Professional Documents

Culture Documents

992G Torqon Troubleshot

Uploaded by

lisahunCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

992G Torqon Troubleshot

Uploaded by

lisahunCopyright:

Available Formats

992G Wheel Loader AZX00001-UP (MACHINE) POWERED BY 3508B Engine(SEBP4013 - 47) - Documentation

1 of 9

Welcome: j210bat

Product: WHEEL LOADER

Model: 992G WHEEL LOADER AZX

Configuration: 992G Wheel Loader AZX00001-UP (MACHINE) POWERED BY

3508B Engine

Troubleshooting

992G Wheel Loader and 854G

Wheel Dozer Power Train

Media Number -SENR1347-08

Publication Date -01/07/2012

Date Updated -24/07/2012

i02775019

Torque Converter Troubleshooting

SMCS - 3101-035

992G Wheel Loader AZX00001-UP (MACHINE) POWERED BY 3508B Engine(SEBP4013 - 47) - Documentation

2 of 9

Illustration 1

Schematic for the transmission hydraulic control

(1) Number 2 clutch solenoid

(2) Number 3 clutch solenoid

(3) Priority valve

(4) Number 1 clutch solenoid

(5) Number 5 clutch solenoid

g00109831

992G Wheel Loader AZX00001-UP (MACHINE) POWERED BY 3508B Engine(SEBP4013 - 47) - Documentation

3 of 9

(6) Number 4 clutch solenoid

(7) Flow control orifice

(8) Lockup clutch solenoid valve (if equipped)

(9) Impeller clutch solenoid valve

(10) Slug

(11) Torque converter inlet ratio valve

(12) Slug

(13) Modulating relief valve

(14) Direction selection spool

(15) Torque converter

(16) Lockup clutch (if equipped)

(17) Impeller clutch

(18) Selector spool for first speed and for third speed

(19) Pressure differential valve

(20) Load piston

(21) Flow control orifice

(22) Selector spool for second speed

(23) Transmission oil filter

(24) Transmission oil filter

(25) Flow control orifice

(26) Oil pump

(27) Torque converter outlet relief valve

(28) Oil cooler

(29) Magnetic Screen

(30) Lubrication passage for transmission

(31) Reservoir

(32) Reservoir

(A) Oil pump output pressure tap

(B) Pump pressure tap

(C) Pressure tap for lockup clutch (if equipped)

(D) Inlet pressure tap for the torque converter P3

(E) Speed clutch pressure tap P1

(F) Pressure tap for impeller clutch

(G) Direction clutch pressure tap P2

(H) Pump pressure tap

992G Wheel Loader AZX00001-UP (MACHINE) POWERED BY 3508B Engine(SEBP4013 - 47) - Documentation

4 of 9

(I) Torque converter outlet pressure tap

(J) Transmission lubrication pressure tap

Personal injury or death can result from sudden machine movement.

Sudden movement of the machine can cause injury to persons on or

near the machine.

To prevent injury or death, make sure that the area around the machine

is clear of personnel and obstructions before operating the machine.

Personal injury can result from hydraulic oil pressure and hot oil.

Hydraulic oil pressure can remain in the hydraulic system after the

engine has been stopped. Serious injury can be caused if this pressure is

not released before any service is done on the hydraulic system.

Make sure all of the attachments have been lowered, oil is cool before

removing any components or lines. Remove the oil filler cap only when

the engine is stopped, and the filler cap is cool enough to touch with

your bare hand.

Escaping fluid under pressure, even a pinhole size leak, can penetrate

body tissue, causing serious injury, and possible death. If fluid is

injected into your skin, it must be treated immediately by a doctor

familiar with this type of injury.

Always use a board or cardboard when checking for a leak.

NOTICE

Care must be taken to ensure that fluids are contained during

performance of inspection, maintenance, testing, adjusting and repair

of the product. Be prepared to collect the fluid with suitable containers

before opening any compartment or disassembling any component

containing fluids.

Refer to Special Publication, NENG2500, "Caterpillar Dealer Service

992G Wheel Loader AZX00001-UP (MACHINE) POWERED BY 3508B Engine(SEBP4013 - 47) - Documentation

5 of 9

Tool Catalog" for tools and supplies suitable to collect and contain

fluids on Caterpillar products.

Dispose of all fluids according to local regulations and mandates.

Operational Checks

Note: Operate the machine in each direction and in all speeds. Note the noises that are not normal and

find the sources of the noises. If the machine is not operating correctly, refer to the "Troubleshooting

Problem List" below.

Troubleshooting Problem List

Torque converter pressure is high.

Torque converter pressure is low.

The torque converter overheats.

The torque converter does not respond correctly for the left service brake pedal.

The lockup clutch does not engage.

The lockup clutch engages intermittently.

The impeller clutch does not engage.

Troubleshooting

Note: In the following section, when components are referenced with a number, refer to the schematic in

1.

Use the built-in electrical diagnostics that are performed with the Vital Information Management System

(VIMS) or Vital Information Display System (VIDS) and with the electronic control module in order to

determine the service codes for the power train electronic control module.

Note: This machine is equipped with a power train electronic control. The power train electronic control

has built-in system diagnostics that detect faults in the electronic system of the power train.

ReferenceFor additional information on the operation of the power train electronic control module

(ECM) and troubleshooting the power train ECM, refer to the Service Manual module for Systems

Operation, Testing and Adjusting, "Power Train Electronic Control System" for the machine that is being

serviced.

ReferenceFor additional information on troubleshooting the power train electronic control module

(ECM), refer to the Service Manual Module Systems Operation, Testing and Adjusting, SENR6059,

"Vital Information Management System (VIMS)" or Systems Operation, Testing and Adjusting,

RENR6318, "Vital Information Management System (VIMS)" for VIMS diagnostic procedures.

ReferenceFor additional information on troubleshooting the power train electronic control module

(ECM), refer to the Service Manual Module Service Manual, SENR1371, "Vital Information Display

992G Wheel Loader AZX00001-UP (MACHINE) POWERED BY 3508B Engine(SEBP4013 - 47) - Documentation

6 of 9

System (VIDS)" for VIDS diagnostic procedures.

Probable Causes of Problems in the Torque Converter

Torque converter pressure is high

Probable causes

1. There is a restriction inside the torque converter.

2. There is a restriction in an oil passage or in the oil cooler.

3. Torque converter inlet ratio valve (11) is stuck in the closed position.

Torque converter pressure is low

Probable causes

1. Torque converter inlet ratio valve (11) is stuck in the open position.

2. Adjustment of torque converter outlet relief valve (27) is not correct.

3. The valve spool in torque converter outlet relief valve (27) does not move.

4. Pump flow or oil pressure is low. This may be caused by any of the following conditions:

a. The oil level is low.

b. There is a restriction in the oil flow circuit or a dirty oil strainer.

c. Oil pump failure.

d. Air leaks on the inlet side of the pump.

e. Leakage inside the transmission (worn seals around the clutch piston)

f. Modulating relief valve (13) is stuck open.

The torque converter overheats

Probable causes

1. The machine is being used for the wrong application. There is too much torque converter slip,

which is caused by too much load.

2. Incorrect transmission gear is being used for the load that is on the machine. Shift to a lower gear.

3. The oil level in the transfer gear case is incorrectly high or low.

4. The coolant level in the engine radiator is low.

5. The oil cooler or oil lines are restricted.

992G Wheel Loader AZX00001-UP (MACHINE) POWERED BY 3508B Engine(SEBP4013 - 47) - Documentation

7 of 9

6. Oil flow through the torque converter is too low. This may be caused by any of the following

conditions:

a. The torque converter inlet ratio valve (11) is bypassing too much oil flow.

b. Pump flow or oil pressure is low. Refer to the Problem: Torque converter pressure is low.

The torque converter does not respond correctly to the left service brake pedal

Probable causes

1. The torque converter is in the mode for reduced rimpull (if equipped). This changes the response of

the left service brake pedal.

2. The sensor for the left service brake pedal is calibrated incorrectly.

3. The left service brake pedal position sensor is faulty.

4. The impeller clutch solenoid or the impeller clutch solenoid valve is faulty.

5. There is a problem in the electrical circuit.

The lockup clutch does not engage

Probable causes

1. The on/off switch for the lockup clutch is not in the ON position.

2. The on/off switch for the lockup clutch is faulty.

3. The lockup clutch solenoid or the lockup clutch solenoid valve is faulty.

4. There is a problem in the electrical circuit.

The lockup clutch engages intermittently.

Probable causes

1. Erratic signals from the engine speed sensor or the torque converter speed sensor can cause the

lockup clutch in the torque converter to cycle on and off when the lockup clutch is enabled.

The impeller clutch does not engage

Probable causes

1. The impeller clutch solenoid or the impeller clutch solenoid valve is faulty.

2. There is a problem in the electrical circuit.

Troubleshooting the Calibration of the Impeller Clutch

992G Wheel Loader AZX00001-UP (MACHINE) POWERED BY 3508B Engine(SEBP4013 - 47) - Documentation

8 of 9

The calibration of the impeller clutch can generate error messages if a problem is encountered during

calibration. The following information is used to aid in troubleshooting the problem that was based on the

error message.

Table 1

Troubleshooting Information for the Calibration of the Impeller Clutch

Error Message

Torque converter output

speed is low.

Probable Causes

Engine speed is too

low.

Use the throttle lock to set the engine speed

above the following minimum values:

2050 rpm ( 988G, 834G, 836G)

1650 rpm (992G,994D,854G)

Speed sensor problem

Check for fault codes on the torque converter

output speed sensor.

Check the sensor connector.

Adjust or replace the sensor, if necessary.

Check valve function.

Check the connector.

Impeller clutch pressure

Check ECM output.

is too low.

Check the converter for excessive leakage in the

circuit for the impeller clutch.

Damaged impeller

clutch

Check transmission screens.

Inspect the impeller clutch.

Excessive drag in

transmission

Check transmission screens.

Inspect the impeller clutch.

Speed sensor problem

Torque converter output

speed is high.

Engine speed is too

high.

Speed sensor problem

The speed change of the

torque converter is in the

low range.

Possible Corrective Actions

Check for fault codes on the torque converter

output speed sensor.

Check the sensor connector.

Adjust or replace the sensor, if necessary.

Adjust the engine high idle speed.

Check for fault codes on the torque converter

output speed sensor

Check the sensor connector.

Adjust or replace the sensor, if necessary.

Check valve function.

Check the solenoid connector.

Impeller clutch pressure

Check ECM output.

is too low.

Check the converter for excessive leakage in the

circuit for the impeller clutch.

Drag in the lockup

clutch.

Check for residual pressure in the circuit for the

lockup clutch.

Check the screens in the transmission for

material from the clutch.

992G Wheel Loader AZX00001-UP (MACHINE) POWERED BY 3508B Engine(SEBP4013 - 47) - Documentation

Inspect the lockup clutch for damaged discs or

damaged plates.

If the lockup clutch has new discs, operate the

machine and engage the lockup clutch several

times. Repeat the calibration.

Excessive drag in the

transmission

Holding pressure is too

high.

Check valve function.

Check the solenoid connector.

Check the ECM output.

Check the converter for excessive leakage in the

Impeller clutch pressure

circuit of the impeller clutch.

is out of tolerance.

Check for high torque converter inlet pressures

and outlet pressures.

Check the PTO system which is downstream of

the converter for restrictions.

Holding pressure is too

low.

Check valve function.

Impeller clutch pressure

Check the solenoid connector.

is out of tolerance.

Check ECM output.

Holding pressure

inconsistent

Check valve function.

Check the solenoid connector.

Impeller clutch pressure

Check ECM output.

is not responding

Check the converter for excessive leakage in the

properly.

circuit of the impeller clutch.

Check the transmission screens for debris.

Copyright 1993 - 2014 Caterpillar Inc.

All Rights Reserved.

Private Network For SIS Licensees.

9 of 9

Check the screens in the transmission for

material from the clutch.

Inspect the transmission for warped direction

clutches or damaged direction clutches.

Fri May 09 2014 10:26:59 GMT+0700 (SE Asia Standard Time)

j210bat

You might also like

- Torque Converter TroubleshootingDocument12 pagesTorque Converter Troubleshootingzawmoe aungNo ratings yet

- 962g Trans Clutch CalibrateDocument8 pages962g Trans Clutch Calibrateluis eduardo corzo enriquez100% (1)

- Test de Presiones de Transmision 938g2Document12 pagesTest de Presiones de Transmision 938g2cristian chuquicondor torres100% (2)

- 938 Pressures - Test and AdjustDocument12 pages938 Pressures - Test and AdjustFaginawati CuteNo ratings yet

- Power Train Troubleshooting: Essai Et RéglageDocument15 pagesPower Train Troubleshooting: Essai Et RéglageAly AbdelhamedNo ratings yet

- Transmission Pressures - Test and AdjustDocument8 pagesTransmission Pressures - Test and Adjustjuankielec100% (3)

- Valvula de CargaDocument9 pagesValvula de CargaUlises BarreraNo ratings yet

- Troubleshooting 966H WL POWERTRAINDocument12 pagesTroubleshooting 966H WL POWERTRAINAhmet100% (1)

- CATERPILLAR Calibracion de TransmisionDocument6 pagesCATERPILLAR Calibracion de TransmisionJUAN CARLOS PAZ67% (3)

- Techdoc Print Page TEST TRANSMISSIONDocument11 pagesTechdoc Print Page TEST TRANSMISSIONtyok sajaNo ratings yet

- Location of Pressure TapsDocument4 pagesLocation of Pressure TapsAbdellatef BakrNo ratings yet

- Presiones Transmision R1300GDocument12 pagesPresiones Transmision R1300GgeniusnetxxxxNo ratings yet

- Pilot Pressure To The Main Control Valve - CheckDocument8 pagesPilot Pressure To The Main Control Valve - CheckMiguel Angel Moreno100% (8)

- 938F 7SN Wheel Loader and It38f Integrated Toolcarrier Power TrainDocument23 pages938F 7SN Wheel Loader and It38f Integrated Toolcarrier Power Trainale aleNo ratings yet

- Testing and Adjusting: Troubleshooting The Transmission Hydraulic SystemDocument21 pagesTesting and Adjusting: Troubleshooting The Transmission Hydraulic Systemlin koNo ratings yet

- 789C Prueba de Calado ConvertidorDocument5 pages789C Prueba de Calado ConvertidorSergio Velarde Romay100% (1)

- Piot Valve Control Stering Press Test AdjustDocument5 pagesPiot Valve Control Stering Press Test AdjustDidi PrawiraNo ratings yet

- Prueba y Ajuste Presion de Valvula de Salida de ConvertidorDocument5 pagesPrueba y Ajuste Presion de Valvula de Salida de ConvertidorguayanecitroNo ratings yet

- Testing and Adjusting: Cerrar SISDocument35 pagesTesting and Adjusting: Cerrar SISWilliams ArayaNo ratings yet

- Presion Bomba Fija 994FDocument8 pagesPresion Bomba Fija 994FCarlos CevNo ratings yet

- Margin Press Test AdjustDocument8 pagesMargin Press Test AdjustDidi PrawiraNo ratings yet

- Transmission 950gDocument17 pagesTransmission 950gAbi JithNo ratings yet

- Brake System Pressure - Test and Adjust: Shutdown SISDocument5 pagesBrake System Pressure - Test and Adjust: Shutdown SISguayanecitroNo ratings yet

- Brake Adjust Press 938gDocument9 pagesBrake Adjust Press 938grjan7peNo ratings yet

- Hydraulic System Tr. ShootingDocument11 pagesHydraulic System Tr. Shootinghassan hamdyNo ratings yet

- Low Power/Poor or No Response To Throttle: Shutdown SISDocument6 pagesLow Power/Poor or No Response To Throttle: Shutdown SISAntonio Mejicanos100% (1)

- Presiones de Sisytema de Direccion 992kDocument10 pagesPresiones de Sisytema de Direccion 992kEvan AT YoelNo ratings yet

- Presion Bomba Variable 994FDocument8 pagesPresion Bomba Variable 994FCarlos CevNo ratings yet

- d5n Bma Calib Clucth d5nDocument10 pagesd5n Bma Calib Clucth d5nChristian Vinueza VillavicencioNo ratings yet

- 1.troubleshoot Engine Crank But Cant StartDocument3 pages1.troubleshoot Engine Crank But Cant StartsyahrilNo ratings yet

- Check ListDocument155 pagesCheck Listahmad sulaimanNo ratings yet

- ZF DKKFDocument6 pagesZF DKKFSugiyatno GiantoNo ratings yet

- Low Press Standby Test and AdjustDocument7 pagesLow Press Standby Test and AdjustDidi PrawiraNo ratings yet

- Ets Control CaterpillarDocument15 pagesEts Control Caterpillarpablo88% (8)

- Ajuste Freno de MotorDocument8 pagesAjuste Freno de MotorAlvaro Escalona GtzNo ratings yet

- 938GDocument8 pages938GUbaldo Enrique Caraballo Estrada100% (3)

- Relief Valve (Signal Limiter Heavy Lift) PDFDocument8 pagesRelief Valve (Signal Limiter Heavy Lift) PDFjuan castaedaNo ratings yet

- ETS Component DescriptionsDocument15 pagesETS Component DescriptionsTejas Mehta80% (5)

- Ayl Pruebas y Ajustes Sistema HidraulicoDocument6 pagesAyl Pruebas y Ajustes Sistema HidraulicoIvan CuterNo ratings yet

- Acceleration Is Poor or Throttle Response Is PoorDocument6 pagesAcceleration Is Poor or Throttle Response Is Poorfalah100% (2)

- Valvula de Alivio Principal-AjustarDocument6 pagesValvula de Alivio Principal-AjustarUlises BarreraNo ratings yet

- Cat MEUI DiagnosisDocument126 pagesCat MEUI DiagnosisJoe67% (3)

- Hydraulic System TroubleshootingDocument8 pagesHydraulic System Troubleshootingaras aliNo ratings yet

- Relief Valve (Line) - Test and Adjust - Travel Motor PDFDocument4 pagesRelief Valve (Line) - Test and Adjust - Travel Motor PDFjuan castaedaNo ratings yet

- Ajustes de Transmision CaterpillarDocument23 pagesAjustes de Transmision CaterpillarPlstina RamsNo ratings yet

- Pacotes 12GDocument13 pagesPacotes 12GTatiano BrolloNo ratings yet

- Prueba y Ajuste Presiones de TransmisionDocument11 pagesPrueba y Ajuste Presiones de TransmisionguayanecitroNo ratings yet

- Piston Pump (Steering) Low Pressure Standby - TestDocument5 pagesPiston Pump (Steering) Low Pressure Standby - Testbangaly amadouNo ratings yet

- Teste Freio e Acumulador 938HDocument10 pagesTeste Freio e Acumulador 938HCesar AugustoNo ratings yet

- Pump Performance (Steering) - TestDocument2 pagesPump Performance (Steering) - Testbangaly amadouNo ratings yet

- 420 D Transmission TestDocument10 pages420 D Transmission TestShohan TaylorNo ratings yet

- VALVUL DE ALIVIO DE LINEADocument34 pagesVALVUL DE ALIVIO DE LINEAElías AguilarNo ratings yet

- Engagement Pressure For The Transmission Clutch - CalibrateDocument8 pagesEngagement Pressure For The Transmission Clutch - CalibrateVictor NunezNo ratings yet

- Cargador 924GDocument14 pagesCargador 924GRonaldo GaleanoNo ratings yet

- Transmission Pressures - Test and AdjustDocument9 pagesTransmission Pressures - Test and AdjustEver SaavedraNo ratings yet

- Transmission Pressures - Test and AdjustDocument11 pagesTransmission Pressures - Test and AdjustBernabe Ruben Alayo RamosNo ratings yet

- Specifications Systems Operation Testing and Adjusting - CS-531D, CP-533D and CS-533D Vibratory Compactors Vibratory SystemDocument64 pagesSpecifications Systems Operation Testing and Adjusting - CS-531D, CP-533D and CS-533D Vibratory Compactors Vibratory SystemTony Melendez50% (2)

- Piston Pump (Steering) PressureDocument8 pagesPiston Pump (Steering) Pressureal muhajirinNo ratings yet

- 3512 Techdoc - Print - PageDocument4 pages3512 Techdoc - Print - Pagefromgod83100% (1)

- Beyond Mine Dispatch - Optimizing The Mining Value Chain - Wenco Mining SystemsDocument5 pagesBeyond Mine Dispatch - Optimizing The Mining Value Chain - Wenco Mining Systemslisahun100% (1)

- Customer Cat ET OverviewDocument36 pagesCustomer Cat ET Overviewlisahun100% (5)

- 992G HYD TroubleshootingDocument9 pages992G HYD TroubleshootinglisahunNo ratings yet

- 773E ToolingListDocument12 pages773E ToolingListlisahunNo ratings yet

- AMMJ Knowledge Centre Past Issue SummariesDocument4 pagesAMMJ Knowledge Centre Past Issue SummarieslisahunNo ratings yet

- Fuel Filter RestrictionDocument2 pagesFuel Filter RestrictionlisahunNo ratings yet

- Gps Positioning and SurveyingDocument62 pagesGps Positioning and SurveyinglisahunNo ratings yet

- Manpower Calculator Introduction V1.5Document18 pagesManpower Calculator Introduction V1.5lisahunNo ratings yet

- Coda Training31Document5 pagesCoda Training31lisahunNo ratings yet

- Geosat 8 UpdDocument19 pagesGeosat 8 UpdlisahunNo ratings yet

- Fuel Dilution of Engine OilDocument2 pagesFuel Dilution of Engine Oillisahun100% (3)

- DT 101 HydraulicDocument2 pagesDT 101 HydrauliclisahunNo ratings yet

- Dealer Stocking ListDocument6 pagesDealer Stocking ListlisahunNo ratings yet

- Lowongan Kerja Husky-CNOOC Madura Limited Februari 2015Document4 pagesLowongan Kerja Husky-CNOOC Madura Limited Februari 2015lisahunNo ratings yet

- DT-94 EventDocument6 pagesDT-94 EventlisahunNo ratings yet

- Lowongan Kerja MRT Jakarta Februari 2015Document5 pagesLowongan Kerja MRT Jakarta Februari 2015lisahunNo ratings yet

- DT 102 EventDocument17 pagesDT 102 EventlisahunNo ratings yet

- McBride Music Company - Woodwind and Brass Instrument RepairDocument2 pagesMcBride Music Company - Woodwind and Brass Instrument Repairlisahun0% (1)

- Welding PrecautionDocument2 pagesWelding Precautionlisahun100% (1)

- Maintenance ORSDocument4 pagesMaintenance ORSlisahun100% (1)

- ORS Hardware and SchematicsDocument11 pagesORS Hardware and Schematicslisahun100% (1)

- Marketing BulletinDocument7 pagesMarketing BulletinlisahunNo ratings yet

- Powered Stairway SystemDocument4 pagesPowered Stairway Systemlisahun0% (1)

- Automatic Retarder Control (ARC)Document5 pagesAutomatic Retarder Control (ARC)lisahun100% (1)

- Certified Marine AnalystDocument1 pageCertified Marine AnalystlisahunNo ratings yet

- Powered Stairway SystemDocument4 pagesPowered Stairway Systemlisahun0% (1)

- Engine ReportDocument2 pagesEngine ReportlisahunNo ratings yet

- PECJ0003-05 July2014Document448 pagesPECJ0003-05 July2014lisahunNo ratings yet

- EM SystemDocument11 pagesEM SystemlisahunNo ratings yet

- 2.0l 4 Cyl Nissan b13Document52 pages2.0l 4 Cyl Nissan b1325912530No ratings yet

- Man B&W: Main BearingDocument72 pagesMan B&W: Main BearingRobert LuuNo ratings yet

- Moduspec ChecklistDocument64 pagesModuspec Checklistbehnam197100% (8)

- 9 Automobile NSQFDocument143 pages9 Automobile NSQFabhilashNo ratings yet

- 2 20Document29 pages2 20slv_prasaadNo ratings yet

- Screamin Eagle Milwaukee-Eight™ 128/131 Stage Iv Kit: General InformationDocument8 pagesScreamin Eagle Milwaukee-Eight™ 128/131 Stage Iv Kit: General InformationAdrian Surya K.No ratings yet

- ATTACHMENT 3 Start-Up and Operational Manual For Steam TurbineDocument116 pagesATTACHMENT 3 Start-Up and Operational Manual For Steam TurbineMuhammad Junaid KhanNo ratings yet

- Sisu Citius ManualDocument118 pagesSisu Citius ManualAlex83% (12)

- Voith Manualspare Part ListDocument483 pagesVoith Manualspare Part ListEdiNo ratings yet

- 941 WS3Document194 pages941 WS3Luis Jesus100% (1)

- Crown CatalogDocument94 pagesCrown CatalogPhineas MagellanNo ratings yet

- 5fd60 Parts Catalog 11092Document344 pages5fd60 Parts Catalog 11092Andrea FilottoNo ratings yet

- محمد مجدي محمد عبدالله - سكشن 8Document12 pagesمحمد مجدي محمد عبدالله - سكشن 8tdvytecgjynwlniftzNo ratings yet

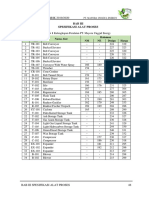

- Perpab6-Spesifikasi AlatDocument38 pagesPerpab6-Spesifikasi AlatardiNo ratings yet

- Gilera Runner 125 - 200 (EN)Document335 pagesGilera Runner 125 - 200 (EN)Manualles81% (16)

- Diesel Shed Report on Expressor/Compressor MaintenanceDocument34 pagesDiesel Shed Report on Expressor/Compressor MaintenanceAniket PrasadNo ratings yet

- PDocument34 pagesPGustavo PalaciosNo ratings yet

- Shop Manual IVECODocument356 pagesShop Manual IVECORath Asypaden89% (9)

- 1983 Data-Tech Chevrolet S10 2.8L Vin B Especificaciones de Motor EspecificacionesDocument24 pages1983 Data-Tech Chevrolet S10 2.8L Vin B Especificaciones de Motor EspecificacionesRubenNo ratings yet

- Diesel Engine TestDocument9 pagesDiesel Engine TestSamuel Blandes RwegasiraNo ratings yet

- FP Diesel New Numbers Announcement Aug 17Document3 pagesFP Diesel New Numbers Announcement Aug 17Hebert MedinaNo ratings yet

- Pgo PMX Sport ServicemanualDocument116 pagesPgo PMX Sport ServicemanualMoppie HofstedeNo ratings yet

- CSP11000 KB7S Operation and Maintenance Manual - 2016Document494 pagesCSP11000 KB7S Operation and Maintenance Manual - 2016Design LaboratoryNo ratings yet

- Deutz MWM 601-6sDocument111 pagesDeutz MWM 601-6sDavid NguyenNo ratings yet

- Tourer 125 - Workshop Manual PDFDocument293 pagesTourer 125 - Workshop Manual PDFjo100% (1)

- Grand Cherokee 2011 5.7LDocument300 pagesGrand Cherokee 2011 5.7Lramon fuenmayorNo ratings yet

- Esco BrochureDocument12 pagesEsco BrochurefjaristizabalNo ratings yet

- DG L23-30H - Mk2 Operation ManualDocument928 pagesDG L23-30H - Mk2 Operation Manualdionpanag100% (21)

- Instruction ManualDocument36 pagesInstruction ManualJoséNo ratings yet

- 950f - 950f - Series - II - and - 960fDocument5 pages950f - 950f - Series - II - and - 960falexander_1985100% (1)

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 5 out of 5 stars5/5 (1)

- Shorting the Grid: The Hidden Fragility of Our Electric GridFrom EverandShorting the Grid: The Hidden Fragility of Our Electric GridRating: 4.5 out of 5 stars4.5/5 (2)

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesFrom EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesRating: 4.5 out of 5 stars4.5/5 (21)

- Idaho Falls: The Untold Story of America's First Nuclear AccidentFrom EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentRating: 4.5 out of 5 stars4.5/5 (21)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialFrom EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo ratings yet

- OFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyFrom EverandOFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyNo ratings yet

- Asset Integrity Management for Offshore and Onshore StructuresFrom EverandAsset Integrity Management for Offshore and Onshore StructuresNo ratings yet

- Renewable Energy: A Very Short IntroductionFrom EverandRenewable Energy: A Very Short IntroductionRating: 4.5 out of 5 stars4.5/5 (12)

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successFrom EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successRating: 4.5 out of 5 stars4.5/5 (3)

- Build Your Own Electric Vehicle, Third EditionFrom EverandBuild Your Own Electric Vehicle, Third EditionRating: 4.5 out of 5 stars4.5/5 (3)

- The Boy Who Harnessed the Wind: Creating Currents of Electricity and HopeFrom EverandThe Boy Who Harnessed the Wind: Creating Currents of Electricity and HopeRating: 4 out of 5 stars4/5 (130)

- The Grid: The Fraying Wires Between Americans and Our Energy FutureFrom EverandThe Grid: The Fraying Wires Between Americans and Our Energy FutureRating: 3.5 out of 5 stars3.5/5 (48)

- Implementing an Integrated Management System (IMS): The strategic approachFrom EverandImplementing an Integrated Management System (IMS): The strategic approachRating: 5 out of 5 stars5/5 (2)

- Handbook on Battery Energy Storage SystemFrom EverandHandbook on Battery Energy Storage SystemRating: 4.5 out of 5 stars4.5/5 (2)

- Energy, Light and Electricity - Introduction to Physics - Physics Book for 12 Year Old | Children's Physics BooksFrom EverandEnergy, Light and Electricity - Introduction to Physics - Physics Book for 12 Year Old | Children's Physics BooksNo ratings yet

- Industrial Piping and Equipment Estimating ManualFrom EverandIndustrial Piping and Equipment Estimating ManualRating: 5 out of 5 stars5/5 (7)

- The Rare Metals War: the dark side of clean energy and digital technologiesFrom EverandThe Rare Metals War: the dark side of clean energy and digital technologiesRating: 5 out of 5 stars5/5 (2)

- ISO 50001: A strategic guide to establishing an energy management systemFrom EverandISO 50001: A strategic guide to establishing an energy management systemNo ratings yet

- The Way Home: Tales from a life without technologyFrom EverandThe Way Home: Tales from a life without technologyRating: 4 out of 5 stars4/5 (45)

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsFrom EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNo ratings yet

- Machine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesFrom EverandMachine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesPatrick BangertRating: 3 out of 5 stars3/5 (2)

- Solar Electricity Basics: Powering Your Home or Office with Solar EnergyFrom EverandSolar Electricity Basics: Powering Your Home or Office with Solar EnergyRating: 5 out of 5 stars5/5 (3)

- Oil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionFrom EverandOil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionRating: 4.5 out of 5 stars4.5/5 (16)