Professional Documents

Culture Documents

Kinematics of Selected Parts of Metal Cutting Machine: Keywords

Uploaded by

RaviOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Kinematics of Selected Parts of Metal Cutting Machine: Keywords

Uploaded by

RaviCopyright:

Available Formats

American Journal of Mechanical Engineering, 2013, Vol. 1, No.

7, 241-245

Available online at http://pubs.sciepub.com/ajme/1/7/18

Science and Education Publishing

DOI:10.12691/ajme-1-7-18

Kinematics of Selected Parts of Metal Cutting Machine

Jozef Filas, Vladimr Marton*

Faculty of Mechanical Engineering, Department of Applied Mechanics and Mechatronics, Technical University of Koice, Letn 9,

Koice, Slovak Republic

*Corresponding author: jozef.filas@tuke.sk

Received October 11, 2013; Revised October 22, 2013; Accepted November 19, 2013

Abstract This article deals with kinematics of mechanical part of lathe in cases of highest and lowest speeds

during machining for selected parts of the machine. Calculations are made or cut in startup mode in steady state.

Not stated all calculations because of their large-scale. Calculations are for real machine tool, which is used in

workshop practice. Analogy, it can do the same when other machine in which the gear unit and the various modes

of operation.

Keywords: metal cutting machine, lathe, kinematics

Cite This Article: Jozef Filas, and Vladimr Marton, Kinematics of Selected Parts of Metal Cutting

Machine. American Journal of Mechanical Engineering 1, no. 7 (2013): 241-245. doi: 10.12691/ajme-1-7-18.

1. Introduction

The use of metal cutting machines as well as lathes for

machining components from various materials with

different dimensions requires the drive of lathe to be able

to change the cutting speed on the surface of the machined

component.

It is therefore very important to know the kinematics of

motion of the whole machine part of lathe, but also its

individual members.

In this paper we focus on the calculation of selected

kinematic parameters of the parts of lathe connected so

that the spindle of lathe had the intended rates. We

focused on two parameters: the minimum speed and the

maximum speed. Analogy would be followed for any

other speed.

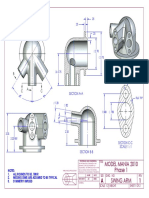

Figure 1 shows an overall view of specific type of center

lathe, which will undergo partial kinematic analysis.

The lathe is intended for various uses. Machining of

outer surface of cylinders and cones, machining by

copying, coils production, shaping by grooving tools and

so on.

Figure 2, Figure 3, Figure 4 show other parts of the

lathe.

Figure 2. Transmission of the lathe

Figure 1. Center lathe

Figure 3. Levers for setting the rates

242

American Journal of Mechanical Engineering

Input (motor) is 1750 rates per minute and by

multistage transmission, illustrated on Figure 6, head of

the lathe reaches 2000 rates per minute.

Figure 6. Positioning of shafts and wheels in transmission

Figure 7 shows a simplified schematic view of mutually

meshing cogwheels positioned on multiple shafts.

Figure 4. Belt pulleys on engine and transmission

Figure 7. Schema of meshing cogwheels

2. Transfer of Drive from Engine to Head

of the Lathe

Calculation of transfer ratio (uR), angular velocities (),

tangential (at) and normal components (an) accelerations

on circumferences of individual cogwheels goes as

following:

Transfer number:

Transmission of lathe has multiple shafts. Overall

simplified schema of the drive is illustrated on Figure 5.

Gearbox

Head lath

u=

MS

uMS =

Figure 5. Schema of lathes drive

Table 1 shows rates of lathes head depending on levers

setting Figure 3.

630

800

1000

1250

1600

2000

12,5

16

20

25

31,5

40

50

63

80

100

125

160

200

250

315

400

500

3.1. Calculation of Kinematic Parameters for

the Fastest Gear

nM

n

nS = M = 1003,5,

nS

uMS

(1)

2 1003,5

= 105rads 1 ,

60

vS1 =S RS1 =7,356ms 1 ,

S = S s= 210rads 2 ,

atS1 = S RS1 =14, 7 ms 2 ,

a=

nS1

630

3. Calculation of Kinematic Parameters

dS

250

= = 1, 724,

d M 145

Wheel on shaft S:

S

=

Table 1. Output rates (min-1)

1

dA1 dB3 dC1 90 80 140

=

= 0,513,

dS1 dA5 dB5 140 85 165

n

n

1003,5

u R = S nvyst = S =

=1956,

nvyst

uR

0,513

Engine

Poloha

pky

uR =

aS 1 =

vS12

= 773ms 2 ,

RS1

a 2tS1 + a 2nS1 = 733,14ms 2

Wheels on shaft A:

1

v A=

1 v=

S 7,356m ,

(2)

American Journal of Mechanical Engineering

243

atC1 = C RC1 =28, 62ms 2 ,

v A5 v A1

=

,

rA5 rA1

a=

nC1

v A5 rA5

6,94ms 1 ,

=

v A5 =

rA1

v 2C1

= 2925,37 ms 2 ,

RC1

(5)

aC1 = a 2tC1 + a 2nC1 = 2925,51ms 2 .

Figure 8, Figure 9, Figure 10, Figure 11 illustrate

kinematic parameters of points on circumferences of

meshing cogwheels on the transmission.

v A1

=

= 163, 7 rads 1 ,

A

rA1

A = A s= 327,34rads 2 ,

atA1 = A RA1 =14, 7 ms 2 ,

v 2 A1

= 1205, 4ms 2 ,

RA1

a=

nA1

a 2tA1 + a 2nA1 = 1205,5ms 2 ,

a A1 =

atA5 = A RA5 =13,9ms 2 ,

v 2 A5

= 1133, 26ms 2 ,

RA5

a=

nA5

a 2tA5 + a 2nA5 = 1133,35ms 2 .

a A5 =

Figure 8. Shaft S

(3)

Wheels on shaft B:

1

v=

A5 v=

B 3 6,94m ,

vB 5 vB 3

,

=

rB5 rB3

vB 5

=

vB 2 rB5

= 14,31ms 1 ,

rB3

vB 5

= 173,5163, 7 rads 1 ,

rB5

Figure 9. Shaft A

B = B s= 347327,34rads 2 ,

atB3 = B RB3 =13,88ms 2 ,

a=

nB 3

aB 3 =

v 2 B3

= 1204,1ms 2 ,

RB3

a 2tB3 + a 2nB3 = 1204,18ms 2 ,

atB5 = B RB5 =28, 62ms 2 ,

Figure 10. Shaft B

v 2 B5

a=

= 2482,13ms 2 ,

nB 5

RB5

aB 5 =

a 2tB5 + a 2nB5 = 2482,3ms 2 .

(4)

Wheel on shaft C:

1

v=

B 5 v=

C1 14,31ms ,

vC1

= 204, 42rads 1 ,

rC1

C = C s= 408,86rads 2 ,

Figure 11. Shaft C

244

American Journal of Mechanical Engineering

3.2. Calculation of Kinematic Parameters for

the Slowest Gear

Rate of motor at the beginning of kinematic chain is

1750 rates per minute, which is transformed in

transmission to 12 rates per minute on head of the lathe.

Figure 12 shows schema of positioning of shafts and

cogwheels for the slowest gear.

Calculations of kinematic variables on shafts A, B, D,

Care analogous calculations in Section 1.3.

Figure 14, Figure 15, Figure 16, Figure 17, Figure 18

illustrate kinematic parameters of point on circumferences

of mutually meshing cogwheels in the transmission.

Figure 14. Shaft S

Figure 12. Positioning of shafts and cogwheels in transmission

Figure 13 shows simplified schema of mutually

meshing cogwheels, which are positioned on multiple

shafts.

Figure 15. Shaft B23

Figure 13. Schema of cogwheels connection

Transfer number:

uP =

dA1 dB2 dD1 dB3 dC2 90 80 140

=

= 78,3,

dS2 dA2 dB5 dD3 dB7 140 85 165

n

n

1003,5

u P = S nvyst = S =

=12,81.

78,31

nvyst

uP

Figure 16. Shaft D

Transfer from motor to shaft S:

u=

MS

dS

250

= = 1, 724.

d M 145

Input rates to transmission:

uMS =

nM

n

nS = M = 1003,5.

nS

uMS

Wheel on shaft S:

=

S

2 1003,5

= 105rads 1 ,

60

Figure 17. Shaft B78

vS 2 = S RS = 6,3ms 1 ,

S = S s= 210rads 2 ,

atS 2 = S RS = 12, 6ms 2 ,

a=

nS 2

aS 2 =

vS 22

= 661,5ms 2 ,

RS 2

a 2tS 2 + a 2nS 2 = 661, 62ms 2 .

(6)

Figure 18. Shaft C

American Journal of Mechanical Engineering

4. Conclusion

References

Similarly, it would be possible to determine the selected

kinematic variables for other modes work machine Results

can be verified by other methods of kinematics.

[1]

[2]

[3]

Acknowledgement

The works has been accomplished under the research

project VEGA 1/1205/12 Numerical modelling of

mechatronic systems.

[4]

[5]

245

Janina,J.,

Pekrek,

F.,:

MECHANIKAII-KINEMATIKA.

Bratislava, 1987.

Medvec, A., Stradiot, J., Zhorec, O., Caban, S.,:

MECHANIKAIII-DYNAMIKA, Bratislava 1996.

imk,F.,Trebua,F.,:METDYEXPERIMENTLNEJANALZY

NAPATOSTI, Koice, 2011.

olek, P.,: TECHNICKMECHANIKA. Bratislava, 2009.

Marton,V.,:

Kinematickanalzapohonuobrbaciehostroja

(Bakalrska prca), SjF TU Koice, 2013.

You might also like

- A CD Rive Final StrategyDocument4 pagesA CD Rive Final Strategyjiwani87No ratings yet

- Savonius Windrotor Basics PDFDocument6 pagesSavonius Windrotor Basics PDFjairtorrezanNo ratings yet

- Exercise 4Document15 pagesExercise 4KALIDAS MANU MNo ratings yet

- Design Techniques For Reducing Cogging Torque in Permanent Magnet Flux Switching MachineDocument4 pagesDesign Techniques For Reducing Cogging Torque in Permanent Magnet Flux Switching MachinejalilemadiNo ratings yet

- Design and Analysis of Rocker ArmDocument23 pagesDesign and Analysis of Rocker ArmAvt Shubhash25% (4)

- Machine Tool Gearbox Design.Document9 pagesMachine Tool Gearbox Design.Mohamed Osama67% (3)

- Naf Ems 2013 RotorDocument12 pagesNaf Ems 2013 Rotorletter_ashish4444No ratings yet

- An Serv 002 PDFDocument20 pagesAn Serv 002 PDFMario TapiaNo ratings yet

- MANE-4030: Elements of Mechanical Design: Worksheet #14Document3 pagesMANE-4030: Elements of Mechanical Design: Worksheet #14azizieh5701No ratings yet

- 9 Ball and BeamDocument15 pages9 Ball and BeamshaheerdurraniNo ratings yet

- Morphing BlDE FinalDocument21 pagesMorphing BlDE FinalSoumian NarayananNo ratings yet

- BLDC Veh DecouplingDocument6 pagesBLDC Veh Decouplingtarunteotia19No ratings yet

- Machine DesignDocument76 pagesMachine DesignTerenz Calangi67% (3)

- Paval Marius Catalin IMEN 1531: An Example of Peculiar Press Structure: Shop PressDocument14 pagesPaval Marius Catalin IMEN 1531: An Example of Peculiar Press Structure: Shop PressMihailNo ratings yet

- CHAIN CalculationDocument18 pagesCHAIN CalculationDmitrijs MuhinsNo ratings yet

- Application of Planetary Reduction Gear in Operation of The Two Rope GrabDocument5 pagesApplication of Planetary Reduction Gear in Operation of The Two Rope GrabSumanth VasistaNo ratings yet

- DTS - Unit - 2 PDFDocument14 pagesDTS - Unit - 2 PDFmani100% (1)

- 6.3 SnowploughDocument106 pages6.3 SnowploughsitehabNo ratings yet

- Winder and Unwinder Scheduling EquationsDocument13 pagesWinder and Unwinder Scheduling EquationsRoberto BarbozaNo ratings yet

- DC Drive System For EscalatorDocument29 pagesDC Drive System For EscalatorMamta Mrjn100% (2)

- Taaghtnfl Constru Etionv: Elevation ViewDocument3 pagesTaaghtnfl Constru Etionv: Elevation ViewMostafaNo ratings yet

- Direct Drive and Servo MotorsDocument8 pagesDirect Drive and Servo MotorsChandaKundaNo ratings yet

- HES3350 Machine Design, Semester 1, 2012, Assignment 1 - Compound Reverted Gear Train DesignDocument18 pagesHES3350 Machine Design, Semester 1, 2012, Assignment 1 - Compound Reverted Gear Train DesignStephenPYBong100% (6)

- 5.2 - ABS Braking System (OCR)Document126 pages5.2 - ABS Braking System (OCR)mnbvqwert100% (1)

- 25122017journal Bearing ApparatusDocument7 pages25122017journal Bearing Apparatus3059 SUNARAM HANSDAHNo ratings yet

- MD Handb2 Belt CalcDocument5 pagesMD Handb2 Belt Calcoana2507No ratings yet

- Unisa MOM3602 Theory of Machines III Mock Exam 2015 - Preparation Practice ProblemsDocument9 pagesUnisa MOM3602 Theory of Machines III Mock Exam 2015 - Preparation Practice ProblemsDaniel MabengoNo ratings yet

- Dom Lab Manual NewDocument44 pagesDom Lab Manual NewjeyashrirangamNo ratings yet

- Cam Experimental Lab: ObjectiveDocument8 pagesCam Experimental Lab: ObjectiveMuhammad Changez Khan100% (2)

- Errata For APA V1Document4 pagesErrata For APA V1SukhoiLoverNo ratings yet

- Taachinu, Construction: ElevationDocument3 pagesTaachinu, Construction: ElevationMostafaNo ratings yet

- Aircraft Design ProjectDocument30 pagesAircraft Design ProjectSANDEEP CHOWDARYNo ratings yet

- Suspension Analysis of Racecars at Sebring International RacewayDocument9 pagesSuspension Analysis of Racecars at Sebring International RacewayAngel MarinNo ratings yet

- Sdp-Si Worm GearDocument9 pagesSdp-Si Worm GearIvo CarvalhoNo ratings yet

- PR5 2013 PDFDocument2 pagesPR5 2013 PDFMuhammad Fazjri Karta WijayaNo ratings yet

- X25 XXX 01 SP E-1Document15 pagesX25 XXX 01 SP E-1Richard ZerpaNo ratings yet

- Block Diagram Model of Lathe MachineDocument6 pagesBlock Diagram Model of Lathe MachineLamis EssamNo ratings yet

- ProblemswithSolutions Chapter2Document26 pagesProblemswithSolutions Chapter2samanmech100% (1)

- Section Modulus & Stress Calculation of Rail SectionDocument13 pagesSection Modulus & Stress Calculation of Rail SectionfiemsabyasachiNo ratings yet

- Report 5Document28 pagesReport 5Chrome BrowserNo ratings yet

- Furnace Boiler App8 7Document13 pagesFurnace Boiler App8 7e.bathiyaNo ratings yet

- FORMATO MATPR EES 8-PagDocument8 pagesFORMATO MATPR EES 8-Pagarlette caizaNo ratings yet

- Mod-3A. Spur GearDocument7 pagesMod-3A. Spur GearSharthak GhoshNo ratings yet

- Flywheel ProblemsDocument51 pagesFlywheel Problemsgiriaj kokareNo ratings yet

- Calculation 2Document5 pagesCalculation 2salhikarimNo ratings yet

- 77-1 Spur GearDocument12 pages77-1 Spur Gearrip11117675% (4)

- Speed Control of Switched Reluctance Motor-LibreDocument9 pagesSpeed Control of Switched Reluctance Motor-LibreIndrajithSrNo ratings yet

- Analysis of Windscreen Wiper Mechanism Using MSC AdamsDocument15 pagesAnalysis of Windscreen Wiper Mechanism Using MSC AdamsDeepak SomanNo ratings yet

- Perencanan Ulang Transmisi Daya Mekanik Mesin Penghancur Es Balok Di Pasar Bina Usahakota MeulabohDocument9 pagesPerencanan Ulang Transmisi Daya Mekanik Mesin Penghancur Es Balok Di Pasar Bina Usahakota MeulabohSyibbran MulaesyiNo ratings yet

- Gear Box DesignDocument24 pagesGear Box DesignBada KimNo ratings yet

- Advanced Electric Drives: Analysis, Control, and Modeling Using MATLAB / SimulinkFrom EverandAdvanced Electric Drives: Analysis, Control, and Modeling Using MATLAB / SimulinkNo ratings yet

- Shape Memory Alloy Actuators: Design, Fabrication, and Experimental EvaluationFrom EverandShape Memory Alloy Actuators: Design, Fabrication, and Experimental EvaluationNo ratings yet

- Control of DC Motor Using Different Control StrategiesFrom EverandControl of DC Motor Using Different Control StrategiesNo ratings yet

- High Speed Off-Road Vehicles: Suspensions, Tracks, Wheels and DynamicsFrom EverandHigh Speed Off-Road Vehicles: Suspensions, Tracks, Wheels and DynamicsNo ratings yet

- Mathematical Modeling of Wheeled Mobile Robots: KeywordsDocument5 pagesMathematical Modeling of Wheeled Mobile Robots: KeywordsRaviNo ratings yet

- Design of Two Legged RobotDocument6 pagesDesign of Two Legged RobotRaviNo ratings yet

- Design of Portal Supporting Structure Using FEM and Technical StandardsDocument6 pagesDesign of Portal Supporting Structure Using FEM and Technical StandardsRaviNo ratings yet

- Analysis of Sluice Gates of Hydroelectric Power Stations: KeywordsDocument5 pagesAnalysis of Sluice Gates of Hydroelectric Power Stations: KeywordsRaviNo ratings yet

- Mathematical Modeling of Wheeled Mobile Robots: KeywordsDocument5 pagesMathematical Modeling of Wheeled Mobile Robots: KeywordsRaviNo ratings yet

- Enter Data:: MM M Weld Size (Leg) Unit Weld LengthDocument11 pagesEnter Data:: MM M Weld Size (Leg) Unit Weld LengthRaviNo ratings yet

- Enter Data:: MM M Weld Size (Leg) Unit Weld LengthDocument11 pagesEnter Data:: MM M Weld Size (Leg) Unit Weld LengthRaviNo ratings yet

- Archangel Michael Becoming A World Server and Keeper of The Violet FlameDocument7 pagesArchangel Michael Becoming A World Server and Keeper of The Violet FlameIAMINFINITELOVE100% (3)

- Session 11 Physical Vapour DepositionDocument26 pagesSession 11 Physical Vapour DepositionMurali DontuNo ratings yet

- Quantitative Analysis of A Sulfate: I. RationaleDocument5 pagesQuantitative Analysis of A Sulfate: I. RationaleBhupesh MulikNo ratings yet

- Philosophy of Quantum Mechanics For EveryoneDocument14 pagesPhilosophy of Quantum Mechanics For Everyonelo laNo ratings yet

- Phase 1Document1 pagePhase 1Gilberto Perez HernandezNo ratings yet

- Micro SoundDocument423 pagesMicro SoundFernando Soberanes88% (8)

- Siol Mechanics 2008JUNDocument12 pagesSiol Mechanics 2008JUNAnkit AkNo ratings yet

- Definition of Weight and Inertia Loading: Appendix C2Document32 pagesDefinition of Weight and Inertia Loading: Appendix C2Speeder JohnNo ratings yet

- Physics CompDocument0 pagesPhysics Compwww.bhawesh.com.npNo ratings yet

- WS 1 Nelson Vaugh RotorDocument24 pagesWS 1 Nelson Vaugh RotorrgruizNo ratings yet

- 3D ExerciseDocument1 page3D ExerciseRashiqah RazlanNo ratings yet

- Final Exam 2010 SolnDocument7 pagesFinal Exam 2010 SolnSimon AlmeidaNo ratings yet

- MM 361: Advanced Manufacturing: InstructionsDocument3 pagesMM 361: Advanced Manufacturing: InstructionsSimLo Lulumani Ko'osiko Taloanimae'aNo ratings yet

- Classification of The Concrete Based On Physical, Chemical, Technical Characteristics and ResistanceDocument21 pagesClassification of The Concrete Based On Physical, Chemical, Technical Characteristics and ResistanceJOSE BERRU USHIÑAHUANo ratings yet

- KOM Expt. No. 2Document5 pagesKOM Expt. No. 2Vatsal PatelNo ratings yet

- Experiment 5Document6 pagesExperiment 5Vinicius GuimarãesNo ratings yet

- Module 3: Mass Transfer Coefficients: Lecture No. 5Document3 pagesModule 3: Mass Transfer Coefficients: Lecture No. 5walisyhNo ratings yet

- Medical Image Retrieval With Probabilistic Multi-Class Support Vector Machine Classifiers and Adaptive Similarity FusionDocument14 pagesMedical Image Retrieval With Probabilistic Multi-Class Support Vector Machine Classifiers and Adaptive Similarity FusionDuraiPandyNo ratings yet

- Fountain: Date: 08-Apr-18Document20 pagesFountain: Date: 08-Apr-18MikhaelA.RodriguezNo ratings yet

- Quantitative Application of UV-Visible SpectrosDocument7 pagesQuantitative Application of UV-Visible SpectrosRoshan Mohammad100% (1)

- June 2014 (R) QP - Unit 1 Edexcel Physics A-LevelDocument28 pagesJune 2014 (R) QP - Unit 1 Edexcel Physics A-LevelArun MosesNo ratings yet

- Class IX: Science Chapter 11: Work and Energy Chapter Notes Key LearningDocument2 pagesClass IX: Science Chapter 11: Work and Energy Chapter Notes Key LearningMohanNayakNo ratings yet

- Example 1-020 ChopraDocument3 pagesExample 1-020 ChopraAnonymous PDEpTC40% (1)

- Von Karman Collection GuideDocument130 pagesVon Karman Collection GuideKitana Hananda SuhattaNo ratings yet

- Muffle FurnaceDocument7 pagesMuffle FurnaceRonNo ratings yet

- Lpile Description SheetDocument2 pagesLpile Description SheetMed El Hadi AbidiNo ratings yet

- Measuring DFT On Steel I BeamsDocument5 pagesMeasuring DFT On Steel I BeamsMuthuKumarNo ratings yet

- Design and Analyses of Car Model by CFD SoftwareDocument2 pagesDesign and Analyses of Car Model by CFD SoftwareKrishan KamtaNo ratings yet

- Ch09 TestbankDocument61 pagesCh09 Testbanklimpaj35No ratings yet

- Hipparchus and Ptolomy PDFDocument35 pagesHipparchus and Ptolomy PDFavisanNo ratings yet