading To Is Standardssongkk100% (1)

- Ch06 Shallow FoundationsDocument26 pagesCh06 Shallow FoundationsVaibhav Sharma100% (1)

- Method Statement Horizontal DrainDocument1 pageMethod Statement Horizontal DrainAlsonChin100% (1)

- 0852-2216-5912 (TSEL), Bore Pile, Bore Pile Contractor, Bore Pile BatamDocument1 page0852-2216-5912 (TSEL), Bore Pile, Bore Pile Contractor, Bore Pile Batambore pile batamNo ratings yet

- High Impact Energy Dynamic Compaction applications for ground improvement and earthworksDocument10 pagesHigh Impact Energy Dynamic Compaction applications for ground improvement and earthworkssezaitanyoluNo ratings yet

- GEOTECHNIC 2 - Site InvestigationDocument14 pagesGEOTECHNIC 2 - Site InvestigationMohd Farhan Syazwan100% (1)

- Rebar Cage SuspensionDocument4 pagesRebar Cage SuspensionAnonymous S7Cq7ZDgPNo ratings yet

- Shallow Foundations (Rafts)Document15 pagesShallow Foundations (Rafts)bogdan tanasoiu100% (1)

- Rigid Inclusion StrengthDocument3 pagesRigid Inclusion StrengthFelicia LingNo ratings yet

- Method of Statement For Micropile 01Document7 pagesMethod of Statement For Micropile 01NedyHortetlNo ratings yet

- Application of Jet Grouting TechniquesDocument7 pagesApplication of Jet Grouting TechniqueskaistengineerNo ratings yet

- HK Soil Nail DesignDocument20 pagesHK Soil Nail DesignDaltonWong100% (1)

- CE8401 Construction Techniques and Practices Notes 3Document115 pagesCE8401 Construction Techniques and Practices Notes 3christi SNo ratings yet

- Pile ShoesDocument8 pagesPile ShoesfarahazuraNo ratings yet

- Comparison of CMC Rigid Inclusions and Deep FoundationsDocument10 pagesComparison of CMC Rigid Inclusions and Deep FoundationsAnonymous MklNL77No ratings yet

- MS For BoredDocument18 pagesMS For BoredsinlekmNo ratings yet

- Rock EmbankmentDocument8 pagesRock EmbankmentSuhaidi AliasNo ratings yet

- Improving Slope Stability TechniquesDocument34 pagesImproving Slope Stability TechniquesAbdul Rauf NoohaniNo ratings yet

- Dewatering For Tunnels and ShaftsDocument14 pagesDewatering For Tunnels and ShaftsDEBASIS BARMANNo ratings yet

- Joints in Concrete Pavement Technical PaperDocument22 pagesJoints in Concrete Pavement Technical Paperphyo_thar_1100% (1)

- Retaining WallDocument20 pagesRetaining WallCharlesNo ratings yet

- Pile Load Test MethodsDocument27 pagesPile Load Test MethodsVenancio Diomampo Jr.No ratings yet

- Pile Installation Methods - BhushanDocument36 pagesPile Installation Methods - BhushanBhushan1107No ratings yet

- Pile FoundationDocument16 pagesPile FoundationNikita Sheth100% (1)

- Pipe Jacking & Microtunnelling GuideDocument48 pagesPipe Jacking & Microtunnelling GuideHizbar ArsjadNo ratings yet

- Controlled Modulus Columns - C Plomteux & M LacazedieuDocument7 pagesControlled Modulus Columns - C Plomteux & M Lacazedieuvidyaranya_bNo ratings yet

- MS For Bored Pile Hacking and Pile Head Treatment RevisedDocument7 pagesMS For Bored Pile Hacking and Pile Head Treatment RevisedK H V V MADUSHANKA100% (1)

- Site Investigation and Field Tests PDFDocument51 pagesSite Investigation and Field Tests PDFMahmoud MansourNo ratings yet

- MokwaDocument403 pagesMokwaMUHAMMAD ALINo ratings yet

- 17 - Bored Piling Ch. Lis.Document19 pages17 - Bored Piling Ch. Lis.Dilhara WickramaarachchiNo ratings yet

- Buse - Proposed National Sports Academy Phase OneDocument3 pagesBuse - Proposed National Sports Academy Phase OneBright MuzaNo ratings yet

- Progress ReportDocument1 pageProgress ReportBright MuzaNo ratings yet

- BUQS 7022 - Lecture 2 - Construction Procurement Strategy - 2023 PDFDocument32 pagesBUQS 7022 - Lecture 2 - Construction Procurement Strategy - 2023 PDFBright MuzaNo ratings yet

- V62 P6.2-Text 2018-10Document33 pagesV62 P6.2-Text 2018-10Bright MuzaNo ratings yet

- Construction Law by John Uff - 12 EdDocument684 pagesConstruction Law by John Uff - 12 EdBright MuzaNo ratings yet

- Great Zimbabwe Hotel Access RoadDocument1 pageGreat Zimbabwe Hotel Access RoadBright MuzaNo ratings yet

- ERRP2 LOT E MasvingoDocument2 pagesERRP2 LOT E MasvingoBright MuzaNo ratings yet

- Machongwe-Risitu Priming Method StatementDocument9 pagesMachongwe-Risitu Priming Method StatementBright MuzaNo ratings yet

- Zvishavane Town Council Site VisitDocument4 pagesZvishavane Town Council Site VisitBright MuzaNo ratings yet

- Reinforced Concrete Wall Form Design ProgramDocument153 pagesReinforced Concrete Wall Form Design ProgramBright MuzaNo ratings yet

- Bus Stop Shed DrawingDocument1 pageBus Stop Shed DrawingBright MuzaNo ratings yet

- Masvingo Road Widening Project Site Meeting MinutesDocument3 pagesMasvingo Road Widening Project Site Meeting MinutesBright MuzaNo ratings yet

- Late Submission of Lab Results - Soil TechDocument1 pageLate Submission of Lab Results - Soil TechBright MuzaNo ratings yet

- Aicd Background Paper 14 Roads Sect Summary enDocument10 pagesAicd Background Paper 14 Roads Sect Summary enBright MuzaNo ratings yet

- ch12 PDFDocument30 pagesch12 PDFRadhika VeeralaNo ratings yet

- UNB Fredericton Tuition & Fees 2017-2018 Course Based Part Time StudentDocument1 pageUNB Fredericton Tuition & Fees 2017-2018 Course Based Part Time StudentBright MuzaNo ratings yet

- 231 Regent ST #302, Fredericton, NB E3B 3W8Document5 pages231 Regent ST #302, Fredericton, NB E3B 3W8Bright MuzaNo ratings yet

- Article ReviewDocument2 pagesArticle ReviewBright MuzaNo ratings yet

- Project Manager Resignation LetterDocument1 pageProject Manager Resignation LetterBright MuzaNo ratings yet

- 1 Ha Bean - 11 March 2014 - WebDocument1 page1 Ha Bean - 11 March 2014 - WebBright MuzaNo ratings yet

- Tomato Production Guideline 2014Document11 pagesTomato Production Guideline 2014Bright MuzaNo ratings yet

- Pump B 2nd Lift 1 and 1st Lift 2Document2 pagesPump B 2nd Lift 1 and 1st Lift 2Bright MuzaNo ratings yet

- Guidelines For Participant Consent and Debriefing FormsDocument4 pagesGuidelines For Participant Consent and Debriefing FormsBright MuzaNo ratings yet

- Concrete Casting - Pump Station ADocument13 pagesConcrete Casting - Pump Station ABright MuzaNo ratings yet

- Excavation QuantitiesDocument1 pageExcavation QuantitiesBright MuzaNo ratings yet

- Miracles The Great DebateDocument3 pagesMiracles The Great DebateBright MuzaNo ratings yet

- Debriefing FormDocument1 pageDebriefing FormBright MuzaNo ratings yet

- All Questions: Open Book ExaminationDocument3 pagesAll Questions: Open Book ExaminationBright Muza100% (1)

- TCW5202200505 Foundation Engineering DesignDocument5 pagesTCW5202200505 Foundation Engineering DesignBright MuzaNo ratings yet

- TCW5202200605 Foundation Engineering DesignDocument2 pagesTCW5202200605 Foundation Engineering DesignBright MuzaNo ratings yet

- D5G6 DatasheetDocument3 pagesD5G6 DatasheetchichedemorenoNo ratings yet

- A35769EDocument44 pagesA35769Ealsief1951No ratings yet

- ALEJDocument6 pagesALEJAlejandro OdinNo ratings yet

- Trabajo Fisica IDocument5 pagesTrabajo Fisica IMVAZ233No ratings yet

- Calculus and Analytical GeometryDocument8 pagesCalculus and Analytical Geometrynep llNo ratings yet

- Compilation of Random Problems From Various OlympiadsDocument4 pagesCompilation of Random Problems From Various OlympiadsaayamNo ratings yet

- Reservoir Engineering-1 Unit 1Document21 pagesReservoir Engineering-1 Unit 1PE9001 AarthiNo ratings yet

- Design Codes and StandardsDocument22 pagesDesign Codes and StandardsFederico.IoriNo ratings yet

- Microsoft Word: The Most Popular Word ProcessorDocument93 pagesMicrosoft Word: The Most Popular Word ProcessorNirmal KambojNo ratings yet

- Heredity and Genetics ExplainedDocument43 pagesHeredity and Genetics ExplainedNewsonNo ratings yet

- Niels Bohr Proposed The Bohr Model of The Atom in 1915. ... The Bohr Model Is ADocument3 pagesNiels Bohr Proposed The Bohr Model of The Atom in 1915. ... The Bohr Model Is AKatherineNo ratings yet

- Generation of High Voltages & CurrentsDocument79 pagesGeneration of High Voltages & CurrentshamzaNo ratings yet

- معوقات انتشار التجارة الإلكترونية في مجال تسويق وثائق التامين فى سوق التأمين المصرىDocument3 pagesمعوقات انتشار التجارة الإلكترونية في مجال تسويق وثائق التامين فى سوق التأمين المصرىIslam SiamNo ratings yet

- GMQ1M2 Week 1Document12 pagesGMQ1M2 Week 1Lerwin GaringaNo ratings yet

- Fundamental Part 1Document28 pagesFundamental Part 1Deev PokhrelNo ratings yet

- Power Wave I400: MIG, Pulsed-MIG, Flux-Cored, Metal-Cored, TIG (Lift Start Only)Document6 pagesPower Wave I400: MIG, Pulsed-MIG, Flux-Cored, Metal-Cored, TIG (Lift Start Only)nobamoNo ratings yet

- 3064 A CG Assignment-2Document57 pages3064 A CG Assignment-2nokexo6067No ratings yet

- Tower Crane Raft Design ReportDocument22 pagesTower Crane Raft Design ReportFranklyn Genove100% (4)

- Priority List JEEDocument3 pagesPriority List JEE6r5x5znb8bNo ratings yet

- Course Caterpillar c6 6 Engines Acert Technology BenefitsDocument34 pagesCourse Caterpillar c6 6 Engines Acert Technology BenefitsGanapati Hegde100% (9)

- Programs and ExamplesDocument346 pagesPrograms and Examplesali yousifzaiNo ratings yet

- Oracle Fusion Middle Ware Installation Guide For Oracle WebLogic Server 11g Release 1Document86 pagesOracle Fusion Middle Ware Installation Guide For Oracle WebLogic Server 11g Release 1EttoreNo ratings yet

- Specific Heat Capacity GLY11Document1 pageSpecific Heat Capacity GLY11Alyssa ColeNo ratings yet

- Mid exam-QPDocument3 pagesMid exam-QPaeronayakNo ratings yet

- ps08 sp12 PDFDocument8 pagesps08 sp12 PDFQ_TNo ratings yet

- Heart Failure Prediction Using ANNDocument13 pagesHeart Failure Prediction Using ANNSHIVANSH KASHYAP (RA2011003010988)No ratings yet

- Actuator BrochureDocument6 pagesActuator BrochureCarlos Ramirez100% (1)

- Learn 2D AutoCAD Commands in 40 CharactersDocument10 pagesLearn 2D AutoCAD Commands in 40 CharactersAnne SotalboNo ratings yet

- OutlineDocument88 pagesOutlineLorrayne Zhen T. CarabidoNo ratings yet

- Site Visit Form RF Antenna AdjustmentDocument8 pagesSite Visit Form RF Antenna AdjustmentazfahaidarNo ratings yet