Professional Documents

Culture Documents

Seminar Report on Ultrasonic Motors

Uploaded by

Harshit SinghOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Seminar Report on Ultrasonic Motors

Uploaded by

Harshit SinghCopyright:

Available Formats

Seminar Report, 2013

Chapter 1

INTRODUCTION

Air, cheer, water, shelter.....motor, yes; a motor is something that we cant live without.

Motor is a device that converts electrical energy to mechanical energy. If you are lazy to move, if

you arent close enough to move, if you arent bold enough to make the move, well, this is a

machine that you ought to have.

An electric motor is a machine that converts electrical energy into mechanical energy for

obtaining useful work. In normal motoring mode, most electric motors operate through the

interaction between an electric motor's magnetic field and winding currents to generate force

within the motor. i.e. Almost all the motor that dominates the present world such as DC motors,

induction motors, synchronous motors etc. work on the principle of Faradays Law of

Electromagnetic Induction when a current carrying conductor is kept in a magnetic field, it

experiences a force or a torque.

The energy conversion in such motors involves two stages, where initially electrical

energy is converted to magnetic energy and further, the magnetic energy is converted to

mechanical energy. Because of this two-stage energy conversion, the electromagnetic motor

suffers from several losses that lead to a rigorous energy wastage.

The ultrasonic motors belong to the class of piezoelectric motors. In this prose, the term

USM will be used for denoting the machine. The working principles have been well known for at

least 50 years. However they gained widespread interest with the influential work of T Sashida in

1982. Before that piezo-ceramic materials with high conversion efficiency and fast electronic

power control of ultrasonic vibrations were not available. Because of their specific advantages

compared to conventional electromagnetic motors, USMs fill a gap in certain motor & actuator

applications. Besides that, USMs also offer a high potential for miniaturization.

The study deals with the fundamentals of this modern machine such as, principles, parts,

working and eventually mentions the pros and cons. The study wraps up with the major

applications of this quick response device and the scope for further development.

SSET, Karukutty

Dept. of EEE

Seminar Report, 2013

Chapter 2

NEED FOR A BETTER MACHINE

The electromagnetic motors that are widely used in home, industries and other sectors

suffer from several severe disadvantages. Viz.

Noisy operation.

Surge currents and spikes.

Electromagnetic interference.

Magnetic losses (Eddy currents & Hysteresis).

High power consumption & high temperature.

Low power factor.

Comparatively lesser efficiency.

Here emerged the requirement of a better machine. After years of studies and researches

the engineers developed an entirely different kind of motor that directly converted electrical

energy to mechanical energy. One among such motors was the Ultrasonic Piezoelectric Motor or

simply, the Ultrasonic Motor (USM).

USMs play an important role in a few niche markets, where the size, torque, speed or

other requirements couldnt be satisfied by the traditional electromagnetic motor. As

technologies improved in course of time, USMs replaced not only the EM motors, but also the

servomotors, stepper motors and sycnhros.

SSET, Karukutty

Dept. of EEE

Seminar Report, 2013

Chapter 3

ULTRASONICS A HEALTHIER OPTION

Ultrasonics are vibrations of frequencies greater than the upper limit of the audible range

for humans i.e., greater than about 20 kHz. The term sonic is applied to ultrasound waves of very

high amplitudes. Hyper sound, sometimes

called praetor sounds or

micro sounds

are sound waves of frequencies greater than 1013 hertz. At such high frequencies it is very

difficult for a sound wave to propagate efficiently; indeed, above a frequency of about 1.25

1013 hertz it is impossible for longitudinal waves to propagate at all, even in a liquid or a solid,

because the molecules of the material in which the waves are traveling cannot pass the vibration

along rapidly enough.

An ultrasonic transducer is a device used to convert some other type of energy into an

ultrasonic vibration. There are several basic types, classified by the energy source and by the

medium into which the waves are being generated. Mechanical devices include gas-driven, or

pneumatic, transducers such as whistles as well as liquid-driven transducers such as

hydrodynamic oscillators and vibrating blades. These devices, limited to low ultrasonic

frequencies, have a number of industrial applications, including drying, ultrasonic cleaning, and

injection of fuel oil into burners. Electromechanical transducers are far more versatile and

include piezoelectric and magnetostrictive devices.

By far, the most popular and versatile type of ultrasonic transducer is the piezoelectric

crystal, which converts an oscillating electric field applied to the crystal into a mechanical

vibration. Piezoelectric crystals include quartz, Rochelle salt and certain types of ceramics.

Piezoelectric transducers are readily employed over the entire frequency range and at all output

levels. Particular shapes can be chosen for particular applications. For example, a disc shape

provides a plane ultrasonic wave, while curving the radiating surface in a slightly concave or

bowl shape creates an ultrasonic wave that will focus at a specific point.

SSET, Karukutty

Dept. of EEE

Seminar Report, 2013

Chapter 4

PRINCIPLE OF OPERATION

Before learning about USMs it is required to know about piezoelectric effect.

Piezoelectric effect was discovered by Jacques Curie & Pierre Curie [France-1880]. It was found

that in certain types of crystals when a pressure is applied across a pair of opposite faces, an

equivalent potential difference is developed across the other pair of opposite faces.

Further, if we reverse the direction of application of force, the polarity of the potential

difference developed also reverses. In fig 4.1, a compressive force is applied across the crystal

and we obtain a potential difference as shown. If the compressive force is replaced by an

elongation force, the polarity reverses (i.e. the top face becomes negative and the bottom face

become positive).

Fig 4.1

It was later discovered that the converse of this phenomenon is also possible. When a

potential difference is applied across the pair of opposite faces, compressions or elongations are

obtained across the other pair of opposite faces depending upon the polarity of the applied PD.

SSET, Karukutty

Dept. of EEE

Seminar Report, 2013

Further, the application of AC voltage across these faces resulted in alternating

compressions and elongations (mechanical vibrations) across the other pair of faces. This is the

driving force behind the USMs. Crystals that exhibit the above phenomenon are called

piezoelectric materials. The interesting fact is that converse piezoelectric effect was discovered

on a later occasion, 2 years after the discovery by the Curie brothers. Almost 80 years, the

immense potential of motoring produced by this discovery was unknown to the scientific world,

until the V V Lavrinenko modeled the 1st ever USM in the year 1946.

In short, the Ultrasonic Motors works on the principle of converse piezoelectric effect.

SSET, Karukutty

Dept. of EEE

Seminar Report, 2013

Chapter 5

CONSTRUCTION

The Ultrasonic Motors constitutes mainly 4 parts, viz.

1. Actuator

2. Stator

3. Rotor

4. Casing

5.1 ACTUATOR

Actuator is the driving unit of the USM. It is made up of a piezoelectric material such as

Quartz, Barium Titanate, Tourmaline, Rochelle salt etc. Actuator is directly connected to the

supply. It is fixed on the stator using thin metal sheets and bearings.

5.2 STATOR

Stator is the stationary but vibrating part. It is constructed using a malleable material,

usually, steel. It can be of ring, cylindrical or rod shaped.

5.3 ROTOR

Rotor is the rotating part, which acquires the energy conversion and produces the desired

torque (work) on the shaft. Rotor is made of the same material as that of the stator and does have

the same shape. Rotor and stator are coupled by a certain method called the frictional coupling

which is much effective and simpler. The idea of frictional coupling is discussed in Chapter 6.

5.4 CASING

Casing is used to protect the USM from external interferences and abrasive forces and

extreme environmental conditions. They are made of non- corrosive alloys or fiber. They too can

be constructed in any of the desired shape as per requirement.

SSET, Karukutty

Dept. of EEE

Seminar Report, 2013

5.5 ASSEMBLY

Fig 5.1

Comb tooth grooves are created on the stator surface that adheres to the rotor. These are

devised to make the amplitude of elliptic motion large and to reduce abrasions. Further feature of

comb tooth is to amplify vibrations. The grooves also allow the dust created by friction to escape

and thus keep the contact surface dust free.

So the USMs are well known for their low speed operation. Torque ratings averaging 10

times greater than a comparably sized electromagnetic motor can be achieved.

Voltage inputs vary piezo-crystal assembly. That is, if the piezo-ring assembly is of a

thinner design, the voltage requirements will be less than that of a thicker type piezo-ring

assembly. Power requirements for the USM usually rate in the low range.

SSET, Karukutty

Dept. of EEE

Seminar Report, 2013

Chapter 6

WORKING

Ultrasonic motor involves direct conversion of electrical energy to mechanical energy.

We have seen in the previous chapter that actuator is directly connected to the electrical supply

mains. When the supply is switched ON, the actuator starts vibrating owing to converse

piezoelectric effect. The stator, upon which the actuator is fixed, also receives the vibration. The

particles of the stator receive energy from the actuator and starts vibrating in the plane. This

results in the formation of a surface wave. The stator and rotor are placed so close to each other

that their surfaces almost grazes upon each other.

The surface waves so produced have a frequency in the ultrasonic range and are not

visible by our bare eyes. These waves cause the stator to slide against the rotor. As the wave

propagates, the rotor is pulled back in the opposite direction of movement of the wave. In the fig

6.1 the surface wave produced is propagating in the anti-clockwise direction, whereby, the rotor

is pulled to rotate in the clockwise direction. The shaft, upon which the rotor is mounted, now

rotates and the output torque is thus obtained.

Fig 6.1

SSET, Karukutty

Dept. of EEE

Seminar Report, 2013

From the figure, it is evident that the stator and rotor always possess the same shape. The

figure depicts a rotational USM. Fig 6.2 is the schematic diagram of a linear USM driven by dual

actuators.

Fig 6.2

SSET, Karukutty

Dept. of EEE

Seminar Report, 2013

Chapter 7

FRICTIONAL COUPLING

We have already discussed in the working of USM that a surface wave is generated in the

stator, by the converse piezoelectric effect occurring in the actuator. As the wave propagates

through the stator, the rotor is pulled back in the opposite direction. Refer fig 6.1. Here the

surface wave generated in the stator propagates in the anti-clockwise direction, whereby, the

rotor is pulled in the reverse direction. Now, there is a chance that the rotor may get slipped off

from the stator. To avoid this hitch, the surface of contact between rotor and stator is made rough

or rather uneven. This method of coupling of rotor and stator is known as frictional coupling.

There are other methods of coupling involved in the modern USMs, but frictional coupling is

found to be the simplest and rugged.

In course of time, the qualm arises whether the friction between the rotor-stator combo

lead to wear and tear, and the counter was found to be NO, because, during its operation, as the

motor gathers speed, the rotor is slightly levitated in the perpendicular direction owing to

centrifugal force. Concurrently, the real area of contact of the stator and rotor decreases. Under

the assumption that friction force is proportional to real area of contact, frictional coefficient of

stator/rotor decreases under ultrasonic dynamic contact.

But still, the slightest of contacts produces wear on the interface. The grooves are

designed in such a shape as to toss away the dust produced by this process. During the design of

frictional grooves, care is to be taken that during slow speeds, interlocking of rotor and stator

doesnt occur.

SSET, Karukutty

10

Dept. of EEE

Seminar Report, 2013

Chapter 8

TYPES OF ULTRASONIC MOTORS

There are several classifications for ultrasonic motors depending upon their shape, size,

type of motion, application etc. The USMs are also classified according to the type of wave that

is being generated in the stator. If the wave produced in the stator has its particles vibrating only

in the vertical direction, i.e. if the wave produced is a standing wave (static wave), such type of

motors are called Standing Wave type USMs. And, if the wave produced in the stator has its

particles vibrating both in the vertical direction as well as horizontal direction (travelling wave),

such type of motors are called Travelling Wave type USMs.

Even though the type of wave produced is different, both these types of USMs has got the

same construction and working principles. However, the Travelling Wave-type USMs are found

to have better operating characteristics. The mechanics of standing and travelling waves are

beyond the scope of this paper.

The other methods of classifications of ultrasonic motors are,

1. Mode of operation:

a.

Static

b.

Resonant

2. Type of motion:

a.

Rotary

b.

Linear

c.

Spherical

3. Shape of implementation:

a.

Beam

b.

Rod

c.

Disk

SSET, Karukutty

11

Dept. of EEE

Seminar Report, 2013

Chapter 9

ADVANTAGES & DISADVANTAGES

9.1 ADVANTAGES OF USMs

Since the ultrasonic motors are designed after much of studies and researches, so as to

eliminate the drawbacks of electromagnetic motors, they ought to have new features and

advantages.

The foremost advantage of USMs is that they have got high o/p torque & efficiency.

Compared to the conventional electromagnetic motors they exhibit high power to weight ratio. A

small sized USM is capable of producing the same amount of output power as that of an EM

motor which is 14 times its size. Owing to its good positioning accuracy, the USMs in the

modern times are used as a substitute for synchros, servomotors and stepper motors. The rugged

structure and construction makes it capable of working in extreme environmental conditions. The

major advantage of using ultrasonics as the principle is that no magnetic interference occurs. The

simplest of constructions makes it economical to the layman.

The device is well known for its miniaturization and simplicity, yet boasts for it immense

output power and can withstand extreme environmental conditions. No magnets, no losses, no

interference, as clean as a whistle!

9.2 DISADVANTAGES OF USMs

However, no machine is efficient to a cent per cent ceiling as is the case of USMs also.

These motors do eliminate the major drawbacks of the conventional motors but still lags behind

in certain constraints.

Even being the most modern of all the technologies, the ultrasonic motor has got a major

disadvantage of requiring a high frequency power supply in the ultrasonic range. The normal

50Hz supply has to be stepped up to the kHz range by making use of cycloconverters, inverters

SSET, Karukutty

12

Dept. of EEE

Seminar Report, 2013

and other mandatory devices. By the advent of power electronics, SCRs and other lossless

switching devices, the construction of the so called frequency boosters has neither elevated the

capital costs, nor diminished the efficiency. The piezoelectric material which has been the

driving unit of the USM is quite expensive by which, the construction of larger USMs has been

hampered.

Other than these, the USMs suffers from the trouble of ultrasonic noise, but has not

curtailed the operating characteristics to a great extent. The ultrasonic noise, since not captured

by the bare ears, makes us feel better but not the structure. The drooping torque-speed

characteristics are an area where further researches and explanations are yet to be made.

It is also necessary to increase the frictional force to an extreme degree, but this

inevitably put excessive stress on the bearings which causes the bearings to wear out and shorten

the life of the motor. It is difficult to obtain high torque form an ultrasonic motor if it is

miniaturized beyond a certain size.

SSET, Karukutty

13

Dept. of EEE

Seminar Report, 2013

Chapter 10

APPLICATIONS

Though not much used for heavy duty applications, USMs are best known for their

miniaturization of equipments. The 90% of the USMs constructed in the era are used in SLR,

DSLR cameras for the auto focusing & optical zooming. The positioning of surveillance cameras

are also carried out using these motors.

In the automobile industry, the USMs are used for the operation of power steering, power

windows, tilt steering, ORVMs, car seat adjustment and almost all motoring devices etc.

In the computer hardware industry the USMs has got wide applications. The disk heads

of hard disks, floppies & CD drives can be controlled by the USM. Ever wondered the name

quartz written on wrist watches & clocks??? It is the quartz USM that drives the motor inside

it.

The ultrasonic motor has got applications also in robotics, aerospace and medicine.

SSET, Karukutty

14

Dept. of EEE

Seminar Report, 2013

Chapter 11

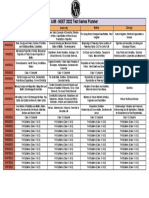

HISTORY OF USM

2009

Invented spherical USM & 2 DOF optical sensing system for

MRI scanning.

2005

Draft works of multiple DOF cameras was commenced.

2003

A reduced size micro USM was put forward by Cannon.

1990

1st micro USM was developed by Cannon.

1986

Cannon uses the ring type USM in the SLR camera autofocus.

1980

1st practical model of USM was developed by Sashida.

1965

1st Ultrasonic Motor was developed by V V Lavrinenko.

1880

Piezoelectric effect was discovered by Curie brothers.

Fig11.1

SSET, Karukutty

15

Dept. of EEE

Seminar Report, 2013

Chapter 12

CONCLUSION

The above prose has gone through almost all the fundamental details of this modern

technology machine. Though USMs are not widely used for heavy motoring activities, it still has

got its unique stand in the miniature applications as mentioned above. The main reason for

USMs not being used in the heavy duty activities is because of the requirement of a larger &

expensive piezoelectric material that causes the production cost to shoot up double fold.

However, researches are in progress to improve the technology to meet the heavy industrial

requirements and also to minimize the problems caused by ultrasonic noise.

A world might be expected in the near future that replaces the futile electromagnetic

motors by the proficient ultrasonic motors.

SSET, Karukutty

16

Dept. of EEE

Seminar Report, 2013

REFERENCES

1. Published in: Ultrasonics Symposium, 1988. Proceedings., IEEE 1988. Date of

Conference: 2-5 Oct 1988, Page(s): 519 - 522 vol.1, INSPEC Accession Number:

3439385, Conference Location: Chicago, IL, Product Type: Conference Publications.

Meeting Date : 02 Oct 1988-05 Oct 1988.

2. http://en.wikipedia.org/wiki/Ultrasonic_motor

3. http://www.britannica.com/EBchecked/topic/613488/ultrasonics

4. http://www.seminarsonly.com/electrical%20&%20electronics/Ultrasonic%20Motor.php

SSET, Karukutty

17

Dept. of EEE

You might also like

- Solar Operated Grass CutterDocument12 pagesSolar Operated Grass CutterGorishsharma100% (1)

- Wireless Power TransmissionDocument19 pagesWireless Power TransmissionVarun Dabla0% (1)

- Water Level Indicator Using Iot Blynk App With Sms NotificationDocument7 pagesWater Level Indicator Using Iot Blynk App With Sms NotificationHassan AliNo ratings yet

- Solar based mini fridge for rural healthcareDocument12 pagesSolar based mini fridge for rural healthcareMUHAMMED FAISALNo ratings yet

- Final Project Report Foot Step (With Out Footer)Document47 pagesFinal Project Report Foot Step (With Out Footer)Deepak Raj R100% (3)

- Underwater Windmill Seminar ReportDocument37 pagesUnderwater Windmill Seminar ReportPappu Mala33% (3)

- MHD Power Generation ExplainedDocument15 pagesMHD Power Generation ExplainedMANN BATTISENo ratings yet

- A ProjectDocument9 pagesA Projectjnanesh tk100% (1)

- GurobusDocument24 pagesGurobuspraveenpv7No ratings yet

- The Ultrasonic Motor AbstractDocument28 pagesThe Ultrasonic Motor AbstractAnajkumarNo ratings yet

- Walk N Charge - FinalDocument15 pagesWalk N Charge - FinalKaushik ChakrabortyNo ratings yet

- Ultrasonic Motor AbstractDocument2 pagesUltrasonic Motor AbstractVishal Singh Rahangdale100% (2)

- Project ReportDocument65 pagesProject ReportMusical world100% (1)

- Seminar Report - Ultrasonic MotorDocument31 pagesSeminar Report - Ultrasonic MotorDurgesh Kumar100% (1)

- SRMDocument60 pagesSRMKrupa KaranNo ratings yet

- A SEMINAR REPORT On WIRELESS POWER TRANS PDFDocument29 pagesA SEMINAR REPORT On WIRELESS POWER TRANS PDFABHIJIT CHANDRANo ratings yet

- Seminar Report Solar TreeDocument30 pagesSeminar Report Solar TreeAshish Kumar100% (1)

- Magenn Air Rotor System (M.a.r.sDocument21 pagesMagenn Air Rotor System (M.a.r.sccritamNo ratings yet

- MPPT Based PV System For Partial ShadingDocument73 pagesMPPT Based PV System For Partial ShadingSwarnav MajumderNo ratings yet

- Paper Battery Seminar Report: Lightweight Power for IoT DevicesDocument17 pagesPaper Battery Seminar Report: Lightweight Power for IoT DevicesIshuNo ratings yet

- Project On Electricity Generator From Speed BreakersDocument50 pagesProject On Electricity Generator From Speed BreakersAlvi Mirza91% (11)

- Active Magnetic Bearing PDFDocument11 pagesActive Magnetic Bearing PDFSujan KumarNo ratings yet

- 1.protection of Busbar Distribution From Over LoadDocument4 pages1.protection of Busbar Distribution From Over LoadPooja BanNo ratings yet

- Universal - Current - Sensors - Report KARTHIKDocument23 pagesUniversal - Current - Sensors - Report KARTHIKKarthik SDNo ratings yet

- A Detailed Study On Power Generation Using Speed BreakersDocument5 pagesA Detailed Study On Power Generation Using Speed BreakersInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Intelligent Braking System - SynopsisDocument6 pagesIntelligent Braking System - SynopsisTanviNo ratings yet

- Foot Step Power GenerationDocument5 pagesFoot Step Power GenerationAbhishek Kumar0% (2)

- Power TheftDocument16 pagesPower TheftSreenu vasuNo ratings yet

- Cell Phone Operated Land Rover SynopsisDocument13 pagesCell Phone Operated Land Rover SynopsiscatkatiyarNo ratings yet

- Contact Less Energy Transfer SystemDocument28 pagesContact Less Energy Transfer SystemAditi Goyal100% (4)

- Vertical Axis Wind Turbine Project ReportDocument18 pagesVertical Axis Wind Turbine Project ReportJace Thompson100% (2)

- Power Generation Using Speed Breakers and Efficient Use of Energy Created by It.Document57 pagesPower Generation Using Speed Breakers and Efficient Use of Energy Created by It.Vaibhav KhareNo ratings yet

- Nano Wire Full ReportDocument21 pagesNano Wire Full Reportnikhil210492100% (1)

- Industrial Boiler Flame Remote Adjustment SystemDocument5 pagesIndustrial Boiler Flame Remote Adjustment SystemChandra Sekar100% (1)

- Solar BikeDocument16 pagesSolar BikeRobi Sixer Axial0% (1)

- Power Generation Through Speed BreakersDocument22 pagesPower Generation Through Speed BreakersSaikumar MysaNo ratings yet

- Solar Car Seminar ReportDocument30 pagesSolar Car Seminar ReportAamir Khan100% (1)

- GyrobusDocument24 pagesGyrobusajay kumar royNo ratings yet

- Major Project Shopping TrolleyDocument50 pagesMajor Project Shopping TrolleyRohith SharmaNo ratings yet

- Solar Mobile Charger Rural AreasDocument4 pagesSolar Mobile Charger Rural AreasYellaturi Siva Kishore ReddyNo ratings yet

- Seminar Report On: Visvesvaraya Technological UniversityDocument29 pagesSeminar Report On: Visvesvaraya Technological UniversityTejas Xd0% (1)

- A Major ProjectDocument27 pagesA Major ProjectJanak KishorNo ratings yet

- Electric Rocket EngineDocument26 pagesElectric Rocket EngineSanal Raj100% (1)

- Hybrid Power Full Seminar ReportDocument106 pagesHybrid Power Full Seminar ReportD Avi Na Sh100% (1)

- Final ReportDocument18 pagesFinal ReportYusha Patel100% (1)

- Train Tracking and Obstacle Detection SystemDocument26 pagesTrain Tracking and Obstacle Detection Systemeshu50% (2)

- Solar Tracker Using ArduinoDocument3 pagesSolar Tracker Using ArduinoInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Seminar Report VACCUM BRAKING SYSTEM (1sb16me042)Document22 pagesSeminar Report VACCUM BRAKING SYSTEM (1sb16me042)Manasa100% (1)

- Android SOLAR GRASS CUTTER ReportDocument47 pagesAndroid SOLAR GRASS CUTTER ReportAnuj Tripathi80% (5)

- Main Project PrsDocument40 pagesMain Project PrsSabari NathanNo ratings yet

- Power Generation01Document20 pagesPower Generation01Jaya Prakash SeelamNo ratings yet

- Project Report On Speed Control of DC Motor by Using PWM TechniqueDocument75 pagesProject Report On Speed Control of DC Motor by Using PWM Techniquepandyamech80% (15)

- Introduction To Regenerative Braking SystemDocument6 pagesIntroduction To Regenerative Braking SystemdfgvdfsghdgfNo ratings yet

- Ultrasonic Motors: Department of Electrical&Electronics Engineering Jntua College of Engineering Anantapur (Anantapur)Document27 pagesUltrasonic Motors: Department of Electrical&Electronics Engineering Jntua College of Engineering Anantapur (Anantapur)Shaik Towheed BanuNo ratings yet

- Ultrasonic Motor 29122012193508 Ultrasonic MotorDocument21 pagesUltrasonic Motor 29122012193508 Ultrasonic MotorMuttu KonnurNo ratings yet

- 4 AdvDocument13 pages4 AdvHemanth SaiNo ratings yet

- Ultrasonic MotorDocument21 pagesUltrasonic Motorjyothsna123456100% (1)

- Piezoelectric Actuators: Vector Control Method: Basic, Modeling and Mechatronic Design of Ultrasonic DevicesFrom EverandPiezoelectric Actuators: Vector Control Method: Basic, Modeling and Mechatronic Design of Ultrasonic DevicesNo ratings yet

- ECE Ultrasonic Motor ReportDocument21 pagesECE Ultrasonic Motor ReportAbhishek GhateNo ratings yet

- Research Paper On Ultrasonic MotorDocument8 pagesResearch Paper On Ultrasonic Motorgzrvpcvnd100% (1)

- ProjectDocument41 pagesProjectHarshit Singh100% (1)

- SeminarDocument25 pagesSeminarSwapnajitRayNo ratings yet

- L1 Intro Final 05Document47 pagesL1 Intro Final 05mwaseem2011No ratings yet

- Supercon PDFDocument16 pagesSupercon PDFHarshit SinghNo ratings yet

- Surge Current Protection Using Superconducting Fault Current LimiterDocument24 pagesSurge Current Protection Using Superconducting Fault Current LimiterHarshit SinghNo ratings yet

- Ece Polyfuse ReportDocument24 pagesEce Polyfuse ReportHarshit SinghNo ratings yet

- Simulation of Bracket: Strength Analysis For The BracketDocument10 pagesSimulation of Bracket: Strength Analysis For The BracketGabriela PricopeNo ratings yet

- Polyisobutylene: A Most Unusual Polymer: AbstractDocument10 pagesPolyisobutylene: A Most Unusual Polymer: AbstractSamuelNo ratings yet

- Reinforced Concrete Beam Design ProblemsDocument5 pagesReinforced Concrete Beam Design ProblemsCeyn Lumabad0% (1)

- Azeotropic and Extractive DistillationDocument9 pagesAzeotropic and Extractive DistillationShahzaib IqbalNo ratings yet

- Chemical Reaction Engineering-II - R2015 - 13-11-2018Document2 pagesChemical Reaction Engineering-II - R2015 - 13-11-201818135A0806 MAKKUVA BHAVYANo ratings yet

- Rayleigh Line Flows AnalysisDocument14 pagesRayleigh Line Flows AnalysisKantharaj ChinnappaNo ratings yet

- 07 Fatigue Failure IDocument33 pages07 Fatigue Failure Iforemar100% (1)

- A Detailed Lesson Plan in Science and HeDocument4 pagesA Detailed Lesson Plan in Science and HeRichelle Millano BrownNo ratings yet

- Vidicon Camera Is A Term Which Commonly Used For All Types of Television CamerasDocument2 pagesVidicon Camera Is A Term Which Commonly Used For All Types of Television CamerasgsivakvpNo ratings yet

- Control Valves For Critical Applications PDFDocument8 pagesControl Valves For Critical Applications PDFonizuka-t2263No ratings yet

- Physical Chemistry I (Gases) : Maxwell and Boltzmann (1859) Developed A MathematicalDocument51 pagesPhysical Chemistry I (Gases) : Maxwell and Boltzmann (1859) Developed A MathematicalDina GaranNo ratings yet

- 20ft T75 Spec 18barDocument6 pages20ft T75 Spec 18barlucholadeNo ratings yet

- Kehinde Taiwo Obafemi Awolowo University NigeriaDocument49 pagesKehinde Taiwo Obafemi Awolowo University NigeriaAnanthNo ratings yet

- AIM - NEET 2022 Test Series PlannerDocument1 pageAIM - NEET 2022 Test Series Planner6 months AgoNo ratings yet

- Physics ProjectDocument25 pagesPhysics Projectaryan sharrma100% (1)

- Aircraft and Jet Propulsion Systems: Ajith .J. Deshpande USN:1RC09ME006 SEM:VIII A' (Mech) College: SRSITDocument32 pagesAircraft and Jet Propulsion Systems: Ajith .J. Deshpande USN:1RC09ME006 SEM:VIII A' (Mech) College: SRSITAida Brkić - BurićNo ratings yet

- D 6815 - 02 - Rdy4mtutmdiDocument11 pagesD 6815 - 02 - Rdy4mtutmdiM Mirza Abdillah PratamaNo ratings yet

- Chemistry MCQs PPSCDocument92 pagesChemistry MCQs PPSCMuhammad Zain Kaleem100% (1)

- Type 101 Sealing Glass: Standard Specification ForDocument3 pagesType 101 Sealing Glass: Standard Specification ForRob GridleyNo ratings yet

- Composition of Soil Terminology & DefinitionsDocument18 pagesComposition of Soil Terminology & Definitionsedouard dudeNo ratings yet

- Comprehensive Exam InformationDocument8 pagesComprehensive Exam InformationMultiNo ratings yet

- F 85144Document2 pagesF 85144Nestor GalianoNo ratings yet

- Fluid Properties and Unit Conversions ProgramDocument13 pagesFluid Properties and Unit Conversions ProgramNawaz KhanNo ratings yet

- Uniform Circular Motion: PSI AP Physics 1Document6 pagesUniform Circular Motion: PSI AP Physics 1Boldie LutwigNo ratings yet

- CIVL3133 Ground Improvement:: What Are The Expected Outcomes of This Lecture?Document35 pagesCIVL3133 Ground Improvement:: What Are The Expected Outcomes of This Lecture?Louis BrightonNo ratings yet

- Vacuum Drying of Gas Pipelines - Rotary Vane Vacuum Pumps and Air CompressorsDocument1 pageVacuum Drying of Gas Pipelines - Rotary Vane Vacuum Pumps and Air CompressorsSoner SalarNo ratings yet

- Air Valves For Offshore and Seawater ApplicationsDocument4 pagesAir Valves For Offshore and Seawater ApplicationsSergio MuñozNo ratings yet

- Pile Foundation PresentationDocument110 pagesPile Foundation Presentationmujeebtalib100% (4)

- ANSYS Theory Reference For The Mechanical APDL and Mechanical Applications R13 PDFDocument0 pagesANSYS Theory Reference For The Mechanical APDL and Mechanical Applications R13 PDFfrancisco_gil_510% (1)

- Principles of Fluid DynamicsDocument2 pagesPrinciples of Fluid DynamicsMicheleFontanaNo ratings yet