Professional Documents

Culture Documents

Manual TK-50 PDF

Uploaded by

electroliticoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Manual TK-50 PDF

Uploaded by

electroliticoCopyright:

Available Formats

MAINTENANCE

TK50G

TK50G MANUAL

Overseas Engineering Team

ThyssenKrupp Dongyang Elevator

-1-

Printed in KOREA January, 2007

MAINTENANCE

TK50G

2. Inspection operation preparation

2.1 Voltage check before Main power turn ON

Check Point

Check

Remarks

P24G, G24

DC24V Voltage

TRANS Voltage

P24, G24

DC24V Voltage

SMPS Voltage

R-S, S-T, T-R

AC380V Voltage

R-N, S-N, T-N

AC220V Voltage

Building main power

supply

R-AC1, S-AC1, T-AC1, - AC

AC220V Voltage

C/P power supply

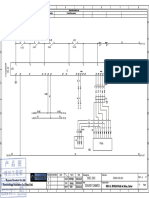

2.2 M/R Wiring

17,18

Motor PG ; X907

EE,U,V,W,1,2

U,V,W,EE

BM1,BM2

R,S,T,N

Picture 1

Picture 2

Motor wiring Box

C/P CPIK wiring

1. U,V,W,EE of Picture 1

connect to

U(24),V(25),W(26),EE of picture 2 (CPIK).

2. Motor temperature detection sensor 1, 2

connect to 17(TM1),18(TM2) of picture 2

(CPIK).

3. Break signal BM1,BM2 connect to C/P

PWR terminal 46(40),47(41).

1. Motor PG cable of picture 2 connect to

CPIK connector X907.

2. U,V,W,EE connect to Motor U,V,W,EE.

3. R,S,T,N connect to Main supply panel of

building R,S,T,N.

4. 17(TM1),18(TM2) connect to Motor Box

1,2.

ThyssenKrupp Dongyang Elevator

-2-

Printed in KOREA January, 2007

MAINTENANCE

TK50G

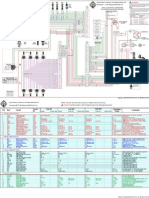

Temporary Remote

control ; CNL2

Gov. PG

CNHV 3

Pin No. 1,2

CNHV 4

Pin No. 1,2,3,4,7/6,8

Picture 3

IOC PCB

1. Gov. PG connect to Gov. PG connector (When Inspection operation, no required)

2. Pin No. 1,2 of CNHV 3 are Jumper (123A,123)

3. Pin No. 1,2,3,4,7 of CNHV 4 are Jumper (CDCF,HDIF,DLT,DLB,AC1B)

Pin No. 6,8 of CNHV 4 are Jumper (If dont have Back Door)

4. Temporary remote control connect to pin 1 (Common), pin 3 (UP), pin 4 (DOWN).

E,F

3,4

40,41,44,45

Picture 4

C/P Wiring

1. Gov. S/W connect to 3 and 4.

2. MOTOR Brake connect to 40 and 41.

3. 5,7,9,11 Jumper ; Hoist-way and Car Safety line jumper.

4. Rope Brake Jumper ; E.F

5. SDB & SDT connect to 44 and 45.

ThyssenKrupp Dongyang Elevator

-3-

Printed in KOREA January, 2007

MAINTENANCE

TK50G

2.3 Brake wiring check

. Remove BRK+ and BRK- from Brake Controller(BRC) and check short or not

between BRK+ and Earth and BRK- and Earth. (Insulation check)

. Ohm check between BRK+ and BRK- by Ohmmeter - 260-290.

. Brake Coil should connect by serial connection.

. Brake Controller(BRC) receive 220VAC and make DC voltage and control Brake.

There are T-VR(Forcing= 1 sec) and V-VR(Holding voltage= DC100V).(Initial

voltage = 185-190V, Holding voltage = 100V)

2.4 Encoder Wiring and check

. Gov. Encoder Wiring (Wiring to CNL3 of IOC PCB)

. Specification

105m/min below = GDY-1A(242mm) P 16 = 465 Check

120m/min over = GD-4A1(240mm) P 16 = 465 Check

. Type : Incremental Type

Output pulse :

300 (Pulse/revolution)

Output type :

Line Drive(A, A/, B, B/)

Supply voltage :

. Wiring check :

DC 5V

1 PIN = PEA (Green)

2 PIN = PEA/ (Blue)

3 PIN = PEB (White)

4 PIN = PEB/ (Pink)

5 PIN = PENC(+5V) (Red)

6 PIN = GND(Grounding) (Black)

7 PIN = SHIELD

8 PIN = SPARE

*. If use Motor encoder only P 16 = 465 -> 15815 setting (This data is not fixed data)

This data will be changed depend on car speed.

ThyssenKrupp Dongyang Elevator

-4-

Printed in KOREA January, 2007

MAINTENANCE

TK50G

. Motor Encoder Wiring (X907 of CPI-K)

.Specification : DY88-30C-1024VL

.Type : Incremental Type

Output Pulse : 1024 (Pulse/revolution)

Output type : Line Drive(A, A/, B, B/, Z, Z/)

Supply voltage : DC 5V

. Wiring check : X907

1 = A/ (Blue)

2 = A (Green)

3 = B (White)

4 = B/ (Pink)

5 = Z/ (Orange)

6 = Z (Yellow)

7 = GND (Black)

8 = SHIELD

9 = +5V (Red)

. Check by Remote FAST - M 50 = 1024 (45-105m/min) check

(TK50M (MRL) - M 50 = 2048)

. Installed bracket(Steal) is difference between TW(ThyssenKrupp Worm Gear)63

and TW130,160.

TW63

ThyssenKrupp Dongyang Elevator

TW130,160

-5-

Printed in KOREA January, 2007

MAINTENANCE

TK50G

2.5 Jumper for Inspection operation

1. JUMPER check

GOV JUMPER = 101, 102 ( CHRT - 3, 4 )

HOISTWAY JUMPER = 103, 109 ( CHRT - 5, 7 )

CAR JUMPER = 109, 121 ( CHRT - 7, 11 )

ETSD JUMPER = 123, 123A ( IOC PCB ; CNHV 3 Pin No. 1, 2 )

Front CAR Door (CDCF) = AC1B, 202 ( IOC PCB ; CNHV 4 - 1, 7 )

Front HALL Door (HDIF) = AC1B, 215 ( IOC PCB ; CNHV 4 - 2, 7 )

Rear CAR Door = AC1B, 204 ( IOC PCB ; CNHV 5 1 and CNHV 4 - 7 )

Rear HALL Door = AC1B, 225 ( IOC PCB ; CNHV 5 - 2 CNHV 4 - 7 )

=> If no Rear Door jumper DZB and DZC ( CNHV 4 - 6, 8 )

DLB(3LS), DLT(4LS) JUMPER = DLB, DLT ( IOC PCB ; CNHV 4 - 3, 4, 7 )

EPNP(Emergency and Normal Power) JUMPER = IOC PCB - NP JUMPER PIN

RGOK(Rope Gripper Okay) JUMPER = IOC PCB - CNL 8 2 and G24

IOC DIP S/W(INRB=INS RUN BUG) Turn ON

and check INRB LED ON position.

2. Temporary remote control connection (Refer to Picture 3)

Connect it to CNL 2 of IOC PCB to move low speed operation.

UP = CNL 2-3 (INCNU)

DOWN = CNL 2-4 (INCND)

Common = CNL 2-1 ( P24 )

2.6 LED Check

1. IOC PCB - 101, AC1B, P24(DC24V), P24G(DC24V), P5B(DC5V), P5 6 pcs of LED are

must ON

2. 186C PCB - EGOOD/EBAD LED must ON/OFF repeatedly (Flickering).

After setting ESTD (120m/min above), EGOOD is ON and EBAD is OFF.

3. 186C PCB - WD/STAT LED are FLICKER then OFF

4. After few second later, WD LED must ON.

(If WD LED is not ON, 186C Program is something wrong)

5. INRB(Ins Run Bug=Normal signal from Car top) LED must ON.

ThyssenKrupp Dongyang Elevator

-6-

Printed in KOREA January, 2007

MAINTENANCE

TK50G

2.7 Moving Direction check

1. In Remote FAST, INS speed(M16 = 50fpm(15m/min)), MOTOR Encoder PPR(Pulse

per Revolution)(M50 =1024, MRL;M50=2048) check (1 fpm = 0.3048 m/min)

2. If not install Gov. Encoder, set M 60 = 0 or 25.

Otherwise, Encoder Cross Check between Motor encoder and Gov. Encoder, Error

will be happened.

If M 60 = 255, Doing Encoder Cross Check between Motor and Gov. Encoder.

3. Revolution direction is wrong, change CPIK Parameter 3 and Parameter 4.

4. After change any DATA in Remote FAS, you should write WRT for saving data.

5. If car speed difference, you should check CPIK Parameter SHEAVE Diameter(P14),

GEAR RATIO (P13).

6. In IMS Motion Diagnostic, check the Demand Velocity and Car Velocity whether it is

same or not. If not same these data, check M51(Motor RPM).

- M51 is only Monitoring of car speed, can not change actual car speed.

2.8 Signal explanation

Inspection mode under installation

Input/

Output

Ready-To

-Run

Status

After High speed

I/O

Running

Explanation

Status

Mnemonic

Inspection

Not

Running

Up Run

Automatic

Not

Running

Up Run

ON=Green , OFF=Grey

BRKC

OFF

ON

B/K open command

BRKC

Grey

Green

Grey

Green

BRKCD

ON

OFF

BRKC RY B contact(NC)

BRKCD

Green

Grey

Green

Grey

BRKD

ON

OFF

BRK RY B contact(NC)

BRKD

Green

Grey

Green

Grey

BRKE

OFF

ON

BRK RY A contact(NO)

BRKE

Green

Grey

Green

Grey

BSLE

OFF

ON

Brake A contact(NO) (TK50M)

BSLE

Green

Green

Green

Green

BSLM

OFF

ON

Brake B contact(NC) (TK50M)

BSLM

Green

Green

Green

Green

CDCF

ON

ON

Car door(Front)

CDCF

Green

Green

Green

Green

CDCFM

OFF

OFF

Car door(Front) RY B

contact(NC)

CDCFM

Grey

Grey

Grey

Grey

CST

OFF

ON

Safety line

CST

Green

Green

Green

Green

CSTO RY B contact(NC)

CSTOM

Green

Green

Green

Green

DLT

OFF

OFF

4 LS(Direction Limit Bottom)

DLT

Green

Green

Green

Green

DLB

OFF

OFF

3 LS(Direction Limit Top)

DLB

Green

Green

Green

Green

ThyssenKrupp Dongyang Elevator

-7-

Printed in KOREA January, 2007

MAINTENANCE

DRVE

ON

TK50G

ON

DRVE

Green

Green

Green

Green

DZ1 RY B contact(NC)

DZ1M

DZ2 RY B contact(NC)

DZ2M

EPNP

ON

ON

Emergency power signal

EPNP

Green

Green

Green

Green

HDIF

ON

ON

Hall Door(Front)

HDIF

Green

Green

Green

Green

HDIFM

OFF

OFF

HDIF RY B contact(NC)

HDIFM

Grey

Grey

Grey

Grey

HDIR

ON

ON

Hall Door (Rear)

HDIR

Green

Green

Green

Green

Green

Green

Green

Green

Hall Door (Rear) B contact(NC) HDIRM

INCN

OFF

ON

M/R Ins

INCN

Green

Green

Grey

Grey

INCND

OFF

ON

M/R Ins DOWN

INCND

Green

Green

Grey

Grey

INCNM

OFF

ON

M/R Normal

INCNM

Green

Green

Grey

Grey

INCNU

OFF

ON

M/R Ins UP

INCNU

Green

Green

Grey

Grey

Car top Ins

INCT

Green

Green

Grey

Grey

Car top Ins DOWN

INCTD

Green

Green

Grey

Grey

Car top Normal

INCTM

Green

Green

Grey

Grey

Car top Ins UP

INCTU

Green

Green

Grey

Grey

INRB

ON

ON

INS RUN BUG

INRB

Grey

Green

Grey

Grey

INRBM

OFF

ON

INRB B contact(NC)

INRBM

Grey

Green

Grey

Grey

MCCD

ON

OFF

MCC RY B contact(NC)

MCCD

Grey

Grey

Grey

Grey

MCD

ON

OFF

MC1 B contact(NC)

MCD

Green

Grey

Green

Grey

NCE

OFF

ON

MC1 A contact

MCE

Grey

Green

Grey

Green

MCPD

ON

OFF

MCP B contact(NC)

MCPD

Green

Green

Green

Green

RGC1

ON

ON

R/G control signal

RGC1

Green

Green

Green

Green

RGC2

ON

ON

R/G control signal

RGC2

Green

Green

Green

Green

RGC1,2 RY B contact(NC)

RGM

Green

Green

Green

Green

RGOK

ON

ON

R/G Feedback Sigan

RGOK

Green

Green

Green

Green

SAF2

ON

ON

Safety + Door are okay

SAF2

Green

Green

Green

Green

SAF3

ON

ON

Safety + Door + CPIK

SAF3

Green

Green

Green

Green

SAF4

ON

ON

Safety+Door+CPIK+LSM(CPU

program)

SAF4

Green

Green

Green

Green

SAFC

ON

ON

Software check signal(LSM)

SAFC

Green

Green

Green

Green

SAFCD

OFF

OFF

SAFC RY B contact(NC)

SAFCD

Grey

Grey

Grey

Grey

SAFE

ON

ON

Safety Line is okay

SAFE

Green

Green

Green

Green

ThyssenKrupp Dongyang Elevator

-8-

Printed in KOREA January, 2007

MAINTENANCE

TK50G

EPW

OFF

OFF

CDCR

ON

ON

Car door(Rear)

CDCRM

OFF

OFF

CDCR RY B contact(NC)

--- D, --- M(Monitoring) NC contact

* : Off in Door Zone

--- E NO contact

# : On out of Door Zone

Temporary Operation I/O Status as seen on IMS Car I/O screen using Positive Logic

2.9 Landing sensor (Landing s/w) operation check

1. Set M16 (Car inspection speed) = 50(15m/min) -> 15 fpm(4.5m/min).

2. Loaded balance load.

3. Door blocking (Door disconnection).(D 26 = 1)

4. Move the lift to middle floor level.

5. Check DZ1, DZ2 , LVU, LVD signal are ON.(Metered Logic)

6. Move the Car 25.4mm lower than Level and check LVU is ON and LVD is OFF.

7. Move the Car 25.4mm upper than Level and check LVD is ON and LVU is OFF.

8. Move the Car 150mm upper than Level and check DZ1 and DZ2 are OFF.

2.10 Position count check

1. In Motion Diagnostic, if car up direction, PULSE should be increase.

2. If Position Count is wrong with car moving, change CNL 3 A(1 pin) and B(3 pin),

A/(2 pin) and B/(4 pin) at IOC PCB.

2.11 Over balance ratio check

1. Set M 99. (105m/min above = 45%, 120m/min above = 48% )

2. Set weight unit by lbs (Pound).

(1 lbs = 0.45359kg,

ThyssenKrupp Dongyang Elevator

1 Kg = 2.2 lbs)

-9-

Printed in KOREA January, 2007

MAINTENANCE

TK50G

2.12 PCB(Printed Circuit Board) LED

1. IOC PCB LED and IOC/186C Fuse

LED

Fuse

AC1B

F13

If no problem of AC220V to IOC PCB and F13 Fuse is okay.

101

F6

Provide voltage to Safety Circuit 101 and F6 Fuse is okay

P24

F2,F4

Provide voltage P24 to IOC PCB and Fuse F2,F4 are okay.

P24G

F1

Function and explanation

Provide voltage P24G to IOC PCB (CNHC1,CNHC2)

P5

Provide voltage P5 to IOC PCB

P5B

Provide PENC(DC5V, Gov. encoder power supply) to IOC PCB

INRB

DIPSW of INRB (INS RUN BUG) at IOC is ON condition

F5

P12(DC12V) power supply

F8

P24 of CNL2 (M/R Ins/Auto switch)

F14

P24 of CNL3 (GOV PG)

F1(186C)

P12 power supply (CON11)

F2(186C)

P5 power supply (186C power supply)

ThyssenKrupp Dongyang Elevator

- 10 -

Printed in KOREA January, 2007

MAINTENANCE

TK50G

2. IOC PCB JUMPER Pin setting explanation

Jumper

HC1S

HC2S

CCS

LCS

DLS

GCS

NP

Position

Function and explanation

ON

HC1 CAN Channel Shield connect to CHASSIS

OFF

HC1 CAN Channel Shield disconnect from CHASSIS

ON

HC2 CAN Channel Shield connect to CHASSIS

OFF

HC2 CAN Channel Shield disconnect from CHASSIS

ON

CC CAN Channel Shield connect to CHASSIS

OFF

CC CAN Channel Shield disconnect from CHASSIS

ON

LC CAN Channel Shield connect to CHASSIS

OFF

LC CAN Channel Shield disconnect from CHASSIS

ON

DL CAN Channel Shield connect to CHASSIS

OFF

DL CAN Channel Shield disconnect from CHASSIS

ON

SDLC CAN Channel Shield connect to CHASSIS

OFF

SDLC CAN Channel Shield disconnect from CHASSIS

ON

If dont have Emergency power operation - ON

OFF

If have Emergency power operation OFF and connect this

signal to CNL9-1 Pin

3. IOC PCB Switch and Connector Jumper explanation

Jumper

RUN/STOP

DOB

(Door open

Button)

123-123A

(CNHV3)

DZB-DZC

(CNHV4)

Location

RUN(Top)

Explanation

Normal operation

STOP

Cut the Safety Circuit

Push

Door Open command

ON

Before ETSD Scan - Jumper

OFF

After ETSD Scan No jumper, Can operation of ETSD

ON

No Rear(Back) Door - Jumper

OFF

Rear(Back) Door No Jumper

ThyssenKrupp Dongyang Elevator

- 11 -

Printed in KOREA January, 2007

MAINTENANCE

TK50G

4. 186C PCB LED explanation

LED

Description

STAT

Microprocess

or

Status

Color LED State(1=on,0=off)

RED

110011001100_Repeat Software UP-Load required by Zed

Modem

100010001000_Repeat

Boot Block require update

ed

1000000000_Repeated

EBAD

ETSD Bad

RED

EGOO

ETSD Good GREEN

D

WD

Watchdog

(Monitoring GREEN

device)

Status

RAM Job file lost

EBAD and EGOOD Flicker

ETSD is not set-up

EBAD - ON

Set-up but problem

EBAD and EGOOD Flicker

ETSD is not set-up

EGOOD - ON

Set-up good and no problem

ON

Program normal

OFF

Program abnormal

5. Brake Controller(BRC) LED Explanation

LED

Color

LED

Status

PWR

RED

ON

If AC220V supply to Brake Controller (BRC), PWR LED

will be ON.

ON

Under output condition

OPER GREEN

ThyssenKrupp Dongyang Elevator

- 12 -

Printed in KOREA January, 2007

MAINTENANCE

TK50G

2.13 CPIK Hyper-terminal handling method

1. Select CPIK_Entry(CPIK-Hyper-terminal).

2. If no good communication with CPI, cant open next step. The picture of telephone is

lift up condition as picture 1, this means communication was started.

3. Push Enter Key or H Key, Password :

will be appeared as picture 1 then

input NAT then picture 2 will be appeared. Possible to no ask Password.

Picture 1

Picture 2

4. Foe example, if you want to change Control type parameter, input P 8 Enter after

> as picture 2 then picture 3 will be appeared.

Parameter

A

Present Parameter

Picture 3

ThyssenKrupp Dongyang Elevator

- 13 -

Present Parameter

al e

Printed in KOREA January, 2007

MAINTENANCE

TK50G

5. If you dont know parameter range of P 8, Enter in A part of picture 3 and

R Enter then picture 4 will be appeared.

Picture 4

6. When you change parameter, refer to B part data of picture 4 and input some data

to A part of picture 3.

7. H Enter after > of picture 2, the following window will be appeared.

Explanation of Shorten key.

; ?, P, R, D, T, V, S, F, C,

>, <, $, !, l

ThyssenKrupp Dongyang Elevator

- 14 -

Printed in KOREA January, 2007

MAINTENANCE

TK50G

4. Summary > R Enter in the above window, picture 5 will be appeared.

R Enter again at cursor location of picture 5 then picture 6 will be appeared.

Changed Parameter

C

Picture 5

Cursor location

Picture 6

6. Picture 5 and 6 are parameter range of CPIK which are allowed to change parameter.

7. CPIK data of picture 5, 6 monitor, drag and copy and paste to MEMO program and

save(Required information should mentioned together such as capacity, speed and so

on), it can be use for back-up file data if any problem occurred.

8. C part symbol means is changed Parameter.

ThyssenKrupp Dongyang Elevator

- 15 -

Printed in KOREA January, 2007

MAINTENANCE

TK50G

9. How to save Parameter.

If S Enter after > of picture 2,

Overwrite old parameters ? (Y/N) then Y input,

Save completed will be appeared then changed Parameter will be saved.

If you are not save data, the lift was operated by changed parameter. But when main

power are Off/On, changed parameter will be changed to original parameter.

2.14 CPIK Inverter Data check for Inspection operation

P2 MOTOR RPM

P3 MOTOR Revolution direction - U,V,W

P4 MOTOR PG Revolution direction

P8 Model selection - MODE 5 (TAC50K)

P13 Gear Ratio, TK50M (MRL) - "1"

P14 Sheave Diameter

TK50M Refer to MOTOR name plate

P15 Roping (1:1- 1, 2:1- 2 set)

P40 MOTOR TYPE

P96 MOTOR PG TYPE ; Data - "0" (1024).

(TK50M - "2048")

ThyssenKrupp Dongyang Elevator

- 16 -

Printed in KOREA January, 2007

MAINTENANCE

TK50G

Gear ratio and Sheave diameter

TM

TW 63

Speed

Gear ratio

(input

value)

Sheave

diameter

passenger

Remarks

45m/min

48:1(48.0)

510

P6 P11

5.7Kw, 340V,1350rpm

60m/min

33:1(33.0)

510

P6 P9

5.7Kw, 340V, 1250rpm

P10, P11

11Kw, 340V, 1250rpm

90m/min

105m/min

45m/min

60m/min

TW 130

48:2(24.1)

42:1(42.0)

90m/min

105m/min

45:2(22.6)

P8 P11

590

P8 P11

11Kw, 340V, 1100rpm

640

11Kw, 340V, 1250rpm

540

640

45m/min

640

50:1(50.0)

720

90m/min

57:2(28.6)

640

105m/min

51:2(25.1)

640

120m/min

45:2(22.6)

640

ThyssenKrupp Dongyang Elevator

11Kw, 340V, 1350rpm

540

120m/min

60m/min

TW 160

510

- 17 -

P13,P15

16Kw, 340V, 1200rpm

16Kw, 340V, 1400rpm

16Kw, 340V, 1350rpm

P17,P20

11Kw, 340V, 1100rpm

P24

16Kw, 340V, 1100rpm

P17,P20,P24

16Kw, 340V, 1350rpm

P17

16Kw, 340V, 1250rpm

P20,P24

20.5Kw, 340V, 1250rpm

P17,P20

20.5Kw, 340V, 1350rpm

P24

27.5Kw, 325V, 1350rpm

P17

20.5Kw, 340V, 1350rpm

P20,P24

27.5Kw, 325V, 1350rpm

Printed in KOREA January, 2007

MAINTENANCE

TK50G

2.15 186C DATA check and input

1. Select IMS and enter.

(Dont connect 186C and laptop computer by 232 cable)

Picture 1

Picture 2

2. In Control Panel of IMS, select Network and click right button of Mouse. In Pull Down

Manu, select Add a Net and click then you can get Net01.(picture 1,2)

3. Select Net01 and click right button of Mouse. In Pull Down Manu, select Add a Group

and click then you can get Group01.(picture 2,3)

Picture 3

ThyssenKrupp Dongyang Elevator

Picture 4

- 18 -

Printed in KOREA January, 2007

MAINTENANCE

TK50G

1. Select Group01 and click right button of Mouse. In Pull Down Manu, select Add a

Car and click then you can get Car01.(picture 3,4)

5. Select Net01 and change the name by

project name and connect RS232 cable.

6. After connecting to 186C, you can get A of

picture 5.

:

Red

Electric

Plug=On

Line

communication

A

Lighted

Bulb=Download

is

success

and

communication is okay between IMS and

Controller.

Picture 5

7. Refer to picture 6 and check the following data by Remote FAST.

Picture 6

DATA input

ThyssenKrupp Dongyang Elevator

- 19 -

Printed in KOREA January, 2007

MAINTENANCE

TK50G

186C parameter check

CEF = 111111111111 (12pcs) (Auto Announcer)

D12 = 7

D24 = Handicap lift 100, Passenger lift 50

(DOOR OPEN TIME when HALL CALL generation, 100=10SEC)

D25 = Handicap lift 100, Passenger lift 50

(DOOR OPEN TIME when CAR CALL generation, 100=10SEC)

D26 = Before High speed operation 1, After High speed operation 0

D27 = 0

D35 = 100

F16 = Option of Fire-man lift (Passenger lift 0, Emergency lift 15)

H10 = Parking floor setting, Lowest floor = 01

H16 = Door open time after landing at Parking floor = 70

J10 = Passenger capacity (15 persons 1000*2.2 = 2200)

J11 = Lift Index, Lift No. 1 = 1, Lift No. 2 = 2

J15 = The total numbers of stopping floor

M16 = 53 Inspection speed (53 = 15~16m/min)

M30=Rating speed (45m/min147,60m/min197,90m/min295,105m/min344,

120m/min393,150m/min492)

M31 = 5~6

M32 = 50 Hunting speed

M35 = 100

M50 = TK50G (Geared Lift) ; 1024, TK50M (MRL) ; 2048

M51 = MOTOR RPM (Table 1, Table 2 Reference)

In case of TK50M(MRL), change this data in Diagnostics of IMS to make same CAR

Speed and Dmd(Damand) speed.

ThyssenKrupp Dongyang Elevator

- 20 -

Printed in KOREA January, 2007

MAINTENANCE

45m/min

( 0.75m/s )

TK50G

60m/min

( 1.0m/s )

90m/min

( 1.5m/s )

105m/min

( 1.75m/s )

120m/min

( 2.0m/s )

150m/min

( 2.5m/s )

TW63 (12*3) TW63 (12*3)

CPIK 15

CPIK 15

P6

5.7kW340V

5.7kW340V

(450kg)

1350rpm

1250rpm

51048:1

51033:1

TW63 (12*3) TW63 (12*3 ) TW63 (12*4 ) TW63 (12*4 )

CPIK 15

CPIK 15

CPIK 15

CPIK 15

P8

5.7kW340V

5.7kW340V

7.5kW340V

9.5kW340V

(550kg)

1350rpm

1250rpm

1350rpm

1350rpm

51048:1

51033:1

51048:2

59048:2

TW63 (12*3 ) TW63 (12*3 ) TW63 (12*4 ) TW63 (12*4 )

CPIK 15

CPIK 15

CPIK 15

CPIK 15

P9

5.7kW340V

5.7kW340V

7.5kW340V

9.5kW340V

(600kg)

1350rpm

1250rpm

1350rpm

1350rpm

51048:1

51033:1

51048:2

59048:2

TW63 (12*4 ) TW63 (12*4 ) TW63 (12*4 ) TW63 (12*4 )

CPIK 15

CPIK 15

CPIK 15

CPIK 32

P10

5.7kW340V

7.5kW340V

9.5kW340V

11kW340V

(680kg)

1350rpm

1250rpm

1350rpm

1350rpm

51048:1

51033:1

51048:2

59048:2

TW63 (12*4 ) TW63 (12*4 ) TW63 (12*4 ) TW63 (12*4 )

CPIK 15

CPIK 15

CPIK 15

CPIK 32

P11

5.7kW340V

7.5kW340V

9.5kW340V

11kW340V

(750kg)

1350rpm

1250rpm

1350rpm

1350rpm

51048:1

51033:1

51048:2

59048:2

TW130

TW63 (12*5 ) TW63 (12*5 ) TW130 (12*5 ) TW130 (12*5 )

(12*7 )CPIK

CPIK 15

CPIK 15

CPIK 32

CPIK 32

P13

48

7.5kW340V

9.5kW340V

11kW340V

13kW340V

(900kg)

16kW340V

1350rpm

1250rpm

1200rpm

1400rpm

1350rpm

51048:1

51033:1

54045:2

54045:2

64045:2

TW160

(14*6 )

CPIK 48

18.5kW340V

1350rpm

80045:2

TW130

TW63 (12*5 ) TW63 (12*5 ) TW130 (12*5 ) TW130 (12*5 )

(12*7 )CPIK

CPIK 15

CPIK 15

CPIK 32

CPIK 48

48

P15

7.5kW340V

9.5kW340V

13kW340V

16kW340V

16kW340V

(1000kg)

1350rpm

1250rpm

1200rpm

1400rpm

1350rpm

51048:1

51033:1

54045:2

54045:2

64045:2

TW160

(14*6 )

CPIK 60

20.5kW340V

1350rpm

80045:2

ThyssenKrupp Dongyang Elevator

- 21 -

Printed in KOREA January, 2007

MAINTENANCE

TK50G

45m/min

( 0.75m/s )

60m/min

( 1.0m/s )

90m/min

( 1.5m/s )

105m/min

( 1.75m/s )

120m/min

( 2.0m/s )

150m/min

( 2.5m/s )

TW130

(12*6 )

CPIK 15

9.5kW340V

1125rpm

54042:1

TW130

(12*7 )CPI

K 32

9.5kW340V

1125rpm

54042:1

TW130

(12*6 )

CPIK 32

11kW340V

1250rpm

64042:1

TW130

(12*7 )CPIK

32

13kW340V

1250rpm

64042:1

TW130

(12*6 )

CPIK 48

16kW340V

1200rpm

54045:2

TW130

(12*7 )

CPIK 48

18.5kW340V

1200rpm

54045:2

TW130

(12*6 )

CPIK 48

16kW340V

1400rpm

54045:2

TW130

(12*7 )

CPIK 48

18.5kW340V

1400rpm

54045:2

TW130

(12*7 )

CPIK 48

18.5kW340V

1350rpm

64045:2

TW160

(14*6 )CPIK

60

20.5kW340V

1350rpm

64045:2

P24

(1600kg)

TW160

(14*6 )

CPIK 32

13kW340V

1125rpm

64050:1

TW160

(14*6 )

CPIK 48

16kW340V

1350rpm

72050:1

TW160

(14*6 )

CPIK 48

20.5kW340V

1250rpm

64057:2

TW160

(14*6 )

CPIK 60

22kW340V

1350rpm

64051:2

TW160

(14*7 )

CPIK 60

27.5kW340V

1350rpm

64045:2

TW160

(14*6)

CPIK 60

22kW340V

1350rpm

80045:2

TW160

(14*7 )

CPIK 60

27.5kW340V

1350rpm

80045:2

TM90D

(16*6 )

CPIK 105

30kW340V

1450rpm

80073:3

[148.1A]

P27

(1800kg)

TW160

(14*7 )

CPIK 48

13kW340V

1125rpm

64050:1

P30

(2000kg)

TW160

(14*7 )

CPIK 48

16kW340V

1125rpm

64050:1

TM90D

(16*6 )

CPIK 60

19kW340V

1450rpm

75056:1

[99.9A]

TM90D

(16*6 )

CPIK 60

22kW340V

1450rpm

75056:1

[106.3A]

TM90D

(16*6 )

CPIK 105

30kW340V

1450rpm

75077:2

[114.7A]

TM90D

(16*6 )

CPIK 105

30kW340V

1450rpm

75077:2

[122.9A]

TM90D

(16*6 )

CPIK 105

30kW340V

1450rpm

75065:2

[128.5A]

TM90D

(16*6 )

CPIK 105

30kW340V

1450rpm

75065:2

[138.0A]

P17

(1150kg)

P20

(1350kg)

Table 1 Geared TM for Passenger E/L (1:1)

ThyssenKrupp Dongyang Elevator

- 22 -

Printed in KOREA January, 2007

MAINTENANCE

TK50G

45m/min (0.75)

60m/min (1.0)

90m/min (1.5)

105m/min (1.75)

P6

(450kg)

TW63 (12*3)

TW63 (12*3)

5.7kW340V1350rpm 5.7kW340V1250rpm

CPIK 15

CPIK 15

51048:1

51033:1

P8

(550kg)

TW63 (12*4)

TW63 (12*4)

TW63 (12*4)

TW63 (12*4)

5.7kW340V1350rpm 5.7kW340V1250rpm 7.5kW340V1350rpm

9.5kW340V

CPIK 15

CPIK 15

CPIK 15

1350rpmCPIK 15

51048:1

51033:1

51048:2

59048:2

P9

(600kg)

TW63 (12*4)

TW63 (12*4)

TW63 (12*4)

TW63 (12*4)

5.7kW340V1350rpm 5.7kW340V1250rpm 7.5kW340V1350rpm

9.5kW340V

CPIK 15

CPIK 15

CPIK 15

1350rpmCPIK 15

51048:1

51033:1

51048:2

59048:2

P10

(680kg)

TW63 (12*5)

TW63 (12*5)

TW63 (12*5)

TW63 (12*5)

5.7kW340V1350rpm

7.5kW340V

9.5kW340V1350rpm

11kW340V

CPIK 15

1250rpmCPIK 15

CPIK 15

1350rpmCPIK 32

51048:1

51033:1

51048:2

59048:2

P11

(750kg)

TW63 (12*5)

TW63 (12*5)

TW63 (12*5)

TW63 (12*5)

5.7kW340V1350rpm

7.5kW340V

9.5kW340V1350rpm

11kW340V

CPIK 15

1250rpmCPIK 15

CPIK 15

1350rpmCPIK 32

51048:1

51033:1

51048:2

59048:2

120m/min (2.0)

P13

(900kg)

TW130 (12*6)

7.5kW340V

1125rpmCPIK 15

54042:1

TW130 (12*6)

TW130 (12*6)

TW130 (12*6)

TW130 (12*7)

9.5kW340V

13kW340V1200rpm 13kW340V1400rpm

16kW340V

1250rpmCPIK 32

CPIK 32

CPIK 48

1350rpmCPIK 48

64042:1

54045:2

54045:2

64045:2

P15

(1000kg)

TW130 (12*6)

7.5kW340V

1125rpmCPIK 15

54042:1

TW130 (12*6)

TW130 (12*7)

TW130 (12*6)

TW130 (12*6)

16kW340V

9.5kW340V

13kW340V1200rpm 16kW340V1400rpm

1350rpmCPIK 48

1250rpmCPIK 32

CPIK 32

CPIK 48

64045:2

64042:1

54045:2

54045:2

P17

(1150kg)

TW160 (14*6)

9.5kW340V

1125rpmCPIK 32

64050:1

TW160 (14*6)

11kW340V

1350rpmCPIK 48

72050:1

TW160 (14*6)

16kW340V

1250rpmCPIK 48

64057:2

TW160 (14*6)

18.5kW340V

1350rpmCPIK 48

64051:2

TW160 (14*6)

18.5kW340V

1350rpmCPIK 48

64045:2

P20

(1350kg)

TW160 (14*6)

11kW340V

1125rpmCPIK 32

64050:1

TW160 (14*6)

13kW340V

1350rpmCPIK 48

72050:1

TW160 (14*7)

18.5kW340V

1250rpmCPIK 48

64057:2

TW160 (14*7)

20.5kW340V

1350rpmCPIK 60

64051:2

TW160 (14*7)

22kW340V

1350rpmCPIK 60

64045:2

P24

(1600kg)

TW160 (14*7)

13kW340V

1125rpmCPIK 32

64050:1

TW160 (14*7)

16kW340V

1350rpmCPIK 48

72050:1

TW160 (14*7)

20.5kW340V

1250rpmCPIK 48

64057:2

TW160 (14*7)

27.5kW340V

1350rpmCPIK 60

64051:2

TW160 (14*7)

27.5kW340V

1350rpmCPIK 60

64045:2

Table 2 Geared TM for Observation E/L (1:1)

ThyssenKrupp Dongyang Elevator

- 23 -

Printed in KOREA January, 2007

MAINTENANCE

TK50G

30m/min

( 0.5m/sec )

45m/min

( 0.75m/sec )

60m/min

( 1.0m/sec )

TW130 (12*5)

9.5kW340V

1250rpmCPIK 32

64042:1

TW130 (12*6)

11kW340V

1250rpmCPIK 32

64042:1

TW160 (12*6)

13kW340V

1350rpmCPIK 48

72050:1

TW160 (14*6)

16kW340V

1350rpmCPIK 48

72050:1

TM90D (14*6)

19kW340V

1450rpmCPIK 60

75056:1

TM90D (16*6)

22kW340V

1450rpmCPIK 60

75056:1

TW130 (12*5)

7.5kW340V

1125rpmCPIK 15

54042:1

TW130 (12*6)

7.5kW340V

1125rpmCPIK 15

54042:1

TW130 (12*5)

11kW340V

1200rpmCPIK 32

54045:2

TW130 (12*6)

16kW340V

1200rpmCPIK 48

54045:2

TW160 (12*6)

18.5kW340V

1250rpmCPIK 48

64057:2

TW160 (14*6)

22kW340V

1250rpmCPIK 60

64057:2

TM90D (14*6)

30kW340V

1450rpmCPIK 105

75077:2

TM90D (16*6)

30kW340V

1450rpmCPIK 105

75077:2

TW130 (12*5)

7.5kW340V

1250rpmCPIK 15

64042:1

TW130 (12*6)

9.5kW340V

1250rpmCPIK 32

64042:1

TW130 (12*5)

16kW340V

1350rpmCPIK 48

64045:2

TW130 (12*6)

18.5kW340V

1350rpmCPIK 48

64045:2

TW160 (12*6)

22kW340V

1350rpmCPIK 60

64045:2

TW160 (14*6)

27.5kW340V

1350rpmCPIK 60

64045:2

750 kg

(1:1 roping)

1000 kg

(1:1 roping)

1500 kg

2000 kg

2500 kg

3000 kg

3500 kg

4000 kg

30m/min

(3:1 or 4:1 roping)

TW160 (14*6)3:1

22kW340V

1250rpmCPIK 60

64057:2

TW160 (14*6)4:1

27.5kW340V

1350rpmCPIK 105

64045:2

TW160 (14*6)4:1

27.5kW340V

1350rpmCPIK 105

64045:2

4500 kg

5000 kg

6000 kg

Table 3 Geared TM for Freight E/L (2:1)

ThyssenKrupp Dongyang Elevator

- 24 -

Printed in KOREA January, 2007

MAINTENANCE

TK50G

M52=Rating speed(45m/min147,60m/min197,90m/min295,105m/min344,

120m/min393,150m/min492)

M60 = Under ins operation (Not connection Gov. encoder) 0 or 25, High speed operation 255

M61 = Under inspection operation 100 (Not connection Gov. encoder), High speed operation 50

M92 = 250 weight, pound (Anti-nuisance call)

M94 = 100 (Overload)

M99 = 45 (Over Balance)

O10 = 3 (Anti-nuisance call number)

O25 = 0 (DOOR short)

O26 = 1 (DOOR short)

O35 = 180 (18 sec) (LIGHT,FAN OFF time without CALL)

O43 = 11

X11 = 2

X22 = 0

Z21 = 16 HALL Position Indicator LAMP1

Independent: 4

Z22 = 4 HALL Position Indicator LAMP2

Inspection: 41(32+8+1)

Z23 = 1

Fire-man: 16

Z24 = 41 HALL Position Indicator LAMP3

27

26=2x2x2x2x2x2

25

24

23

22

21

20

128

64

32

16

bit7

bit6

bit5

bit4

bit3

bit2

bit1

bit0

Auto

Full(80%) Inspection

Fire- FD(Fault

Independent Overload Parking

man Detection)

After changing any data, doing WRT enter until displaying Write complete,

WRT enter interval is 4~5 sec.

ThyssenKrupp Dongyang Elevator

- 25 -

Printed in KOREA January, 2007

MAINTENANCE

TK50G

3. Inspection operation

-. After wiring and data input as above, please check the hoist-way condition.

Try UP/DN and cant move the lift by inspection mode, check the following point.

- Power supply is okay ?

- 186C PCB is working normally ? (WD LAMP ON?)

- Wiring is okay ?

- CPIK and 186C Data are correct ?

- If not correct UP/DN direction, please change P3 of CPIK.

(0->1, 1->0)

4. Preparation work of High speed operation

4.1 CAR DUCT Wiring

1. Gov. link S/W : 112 - 113

2. Exit door S/W : 113 - 114

3. Car top STOP S/W : 116 -117

4. COP STOP S/W : 117A - 118

5. CAR DOOR S/W : 201 - 202

6. DLS(Safety Edge) S/W : SE(Safety Edge) G24(Grounding)

7. LDS S/W : EE(Electric Eye:Photo-cell, Micro

Scan, Pana-40, Mini-max)

- G24

8. 1WLS : LWO(Overload 100%)

9. 3WLS : LWB(Balance Load 45%)

10. 8WLS : LWA(Anti-Nuisance call

150kg)

11. NC2 = G24

ThyssenKrupp Dongyang Elevator

- 26 -

Printed in KOREA January, 2007

MAINTENANCE

TK50G

4.2 CN wiring

CWIK PCB wiring

CNT(Traveling cable)1 : Safety line

CNT2 : Power and LANDING S/W

CNT8 : Car communication input

CN2 : Car communication output

CND(Duct)1 : Safety line

CND2 : Light and FAN

CND3 : Car communication and

power

CND401 : LANDING S/W

Passenger lift : CN1-4(CSTOM)

G24 jumper

CN PCB Wiring

CN1, CN5 : Normal and handicap

button

CN3, CN7 : Normal and handicap

button lamp

CN9 : COP S/W INPUT

CN17 : COP S/W I/O PORT

ETC

CN23 : Interphone, BGM

CNT3 : Light and power

BGM2,BGM4,1,2 : TB terminal 3

TB terminal G24 and CWIK CN1-4

4.3 DOOR Controller(DCU-2A) Wiring

CN1: DOOR C/P communication line

CN2: DLS,LDS,P24,G24

CN3: DOOR MOTOR U,V,W 3 phase

CN4: DOOR MOTOR Pulse Generator

CN5: 18DS(Door open limit

sensor),23DS(Door close limit

sensor)

CN6: DOOR C/P power(AC220V)

ThyssenKrupp Dongyang Elevator

- 27 -

Printed in KOREA January, 2007

MAINTENANCE

TK50G

4.4 Hoist-way Wiring (Limit S/W)

SDB(Slow down

2LS

DLT(4LS)

Car speed

1,2LS

Final limit

s/w

(NC)

DLB,DLT

Direction

limit s/w

(NC)

down top)

(Slow down limit

s/w)

(NO)

SDT(6LS)

SDB(5LS)

bottom),SDT(slow

30m/min

- 200

- 30

+ 130

45m/min

- 200

- 30

+ 320

60m/min

- 200

- 30

+ 550mm

90m/min

- 200

- 30

+ 1000

105m/min

- 200

- 30

+ 1300

DLB(3LS)

1LS

ThyssenKrupp Dongyang Elevator

120m/min - 200

- 30

ESTD Van

150m/min - 200

- 30

ESTD Van

- 28 -

Printed in KOREA January, 2007

MAINTENANCE

TK50G

5. High speed operation

5.1 DATA input

Input data when INS operation, change some required data of High speed operation.

5.2 CAR communication check

Picture 1

CN Teach-In operation

TECCR ENTER, TECC ENTER => Car CN board Teach-In operation command.

Car CN communication check

DCN ENTER then in Remote Fast, you can see Main COP --- 1

(Normal) in picture 2, if it is 0 No good communication.

If Car CN communication is okay, CSTOM must Green color, CAR

top auto INCTM(INs Car Top Monitoring)Green and Car top INS

INCT Green in Picture 1.

Picture 2

CN PCB identify method

TP Passenger

CN-1A 08

~16 stop

CN-2A 12

~32 stop

CN-3A 16

~48 stop

Handicap

~8 stop

~16 stop

~24 stop

DCNAT^0^16 enter -> WRT -> Power reset -> TECCR, TECC

ThyssenKrupp Dongyang Elevator

- 29 -

Printed in KOREA January, 2007

MAINTENANCE

TK50G

5.3 Hoist-way Hall HN(Hall Node) communication

HN Teach-In Command

TECCR ENTER, TECF(Teach-In Front, TECR;Teach-In Rear)ENTER, TECC ENTER in

Remote fast for checking Hoist-way Hall HN communication.

AS pictures 3,

Teach-In failed at HN4

check All Connections will display,

this means HN cant communication from lowest

floor to 4 floors.

Ex) Building has 18stop, if display Teach In failed

at HN16, check All Connections, this means that

17~18 floor - Communication okay

1~16 floor - Communication no good.

If all floors(18stop) are no problem,

Picture 3

Teach In Complete_found 18HNs should displayed.

DHNF ENTER in Remote Fast, if display ON

column to 1, this means no problem of HN

communication.

If display ON column to 0, this means HN

communication has problem.

Ex)

ON

0 1 floor ; communication problem

1 2 floor ; communication no problem

1 3 floor

1 4 floor

1 5 floor

1 6 floor

HN PCB version V28

When power ON/OFF, HN PCB LED will display

V01 Version12

V02 Version24

V03 Version28

ThyssenKrupp Dongyang Elevator

End terminal resistor Resistor jumper at lowest

floor.

Resistor spec - 120 ohm

- 30 -

Printed in KOREA January, 2007

MAINTENANCE

TK50G

5.4 Hoist-way Scan

After finish CN and HN Teach In, please doing Hoist-way Scan(Pulse Date-SET)

operation as follow.

1. D26(Door Disconnection)=0->1

2. Select

icon of Custom toolbar in IMS or select Service Hoist-way Setup

Hoist-way Scan.

3. Hoist-way Scan window will be displayed.

4. Click Run Setup -> Turn to Auto at INS/Auto S/W at C/P.

5. Click YES.

6. The lift will be moved to lowest floor and moved to top floor automatically.

7. The lift will be re-level automatically.

8. Finished Hoist-way Scan(PDSET) successfully.

When the lift touch DLB (Down Limit Bottom

limit) limit s/w, it will be changed NO ->PASS.

When the lift re-level, it will be changed NO ->PASS.

When DLT has on -> off, it will be changed NO ->PASS.

ThyssenKrupp Dongyang Elevator

- 31 -

Printed in KOREA January, 2007

MAINTENANCE

TK50G

5.5 DOWN LOAD

After finish Hoist-way scan operation and all commissioning works, you have to

download Job file(Specific files) as follows.

- Select Car01 in Control panel.

- Click

icon of Custom toolbar in IMS or select Service Transfer.

- The above window will be displayed and click Start then Download will be started.

- If finished Download, Download Complete will be displayed in the above picture "A" part.

- Finished save.

- File saved destination is My computer Local disk C Program Files Thyssen

IMS Project name.

- You can see _050000.11 then copy this file and paste and rename to _058000.11

- Delete others files (2 pcs).

ThyssenKrupp Dongyang Elevator

- 32 -

Printed in KOREA January, 2007

MAINTENANCE

TK50G

5.6 DATA UP LOAD

- Click 186C Hyper-terminal.

- Click Transfer.

- Click Send then the above picture will be displayed.

- Find files(Generic files or Specific files) which you want to upload and click open.

- Click send. (Cant select 2 files at same time, therefore change file name *.11 to

send 2 files at same time)

- Push UDL first and then push RST at 186C PCB.

- Release RST button.

- If display Transfer as below picture, release UDL button.

- Waiting 186C re-booting and WD LED ON.

ThyssenKrupp Dongyang Elevator

- 33 -

Printed in KOREA January, 2007

MAINTENANCE

TK50G

6. TK50M Wiring and Inspection & High speed operation

6.1 Wiring

Temporary Remote control

Gov. PG ; CNL 3

IOC-3A

PCB

1,2

1,2,3,4,7/6,8

Picture 10

- Gov. PG connect to CNL3 connector as above picture 10.

(No required connect it when inspection operation)

- CNHV3 connector pin No. 1 and 2 (123A, 123) jumper when inspection operation.

- CNHV4 connector pin No. 1, 2, 3, 4, 7 Jumper when inspection operation.

(CDCF,HDIF,DLT,DLB,AC1B), pin No. 6, 8 Jumper(If no Back Door)

- Temporary remote control cable connect to pin No. 1(Common), 3 (UP), 4 (Down).

CHRT

R20 & T20 - AC220V

L1

L2

L3

L12

L22 L32

U U1

PE

PE

R20 T20

Picture 11

ThyssenKrupp Dongyang Elevator

- 34 -

Printed in KOREA January, 2007

MAINTENANCE

TK50G

- CHRT Wiring (Picture 11)

Hoist-way light : WL1, WL4

GOV21, GOV22 Jumper : Battery operation

BM3, BM4 Jump : Brake release

Governor machine TRIP coil : V203, TRP

Governor machine RESET coil :V203, RST

Governor S/W : 109, 110

Hoist-way Top Stop S/W : MS, DESTOP

Hoist-way TOP consent : WL1, WL4

L1.L2.L3 : Main power supply from building side

L12,L22,L32 : Connect it to L12,L22,L32 of CPIK

U, U1 : Ampere measuring when Government inspection

PE : EARTH from building side / PE : Connect it to PE of CPIK

N : N phase from building side

N : Connect it to T20 (5.5SQ above)

R20 : Connect it to L1 (5.5SQ above)

T20 : Connect it to N (5.5SQ above)

- Please jumper below signal for Inspection operation, refer to picture 11.

MS, DESTOP, CESTOP Jumper

101, 113, 120, 121, 202, 215 Jumper

U,V,W of Picture 12

connect to U,V,W of

CPIK.

1,2(Motor thermal)

connect to 17, 18 of

CPIK. (Refer to electrical

diagram 18 page)

1,2

U, V, W, E

Picture 12

ThyssenKrupp Dongyang Elevator

- 35 -

Printed in KOREA January, 2007

MAINTENANCE

TK50G

1) L12,L22,L32 :

connect it to L12,L22,L32

of C/P.

2) U,U1 :

Ampere measuring when

Government inspection.

3) U,V,W :

Connect it to U,V,W of

MOTOR.

L12,L22,L32,U,U1,U,V,W

CLW(Car

Load

Weigher) PCB

Gov. link S/W : 111, 113

Car Door S/W

: 121, 202

Safety S/W

: G24, SE

Photo cell : G24, EE(Normal Close

contact)

Micro scan

: G24, EE

Machine fix device : 113, 114

(Connect it by serial connection)

Safety fence S/W : 117, 118A

(ON contact when not use it lift down)

Safety fence S/W : 118B, 119

(ON contact when use it lift up)

Exit S/W

: 115, 116

: Car communication line

: Potential-meter connection

Red 1, White 2, Black 3

: Leveling Sensor (Landing S/W)

Car Duct front side

ThyssenKrupp Dongyang Elevator

- 36 -

Printed in KOREA January, 2007

MAINTENANCE

TK50G

DCU-2A

CN1 : Communication line

CN2 : LDS, DLS

CN1

CN3 : DOOR MOTR U,V,W

CN6

CN2

CN4 : DOOR MOTOR PG

CN5

CN5 : 18DS(Door open limit

sensor),

CN4

CN3

23DS(Door close limit sensor)

SENSOR

CN6 : DOOR C/P power

AC220V

Door PCB ; DCU-2A

6.2 Inspection operation

Almost same as TK50G model and some data of CPIK and 186C are difference.

(Reference to CPIK, 186C inspection DATA of TK50G)

6.3 High speed operation

Almost same as TK50G model and some data of CPIK and 186C are difference.

(Reference to CPIK, 186C inspection DATA of TK50G)

- Balance load check

Connect laptop computer to X908 of CPIK and open CPIK hyper-terminal.

P107 Monitoring of actual Ampere, move the Car by Up/down and check the Ampere

by P107 when car reach middle floor, this Ampere should be same both up and down

direction at middle floor. If not same, add or remove counterweight from counterweight

frame. P107 can be check by PEP(Parameter Entry Panel).

6.4 Load compensation

- Make No load.

- Adjust potential-meter to make 3.5VDC between G24(-) and VO(+) check pin by

Volt-meter at CLW-1A PCB of Car Duct.

- Make auto mode and set D26=1.

- Move the Car to lowest floor and DLW Enter in Remote Fast of IMS then you can get

below window.

ThyssenKrupp Dongyang Elevator

- 37 -

Printed in KOREA January, 2007

MAINTENANCE

TK50G

- Check Avg=58~68

(A part, this data can be difference per job

site)

- Locate CAR to lowest floor and NLD(No Load)

Enter in REMOTE FAST of IMS to input lowest

floor NO load status. (B part)

A

- Locate CAR to TOP floor and NLD Enter in

REMOTE FAST of IMS to input top floor NO

load status. (C part)

B

- Locate CAR to lowest floor and DLW Enter in

REMOTE FAST of IMS and check Loo value is

632.

(D part, this data can be difference per job

site)

- Locate CAR to lowest floor and make FULL

LOAD(100% load).

- Locate CAR to lowest floor and FLD(Full Load)

Enter in REMOTE FAST of IMS to input lowest

D

floor full load status. (E part)

ThyssenKrupp Dongyang Elevator

- 38 -

Printed in KOREA January, 2007

MAINTENANCE

TK50G

- Locate CAR to lowest floor and DLW Enter

in REMOTE FAST of IMS and check PreTorque Enable (F part)

-. P50(CPIK) : Load Data Setting

-. P54 : Load Gain Setting

-. Roll-back adjustment method (CPI PEP Parameter)

Address

Meaning

Value

P50

Load Weighting option

ON/OFF

P51

Measured Value Of Load Weight

P52

Input Value Load Compensation

+50

P53

Load-Weighting Gain Of Load Current

0.0

-80

P54

Gain Of Load Weight

unit

Adjustment range

Load mode

Present car load

display

Balance ratio

Roll-back

adjustment

(Auto)

Roll-back

adjustment

(Auto)

P53 Setting method

1. P50(load Weighting) Off (0).

2. Move to P53 by PEP and push Param/Wert button.

3. When No Load (0%) Top floor, move lift by INS Down and when Ampere is stable,

push (+) button of PEP (Parameter Entry Panel).

ThyssenKrupp Dongyang Elevator

- 39 -

Printed in KOREA January, 2007

MAINTENANCE

TK50G

4. Reading the value of P53 will be saved to P54 automatically.

P53 will be change 0.001A again.

5. Push Param/Wert button and move P54.

4. Checking value of P54 and push Sichern (Enter key) button to save.

Try move the lift by INS down, check Roll-back and if happen to Roll-back

problem, increase or decrease parameter of P54 to remove Roll-back problem.

5. Change P50(Load Weighting) to ON(Data =1) and move NOR operation and check

Roll-back.

6.5 Adjusting method of Encoder Rotor(Motor Encoder) Position(Off-Set)

1. When Balance Load, move the lift to middle floor. When open brake, the lift should not move.

2. Turn to inspection s/w to INS.

3. Check the P96(=2048) Encoder specification.

4. Change P86 from <0> Normal Operation <1> Align Rotor.

(Cursor located P86, Ready signal will be OFF ON)

5. Push up or down button during 1~2sec, the motor happen to noise to move and stop automatically.

6. P86 will be change from <1> Align Rotor <2> Store Reference Position

<0> Normal Operation and Ready LED of TMI PCB at CPI-K will be OFF and ON

automatically. (Cursor located P86)

7. Check P86 parameter to 0(Rotor Position Store in Encoder), Error-Stack message

change to Rotor Position Store in Encoder.

8. Power reset (Off and On).

9. If required Hoist-way Scan, do it again.

- Geared lift

1. Applied Load S/W (1 WLS Overload 100%, 3 WLS Full load 80% ,8 WLS Anti-nuisance call 150kg)

Load compensation value 0 8 WLS OFF, 3 WLS OFF

Load compensation value 50 8 WLS ON, 3 WLS off

Load compensation value 100 8 WLS ON, 3 WLS ON

2. Data check

186C M91=0, M98=1

CPI-K P50=ON, P54=Gain adjustment (Increase or decrease) for roll-back problem.

ThyssenKrupp Dongyang Elevator

- 40 -

Printed in KOREA January, 2007

MAINTENANCE

TK50G

12. CPIK / 186C Hyper-Terminal installation method

12.1 Starting

In window, click START and find "Hyper-terminal.

All program

Accessories

Communication

Hyper-terminal

(1) The following window will be appeared and make program name

CPIK_EnteryPanel as follow.

186C-Hyper

Confirm

Cancel

(2) Click the CONFIRM button.

(2) Select COM Port.

In Windows, find Control Panel System Hardware Device manager

Port(COM and LPT) and check communication port, select used modem(N).

(Ex : COM1 or COM2).

ThyssenKrupp Dongyang Elevator

- 41 -

Printed in KOREA January, 2007

MAINTENANCE

TK50G

Confirm

Cancel

(3) Click the Confirm button.

(4) Select the each value of CPIK_EntryPanel and 186C upload.

9600

38400

None

None

None

Hardware

CPIK_EntryPanel

ThyssenKrupp Dongyang Elevator

186C upload

- 42 -

Printed in KOREA January, 2007

MAINTENANCE

TK50G

13. How to set Add Or Change An I/O Manu of IMS I/O MAP.

(1) Select START and RUN, type regedit and click confirm button.

(2) Please find

HKEY_CURRENT_USER

Software

Thyssen Dover

IMS

Settings

(3) Click Setting and then the following window will be appeared.

ThyssenKrupp Dongyang Elevator

- 43 -

Printed in KOREA January, 2007

MAINTENANCE

TK50G

(4) Click AddIO and then the following window will be appeared.

Value data (V) :

Confirm

(5) Value data(V): change 0 to 1 and click confirm button.

(6) Check whether Add Or Change An I/O Menu was created or not.

ThyssenKrupp Dongyang Elevator

- 44 -

Printed in KOREA January, 2007

MAINTENANCE

TK50G

8. Car Adjustments Table

NOTE : Utilize Car Remote Fast / Smart Fast for the following adjustments

ADJ

FAST

DESCRIPTION

REMOTE

SMART

(Enable)

Disable

ASI

Add Special Inversion

B10

Coded Car Call Entry Code Digit 0

B11

Code Digit 1

B12

Code Digit 2

B13

Code Digit 3

B14

Code Digit 4

B15

Code Digit 5

B16

Code Digit 6

B17

Code Digit 7

B18

Code Digit 8

B19

Code Digit 9

B20

Coded Car Call Code Entry Time

B21

Coded Car Call Code Entry Count

B22

Coded Car Call Entry Sound Buzzer on Entry

B23

Coded Car Call Acknowledge Time

BCW

Store the position count

BYE

Logically disconnect IMS Monitoring

BKP

Nonvolatile memory BacK uP

CAN

Display CAN errors

CAT

Category

CEF

Enable/disable voice messages

CNN

Display CAN errors

Clear CAN errors

D10

Limited Door Reversal Type

D11

Nudging Enable

CNNC

ThyssenKrupp Dongyang Elevator

- 45 -

Printed in KOREA January, 2007

MAINTENANCE

ADJ

TK50G

FAST

DESCRIPTION

REMOTE

SMART

D12

Front Door Type

D13

Rear Door Type

D14

Safety Edge Door Time

D15

Electric Eye Door Time

D16

Door Open Button Door Time

D17

Door Hold Button Door Time

D18

Open High Speed time

D19

Nudging Door Time

D20

Door Reversal time (optional)

D21

Front Door Watchdog time

D22

Rear Door Watchdog time

D23

ADA Hall Call Door Time

D24

Car Call Door Time

D25

Hall Call Door Time

D26

Door Disconnect

D27

ADA Actuator

D28

Stuck Device Time

D29

Extended Door Time Enable

D30

Extended Door Time

D31

Extended Door Time Landing

D32

Remote Car Station

D33

Pre-Opening Door Enable

D34

Non-Simultaneous door enable

DAT

Date adjustment command

DCN

Arrangement of car CAN boards

DCNP

Ping Node Port

Display Expansion Boards

DEB

ThyssenKrupp Dongyang Elevator

- 46 -

Printed in KOREA January, 2007

MAINTENANCE

ADJ

TK50G

FAST

DESCRIPTION

REMOTE

DHN

HN Help

DHNS

Scan for Unresponsive HN Ports

DHNM

Master / Slave Can Command

DHNF

Display HN Nodes Front

DHNR

Display HN Nodes Rear

DLC

Data Loc Table display

DRD

Data Record Dump

DSF

Display Secured Floors

DSI

Deletes Special I/O Inversion

DSO

Display Scheduler Overruns

DSV

Enable / Disable Daylight Savings Time

EBRKO

Emergency Brake Output

EBRK1

Emergency Brake Level 1

EBRK2

Emergency Brake Level 2

EBRK3

Emergency Brake Level 3

EBRK4

Emergency Brake Level 4

EBRK5

Emergency Brake Level 5

EID

Display elevator ID number for field contract

EIO

Expansion I/O Board Type

ELD

Elevator Designator Display

Emergency Operation Brake Pick

Emergency Operation Brake Pick Monitor

EP1

Emergency Power Type

EP2

Emergency Power Return Floor

EP3

Emergency Power Door

EP4

Emergency Power Manual Select Time

EP5

Emergency Power Hold Doors Open

EOBP

EOBPM

ThyssenKrupp Dongyang Elevator

- 47 -

SMART

Printed in KOREA January, 2007

MAINTENANCE

ADJ

TK50G

FAST

DESCRIPTION

REMOTE

SMART

ERC

Display Encoder Recall Errors

ETSB

Emergency Terminal Bottom

ETSC

Clear ETS Faults

ETSF

ETS Faults

ETSP

ETS Parameters

ETST

Emergency Terminal Top

ETSV

ETS Software Version

F10

Fire Main Landing

F11

Fire Alt Landing

F12

Fire Main Landing Door

F13

Fire Alt Landing Door

F14

Fire Override Time (sec)

F15

Fire Service Switch Type

F16

Fire Service Type

F17

Hall Fire Door Open Time (sec)

F18

Phase 1 Safety Edge operation

F19

Phase 2 Safety Edge operation

F20

Fire Lift

F21

B44 Phase 2 Activation Location

F22

PHASE 2 Reduced Speed Enable

F23

B44 Phase 2 Return Door Speed

FCD

Force Doors Closed

FCN

Display Feature Control

FCP

Floor Count Position Display

FIS

Field Contract # IMS Remote Monitoring

FLTN

Display Faults

FOP

Front Openings Display

ThyssenKrupp Dongyang Elevator

- 48 -

Printed in KOREA January, 2007

MAINTENANCE

ADJ

FSSR

TK50G

FAST

DESCRIPTION

REMOTE

SMART

Fire Service Sensor Reset (Michigan)

FST

Fire Service Sensor High Temp

FTD

Fault Display

FTM

Format Time Display

GET

Get

GIC

Group Inconspicuous Calls

GSC

Group Served Calls

GSS

Displays Slide After Safety Sets

H10

Homing Return Landing 1

H11

Homing Return Door 1

H12

Homing Return Landing 2

H13

Homing Return Door 2

H14

Homing Return Landing 3

H15

Homing Return Door 3

H16

Homing Door Time

HLP

Help

I10

Event Inhibit during Inspection

I11

Event Office Single

I12

Event Owner Single

I13

Remote Monitor Aux

I14

Remote Monitor Service Count

I15

Long Level Time

I16

Stuck Car #1 Time

I17

Stuck Car #2 Time

I18

Car Stop Switch Time

I19

Independent Service Time

I20

Event Door Drag Time

ThyssenKrupp Dongyang Elevator

- 49 -

Printed in KOREA January, 2007

MAINTENANCE

ADJ

TK50G

FAST

DESCRIPTION

REMOTE

SMART

I21

Event AM Alive

IRL

Inconspicuous Riser Lockouts

J10

Capacity (lbs)

J11

Car ID

J12

Car Comm Number

J13

Group ID

J14

Lobby Floor

J15

Number of Floors

J16

Number of I/O Ports

J17

Number of Lon Channel 1 Ports

J18

Number of Lon Channel 2 Ports

J19

Relevel on Stop Switch

J20

Stop Switch Type

JBD

Job Information Display

M13

Restart Delay

M16

Inspection Speed

M17

Brake Step #1 Duration

M18

Brake Step #2 Duration

M19

Brake Step Economy Duration

M20

Number of Brake Steps to Full Lift amps

M21

Brake Step #1 amps

M22

Brake Step #2 amps

M23

Brake Step #3 amps

M24

Brake Step Economy amps

M25

Brake Amps Rate (time)

M26

Wind Sensor Speed

M27

Emergency Brake Pick

ThyssenKrupp Dongyang Elevator

- 50 -

Printed in KOREA January, 2007

MAINTENANCE

ADJ

TK50G

FAST

DESCRIPTION

REMOTE

SMART

M28

Emergency Brake Hold

M29

Emergency Brake Amps

M30

Top Speed fpm

M31

Leveling Speed fpm

M32

Floor Hunt Speed fpm

M33

Velocity Damping

M34

Constant Gain (1/sec)

M35

Final Stop Rate (fpm/sec/sec)

M36

Jerk into Acceleration (fpm/sec/sec)

M37

Jerk into Top Speed (fpm/sec/sec)

M38

Jerk into Deceleration (fpm/sec/sec)

M39

Acceleration (fpm/sec)

M40

Deceleration (fpm/sec)

M41

Target Offset (dpp)

M42

Lag (sec/64)

M43

Start Delay (sec)

M44

PreTorque Calibration Delay (sec)

M45

PreTorque Delay (sec)

M46

Brake Drop Delay (sec)

M50

Motor Encoder Pulses per Rev (ppr)

M51

Motor Encoder RPM (rpm)

M52

Contract Speed (fpm)

M53

UnSafe Motor Rotation (rev)

M60

Enable Encoder Fault Checks (bits)

M61

Speed Tracking Margin (fpm)

M62

Speed Over speed Margin (fpm)

M63

Velocity Error (fpm)

M64

Motor Encoder Tach Attempts

ThyssenKrupp Dongyang Elevator

- 51 -

Printed in KOREA January, 2007

MAINTENANCE

ADJ

TK50G

FAST

DESCRIPTION

REMOTE

SMART

M70

Primary Brake Current Limit

M71

Secondary Brake Current

M91

CAN Loadweigher Scaling

M92

Loadweigher Anti-nuisance

M93

Loadweigher / Load Bypassing

M94

Loadweigher / Load Shutdown

M95

Loadweigher / U-Peak

M96

Loadweigher / Emergency Power

M97

Loadweigher Car Overload Indicator

M98

Load-weigher Pre-torque Enable

M99

Percent Counterweight

NVS

Nonvolatile Memory Status

O10

Anti-nuisance car calls

O11

Hoistway Access Bottom Zone

O12

Car Cycle Floor 1

O13

Car Cycle Floor 2

O14

Hall Independent Return Floor

O15

Hall Independent Return Door

O18

Massachusetts Medical Floor

O19

Massachusetts Medical Door

O20

Independent overrides Lockouts

O21

Hoistway Access Top Floor

O22

Hoistway Access Top Zone (in)

O24

Transfer Calls On Door Close

O25

B44 Type

O26

A17 Type

O27

EN81 Type

ThyssenKrupp Dongyang Elevator

- 52 -

Printed in KOREA January, 2007

MAINTENANCE

ADJ

TK50G

FAST

DESCRIPTION

REMOTE

SMART

O28

Non-Interference Time

O33

Lobby Recall return landing

O34

Lobby Recall Door

O35

Fan-Light Shutdown Timer

O36

Capture Return Ldg

O37

Capture Door To Open

O38

Capture Door Operation

O39

Capture Over Ride Independent Service

O40

Capture Over Ride Car Stop Sw

O41

Attendant Service Call Latch

O42

Reverse Car Call Cancel

O43

CE Fixtures, Vista Monitor

OVT

Over Travel

P10

Slowdown Type

P11

Position Type

P12

Rear Leveling Vane

P13

Front Leveling Type

P14

Rear Leveling Type

P15

Long Terminal Slowdowns

P16

Encoder Counts per Foot

P17

Up Slowdown Distance (512/ft)

P18

Down Slowdown Distance (512/ft)

P19

Encoder Level Distance (512/ft)

P20

Encoder Count Tolerance (512/ft)

P21

Encoder Leveling

PCL

Permission Change Log

ThyssenKrupp Dongyang Elevator

- 53 -

Printed in KOREA January, 2007

MAINTENANCE

ADJ

TK50G

FAST

DESCRIPTION

REMOTE

SMART

PIA

Position Indication Adjustment

PSI

Print Special I/O Inversion

PTI

Pre-Torque Settings Initialize

PUP

Power Up Message display

R10

Inconspicuous Riser Monitor Operation

R11

Inconspicuous Riser Activates On HCP Loss

R12

Inconspicuous Riser Activates On Comm Loss

R13

Inconspicuous Riser Deactivates On Emergency Power

R14

Inconspicuous Riser Deactivates On Up Peak

R15

Inconspicuous Riser Deactivates On Down Peak

R16

Inconspicuous Riser Inhibits Front Car Calls

R17

Inconspicuous Riser Inhibits Rear Car Calls

R18

No Lantern for Onward Car Calls On Inconspicuous Riser

R19

No Inconspicuous Riser Lantern At Front Group Landings

R20

No Inconspicuous Riser Lantern At Rear Group Landings

R21

Inconspicuous Riser Deactivates On Code Blue

R22

Independent Service serves Inconspicuous Riser landings only

R23

Independent Service serves Group landings only

R24

Group Calls only On Group Operation

R25

Inconspicuous Riser Activates On Attendant Service

R26

Inconspicuous Riser Deactivation time

R27

Inconspicuous Riser Activates Program B

R28

Inconspicuous Riser Deactivates Tenant Security

R29

Answer All Group Calls Before Inconspicuous Riser Activates

R30

Answer All Inconspicuous Riser Calls Before Group Activates

ThyssenKrupp Dongyang Elevator

- 54 -

Printed in KOREA January, 2007

MAINTENANCE

ADJ

TK50G

FAST

DESCRIPTION

REMOTE

SMART

RFL

Clear the fault buffer

ROP

Rear Openings Display

RRF

Reset Run monitor Faults

RSC

Resynchronize LON Channel

RUT

Reset Up Time

S10

Security Type

S11

Security Return Landing

S12

Door to Open upon Return

S13

Allow DOB on Security

S14

One Car Call at a Time on Sec

S15

Security Homing Delay

S16

Security Door Time

S17

Security Exit Not Required

S18

Security Homes between Calls

S19

Security Prog. A Lockout Activate

S20

Security Prog. A Lockout Override Activate

S21

Security Program A Home On Init

S22

Security Prog. A Car Shuts Down

S23

Security Prog. A Car Shuts Down

S24

Security Prog. A Independent Service Overrides

S25

Security Prog. A Independent Service Activates Security

S26

Security Prog. A Inconspicuous Riser Overrides

S27

Security Prog. A Lanterns Only on Hall Call

S28

Security Prog. B Lockout Activate

S29

Security Prog. B Lockout Override Activate

S30

Security Prog. B Home On Init

S31

Security Prog. B Car Shuts Down

ThyssenKrupp Dongyang Elevator

- 55 -

Printed in KOREA January, 2007

MAINTENANCE

ADJ

TK50G

FAST

DESCRIPTION

REMOTE

SMART

S32

Security Prog. B Car Shuts Down

S33

Security Prog. B Independent Service Overrides

S34

Security Prog. B Independent Service Activates Security

S35

Security Prog. B Inconspicuous Riser Overrides

S36

Security Prog. B Lanterns

S37

Security Prog. A Car Avail. Delay

S38

Security Prog. B Car Avail. Delay

S39

Car Call Lockout Override Registers Car Call

S40

Neo Natal Landing A

S41

Neo Natal Landing B

SCC

Set Car Call

SCF

Close Floors Display

SFA

Secured Floors All display

SFD

Secured Floors Dispatch

SFL

Secure Floor Lockout

SFT

Secured Floor Tenant

SFS

Security Floor Subset

SLD

Selector Diagnostics Display

SRC

Set Rear Car Call

SRL

Rear Landing Display

SRQ

Show Requests

SSE

Toggle Motion Screen

STBC

Shut Trip Breaker Control (Detroit)

STU

Selector Setup Command

SXZ

Express Zone Display

TAG

Display LAST TAG in memory

TCW

Counterweight Position Count Car Top

ThyssenKrupp Dongyang Elevator

- 56 -

Printed in KOREA January, 2007

MAINTENANCE

ADJ

TK50G

FAST

DESCRIPTION

REMOTE

SMART

TDM

Spawn 485 COM

TECC

Teach CAN Configuration

TECF

Teach Nodes Front

TECR

Teach Nodes Rear

TIM

up TIMe

TR1

Trace Record Type

TR2

Number of Data Words

TR3

Index into Trace Record Buffer

TR4

Trace Record Changes Only

TRA

Trace Recorder

TRG

Data Record Trigger command

UTM

Up Time Display

VER

Software Version Display

WRT

Write

X10

Audible Car Call Enable

X11

Arrow Type

X12

Car Lant. at Door Reversal Limit

X13

Car Lantern at Lobby

X14

Flasher Rate (sec)

X15

Front Lantern Type

X16

Lantern Delay at Lobby

X17

Lantern Fire Position

X18

Lantern off Time

X19

Lantern on Time

X20

PI Timeout Time (min)

X21

Rear Lantern Type

ThyssenKrupp Dongyang Elevator

- 57 -

Printed in KOREA January, 2007

MAINTENANCE

ADJ

TK50G

FAST

DESCRIPTION

REMOTE

SMART

X22

car buzzer floor passing tone

X23

Number of Display Characters

X24

GAL Tone Timer Adjustment

Z10

Emergency Dispatch Enable

Z11

Lobby Stop Landing

Z12

Independent Service Call Latch

Z13

VIP Service

Z14

Door Open Timer Saver Using SE

Z15

Door Closing Forcing

Z16

B44 Nudging

ThyssenKrupp Dongyang Elevator

- 58 -

Printed in KOREA January, 2007

MAINTENANCE

TK50G

11. Trouble Shooting

DESIGNATOR

NAME

INPUT

OR

OUTPUT

ACTIVE

ON

STATE

SIGNAL

ORIGIN OR

DEST.

FUNCTION

I/O TYPE

ACO

Freight Auto Close Override Front

ON

MR

ACOR

Freight Auto Close Override Front

ON

MR

ADC

Auxiliary Door Close

HW

ADCL

Auxiliary Door Close Limit(DCL)

HW

AFI

AT Floor Indicator

HW

ALBA

Alarm Button Activated

CAR

ALBI

Alarm Button Activated Indicator

HW

ALBL

Alarm Bell(Fire Bell)

HW

ARDC

Auxiliary Rear Door Close

HW

ARDCL

Auxiliary Rear Door Close(DCL)

HW

ARL

Arrival Lantern

HW

ARLR

SAPB Arrival Lantern- Rear

HW

ARL1-ARL16

Arrival Lantern-Per Floor

HW

ATB

Attendant Bypass Push Button

CAR

ATBI

Attendant Bypass Indicator

CAR

ATD

Attendant Operation Door Speed

CAR

ATDB

Attendant Down Push Button

CAR

ATDC

Attendant Door Close Speed

CAR

ATDI

Attendant Down Indicator

CAR

ATDR

Attendant Operation Door Speed-Rear

CAR

ATT

Attendant Service

CAR

ATTI

Attendant Service Indicator

CAR

ATUB

Attendant UP Push Button

CAR

ATUI

Attendant UP Indicator

CAR

AUD

Freight Door Auto Open Front

ON

MR

AUDR

Freight Door Auto Open Rear

ON

MR

ThyssenKrupp Dongyang Elevator

- 59 -

Printed in KOREA January, 2007

MAINTENANCE

TK50G

DESIGNATOR

NAME

INPUT

OR

OUTPUT

AUDX

Auto Open-Rear(Freight Doors)

CAR

AUTOI

HW

BEEP

Automatic Operation Indicator

Coded Car Call Entry-Code Button

Acknowledge Output

CTRL

BLO

Bottom Limit Override

CTRL

BLOM

Bottom Limit Override Monitor

CTRL

BLSE

Brake Lift Switch Emergency

CTRL

BLSM

Brake Lift Switch Monitor

CTRL

BK1

Brake Control Level #1

CTRL

BK2

Brake Control Level #2

CTRL

BK3

Brake Control Level #3

CTRL

BPP

Binary Position Parity

CTRL

BRKDRV

Brake Drive

ON

DSP

C

Drive

Oupput

BRKCPUD

CPU Brake Contactor DE-Energize

Control

HI

CPU

Input

BRKCPU

CPU Brake Contactor Control

ON

Controller

Relay

Output

BRK2

Brake Contactor #2

CTRL

BRK3

Brake Contactor #3

CTRL

BRKC

Brake Contactor Control

CTRL

BRKCD

Brake Contactor For Safety Check

CTRL

BRKD

Brake Contactor DE-Energize

LO

CPU

Input

BRKE

Brake Contactor Energize

LO

CPU

Input

BSLE

Brake Lifted Switch-Emergency Brake

CTRL

BSLM

Brake Lifted Switch-Main Brake

CTRL

BSSE

Brake Switch Set-Emergency Brake

CTRL

BSSM

Brake Switch Set-Main Brake

CTRL

BUZ

Buzzer-Floor Passing,Fire&Nudging

CAR

CAPT

Capture Operation

CAR

ThyssenKrupp Dongyang Elevator

- 60 -

ACTIVE

ON

STATE

SIGNAL

ORIGIN OR

DEST.

FUNCTION

I/O TYPE

Printed in KOREA January, 2007

MAINTENANCE

TK50G

DESIGNATOR

NAME

INPUT

OR

OUTPUT

CAPTD

Capture Operation Door Open

CAR

CAPTI

Capture Operation Indicator

CAR

CAPTR

Capture Operation Reset

CAR

CBEL

CTRL

CBELL

Freight Door Call Bell

Door Close Request Call Bell

(Freight Doors)

CAR

CBAI

Code Blue Active Indicator

HW