Professional Documents

Culture Documents

No. 748,348. PATENTED DEC. 29, 1903. Rotary'Fluid Engine.: J. F. Gooley

Uploaded by

monem2014Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

No. 748,348. PATENTED DEC. 29, 1903. Rotary'Fluid Engine.: J. F. Gooley

Uploaded by

monem2014Copyright:

Available Formats

No. 748,348.

PATENTED DEC. 29, 1903.

J. F. GOOLEY.

ROTARY'FLUID ENGINE.

APPLICATION FILED JUNE 16, 1902.

N0 MODEL.

vV\\

$1

A);

x.

q:

/ k.

/

{OZ/26m

\

44 M

m

Nb. 748,348.

Patented December 29, 1903.

UNITED STATES PATENT OFFICE.

JOHN FRANCIS COOLEY, OF BOSTON, MASSACHUSETTS, ASSIGNOR, BY DIRECT

AND MESNE ASSIGNMENTS, TO COOLEY EPICYCLOIDAL ENGINE DEVEL

OPMENT COMPANY, OF JERSEY CITY, NEWJERSEY, AND BOSTON, MAS

SAOHUSETTS, A CORPORATION OF NEW JERSEY, AND COOLEY EPIOY

CLOIDAL ENGINE COMPANY, A CORPORATION OF NEW JERSEY.

ROTARY FLUID-ENGINE.

SPECIFICATION forming part of Letters Patent No. 748,348, dated December 29, 1903.

'

Application ?led June 16, 1902. Serial No. 111,810. (No model.)

To all whom it may concern:

less than the distance between the axis P and 5c

Be it known that 1, JOHN FRANCIS CooLEY, the shoe G, making a preponderance of pres

otBoston, (Allston,) in the county of Su?olk~ sure below the axis P and causing its revolu

and State of Massachusetts, have invented tion in the direction of the arrow, as above

5, certain new and useful Improvements in R0

stated, which continues until the shoe F and

tary Fluid-Engines, of which the following is the shoe Goccupy positions corresponding to 55

a speci?cation.

the present position, Fig. 2, of the ports C

My invention relates to new and useful .im and H, when the radial distances of the shoes

provements in rotary ?uid-engines; and its F and G from the center of revolution P of

I0 object is to simplify the construction of such

engines and increase the area of ?uid admis

the piston E are equal and the port C is in

position over the valve-piece packing-strip I 60

sion and exit ports by placing them in the and the chamber D is about to exhaust into

periphery of the spacer or outside rotary ele

ment and elfecting the same by providing a

thev chest J, from which the steam exhausts.

which rest upon the periphery of the spacer,

the said cylinder acting as a valve-piece in

relation to said ports whereby the ports are

brought successivelyinto com mu nication,and

but at a slower speed, and whose relation in in- 65

tegral numbers may be expressed as two to

through the opening K, the spacer L having

r5" cylinder with diametric internal projections rotated in the same direction as the piston E,

2o exhaust-chests for propelling or being pro

three in complete revolutions of both parts.

The shoe M, occupying a point correspond

ing to the valve-piece packing-strip N, would

pelled by ?uids--in other words, rotary ?uid thus be in a position which, measured upon a 70

engines which may be operated by internal radius drawn from the center of revolution

devices to produce pressure in the ?uid me P of the piston E, would be shorter than the

. dium and, conversely, which operate in con distance from the center of revolution P of

z5'sequence of pressure in a ?uid medium to the piston E to the shoe F in its moved posi

give motion to external devices.

My invention consists of certain novel fea

tion, which would correspond to the present 75

position of the port O, (shown in Fig. 2,) mak

tures hereinafter described, and particularly ing the preponderance of pressure to the

pointed out in the claims.

3o

right of the center of revolution P of the

Inthe accompanying drawings, which illus piston E and causing rotation in the direc-v

trate aconstruction embodying my invention, tion of the arrow, theport 0 then communi- 8o

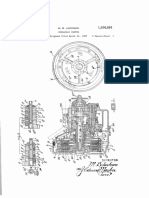

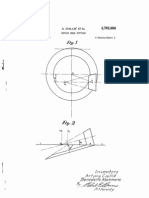

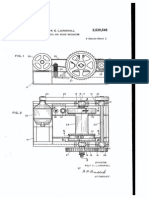

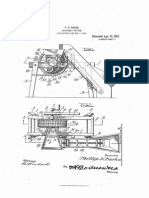

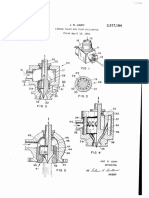

Figure 1 is a central longitudinal sectional

view through the engine on the line 1 1, Fig. 2.

Fig. 2 is a cross-sectional view through the

35 engine on the line 2 2, Fig. 1, looking in the

direction indicated by the arrow.

Like letters of reference refer to like parts

eating with the pressure-chest B and allow

ing the ?uidto enter from the chest B to the

space R, and the operation continues as

above described. The pinions P2, mounted

on the shaft P of the piston E, and the in- 85

ternal gears L, out in openings in the disks

throughout both views.

L2, secured to the spacer L, intermesh and

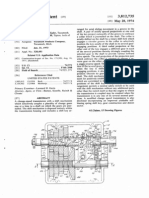

Referring to Fig. 2, steam or other ?uid is operate at the same correlative speed ratio as

40 admitted through the opening A into the pres thepiston and spacer of the engine. The

sure-chest B within the cylinder A and rings S and T, (shown in dotted and section 90

passes through the port 0 in the spacer L lines, Fig. 1,) and of which one, T, is shown

into the space D, pressing upon the piston E in dotted lines, Fig. 2, are provided to pre

between the shoes F and G, the resultant of vent internal leakage to or from the chests.

45 which pressure passes below the axis of revo The wearing-rings L3 are provided with ra

lution P of the piston E, thereby causing its dial projections (shown in dotted lines, Fig. 2) 95

rotation in the'direction of the arrow. In

other words, the distance on the radial line

between the center or axis P to the shoe F is

and are located in the two opposite end disks

L2, as shown in section in Fig. 1. On the outer

ends of the engine are located the cylinder

heads U, through which project the shaft P ing piston within said spacer and rotating

of the piston E, and which cylinder-heads upon a positionally-?xed axis parallel to the

have also inwardly-projecting hubs U, which axis of the spacer, the spacer in continuous

contact with the periphery of said piston at

disks L2 of the spacer L and also for the shaft points situated at radially-equal distances

P. The spring-pressed va1ve~piece packing from the axis of rotation of the spacer and

form a bearing for the hubs L4 on the end

equiangularly-spaced intervals along their

metric internal partitions N and j, as shown, circular path of travel both piston and spacer 75

and said strips and partitions rest upon the pe rotating in the same direction at relatively

strips N and I are located Within the two dia

IO

20

riphcry of the spacer L which is in continu constant but different rates of speed, and en

ous contact with the periphery of the piston trance and exit ports for ?uids laterally situ

E at points situated at radially-equal dis ated in the periphery of said spacer and be

tances from the axis of their rotation Q, which tween the points of contact with said piston.

4. In a rotary ?uid-engine, a cylinder hav

is the center of rotation of the spacer L. The

shoes F, G,an'd M rock, respectively, in spring

ing diametrically-situated interprojecting ra

pressed splines f, g, and on within recesses in

the spacer equidistant from each other. The

entrance and exit ports 0, H, and O for ?uid

are laterally situated in the periphery of the

spacer L and preferably intermediate be

tween the points of contact of the spacer upon

tionally-?xed axis, a like directionally-rotat- 7

the piston.

Having thus described the nature of my in

vention and set forth a construction embody

25 ing the same, what I claim as new, and _de

sire to secure by Letters Patent of the United

States, is

'

dial partitions, a rotating spacer between the

extremities of said partitions and in continu

ous contact therewith rotating upon a posi

85

ing piston within saidlspacer and rotating

upon a positionally-?xed axis parallel to the

axis of the spacer, the spacer in continuous

contact with the periphery of said piston at 90

points situated at radially-equal distances

from the axis of rotation of the spacer and

equiangularly-spaced intervals along their

circular path of travelboth piston and spacer

rotating in the same direction at relatively 95

constant but dift'erentrates of speed, and en

dial partitions, a rotating spacer between the trance and exit ports for ?uids situated in the

extremities of said partitions and in continu periphery of said spacer and between the

ous contact therewith rotating upon a posi points of contact with said piston.

5. In a rotary ?uid-engine, a cylinder hav I00

tionally-?xed axis, a like directionally-rotat

1. In a rotary ?uid-engine, a cylinder hav

ing diametrically-situated interprojecting ra

ing piston within said spacer and rotating ing diametrically-situated interprojecting ra

35 upon a positionally?xed axis parallel to the

axis of the spacer, the spacer in continuous

contact with the periphery of said piston at

dial partitions, a rotating spacer between the

extremities of said partitions and in continu

ous contact therewith and rotating upon a po

points situated at radially-equal distances sitionally-?xed axis, a rotating piston in said 105

from the axisof rotation of the spacer, and cylinder whose axis is parallel to the axis of

equiangularly-spaced intervals along their said cylinder and mounted upon a shaft ec

circular path of travel, and entrance and exit

ports for ?uids laterally situated in the pe

riphery of said spacer and between the points

of contact with said piston.

2. In a rotary ?uid-engine, a cylinder hav

45

ing diametrically-situated interprojecting ra

centric to said cylinder, cylinder-heads pro

vided with eccentric bearings for said piston

shaft, and entrance and exit ports for ?uids

laterally situated in [the periphery of said

spacer and between the points of contact with

said piston.

'

I10

6. In a rotary ?uid-engine, a cylinder hav

dial partitions, a rotating spacer between the

extremities of said partitions and in continu4 ing diametrically-situated interprojecting ra 115

ous contact therewith rotating upon a posi dial partitions, a rotating spacer between the

tionally-?xed axis, a like directionally-rotat extremities of said partitions and in continu

ing piston within said spacer and rotating ous contact therewith and rotating upon a po

upon a positionally-?xed axis parallel to the sitionally-?xed axis, a rotating piston in said

cylinder whose axis is parallel to the axis of IZC

contact with the periphery of said piston at said cylinder and mounted upon a shaft eccen

55 points situated at radially-equal distances tric to said cylinder, cylinder-heads provided

from the axis of rotation of the spacer and with eccentric bearings for said piston-shaft,

equiangularly-spaced intervals along their and entrance and exit ports for ?uids situated

circular path of travel, and entrance and exit in the periphery of said spacer and between I25

ports for ?uids situated in the periphery of the points of contact with said piston.

7. In a rotary ?uid-engine, a cylinder hav

said spacer and between the points of contact

axis of the spacer, the spacer in continuous

with said piston.

3. In a rotary ?uid-engine, a cylinder hav

ingdiametrically-situated interprojecting ra

ing diametrically-situated interprojecting ra

dial partitions, a rotating spacer between the

extremities of said partitions and in continu

dial partitions, a rotating spacer between the ous contact therewith rotating upon a posi

65 extremities of said partitions and in continu

ous contact therewith rotating upon a posi

tionally-?xed axis, a like directionally-rotat

ing piston within said spacer and rotating

tionally-?xed axis, a like directionally-rotat

upon a positionally-?xed axis parallel to the

748,348

axis of the spacer and provided on its shaft cate, and means in the said outer casing to

with gear adapted to interm esh with gearin the cut off communication between said ?uid-in

spacer and cause the like directional rotation let chamber and said ?uid'outlet chamber,

.

of the spacer with the piston, the spacer in substantially as described.

10. In arotary?uid-engine,in combination, 55

continuous contact with the periphery of said

piston at points situated at radially-equal dis a rotary piston, a rotary spacer having ?xed

tances from the axis of rotation of the spacer partitions bearing on the peripheral curved

and equiangularly - spaced intervals along surfaces of the piston,and provided with ports

their circular path of travel, and entrance extended through said spacer, both piston

and'spacer being mounted on di?erent axes

IO and exit ports for ?uids laterally situated in

the periphery of said spacer and between the of rotation and rotating in the same direction

at relatively constant but diiferent rates of

points of contact with said piston.

8. In a rotary ?uid~engine, in combination, speed, an outer casing provided with a ?uid

a rotary piston having its periphery provided inlet adapted to communicate with each space

chamber formed between said rotary piston 65

15 with circular portions of the same radius but or

of di?ereut centers, a rotary spacer having a and said spacer from substantially its mini

cylindrical outer surface, and provided on its mum to substantially its maximum area, a .

inner circumference with three recesses of ?uid-outlet for said casing, means in the said

substantially the same radius as the circular casing for closing the inlet-port. for a space

portions of the piston, partitions between ad or chamber between said piston and spacer

jacent recesses and engaging the peripheral when said space has reached substantially its

surface of the rotary piston, ports in said maximum area, and means in the said casing

spacer communicating with said recesses, for cutting oif the fluid-outlet port from the

said piston and spacer rotating in the same fluid ~ inlet chamber, substantially as de

75

25 direction at relatively constant but different

11. In a rotary ?uid-engine, in combination,

rates of speed, an outer casing within which

said spacer rotates,a ?uid-inlet chamber with a rotary piston, a rotary spacer having ?xed

in saidcasing and of sufficient length to en partitions bearing on the peripheral curved

able two of the ports in the spacer to simul surfaces of the piston and provided with ports

taneously communicate with it, a ?uid-outlet extended through said spacer, both piston

scribed.

'

for said casing, and means in said casing en

gaging the outer circumference of the spacer

intermediate said ?uid-inlet chamberand said

and spacer being mounted on different axes

of rotation and rotating in the same direction

at relatively constant but different rates of

?uid-outlet to cu t off com m unication between

speed, an outer casing provided with a ?uid

said ?uid-inlet chamber and the ?uid-outlet, inlet adapted to communicate with the spaces 85

35 substantially

or chambers formed between. said rotary pis

as described.

9. In a rotary ?uid-engine, in combination, ton and said spacer until said spaces or cham

a rotary piston, a rotary spacer having ?xed bers have reached substantially their maxi

partitions bearing on the peripheral curved mum area, and means in said casing for clos

surfaces of the piston, both piston and spacer iag the inlet-ports of said spaces or chambers

mounted on different axes of rotation and ro

when they have reached substantially their

tating in the same direction at relatively con

stant but di?erent rates of speed, an outer

maximum areas, substantially as described.

In testimony whereof I have signed my

casing within which said spacer rotates, said name to this speci?cation, in the presence of

45 casing having a ?uid-inlet chamber of suffi two subscribing witnesses, this 24th day of 95

.

cient length to simultaneously communicate May, A. D. 1902.

JOHN FRANCIS OOOLEY.

with a plurality of chambers between said

Witnesses:

spacer and piston, and having a ?uid-outlet

A. L. NUSSER,

with which a third chamber between said

E. L. HARLOW.

50 spacer and piston is adapted to- communi

You might also like

- SSntanv Engine.,: No. 630,648. - Pamnfed Aug.-A, - 899Document7 pagesSSntanv Engine.,: No. 630,648. - Pamnfed Aug.-A, - 899monem2014100% (1)

- Anti-Aircraft Fire Control Device (1937)Document10 pagesAnti-Aircraft Fire Control Device (1937)CAP History LibraryNo ratings yet

- H. K. Smith.: No. 60,950. Y. Patented Jan. L, 1867Document3 pagesH. K. Smith.: No. 60,950. Y. Patented Jan. L, 1867asdfasfNo ratings yet

- Us1866891 PDFDocument8 pagesUs1866891 PDFbelchior alvaroNo ratings yet

- Making Eyelets'.: L. RichardsDocument3 pagesMaking Eyelets'.: L. RichardsasdfasfNo ratings yet

- Us1955360 PDFDocument8 pagesUs1955360 PDFRodrigoPomaNo ratings yet

- 1,1 1 5,699 Patented Nov. 3, 1914.: E. D. LooseDocument4 pages1,1 1 5,699 Patented Nov. 3, 1914.: E. D. LoosePedro SeebeckNo ratings yet

- Chapter 2Document25 pagesChapter 2AkashDudi100% (1)

- Axial Movement From Mating Cam Sections Rotating at Different Speeds.-Certain Copper Tubes Used in Connection With Steam-HeatingDocument2 pagesAxial Movement From Mating Cam Sections Rotating at Different Speeds.-Certain Copper Tubes Used in Connection With Steam-Heatingladygaga_pitoNo ratings yet

- Tel - Escope Mounting FDR Guns.: N0. 69 - , 248. V ' Patented Lan. I4, - 902Document4 pagesTel - Escope Mounting FDR Guns.: N0. 69 - , 248. V ' Patented Lan. I4, - 902Radim KadlecNo ratings yet

- @341 A É'Wqkammm: Filed July 28-, 1944Document3 pages@341 A É'Wqkammm: Filed July 28-, 1944devheadbotNo ratings yet

- US22753Document4 pagesUS22753vadimNo ratings yet

- Automatic Fire SprinklerDocument3 pagesAutomatic Fire SprinklerChandaKundaNo ratings yet

- Matri Hand Book SteeringDocument8 pagesMatri Hand Book SteeringAlifNo ratings yet

- 1895 - Us570025Document5 pages1895 - Us570025Enrico Bruce GioloNo ratings yet

- Berthier Us1366863Document9 pagesBerthier Us1366863cll1968No ratings yet

- Sam W Hoke Torch PatentDocument5 pagesSam W Hoke Torch PatentRichard.nlNo ratings yet

- Bob Neal Overunity Compression Unit - US2030759Document5 pagesBob Neal Overunity Compression Unit - US2030759John CarterNo ratings yet

- Engineering Materials Definition of TermsDocument8 pagesEngineering Materials Definition of TermsDave RoneNo ratings yet

- Hypoid Gear CuttingDocument9 pagesHypoid Gear CuttingHano LourensNo ratings yet

- Berthier Us1446635Document12 pagesBerthier Us1446635cll19680% (1)

- N Peters, Photo-Lithografher, Wash Ngton. D CDocument2 pagesN Peters, Photo-Lithografher, Wash Ngton. D CasdfasfNo ratings yet

- W. F. Draper & C. F. - Ruper.: Let-Dff Mechanism For Looms.Document6 pagesW. F. Draper & C. F. - Ruper.: Let-Dff Mechanism For Looms.DavictorNo ratings yet

- US1908080Document3 pagesUS1908080reichanNo ratings yet

- IndicatorsDocument54 pagesIndicatorsmihalikj2190No ratings yet

- Snow v. Lake Shore & Michigan Southern R. Co., 121 U.S. 617 (1887)Document8 pagesSnow v. Lake Shore & Michigan Southern R. Co., 121 U.S. 617 (1887)Scribd Government DocsNo ratings yet

- Helical GearDocument18 pagesHelical GearNitin B maskeNo ratings yet

- L'il Wu" MM: Jan. 30, 1951 R, E - Ljungkull 2,539,545Document12 pagesL'il Wu" MM: Jan. 30, 1951 R, E - Ljungkull 2,539,545lfilippiniNo ratings yet

- (Patente 1) US1489458Document3 pages(Patente 1) US1489458diegoNo ratings yet

- Us 2120533asfafafDocument5 pagesUs 2120533asfafafankitsarvaiyaNo ratings yet

- Patented Oct, 17, 1882, No. 265,987,: G. S. ShieffieldDocument3 pagesPatented Oct, 17, 1882, No. 265,987,: G. S. ShieffieldJorge MosqueraNo ratings yet

- Hanau - Wide Vue InstDocument39 pagesHanau - Wide Vue InstRahul JaiswalNo ratings yet

- Ship Hydrodynamics Lecture Notes Part 2 Propeller GeometryDocument10 pagesShip Hydrodynamics Lecture Notes Part 2 Propeller Geometryborhec123No ratings yet

- 5 2 HergtMiKTeX V5N2Document11 pages5 2 HergtMiKTeX V5N2anggacenter_19No ratings yet

- GB657382ADocument4 pagesGB657382AOctav IanNo ratings yet

- No. 687,172. Patlmtedl Nov. I9, I90I.: Variable Speed GearingDocument4 pagesNo. 687,172. Patlmtedl Nov. I9, I90I.: Variable Speed Gearingbelchior alvaroNo ratings yet

- Us1517483 PDFDocument10 pagesUs1517483 PDFJin SongNo ratings yet

- (1956), June 14) US2970812 Drum Type Heat ExchangerDocument4 pages(1956), June 14) US2970812 Drum Type Heat ExchangeraegosmithNo ratings yet

- MMM-@U: H. M. SpragueDocument4 pagesMMM-@U: H. M. SpraguedjsfNo ratings yet

- US2726694 - Single Screw Actuated Pivoted Clamp (Saxton Clamp - Kant-Twist)Document2 pagesUS2726694 - Single Screw Actuated Pivoted Clamp (Saxton Clamp - Kant-Twist)devheadbot100% (1)

- Pumps: Helical Gear PumpDocument4 pagesPumps: Helical Gear PumpSynesiusNo ratings yet

- Cash Reg. Co. v. Cash Indicator Co., 156 U.S. 502 (1895)Document13 pagesCash Reg. Co. v. Cash Indicator Co., 156 U.S. 502 (1895)Scribd Government DocsNo ratings yet

- Sept. 11, 1951 B. B. Scott 2,567,735: His AttorneyDocument3 pagesSept. 11, 1951 B. B. Scott 2,567,735: His AttorneyTri PujiyantoNo ratings yet

- Apron MechanismDocument7 pagesApron Mechanismgopalpaul0% (2)

- Jan. 4, L 1966 T. W. Spack 3,227,148Document6 pagesJan. 4, L 1966 T. W. Spack 3,227,148MainAvelNo ratings yet

- Illlllllllllilllllllllilllllllllli: United States Patent (191Document3 pagesIlllllllllllilllllllllilllllllllli: United States Patent (191dgfsduuwioNo ratings yet

- Patented Jan. 1, I867 V: Z. SperryDocument3 pagesPatented Jan. 1, I867 V: Z. SperryasdfasfNo ratings yet

- Apl'il 7, 1959 W. Settele ' v2,880,518Document4 pagesApl'il 7, 1959 W. Settele ' v2,880,518राजकुमार यादवNo ratings yet

- Tesla Oscillator - Century Magazine (April 1895)Document4 pagesTesla Oscillator - Century Magazine (April 1895)nickfink101No ratings yet

- March 27, 1934. G - J - Ranque 1,952,281: Filed Dec. 6, 1932' 3 Sheets-Sheet 1Document7 pagesMarch 27, 1934. G - J - Ranque 1,952,281: Filed Dec. 6, 1932' 3 Sheets-Sheet 1mrock_1No ratings yet

- US1157800 - Universal Test-Indicator - Oslund, 1915Document3 pagesUS1157800 - Universal Test-Indicator - Oslund, 1915devheadbotNo ratings yet

- NOV-5, 1940 - C. D. Peterson: Two Speed Forward and Two Speed Reverse TransmissionDocument4 pagesNOV-5, 1940 - C. D. Peterson: Two Speed Forward and Two Speed Reverse TransmissionMohan RaoNo ratings yet

- Us1223254 PDFDocument7 pagesUs1223254 PDFRodrigoPomaNo ratings yet

- US2128620 - Bending MachineDocument5 pagesUS2128620 - Bending MachinedevheadbotNo ratings yet

- US3317184Document4 pagesUS3317184Efabind OtNo ratings yet

- United States Patent (191: Von Kale! Et AlDocument18 pagesUnited States Patent (191: Von Kale! Et AlJoão Paulo Canto RibeiroNo ratings yet

- ??J.Wima: Patented JanDocument3 pages??J.Wima: Patented JanzgregzNo ratings yet

- Scientific American Supplement, No. 611, September 17, 1887From EverandScientific American Supplement, No. 611, September 17, 1887No ratings yet

- 507 Mechanical Movements: Mechanisms and DevicesFrom Everand507 Mechanical Movements: Mechanisms and DevicesRating: 4 out of 5 stars4/5 (28)

- Cumblned Muffle and Mud Guard For Mgtor Ve'Rhbles.: Patented July 22, 2%2Document3 pagesCumblned Muffle and Mud Guard For Mgtor Ve'Rhbles.: Patented July 22, 2%2monem2014No ratings yet

- No. 648,153. - Patented Apr. 24, I900. J. P. Serve. : Means For Lubrigating Engine Fylinbers, 61.0Document3 pagesNo. 648,153. - Patented Apr. 24, I900. J. P. Serve. : Means For Lubrigating Engine Fylinbers, 61.0monem2014No ratings yet

- W, B. Kidder. : Tree Climbing MotorDocument4 pagesW, B. Kidder. : Tree Climbing Motormonem2014No ratings yet

- March23, 1954 J. L, Dunnlgan Y 2,672,853: Sealed Cooling System For Internal-Combustion EnginésDocument3 pagesMarch23, 1954 J. L, Dunnlgan Y 2,672,853: Sealed Cooling System For Internal-Combustion Enginésmonem2014No ratings yet

- Dec. 15, 1942. - R. Lang:1 Al Diesel Engine With Charging PancaDocument3 pagesDec. 15, 1942. - R. Lang:1 Al Diesel Engine With Charging Pancamonem2014No ratings yet

- May 15, l945-W. Kilchenmann: Reversible Supercharged Two-Stroke Internal-Combustion Engine IDocument3 pagesMay 15, l945-W. Kilchenmann: Reversible Supercharged Two-Stroke Internal-Combustion Engine Imonem2014No ratings yet

- March 25,1930. ' . V - (5 - APPLE 1,752,224: Filed Dec. 7, 1928Document4 pagesMarch 25,1930. ' . V - (5 - APPLE 1,752,224: Filed Dec. 7, 1928monem2014No ratings yet

- Sept. 24, 1929. W. Siders: Filed Nov. 5. 1925Document3 pagesSept. 24, 1929. W. Siders: Filed Nov. 5. 1925monem2014No ratings yet

- Nov. 12, 1935. W. D. Appel 2,020,597: Filed Aug. 13, 1934Document3 pagesNov. 12, 1935. W. D. Appel 2,020,597: Filed Aug. 13, 1934monem2014No ratings yet

- 46, Tazecfeafe Fue) : Filed Oct. 5, 195.1IDocument42 pages46, Tazecfeafe Fue) : Filed Oct. 5, 195.1Imonem2014No ratings yet

- Oct. 24, 1944, C. K. Newcombe 7 2,360,969: Supercharger For Internal-Combustion EnginesDocument3 pagesOct. 24, 1944, C. K. Newcombe 7 2,360,969: Supercharger For Internal-Combustion Enginesmonem2014No ratings yet

- Us 2397941Document3 pagesUs 2397941monem2014No ratings yet

- Wwkzii: Jan. 10, 1933. R. H. FarwellDocument3 pagesWwkzii: Jan. 10, 1933. R. H. Farwellmonem2014100% (1)

- June 13, 1961 ' F. Wankel Etal 2,988,065: Rotary Internal Conbustion Engine Filed Nov. 17, 1958 2l Sheets-Sheet 1Document33 pagesJune 13, 1961 ' F. Wankel Etal 2,988,065: Rotary Internal Conbustion Engine Filed Nov. 17, 1958 2l Sheets-Sheet 1monem2014No ratings yet

- Ch. 9 (B) LecDocument38 pagesCh. 9 (B) LecTom UlesNo ratings yet

- ) 1D Consolidation Analysis and Design - SoilWorksDocument59 pages) 1D Consolidation Analysis and Design - SoilWorksDeepthiNo ratings yet

- LUO - 2014 - A New Degassing Membrane Coupled Upflow Anaerobic Sludge BlanketDocument7 pagesLUO - 2014 - A New Degassing Membrane Coupled Upflow Anaerobic Sludge BlanketThobiasNo ratings yet

- Introduction To Computed TomographyDocument19 pagesIntroduction To Computed TomographyMirza Safeer AhmadNo ratings yet

- 15 Design For Safety HazanDocument12 pages15 Design For Safety Hazansauravsagar14No ratings yet

- S MB Bearing CatalogueDocument104 pagesS MB Bearing Cataloguefog900No ratings yet

- JIG AND FIXTURE DESIGN MANUL Eric K HenriksenDocument160 pagesJIG AND FIXTURE DESIGN MANUL Eric K HenriksenPrakashmech4028No ratings yet

- Force Table: Instruction Manual and Experiment Guide For The PASCO Scientific Model ME-9447Document18 pagesForce Table: Instruction Manual and Experiment Guide For The PASCO Scientific Model ME-9447joanally bagoyoNo ratings yet

- Fan7529 Critical Conduction Mode PFC ControllerDocument20 pagesFan7529 Critical Conduction Mode PFC ControllerPompei RusuNo ratings yet

- Energy Guide Midea - Mrc07m6aww Mrc07m6ewwDocument1 pageEnergy Guide Midea - Mrc07m6aww Mrc07m6ewwharry HendersonNo ratings yet

- 0000 Pi SPC 004Document18 pages0000 Pi SPC 004zsmithNo ratings yet

- How To Use A CompassDocument10 pagesHow To Use A CompassShaun JohnsonNo ratings yet

- GeomaticaDocument5 pagesGeomaticaAlcantaraSusyNo ratings yet

- Resident Physics Lectures: Mammography X-Ray SystemDocument42 pagesResident Physics Lectures: Mammography X-Ray SystemLajja Parikh PatelNo ratings yet

- ASTM and Fall Cone TestDocument2 pagesASTM and Fall Cone TestCutsilverNo ratings yet

- Cromax 4140 PDFDocument2 pagesCromax 4140 PDFDidik PrihantoroNo ratings yet

- An Elementary Proof For Fermat's Last Theorem Using An Euler's EquationDocument9 pagesAn Elementary Proof For Fermat's Last Theorem Using An Euler's EquationGagan DeepNo ratings yet

- 2D 1 TutorialDocument208 pages2D 1 TutorialAbdulrahman SaraijiNo ratings yet

- Bouncing Balls Gcse CourseworkDocument5 pagesBouncing Balls Gcse Courseworkrhpvslnfg100% (2)

- Astm D3078 94Document1 pageAstm D3078 94Jusuf Hasan100% (1)

- Hooke's Law (4Document30 pagesHooke's Law (4Clark Harold Balido50% (2)

- L01 Introduction To Particle TechnologyDocument35 pagesL01 Introduction To Particle TechnologyPhan NeeNo ratings yet

- Flender Manual GeneralDocument42 pagesFlender Manual GeneralYenny LaraNo ratings yet

- Modeling The Deformation of Earth Dam During An Earthquake: AbstractDocument6 pagesModeling The Deformation of Earth Dam During An Earthquake: AbstractMahmoud. HlelaiNo ratings yet

- Pharmaceutical ChemistryDocument19 pagesPharmaceutical ChemistryRaj Nemala Raj NemalaNo ratings yet

- Design Guideline For Hydraulic Fluid CleanlinessDocument24 pagesDesign Guideline For Hydraulic Fluid CleanlinessCarlosNo ratings yet

- 50th Anniversary AHSMEDocument13 pages50th Anniversary AHSMEgauss202No ratings yet

- PLSC 0013Document7 pagesPLSC 0013balaji100% (1)

- Semiconductor Memories Semiconductor Memories Semiconductor Memories Semiconductor MemoriesDocument37 pagesSemiconductor Memories Semiconductor Memories Semiconductor Memories Semiconductor MemoriesPriyank DevpuraNo ratings yet

- Signal & System WB SolutionsDocument226 pagesSignal & System WB SolutionsCHANDRIMA UPADHYAYNo ratings yet