Professional Documents

Culture Documents

Pile Design PDF

Uploaded by

Khusairy AhmadOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pile Design PDF

Uploaded by

Khusairy AhmadCopyright:

Available Formats

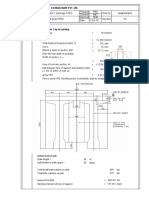

Pile Design Report

FOR INTERNAL USE ONLY

Sample Design Calculations

For Micropiles in Kenny

Hill Formation

Generalized Subsoil Profile

-

Generally flat terrain

Subsoil profile:

0-3m, silty SAND, SPT=1- 5

3-6m, silty SAND, SPT= 15 - 50

6-20m, highly weathered sandstone

Schematic Detail

Soil becoming

weathered rock

Mild Steel Capping Plate

L

=

350mm

B

=

350mm

Thickness

=

10mm

Mild Steel Stiffeners

Thickness =

10mm

Pile Boring

Diameter = 200mm

L = 20.0m

API Pipe

O.D.

Thickness

fy (min)

Grade

=

=

=

=

127.0mm

9.2mm

552 Mpa

N-80

Cementitious Grout

W/c

=

0.45

Fcu

=

25 Mpa

Safe Working Load

Pa

=

80 tonnes

Lsocket

=

20m

Cawangan Jalan, Ibu Pejabat JKR, K.L

Page 1

Pile Design Report

FOR INTERNAL USE ONLY

Subject : Micropile Design

1.0

Material Properties

1.1

Basic Dimensions and Properties

1.1.1

1.1.2

1.1.3

Micropile Diameter, D

Pile Composite Modulus Ep

Moment of Inertia, Ip

1.2

Cementitious Grout

1.2.1

1.2.2

1.2.3

1.2.4

1.2.5

1.2.6

Max. water/cement ratio

Anti-shrink / Additives

Grout Area. Ac

28 day Comp. Strength, Fcu'

Density

Elastic Modulus. Ec

1.3

API Pipe Reinforcement

1.3.1

1.3.2

1.3.3

1.3.4

1.3.5

1.3.6

1.3.7

1.3.8

1.3.9

Source

Outer Diameter, OD

Wall Thickness. t

Inner Diameter. ID

Cross Sectional Area, As

API Specification

Grade Designation

Mm. Yield Strength, fy

Elastic Modulus. Es

1.4

Compliance with British Standards Designed

1.4.1

1.4.2

1.4.3

1.4.4

Working Grout/API Pipe Bond (MPa)

0.8

12

Grout Characteristic Strength, fcu (MPa)

25

20

Cement content (kg/m"3)

400

00

Grout working compressive stress,0.4fcu/FoS 0.2 x fcu 0.25 x fcu

1.5

Minimum Factors of Safety

1.5.1

1.5.2

1.5.3

1.5.4

Against Structural Failure

Against Buckling Failure

Against Geotech. Failure

Against Geotech. Failure

2.0

Structural Design

Assuming that the applied vertical load is carried by the API Pipe alone.

Ultimate Load Capacity Pu

= 0.87 x fy x As

= 1633450 N

= 1633.5 kN

= 163.3 tonnes

Use the Factor of Safety prescribed in Section 1.5 on Plate 2

Allowable Load Capacity Pa

= 82 tonnes

2.1

2.2

Cawangan Jalan, Ibu Pejabat JKR, K.L

= 200mm

= 41

GPa

= 7.85E+07 mm^4

=

=

=

=

=

=

0.45

Adogroud 100g 150kg bag

45686

mm"2

25

MPa

2000

kg /M^3

28

GPa

=

=

=

=

=

=

=

=

=

127

9.19

108.62

3401

5A-80

N-80

552

210

=

=

=

=

2.00

1.60

2.00

2.50

mm

mm

mm

mm^2

MPa

GPa

Req. Min.

(Max)

Source

BS8110

BS8004

BS8004

BS8004

Skin Friction

End Bearing

Page 2

Pile Design Report

FOR INTERNAL USE ONLY

2.3

Design Safe Working Load SWL

= 80 tonnes

3.0

Geotechnical Design

Refer Piler Analysis for derivation of Geotechnical Safe Working Load -Appendix ......

3.1

Design Length

3.1.1

3.1.2

3.1.3

Safe Working Load per Pile

Nominal Diameter

Embedment

3.2

Grout l API Pipe Bond

3.2.1

3.2.2

3.2.3

3.2.4

Ultimate Grout Pipe - Bond Stress, t (u)

Factor of Safety

Working Bond Stress, t (w)

Req'd API Pipe Embedment in Grout

P

D

Ls

Therefore, adopted socket length is

= 800

= 200

= 20.0 m

kN

mm

= 2.0

= 2.5

= 0.8

= 2.5

< 20.0 m

OK

MPa

MPa

m

4.0

Buckling (Pile Slenderness)

4.1

Pile End Conditions (Unfilled Cavities)

4.1.1

4.1.2

4.1.3

4.1.4

Pile Top (at Pilecap Level)

Pile Base (at Rock Head Level)

Ass. length in unfilled cavity L assumed

Effective Length - 0.7 x L L eff.

4.2

Eucler's Buckling Load (Unfilled Cavities)

4.2.1

4.2.2

Effective radius

Euler Critical Load

4.3

Elastic Buckling Load of Pile embedded in Overburden (ie Winkler Medium)

4.3.1

4.3.2

4.3.3

4.3.4

Average SPT in Overburden soils, N

Est. Und. Cohesion Overburden soils, Cu

Modulus of Horiz. Subgrade Reaction, kh'c

20100 kPa

Elastic Buckling Load, Pcr

4.3.5

FOS available

5.0

Rate of Corrosion of Reinforcement

5.1

Ex Oil Drill API Pipe Reinforcement

5.1.1

5.1.2

5.1.3

5.1.4

5.1.5

5.1.6

5.1.7

Outer Diameter

Wall Thickness

Internal Diameter

Cross sectional Area

API Specification

Grade Designation

Min Yield Strength

Cawangan Jalan, Ibu Pejabat JKR, K.L

Analysis not appropriate

for Kenny Hill Formation

r

Pe

FOS available

O.D.

t

I.D.

As

fy

=

=

=

=

Fixed

Fixed

1m

0.7 m

=41.8

=@pi^2 - Ep l(Lelr)^2 = 1428 kN

=9.78

OK

=

=

=

=

=

=

=

50

6 ' N kPa 300 kPa

67*Cu

20.1 MPa

2 x @sgrt (Ep x Ip x kh x d)

16014 kN

20.02 OK

=

=

=

=

=

=

=

127.0

9.2

108.6

3401

5A-80

N-80

552

mm

mm

mm

mm^2

MPa

Page 3

Pile Design Report

FOR INTERNAL USE ONLY

5.1.8

5.1.9

Elastic Modulus Es

=

210

GPa

Allowable Axial Working Stress (Clause 7.4.6.3.1 BS8004)

Fa

=

50% of Yield Strength

=

276 MPa

5.2

Design for allowable corrosion as for sheetpiles w/o grout/

concrete protection

5.2.1

5.2.2

5.2.3

5.2.4

5.2.5

Allowable corrosion rate

Max. pile axial load Pa

Req'd Steel Area

Min. OD of API Pipe

Allowable Corrosion Period

=

=

=

=

=

Asc

O.D.

Tc

0.01

800

2899

124.5

255

mm/year

kN

mm^2

mm

years

Summary

No additional reinforcement required, Tc > Design Life of 50 years.

6.0

Pilehead Capping Details

Safe Working Load

800

kN

=

=

=

x

25

6.85

116800

350

MPa

MPa

mm^2

OK

155

MPa

6.1

Capping Plate Size

6.1.1

6.1.2

6.1 3

Assume characteristic strength of pileca f cu

Permissible direct compressive stress fcu13.65

Req'd bearing area of capping plate

Adopt plate of dimmensions (mm)

350

6.2

Thickness of Stiffners

6.2.1

Allowable Axial Compressive Stress

=

(Table 17 (a). BS449 : Part 2: 1969)

Contact Area of API Pipe on Capping Plate

=

Stiffener projection beyond API pipe OD

=

Required thickness of MS Stiffeners

t(s) =

Adopt

6.2.2

6.2.3

6.2.4

6.3

Thickness of Capping Plate

6.3.1

6.3.2

Allow Shear Stress on Capping Plate

(Table 10. BS449:Part 2:1969)

Effect. Punching Shear Shear Perimeter

6.3.3

Required Thickness of Capping Plate

125

OD of API Pipe + Perimeter

- 8 x thickness of stiffeners

1599 mm

4.0

mm

10

mm

=

=

Adopt

6.4

Allowable Bearing Stress on Capping Plate

6.4.1

Allow. Bearing Stress on Capping Plate

(Table 9. BS449:Part 2:1969)

Proj. Bearing Area (API + Stiffeners)

Actual Bearing Stress

6.4.2

6.4.3

Cawangan Jalan, Ibu Pejabat JKR, K.L

3401 mm^2

184

mm

2.4

mm

10

mm

(4No. MS Stiffeners)

MPa

210

MPa

=

=

10761 mm^2

74

MPa

< All. Bearing Stress, OK

Page 4

Pile Design Report

FOR INTERNAL USE ONLY

6.5

Check Stiffeners for Buckling

6.5.1

6.5.2

Bearing Area of API Pile

=

3401 mm^2

Bearing Area of 4No. Stiffeners

=

7359 mm^2

Assume uniform distribution of Pile Axial Load,

Compressive Load per Stiffener

=

136.8 kN

Pile head Embedment into Pilecap

=

150

mm

Assume Stiffener Depth, d

=

140

mm

(Conservative Estimate)

Slenderness Ratio of Stiffener

d ' @sgrt(3)1 thickness of stiffener

=

24.2

Allow. Compressive Stress

=

146

MPa

(Table 17(a). BS449)

Allow. Buckling Load on Stiffener

=

268.6 kN '

> Compressive Load of Stiffener, OK

6.5.3

6.5.4

6.5.5

6.5.6

6.5.7

6.5.8

6.6

Check Bearing on API Pipe

6.6.1

6.6.2

6.6.3

6.6.4

Moment equilibrium about intersection of Capping Plate and API Pipe,

Bearing Force on API Pipe

=

180

kN

Assume material for API Pipe to be equivalent to G55 steel,

Allow. Bearing Stress

=

320

MPa

Allow Bearing Load

=

448

kN

> Actual Bearing Force, OK

6.7

Fillet Weld Design (Stiffener to API Pipe)

6.7.1

Weld Length per Stiffener

6.7.2

Req'd Shear Load Capacity for weld

Cawangan Jalan, Ibu Pejabat JKR, K.L

=

=

=

Adopt

2xd

280

0.49

7

mm per stiffener

kN/mm

mm Fillet Weld

Page 5

Pile Design Report

FOR INTERNAL USE ONLY

Design Report

1.

Introduction

This report presents the design criteria and design calculations for pile foundation for

Interchange 3 of Project B 15 Road Upgrading Works.

Interchange 3 is a cloverleaf interchange with arch shaped R.C bridge as shown below

From structural analysis the compression load coming over the piles from one half of the

bridge is 12600 ton while the other half is 2800 ton in tension.

2.

Site Condition

The topograph of the site is rolling to undulating. The subsoil condition is generalized as

shown above.

The top 12m to 16m from the OGL of the residual soil is clayey silt with SPT 6-39 (aver

age SPT=20): This is underlain by hard clayey silt sith SPT exceeding 50 up to 28m bgi.

3.

4.

Analysis

Shallow foundation is not suitable because part of the formation is on filled ground and also

part of the foundation is in tension or high compression.

Driven spun piles cannot or not practical to provide adequate tension required. Large diam

eter bored piles are suitable for high compression and tension required.

Design Calculations

4.1

Compression piles

The allowable compression load carrying capacity of the single pile has been cal

culated based on the SPT 'N" values, using the following formula.

Cawangan Jalan, Ibu Pejabat JKR, K.L

Page 6

Pile Design Report

FOR INTERNAL USE ONLY

Allowable load

Ab

Ab, af + As,fs

3

2

2

base area (m )

qf

=

=

unit base resistance

400 Nb (in SI-unit), Meyerhof's Empirical Formula

Nb

average 'N' over 5m above and 3m below depth

being considered (< 50)

As

Pile circumference area (m2)

fs

=

=

unit skin friction

2 Nave (in SI-unit)

Nave

= Average SPT value with depth

Factor of safety of base resistance

= 3 to control settlement

Factor of safety of friction resistance = 2

The detailed pile calculations are given in Appendix B.

4.2

Tension piles

The allowable tension load carrying capacity of single pile has been calculated

based on SPT 'N' values, using following formula

Allowable load

=

As . fs 2

As

Pile circumference area

fs

=

=

Unit skin friction

2 Nave (in SI-unit)

Nave

Average SPT 'N' value with depth

Factory of safety against friction resistance = 2

The detailed pile calculations are given in Appendix B.

5.

Design Calculations

5.1

General

Diameter of Compression pile : 1500 mm with design load of 900 ton

Diameter of Tension piles : 1200m with design load of 400 ton

Estimated pile length = 19m socketing 3 times diameter into hard stratum of SPT> 50

5.2

Preliminary Load Tests Analysis

Compression load tests and pull out tests were carried out at the Interchange bridge site to

assess the performance of the piles installed to the design lengths.

Cawangan Jalan, Ibu Pejabat JKR, K.L

Page 7

Pile Design Report

FOR INTERNAL USE ONLY

(a)

West Abutment

The tension Test Piles (No.81) located on the west abutments satisfied the per

formance criteria. Based on Prof Chin's Stability Plot:

Ultimate load

: 1141 tonne

Average Unit Shaft Friction

16 tonne/m2

The compression Test Pile No. 15 located ont the west abutments satisfied crite

ria at work load and 2 x work load but just failed to satisfy the recovery criteria.

Based on stability plot.

Ultimate capacity

: 2,490 tonne

Ultimate Shaft capacity

1,945 tonne

Mobilised Toe capacity

548 tonne

Ultimate Unit Shaft Resistance

39 tonne/m2

Mobilised Unit Toe Resistance

310 tonne/m2

Based on these assessment, piles were constructed to following toe elevations:

Compression Piles

: RL 33.00

(5m longer than Test Piles)

Tension Piles

(same length as Test Pile)

(b)

RL 31.00

East Abutment

Tension Pile No. 71 was tested. Pile satisfy the deflection criteria at working load

but however failed to attain the 2 x working load without excessive movement.

Based on Stability Plot, the following capacitities can be estimated:

Ultimate Shaft capacity

624 tonne

Unit Shaft Resistance

9 tonne/m2

This is much less than the 16.0 tonne/m2 value of tension pile No. 81. Based on

the evaluated value of 9.0 tonne/m2, all remaining working tension

piles are installed to RL 21.00 toe level, l O.Om longer than the test pile.

Compression pile No. 65 was first tested. It failed to satisfy the performance cri

teria. Estimated capacities are:

Ultimate capacity

: 1600 tonne

Ultimate Shaft capacity

625 tonne

Ultimate Toe capacity

1041 tonne

Cawangan Jalan, Ibu Pejabat JKR, K.L

Page 8

Pile Design Report

FOR INTERNAL USE ONLY

Unit Shaft Resistance

12 tonne/m2

Mobilised Unit Toe Resistance589 tonne/m2 Based on above results, Test Pile

No. 2 (Pile No.66) located 4.50m from P65 was installed to toe level RL 33.00

(5.Om longer). Theoretical ultimate capacity should be of the order of 1,900

tonnes. The test showed the following:

Ultimate capacity

: 1520 tonne

Ultimate Shaft capacity

730 tonne

Mobilised Toe capacity

790 tonne

Ultimate Unit Shaft Resistance

10 tonne/m2

Mobilised Unit Shaft Resistance

447 tonne/m2

These are less than values obtained from P65, indicating significant variation in the sub

soil strength. Concreting procedures are satisfactory and concrete batch records

and test indicate supplied concrete complied with the requirements of the specification.

Concreting volume of pile does not indicate occurrence of collapse of borehole or neck

ing. Since the pile was concrete immediately after boring, strength relaxation due to

aging should not occured.

Based on above, all remaining piles are to be installed to toe levels 23. Pile No. P52 will

be test to assess amount of pile head movement at working load and 2 x working load.

Estimated ultimate capacity of piles to toe level RL 23.00 is order 2,100 tonnes.

(c)

Results of loads tests carried out at Interchange No. 3 are shown in Figure T1 to

T.

Cawangan Jalan, Ibu Pejabat JKR, K.L

Page 9

Road B -15

= 2*Nave (SI-Unit s)

fs

Cawangan Jalan, Ibu Pejabat JKR, K.L

62

61

60

59

58

57

26

27

28

29

30

39

38

37

36

35

50

50

50

50

50

50

50

50

50

50

50

50

50

47

47

32

32

28

28

31

31

29

29

23

23

17

17

16

16

16

75

75

75

75

75

75

75

75

75

32.5

32.5

32.5

32.5

31

31

23.5

23.5

21.5

21.5

23

23

22

22

19

19

16

16

15.5

15.5

15.5

C o r r ect ed

37.53

36.28

34.95

33.52

31.98

30.33

28.54

26.6

24.5

22.2

21.71

21.18

20.58

19.92

19.26

18.53

18.2

17.82

17.54

17.21

16.68

16.05

15.39

14.56

13.93

13.08

12.5

11.63

10.33

7.75

N ave

A ver ag e

75.06

72.57

69.9

67.04

63.96

60.65

57.08

53.21

49

44.41

43.43

42.35

41.16

39.83

38.53

37.06

36.4

35.64

35.08

34.42

33.36

32.1

30.78

29.13

27.86

26.17

25

23.25

20.67

15.5

f s=2 N

141.37

136.66

131.95

127.23

122.52

117.81

113.1

108.38

103.67

98.96

94.25

89.54

84.82

80.11

75.4

70.69

65.97

61.26

58.55

51.84

47.12

42.41

37.7

32.99

28.27

23.56

18.85

14.14

9.42

4.71

As

10612

9917

9223

8529

7837

7146

8456

5767

5080

4395

4093

3792

3491

3191

2905

2620

2401

2184

1984

1784

1572

1361

1160

961

788

817

471

329

195

73

Qs

U LT I M A T E S HA F T R E S I S T A N C E

1. Correct ed N = 15 + 0.5 (N-15), f or N up t o and equal t o 4 t imes N=50

25

Not e:

24

20

45

41

19

40

18

47

46

23

17

48

42

16

49

21

15

51

50

22

14

52

43

13

53

44

11

12

54

63

10

64

55

65

56

D ep t h

Level ( m)

SPT

B ored pile diamet er

Db

2.00

1.20 met ers

FS f or f rict ional res

FS f or base resist ain 3.00

A llowable load = A b*qf / 3 + A s*f s/ 2

A llowable load = Ult imat e load along base/ 3.0 + Ult imat e load along shaf t / 2.0

Nave = average spt value wit h dept h

= SPT value at base

= pile circumf erence (m^2)

As

= 400*Nb(SI-Unit s)

qf

Nb

= base area (m^2)

Ab

R ed uced

where

(WEST SIDE OF THE CENTRE LINE OF THE ROA D)

P ILE LE N G T H E S T IM A T IO N A LO N G T H E IN T E R C H A N G E # 3

75

75

75

75

70

64

59

54

48

43

36

30

29

27

26

25

24

23

22

21

21

20

19

18

17

15

14

13

13

12

10

Nb

30000

30000

30000

30000

27875

25750

23625

21500

19300

17100

14525

11950

11400

10850

10375

9900

9450

9000

8775

8550

8275

8000

7625

7250

6925

5825

5571

5233

5000

4650

4133

q f =4 0 0 N b

1.767

1.767

1.767

1.767

1.767

1.767

1.767

1.767

1.767

1.767

1.767

1.767

1.767

1.767

1.767

1.767

1.767

1.767

1.767

1.767

1.767

1.767

1.767

1.767

1.767

1.767

1.767

1.767

1.767

1.767

1.767

Ab

53014

53014

53014

53014

49259

45504

41749

37994

34106

30218

25668

21117

20145

19174

18334

17495

16700

15904

15507

15109

14623

14137

13474

12812

12237

10294

9846

9248

8836

8217

7304

Qb

U LT I M A T E E N D B E A R I N G R E S I S T A N C E

17671

17671

17671

17671

16420

15168

13916

12665

11369

10073

8556

7039

6715

6391

6111

5832

5567

5301

5169

5036

4874

4712

4491

4271

4079

3431

3282

3083

2945

2739

2435

B ase

5306

4958

4611

4265

3918

3573

3228

2883

2540

2197

2047

1896

1746

1596

1453

1310

1201

1092

992

892

786

681

580

480

394

308

236

164

97

37

S haf t

22977

22630

22283

21936

20338

18741

17144

15548

13909

12270

10602

8935

8461

7987

7564

7141

6767

6393

6161

5928

5660

5393

5072

4751

4473

3739

3517

3247

3043

2776

2435

T o t al ( kN )

A LLO W A B LE LO A D

B oring B H-11(West side)

Hard clayey silt SPT 50

Hard clayey silt SPT 50

Hard clayey silt SPT 50

Hard clayey silt SPT 50

Hard clayey silt SPT 50

Hard clayey silt SPT 50

Hard clayey silt SPT 47

V .Sof t clayey silt SPT 2

V .Sof t clayey silt SPT 2

V .Sof t clayey silt SPT 2

St if f clayey silt SPT 29

St if f clayey silt SPT 23

M ed clayey silt SPT 17

M ed clayey silt SPT 16

B oring

B H-13(Eest side)

24

26

2

0

22

20

16

14

12

10

Hard clayey silt SPT 50

Hard clayey silt SPT 50

Hard clayey silt SPT 50

Hard clayey silt SPT 50

Hard clayey silt SPT 50

Hard clayey silt SPT 50

V .St if f clayey silt SPT

V .St if f clayey silt SPT

V .St if f clayey silt SPT

St if f clayey silt SPT 11

St if f clayey silt SPT 7

M ed clayey silt SPT 9

M ed clayey silt SPT 6

Dept h(m) RD Level 25.75m

6

4

Hard clayey silt SPT 50

Hard clayey silt SPT 50

Hard clayey silt SPT 50

Hard clayey silt SPT 50

Hard clayey silt SPT 50

Hard clayey silt SPT 50

Hard clayey silt SPT 50

Hard clayey silt SPT 50

Hard clayey silt SPT 50

V .St if f clayey silt SPT 39

V .St if f clayey silt SPT 39

St if f clayey silt SPT 12

M ed clayey silt SPT 11

M ed clayey silt SPT 10

Soil Invest igat ion Ph:l

28

26

24

22

20

18

16

14

12

10

RD Level 66.50m

B H-13(West side)

Dept h(m)

B oring

18

Soil Invest igat ion Ph:ll

28

26

24

22

20

18

16

14

12

10

Dept h(m) RD Level 64.89m

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

42

44

46

48

50

52

54

56

58

60

62

64

66

68

Level(m)

Reduced

S UB S O IL P R O F ILE A LO N G T H E B R ID G E LO C A T IO N

A ppe ndix B

FOR INTERNAL USE ONLY

Pile Design Report

Page 10

Road B -15

= 2*Nave (SI-Unit s)

fs

Cawangan Jalan, Ibu Pejabat JKR, K.L

26

27

28

29

30

-1

-2

-3

-4

50

50

50

50

50

50

50

50

50

50

50

50

50

50

50

50

38

38

32

31

21

21

11

11

11

75

75

75

75

75

75

75

75

75

75

75

75

32.5

32.5

32.5

32.5

26.5

26.5

23.5

23

18

18

11

11

11

C o r r ect ed

39.82

38.65

37.4

36.05

34.61

33.06

31.38

29.56

27.59

25.43

23.07

20.48

17.61

16.78

15.85

14.81

13.63

12.71

11.65

10.67

9.55

8.7

7.67

7.25

6.71

5.4

4.5

N ave

A ver ag e

79.65

77.3

74.79

72.11

69.22

66.12

62.76

59.13

55.17

50.86

46.14

40.95

35.21

33.56

31.71

29.63

27.27

25.43

23.31

21.33

19.09

17.4

15.33

14.5

13.43

12

10.8

f s=2 N

113.1

109.33

105.56

101.79

98.02

94.25

90.48

86.71

82.94

79.17

75.4

71.63

67.86

64.09

60.32

58.55

52.78

49.01

45.24

41.47

37.7

33.93

30.16

26.39

22.62

18.85

15.08

11.31

7.54

3.77

As

9008

8451

7895

7340

6785

6231

5678

5127

4576

4027

3479

2933

2389

2151

1912

1675

1439

1246

1054

885

720

590

462

383

304

226

163

102

60

23

Qs

U LT I M A T E S HA F T R E S I S T A N C E

1. Correct ed N = 15 + 0.5 (N-15), f or N up t o and equal t o 4 t imes N=50

25

Not e:

24

20

19

18

23

17

16

10

21

15

11

22

14

12

13

13

11

12

15

14

10

17

18

16

22

19

23

24

25

21

26

20

D ep t h

Level ( m)

SPT

B ored pile diamet er

Db

2.00

1.20 met ers

FS f or f rict ional res

FS f or base resist ain 3.00

A llowable load = A b*qf / 3 + A s*f s/ 2

A llowable load = Ult imat e load along base/ 3.0 + Ult imat e load along shaf t / 2.0

Nave = average spt value wit h dept h

= SPT value at base

= pile circumf erence (m^2)

As

= 400*Nb(SI-Unit s)

qf

Nb

= base area (m^2)

Ab

R ed uced

where

(WEST SIDE OF THE CENTRE LINE OF THE ROA D)

P ILE LE N G T H E S T IM A T IO N A LO N G T H E IN T E R C H A N G E # 3

75

75

75

75

75

75

75

70

64

59

54

48

42

35

29

27

25

22

20

18

16

14

12

10

Nb

30000

30000

30000

30000

30000

30000

30000

27875

25750

23625

21500

19075

16650

14075

11475

10750

10025

8950

7875

7100

6225

5500

4650

4050

3450

2900

2686

2400

2160

1800

1600

q f =4 0 0 N b

1.131

1.131

1.131

1.131

1.131

1.131

1.131

1.131

1.131

1.131

1.131

1.131

1.131

1.131

1.131

1.131

1.131

1.131

1.131

1.131

1.131

1.131

1.131

1.131

1.131

1.131

1.131

1.131

1.131

1.131

1.131

Ab

33929

33929

33929

33929

33929

33929

33929

31528

29123

26719

24316

21573

18831

15918

12978

12158

11338

10122

8906

8030

7040

6220

5259

4580

3902

3280

3037

2714

2443

2036

1810

Qb

U LT I M A T E E N D B E A R I N G R E S I S T A N C E

11310

11310

11310

11310

11310

11310

11310

10509

9708

8906

8105

7191

6277

5306

4326

4053

3779

3374

2969

2677

2347

2073

1753

1527

1301

1093

1012

905

814

679

603

B ase

4504

4226

3947

3670

3393

3116

2839

2563

2288

2013

1740

1467

1195

1075

956

838

720

623

527

442

360

295

231

191

152

113

81

51

30

11

S haf t

15814

15535

15257

14980

14702

14425

14149

13072

11996

10920

9845

8658

7472

6381

5282

4890

4499

3997

3496

3119

2707

2369

1984

1718

1452

1206

1094

956

844

690

603

T o t al ( kN )

A LLO W A B LE LO A D

B oring B H-11(West side)

M ed clayey silt SPT 16

Hard clayey silt SPT 50

Hard clayey silt SPT 50

Hard clayey silt SPT 50

Hard clayey silt SPT 50

Hard clayey silt SPT 50

Hard clayey silt SPT 50

Hard clayey silt SPT 47

V .Sof t clayey silt SPT 2

V .Sof t clayey silt SPT 2

V .Sof t clayey silt SPT 2

St if f clayey silt SPT 29

St if f clayey silt SPT 23

M ed clayey silt SPT 17

Hard clayey silt SPT 50

Hard clayey silt SPT 50

Hard clayey silt SPT 50

Hard clayey silt SPT 50

Hard clayey silt SPT 50

Hard clayey silt SPT 50

Hard clayey silt SPT 50

Hard clayey silt SPT 50

Hard clayey silt SPT 50

V .St if f clayey silt SPT 39

V .St if f clayey silt SPT 39

St if f clayey silt SPT 12

B oring

B H-13(Eest side)

24

26

2

0

22

18

16

14

12

10

Hard clayey silt SPT 50

Hard clayey silt SPT 50

Hard clayey silt SPT 50

Hard clayey silt SPT 50

Hard clayey silt SPT 50

Hard clayey silt SPT 50

V .St if f clayey silt SPT

V .St if f clayey silt SPT

V .St if f clayey silt SPT

St if f clayey silt SPT 11

St if f clayey silt SPT 7

M ed clayey silt SPT 9

M ed clayey silt SPT 6

Dept h(m) RD Level 25.75m

20

4

M ed clayey silt SPT 10

M ed clayey silt SPT 11

Soil Invest igat ion Ph:l

28

26

24

22

20

18

16

14

12

10

RD Level 66.50m

B H-13(West side)

Dept h(m)

B oring

Soil Invest igat ion Ph:ll

28

26

24

22

20

18

16

14

12

10

Dept h(m) RD Level 64.89m

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

42

44

46

48

50

52

54

56

58

60

62

64

66

68

Level(m)

Reduced

S UB S O IL P R O F ILE A LO N G T H E B R ID G E LO C A T IO N

A ppe ndix B

FOR INTERNAL USE ONLY

Pile Design Report

Page 11

Road B -15

= 2*Nave (SI-Unit s)

fs

Cawangan Jalan, Ibu Pejabat JKR, K.L

29

30

19

18

50

50

50

50

50

50

50

50

50

50

50

50

50

50

50

50

50

50

50

50

50

50

50

50

50

50

50

50

50

50

50

75

75

75

75

75

75

75

75

75

75

75

75

75

75

75

75

75

75

75

75

75

75

75

75

75

75

32.5

32.5

32.5

32.5

32.5

C o r r ect ed

68.15

67.92

67.67

67.41

67.13

66.83

66.5

66.15

65.76

65.34

64.88

64.38

6..82

63.19

62.5

61.72

60.83

59.82

58.65

57.29

55.68

53.75

51.39

48.44

44.64

39.58

32.5

32.5

32.5

32.5

32.5

N ave

A ver ag e

136.29

135.83

135.34

134.82

134.26

133.65

133

132.29

131.52

130.68

129.76

128.75

127.63

126.39

125

123.44

121.67

119.64

117.31

114.58

111.36

107.5

102.78

96.88

89.29

79.17

65

65

65

65

65

f s=2 N

113.1

109.33

105.56

101.79

98.02

94.25

90.48

86.71

82.94

79.17

75.4

71.63

67.86

64.09

60.32

56.55

52.78

49.01

45.24

41.47

37.7

33.93

30.16

26.39

22.62

18.85

15.08

11.31

7.54

3.77

As

15414

14850

14287

13723

13160

12597

12034

11471

10908

10346

9784

9222

8661

8100

7540

6980

6421

5864

5307

4752

4198

3647

3100

2558

2020

1492

980

735

490

245

Qs

U LT I M A T E S HA F T R E S I S T A N C E

1. Correct ed N = 15 + 0.5 (N-15), f or N up t o and equal t o 4 t imes N=50

28

20

Not e:

26

27

21

25

22

24

23

20

28

24

19

29

23

18

30

25

17

31

21

16

32

22

15

33

27

14

34

26

12

13

35

11

37

36

10

38

40

39

41

45

44

46

47

42

48

43

D ep t h

Level ( m)

SPT

B ored pile diamet er

Db

2.00

1.20 met ers

FS f or f rict ional res

FS f or base resist ain 3.00

A llowable load = A b*qf / 3 + A s*f s/ 2

A llowable load = Ult imat e load along base/ 3.0 + Ult imat e load along shaf t / 2.0

Nave = average spt value wit h dept h

= SPT value at base

= pile circumf erence (m^2)

As

= 400*Nb(SI-Unit s)

qf

Nb

= base area (m^2)

Ab

R ed uced

where

(WEST SIDE OF THE CENTRE LINE OF THE ROA D)

P ILE LE N G T H E S T IM A T IO N A LO N G T H E IN T E R C H A N G E # 3

75

75

75

75

75

75

75

75

75

75

75

75

75

75

75

75

75

75

75

75

75

70

64

59

54

48

45

40

33

33

33

Nb

30000

30000

30000

30000

30000

30000

30000

30000

30000

30000

30000

30000

30000

30000

30000

30000

30000

30000

30000

30000

30000

27875

25750

23625

21500

19375

17857

15833

13000

13000

13000

q f =4 0 0 N b

1.131

1.131

1.131

1.131

1.131

1.131

1.131

1.131

1.131

1.131

1.131

1.131

1.131

1.131

1.131

1.131

1.131

1.131

1.131

1.131

1.131

1.131

1.131

1.131

1.131

1.131

1.131

1.131

1.131

1.131

1.131

Ab

33929

33929

33929

33929

33929

33929

33929

33929

33929

33929

33929

33929

33929

33929

33929

33929

33929

33929

33929

33929

33929

31526

29123

26719

24316

21913

20196

17907

14703

14703

14703

Qb

U LT I M A T E E N D B E A R I N G R E S I S T A N C E

11310

11310

11310

11310

11310

11310

11310

11310

11310

11310

11310

11310

11310

11310

11310

11310

11310

11310

11310

11310

11310

10509

9708

8906

8105

7304

6732

5969

4901

4901

4901

B ase

7707

7425

7143

6662

6580

6298

6017

5735

5454

5173

4892

4611

4330

4050

3770

3490

3211

2932

2653

2376

2099

1824

1550

1278

1010

746

490

368

245

123

S haf t

19017

18735

18453

18171

17890

17608

17327

17045

16764

16483

16202

15921

15640

15360

15080

14800

14520

14242

13963

13686

13409

12332

11257

10185

9115

8050

7222

6337

5146

5023

4901

T o t al ( kN )

A LLO W A B LE LO A D

M ed clayey silt SPT 16

Hard clayey silt SPT 50

Hard clayey silt SPT 50

Hard clayey silt SPT 50

Hard clayey silt SPT 50

Hard clayey silt SPT 50

Hard clayey silt SPT 50

Hard clayey silt SPT 47

V .Sof t clayey silt SPT 2

V .Sof t clayey silt SPT 2

V .Sof t clayey silt SPT 2

St if f clayey silt SPT 29

St if f clayey silt SPT 23

M ed clayey silt SPT 17

B oring

B H-13(Eest side)

24

26

2

0

22

18

16

14

12

10

Hard clayey silt SPT 50

Hard clayey silt SPT 50

Hard clayey silt SPT 50

Hard clayey silt SPT 50

Hard clayey silt SPT 50

Hard clayey silt SPT 50

V .St if f clayey silt SPT

V .St if f clayey silt SPT

V .St if f clayey silt SPT

St if f clayey silt SPT 11

St if f clayey silt SPT 7

M ed clayey silt SPT 9

M ed clayey silt SPT 6

Dept h(m) RD Level 25.75m

20

4

Hard clayey silt SPT 50

Hard clayey silt SPT 50

Hard clayey silt SPT 50

Hard clayey silt SPT 50

Hard clayey silt SPT 50

Hard clayey silt SPT 50

Hard clayey silt SPT 50

Hard clayey silt SPT 50

Hard clayey silt SPT 50

V .St if f clayey silt SPT 39

V .St if f clayey silt SPT 39

St if f clayey silt SPT 12

M ed clayey silt SPT 11

M ed clayey silt SPT 10

RD Level 66.50m

Soil Invest igat ion Ph:l

28

26

24

22

20

18

16

14

12

10

Soil Invest igat ion Ph:ll

28

26

24

22

20

18

16

14

12

10

Dept h(m)

B H-13(West side)

B oring

B oring B H-11(West side)

Dept h(m) RD Level 64.89m

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

42

44

46

48

50

52

54

56

58

60

62

64

66

68

Level(m)

Reduced

S UB S O IL P R O F ILE A LO N G T H E B R ID G E LO C A T IO N

A ppe ndix B

FOR INTERNAL USE ONLY

Pile Design Report

Page 12

FOR INTERNAL USE ONLY

Cawangan Jalan, Ibu Pejabat JKR, K.L

Pile Design Report

Page 13

FOR INTERNAL USE ONLY

Cawangan Jalan, Ibu Pejabat JKR, K.L

Pile Design Report

Page 14

FOR INTERNAL USE ONLY

Cawangan Jalan, Ibu Pejabat JKR, K.L

Pile Design Report

Page 15

FOR INTERNAL USE ONLY

Cawangan Jalan, Ibu Pejabat JKR, K.L

Pile Design Report

Page 16

Pile Design Report

FOR INTERNAL USE ONLY

5)

Check for buckling load

Qub

Where

Qub

Allowable Qb

Cu El

CU

=

=

10

15 kPa

210 kN/mm2

1/64 B (d14 - d24)

15 x 210 x

B (101.64 - 85.444)

64

106

10

907 kN

907

___

2

454 kN > 300 kN

OK

6) Check for elastic compression

e

PL

P

L

=

=

300 kN

10m

EP

31416 mm2

Ep

= 35.3 kN/mm2

300 x10 x103

31416 x 35.3

3 mm

Cawangan Jalan, Ibu Pejabat JKR, K.L

Page 17

Pile Design Report

FOR INTERNAL USE ONLY

Sample Pile Design Calculations

1.

Project :

KKS Road Project

Piled Embankment for the approaches to Sg. Likas

Bridge.

2.

Generalized subsoil profile.

Piled embankment

Sand Lenses

C

L

Bridge

V.soft to soft clay

Stiff to hard

Sandstone/shale

3.

Flat alluvial formation

Top 24m consists of soft to very soft alluvium with few localized sandy lenses (Cu =

10-20 kPa with an average of about 15 kPa except at lenses of sand). Stiff to hard

strata of about 2 - 4m thick overlying on highly to moderately weathered

sandstone/shale bedrock. WT is near the ground surface.

Analysis

Stability and settlement analysis have concluded that simple ground treatments by partial

sand replacement with high strength woven polyester geotextile reinforcement or vertical

drains are not possible to achieve FOS = 1.5 and or post construction settlement to be less

than 200mm for the first 5 years of service if height of embankment exceeds 4.2m.

Piled raft embankment is adopted in preference to EPS, elevated structure and stone column

treatment because:

a)

EPS embankment is technically not acceptable because the site is subject to flooding

& the cost is high.

4.

b)

Elevated structure is about 30% more expensive (separate analysis)

c)

Though treatment by stone columns is cheaper, it requires longer time to consolidate

and technically less superior

Design calculation

Analysis has shown that driven R.C piles will be the most cost effective.

The site has no vibration or noise or ground heave constraints. Pile capacity of about

600 kN is chosen to get optimum pile spacing of 2 to 3m and raft thickness of 350 450mm for pile depth of about 30m.

Use 250X250 R.C piles at spacing "x" bothways Max design capacity - 625 kN.

Cawangan Jalan, Ibu Pejabat JKR, K.L

Page 18

Pile Design Report

FOR INTERNAL USE ONLY

Load on each pile = x2.d.h, where

625

= x2.20.h

x

For h

For h

For h

For h

For h

=

=

=

=

=

=

x

d

=

=

=

=

spacing

soil density

20kN/m3 h

embankment height

(31.25/h)1/2

6.5m, x = 2.19m, say 2.0m

6.0m, x = 2.2m, say 2.0m

5.5m, x = 2.38m, say 2.25m

5.0m, x = 2.50m, say 2.25m

4.5m, x = 2.64m, say 2.25m (allow some traffic load of 10 kPa)

Conclusion:

Use 250x250 R.C x 30m long at 2.0m spacing for h=6.5 - 6.0m & 2.25m spacing for h = 4-6m

(Pile capacity calculations enclosed).

R.C piles (MS 1314, Class 1) are designed as end bearing piles driven to set.

Cawangan Jalan, Ibu Pejabat JKR, K.L

Page 19

FOR INTERNAL USE ONLY

Cawangan Jalan, Ibu Pejabat JKR, K.L

Pile Design Report

Page 20

Pile Design Report

FOR INTERNAL USE ONLY

Design of Micropile

a) Design load per pile

b) Diameter of micropile

c) Main reinforcement

= 800kN

= 200mm

= 3 Nos of 50mm diam. deformed bars of yield

stress fy = 410N/mm2.

d) Factor of safety

= 2.5 (min)

= 20N/mm2.

e) Grout characteristic strength, fcu

Check Structural Capacity

= B/4 x 502 x 3

= 5892mm2

= 20N/mm2

Area of reinf, Asc

fcu

= B /4 x 2002

= 31,416mm2

= 31,416 - 5892

= 25,524mm2

Area of grout, Ag

..Area of net grout

According to BS 8110, clause 3.8. 4.3

Ultimate axial load, Pu = 0.4 fcu Ac + 0.75Asc fy

= 0.4x20x25,524 + 0.75x5892x410

= 2,016kN.

.. Factor of safety

= Pu/800

= 2.53

> 2.5 O.K.

Check Bond Length Required

- Depth of micropile = 20m

At least l0m will be embedded in very hard decomposed granite SPT, N > 50.

-

Bond between grout & hard formation = 0.4N/mm2

..

Min required bond length in hard

formation, Ib = 800 x 2.5 x l 000N

B x 200 x 0.4

= 7958mm

= 8.0m.

< 10m provided O.K.

Design of M.S. Plate for Pile Head

Use 250mm x 250mm x 20mm M.S. plate

Stress on plate

= 800 x l03N

250 x 250

= 12.8N/mm2

< 155N/mm2 O.K.

(allowable stress BS449)

Details of Micropiles & works specification are encl

Cawangan Jalan, Ibu Pejabat JKR, K.L

Page 21

FOR INTERNAL USE ONLY

Pile Design Report

Works Specification for Design and Installation of

200mm Diameter Micropiles

1.

Scope of work shall include design & installation of 200mm diam micropiles of 20m provi

sional length. The micropiles shall be reinforced with 3 Nos. of 50mm diam deformed bars

(fy = 410N/mm2) The working load of the micropile is 800KN.

2.

Drilling

Initial drilling involves installation of 242mm diam conductor casing through loose soil

(about 1.5m) by means of rotary boring or equivalent. Upon reaching hard/stiff formation

down the hole hammer will be used to advance the borehole till a minimum penetration of

10m in very hard decomposed granite. The drilled hole will be flush clean by compressed

air before the reinforcement bars are inserted into the hole. Suitable coupling device will be

used. During drilling, a complete record of soil strata will, be taken for Engineer's inspec

tion.

3.

Grout Mix

Ordinary Postland cement with water cement ratio of 0.5 will be used Non-shrink cement

admixture will be added to improve bonding.

4.

Grouting Procedure

A high speed Koken grout mixer is used for the mixing of the cement grout. The capacity

of the grout mixer is about 25-0 litres.

For grout mixing, 100 litres of water with some non shrink admixture is poured into the

mixer follow by 4 bags of 50 kg. ordinary Portland cement then allow to mix throughly,

normally a few minutes. After mixing, the cement grout, a pressure hose is connected to the

grouting pipe which acts as tremie pipe for grouting. The other end of the pressure hose is

connected to a diesel engine high pressure pump.

Cawangan Jalan, Ibu Pejabat JKR, K.L

Page 22

FOR INTERNAL USE ONLY

Cawangan Jalan, Ibu Pejabat JKR, K.L

Pile Design Report

Page 23

Pile Design Report

FOR INTERNAL USE ONLY

Micropile Design Calculations

Micropile design for underpinning works for an old building is shown as follows. The subsoil consists of about 3m of very soft clay, 5m to 8m of stiff to hard sandy clay with gravels (SPT = 11 to

42). The bedrock generally consists of highly weathered and fractured sandstone/shale (RQD = 0 25%, UCS = 7.5 Mpa).

1)

Micropile details

Diameter of micropile

Design load of micropile

Pipe diameter

Pipe wall thickness

Steel grade (API pipe)

=

=

=

=

=

Yield strength

= 500 N/mm2

(a)

200 mm

300 kN

101.6 mm

8.08 mm

N80

Check for structural capacity

Ultimate structural capacity

PU = B (101.62 -85.44 2) X 500 kN

4

1000

= 1187 kN

Applying factor of safety of 2.5.

Allowable structural capacity.

PA

= 1187

2.5

= 475 kN > 300 kN

OK

(b)

Check for geotechnical capacity

Based on boreholes BH1 and BI-12, the depth of bedrock (sandstone/shale) varies

from 8.7 m to 11.0 m b.g.l. Since the overburden soil consists of about 3.0 m of very

soft soil, the shaft friction on the remaining overburden soil (5 to 8 m) with N value

of 11 to 42 should be ignored and the micropiles are designed to be socketed into the

bedrock.

The socketing length in rock, L, is worked out as follows:

FS Qa

0.05 qa B D x L + 0.5qa B D2

4

where FS is the factor of safety

=

2.5

Cawangan Jalan, Ibu Pejabat JKR, K.L

Page 24

Pile Design Report

FOR INTERNAL USE ONLY

Qa

qa

= Allowable geotechnical capacity

= Unconfined compressive strength of rock

= 7.5 Mpa for sandstone/shale

Bond stress

D

2.5 x 300

= 5% of UCS of rock

= Diameter of micropile hole

= 0.05 x 7.5 x 103 x B x0.2 L +

0.5 x 7.5 x 103 x B x 0.22

4

750

L

= 235.6 L + 117.8

= 2.68 m

Designed socketing length of pile = 3.0 m

2)

Check overall underpinning pile support

Estimated total load of the whole building (3 storey).

=

2,000 tons

No. of micropile points

Load on each pile

= 95

= 2,000

95

= 21 tons

Working load for each micropile provided = 30 tons

OK

3)

Check for anchorage bond between underpinning pile and the existing foundatic

Since epoxy grout is used to fill the hole formed by the micropile in the existir foundation

and the strength of epoxy grout is much higher than the concrete strength, it can be consid

ered as monolithic for the whole foundation.

Cawangan Jalan, Ibu Pejabat JKR, K.L

Page 25

Pile Design Report

FOR INTERNAL USE ONLY

Critical section

for shear check

Existing

Column

Stump

650mm

Proposed 200mm

micropile

100

mm

1900mm

4)

Check for shear failure of existing foundation.

Perimeter for shear check, p

= 1900 mm

Effective depth of foundation, d = 1050-50-10

= 990 mm

Maximum reaction load,

Shear stress, V

= 300 kN

= V

Pd

= 300 x 103

1900 x 990

= 0.16 N/mm2

From Table 3.9, BS 8110 for d > 400 mm and

100As/bd = 0.25 (nominal reinforcement), allowable shear stress Vc = 0.40 N/mm2

V<Vc

OK

In grouting operation, the cement grout is pumped into the borehole through the pipe by

tremie method. All loose material, cuttings and water in the borehole are displaced by the

cement grout. Pressure applied should be just adequate to displace the cutting and water

from the borehole. Temporary casings should be withdrawn where cement grout overflow

from the casing and top up cement grout if necessary.

Cawangan Jalan, Ibu Pejabat JKR, K.L

Page 26

Pile Design Report

FOR INTERNAL USE ONLY

Item

No.

A.

Description

Quantity Unit

Rate

Design and install cast in-situ 800kN working

capacity micropiles complete with

reinforcement as shown on the drawings in

provisional lengths 20.0m and pressuregrouted with and including approved grouting

material, drilling in all types of soils and

rock and all coring casings, linings, plugs,

etc. and disposal of all excavated material

and debris from site.

Design information:a)

b)

c)

d)

Diameter of piles: 200mm

Main bars: 3Y50

Links: R05 helical link @ 100mm c/c

Steel casings: 292mm O.D x 9mm thick

e) Grout: Cement grout, w/c = 0.5, fcu = 20N/m2

f) Grout additives: Non shrink admixture

g) Factor of safety : 2.5

h) Bond strength: 0.9N/mm2

i) Bond length: 10m

j) Ultimate load: 2016kN

k) Capacity: 800kN

l) Working load: 800kN

m) etc

Design and install all capping plates and

starter bars

Design information:-

B.

Plate size: 250 x 250mm

Plate thickness: 25mm

Starter bar size: 3Y50 or 8Y25

Cawangan Jalan, Ibu Pejabat JKR, K.L

Page 27

Pile Design Report

FOR INTERNAL USE ONLY

Projek :

Cadangan Blok Tambahan pada Hospital

Bersalin di Hospital Besar, K.Lumpur.

1.0

Tujuan

Laporan ini bertujuan untuk menyampaikan laporan penyiasatan tanah dan syor-syor

asas yang sesuai bagi:Projek blok tambahan pada hospital bersalin, Kuala Lumpur.

2.0

Skop Projek

Perlaksanaan projek ini melibatkan pembinaan blok tambahan 2 tingkat di Hospital

Bersalin. Blok yang dicadangkan ini dikelilingi oleh bangunan sedia ada.

3.0

Keadaan Tanah

3.1 Sebanyak 3 ujian gerekan dalam telah dijalankan. Hasil ujian menunjukkan

keadaan lapisan tanah seperti berikut :Jenis Tanah

SPT (blows/ft.)

Ukurdalam(m)

0 - 4.5

Very soft CLAY

0-4

4.5 - 9/10.5

Loose SAND

1-7

9/10.5-13.5/16.0

Stiff silt or CLAY

1-9

13.5/16.0

Limestone

RQD = 73 - 100%.

>16.0

Limestone

3.2

4.0

Kedudukan aras air bawah tanah ialah 1.45m.

syor-syor Asas

4.1 Penapak konkrit tetulang adalah tidak sesuai kerana keupayaan galas yang rendah

dan jugs paras air bawah-tanah adalah tinggi.

"Driven R.C. or steel piles" adalah juga tidak sesuai kerana masalah "noise &

vibration" dikawasan Hospital sukar diterima. "Inclined bedrock" juga mungkin

mengakibat "excessive pile deviations".

Syor-syor asas yang dicadangkan adalah seperti berikut :-

Jenis Bangunan

Jenis Asas

Saiz Panjang Keupayaan

(mm)

(m) galas yg

dibenarkan

Blok Tambahan Cerucuk

200

16.5-19 200kN mikro

with 102

(micropile) API paip

(4)

Geseran

Kulit

negatif

Beba

Ujian

400kN

4.2

Cerucuk mikro hendaklah digerudi sehingga ke paras batukapur dan dikunci

(key) minima 3m ke dalam batukapur.

4.3

Sekurang-kurangnya 2 bilangan cerucuk digunakan untuk setiap tiang.

4.4

Jack pile (200x200xl5m) juga boleh diterima sebagai cerucuk gantian.

Cawangan Jalan, Ibu Pejabat JKR, K.L

Page 28

FOR INTERNAL USE ONLY

5.0

Syor-syor Tambahan

5.1 Jika rongga (cavity) ditemui, cerucuk hendaklah dipanjangkan

melebihi rongga dan dikunci (keyed) minima 3m ke dalam batukapur

tanpa rongga. (rujuk Fig. 1).

5.2

6.0

Pile Design Report

Untuk mengatasi masalah penanaman micropile dirongga, penender mestilah

diarah mengemukakan cadangan sistem 'micropile installation' dan teknik-teknik

'grouting' dirongga semasa tawaran dibuat.

Hal-hal lain

Satu set rekod penanaman cerucuk-cerucuk yang diuji berserta ujian beban hendaklah

dihantar ke Unit Makmal bagi tujuan dokumentasi.

Cawangan Jalan, Ibu Pejabat JKR, K.L

Page 29

Pile Design Report

FOR INTERNAL USE ONLY

Lampiran A

Micropile Specfication

1.

General

The work involves the construction of 200mm (8") diameter micropile. The micropile shall

be fabricated using steel tube and the bond length of micropile shall be 16m or directed

by the S.O. The working load of micropile is 200 kN and factor of safety used in design is

2.0. The whole of work and materials shall be in, accordance with curreht Malaysian or

British Standard or other National Standards approved by the S.O.

2.

Reinforcement

Steel grade - HFS 16 (BS: 1775 - 1964)

External diameter 139mm (51/2)

Thickness - 9.5mm (3/8") 2

Yield strength - 250 N/mm (16 Tsi)

3.

Grout

The grout shall be thcFoughly mixed with Ordinary Portland Cement (MS522) and water

(MS28). The grout shall be Antishrink cement grout. The water cement ratio shall be 0245 0.50. The 28 days. Strength for cement grout shall be 25N/mm (3570 psi). The representa

tive cubes shall be collected on each day of grouting works for testing on the 28th days.

Details of admixture shall be submitted to the S.O. for approval before commencement of

works. The use of the admixture shall comply with instruction by the manufacturer & MS

922. The grout shall be free from segregation, slumping, & bleeding of water and fine

materials during and after placing.

4.

Installation

a)

Drilling

The drilling for installation of micropile shall guarantee the absence of Vibration

which may cause damage to the existing building. Adequate precaution must be

taken to ensure boreholes for micropile do not collapse during drilling.

If necessary, temporary casing shall be used. During drilling of borehole, the con

tractor shall maintain complete record of soil profile. The logging shall include

depth of soil and water table. This drilled hole Viand! soil bore log shall be

signed by contractor's site representative and a copy of which shall be deposited

with the S.O. The contractor shall be required to keep representative sample of

soil for each soil profil in plastic bag for inspection by.the S.O. Sample may only

be disposed after the S.O. is satisfied that the logging has been properly done.

The type-of drilling equipment shall be approved by the S.O. The drilled hole

shall be flushed ckean.with air or water.

b)

Fabrication of micro pile

Method of splicing of bars or pipes shall be approved by the S.O. Centralisers at

about 3m centre must be used to ensure a minimum cover of 25mm or directed

by the S.O.

Cawangan Jalan, Ibu Pejabat JKR, K.L

Page 30

FOR INTERNAL USE ONLY

c)

Pile Design Report

Grouting

The contractor shall also provide details on method and equipment used in grout

mixing. Further information such as grouting pressure, grouting procedure, grout

ing equipment and techniques employed in grouting under water shall also be

furnished and approved by the S.O.

'To prevent deterioration of strength of soil, soil coring, installation of reinforce

ment and cement grouting shall be carried out in one continous operation.

5.

Load Testing

Micro-pile shall be load tested to 2 times design load using the Maintain Load Test.

Minimum of one (1) load test shall be carried out. The contractor shall also specify and pro

vide details of the method of load testing. Micropile shall be constructed only after the pre

liminary pile pass the load test requirements of JKR standard specification for building

Works.

Cawangan Jalan, Ibu Pejabat JKR, K.L

Page 31

Pile Design Report

FOR INTERNAL USE ONLY

Contoh Jadual Sebut Harga

Bil.

1

Description

Unit

Quantity

Rate

MICROPILES

(ALL PROVISIONAL)

A.

B.

Allow for Preliminaries

Item

Provide all necessary piling

equipment on site, maintain on site,

dismantle and remove from site on

completion, allow for all standing

or idling time and cost of operation

for the whole of piling works.

C.

Item

Installation of 200mm diameter

Micropiles in soil, including coring,

4" diameter pipe, steel plate head,

jointing and extension and grouting

MR

in cement, all as specified (50

positions)

D.

Provide all necessary pile testing

equipment on site, dismantle and

remove from site on completion.

T est 200mm diameter Micropiles in soil

as specified.

Cawangan Jalan, Ibu Pejabat JKR, K.L

NO

Page 32

Pile Design Report

FOR INTERNAL USE ONLY

Lampiran E1

Pile Design

for

SMK (Perempuan Raja Zarina)

Kelang

1.

This project consists of construction of one additional 3-storey school block.

2.

Max column load = 57 ton

3.

This is a typical coastal alluvium site where first 60ft to 100 ft consists of very soft clay

4.

Deep Sounding is very suitable and 4 nos of D/S results give consistent results as shown in

Lampiran E-1

5.

The site is a flat land and the first 4 ft is imported fill (about 5 years ago) Negative friction

has to be checked.

6.

Selection of piles (Refer to Fig. 1)

6.1 Non displacement piles not suitable because of low column load and very soft clay

near the first 100 ft.

7.

6.2

Timber pile also not suitable bacause its max length is about 40 ft. only.

6.3

Use 12" x 12" x 100 ft R.C. piles Design load = 30 Ton/pile (max)

Check Pile Capacity (Refer to Lampiran E-1)

From D/S results

Qu

= Qs + Qp

where Qu

= ultimate capacity

Qs

= skin friction

Qp

= end resistance

Cawangan Jalan, Ibu Pejabat JKR, K.L

Page 33

Pile Design Report

FOR INTERNAL USE ONLY

7.1

Skin friction, Qs

Based on total friction (remoulded)

At 30m (100ft), total friction = 3,000 kg.

Qs

= tube friction x-pile perimeter

tube perimeter

= 3,000 x (12" x 2.54 x 4)

11.3

= 32,300 kg

= 30 Ton.

Based on local friction (undisturbed)

Qs

= (8.5 x 0.05 + 7.5 x 0.13 + 13 x 0.27 + 0.9) x 3.28 x 4 x 0.92

= 70 Ton

Sensitivity = Qs (undisturbed)

Qs (remoulded)

= 70

30

= 2.3, within usual range

Q's = " Qs, where " = 0.7 (Bjerrum)

= 0.7 x 70

= 49 Ton

7.2

End Resistance, Qp,

Qp = 80 (kg/cm2) x 1 ft2 x 0.92

= 73.6 Ton

Qu = 49 + 73.6

= 122.6 Ton

Cawangan Jalan, Ibu Pejabat JKR, K.L

Page 34

Pile Design Report

FOR INTERNAL USE ONLY

7.3

Negative friction

Negative friction for piles at spacing more than 3 x diameters is

fn

0.2 Po (Bjerrum)

where Po

= effective overburden

= h

= 100' (100psf - 62.4 psf)

= 3760 psf

Max. fn

= 0.2 Po

= 0.2 x 3760

= 752 psf

Average fn

= (0 + 752)/2

= 376 psf

Total negative friction

7.4

=

=

=

=

fn x As

376 x (100 x 4)

150,400 lb

67 Ton

Allowable load, Qs

The negative skin friction, QN should only considered in combination with dead

load because QN acts mainly at the lower portion of the pile and would only affect

the settlement.

2.5 QD.L = Qu - QN

QD.L = 70% Qa

2.5 x 0.7Qa = Qu - QN

Qa

= (Qu - QN) /1.75

= (122.6 - 67)/1.75

= 31 Ton

say 30 Ton/pile

Notes :

The filling is done about 5 years ago. At least 60 - 70% consolidation com

pleted.

fn used is about the same as the undrained shear strength. Hence QN estimated is on the

light side.

To prevent tensile stress and buckling during driving, free drop hammers is preferred.

8.

Recommendation

Use 12" x 12" x 100 ft R.C. piles

Friction piles, driven to the required pene:,tration and load test to verify the capacity. (No

"set" required).# Load tests after 4 weeks of driving.

Cawangan Jalan, Ibu Pejabat JKR, K.L

Page 35

FOR INTERNAL USE ONLY

Cawangan Jalan, Ibu Pejabat JKR, K.L

Pile Design Report

Page 36

Pile Design Report

FOR INTERNAL USE ONLY

Memo

Daripada:

Penolong Pengarah Makmal,Caw. Rekabentuk & Penyelidikan, IP. JKR

Kepada:

Penolong Pengarah(Binaan), Ibu Pejabat JKR, K.L.

Bil surat:

(X) dlm. PKR.RB 4112

Tarikh :

26.3.1983

Per: Cadangan Masjid Baru di Batu 31/2, Jalan Cheras, K.L.

Berhubung dengan perkara yang tersebut di atas, sukacita dimaklumkan bahawa cadan

gan asas yang disyorkan adalah seperti berikut:1.

Keputusan penyiasatan tanah

Sebanyak 28 Nos. Proba JKR dan 5 Nos. Deep Boring telah dijalankan ditapak projek

itu. Keputusan - keputusan yang diterima menunjukkan bahawa kawasan projek ini

adalah terdiri daripada batu kapur. Paras batu kapur adalah daripada 2.5m hingga 14m

daripada paras permukaan tanah sedia ada. Oleh kerana keadaan batu dasar yang susah

untuk diramalkan, langkah-langkah pengawasan dan faktor keselamatan yang lebih

tinggi perlu diambil di dalam rekabentuk asas.

2.

2.1

Syor-syor asas

Jenis - jenis asas yang disyorkan adalah seperti dicatitkan di dalam Lampiran A.

Sebelum kerja - kerja piling dimulakan sekurang - kurangnya satu ujian Proba JKR

perlu dijalankan di setiap kedudukan tiang untuk menentukan paras batu dasar (>400

blows/kaki). Sekiranya paras batu dasar didapati kurang daripada 4.5m dibawah per

mukaan bumi, adalah dicadangkan supaya menggunakan R.C.cylinder foundation

(sila lihat Lampiran A & B)

2.2

Sekurang - kurangnya 2 cerucuk perlulah digunakan ditiap-tiap kedudukan tiang

kecuali jika R.C.cylinder foundation digunakan. Tiap - tiap tiang hendaklah diikat den

gan rasak bawah dikedua - dua arah. Ini adalah sebagai langkah awas oleh kerana terda

pat rongga - rongga dan kemungkinan masalah surutan.

2.3

Untuk memperolehi pengawasan yang lebih baik semasa memacu cerucuk tukul jatuh

bebas(free drop hammer) dicadangkan supaya digunakan. Ini ialah supaya cerucuk tidak

menerima hentaman dan menyimpang berlebihan (overdriving and excessive deviation)

oleh kerana keadaan batu dasar yang mencerun (inclined bedrock surfaces).

2.4

Hujung cerucuk keluli hendaklah dikelulikan dengan plat yang lebih. Ini adalah perlu

untuk menahan tegasan yang berlebihan (withstand overstressing) apabila cerucuk sam

pai ke paras batu dasar.

2.5

Sekurang - kurangnya 2 nos. kumpulan cerucuk (pile group, NCT single pile) perlulah

dipilih untuk ujian beban. Satu set driving records dan keputusan ujian beban hendak

lah dihantar kepada Unit Makmal ini untuk analisa dan sebagai rekod di Unit Makmal.

2.6

Perhatian hendaklah diberi kepada pengalaman yang lepas iaitu cerucuk - cerucuk tam

bahan mungkin diperlukan untuk menggantikan cerucuk - cerucuk yang menyimpang

Cawangan Jalan, Ibu Pejabat JKR, K.L

Page 37

FOR INTERNAL USE ONLY

Pile Design Report

berlebihan dan cerucuk - cerucuk yang masih tidak set diparas yang dalam (>10m).

Adalah dicadangan supaya tambahan sebanyak 25m disertakan didalam B.Q.

2.7

Oleh kerana keadaan tanah yang rumit (tricky) jurutera tapak bina hendaklah selalu

rujuk kepada keputusan penyelidikan tapak semasa menyelia kerja - kerja pembinaan

asas. Apabila cerucuk dijangka sampai paras batu dasar, kejatuhan pemukul (drop of

hammer) hendaklah dikurangkan. Tujuan langkah ini ialah untuk better keying & bed

ding effect on rock surface. Langkah ini juga akan mengurangkan cerucuk daripada

menyimpang berlebihan.

Sekian disampaikan ulasan kami untuk tindakan tuan selanjutnya.

Berkhidmat Untuk Negara

......................................................

(Ir. Neoh Cheng Aik),

Jurutera Kerja Kanan (R1),

bp. Penolong Pengarah (Makmal),

Ibu Pejabat JKR, K.L.

Cawangan Jalan, Ibu Pejabat JKR, K.L

Page 38

Pile Design Report

FOR INTERNAL USE ONLY

Lampiran A

Cadangan Asas Untuk Pro jek

Mas jid Batu 31/2, Jalan Cheras,K.L.

1.

Bangunan Masjid (13T - 105T)

Sila gunakan cerucul; keluli 203mm x 203mm x 45kg/m (Grade 43A9 BS 4360) den

gan beban keupayaan 210 0/eerucuk. Untuk tujuan tawaran, panjang cerucuk ialah 8.5m

(27ft) ATAU "R-C- cylinder foundation".Sila lihat Para 2.1

2.

Bangunan Quarters Kelas G(9T - 16T)

Sila gunakan eerucuk I-,yu berubat (treated timber pile) 125m x 125m dengan beban

keupayaan 5W/oerucuk. Untuk tujuan taviarany panjang cerucuk ialah 8.5m (27 ft).

Cawangan Jalan, Ibu Pejabat JKR, K.L

Page 39

FOR INTERNAL USE ONLY

Cawangan Jalan, Ibu Pejabat JKR, K.L

Pile Design Report

Page 40

FOR INTERNAL USE ONLY

Pile Design Report

Lampiran E 5

Extension of Terminal Building, Subang Airport

1.

General

The project consists of extension of International and Domestic Transper Corridor for

Subang International Airport. The proposed-site is situated approximately 13 miles west of

Kuala Lumpur.

Due to the close proximity of the proposed site to the existing terminal building v where the

Control Tower for the airport is located, severe vibration such as driving piles is unaccept

abldo Bored and Cast-in-situ piles were considered most suitable.

2.

Soil Condition

The site consists of residual soils of granite.

Lampiran E5-1 represents the generalised poil profile. The top layer of the soil consists of

brown firm sandy silty clay with some organic matters. The depth of this top soil varies

from 6" to 2ft. Beneath this top soil underlies the yellowish with patches of grey medium

sandy clayey silt with some gravelse This medium sandy clayey silt extend to a depth of 40

to 85 ft. below R.L. 86.00'. Between these layers of medium sandy clayey silt and the frac

tured or slightly weathered granite bedrocksq lies the greyish very stiff decomposed granite

residual soil. The thickness of this decomposed granite residual soil varies. Water table is

about Oft. b.g.l.

3.

Load Settlement Criteria

The system of piling to be designed shall meet the followings:a) Safety Factor

The factor of safety for the purpose of computing the working load shall be taken

as 2.5.

b) Working Load

The working load adopted for single pile shall not be greater than the ultimate

load divided by the safety factor of 2.5 and the ultimate load is defined as:

(i)

Load at which the gross settlement continues to increase without any further

increase in load.

(ii)

Load at which gross settlement is 10% of the pile diameter.

c) Settlement Criteria

(i)

Gross settlement of the pile at working load during the first cycle of load

ing, loading to one time working load, shall not exceed 0.5".

(ii)

The residual settlement of the pile at the end of the first cycle of loading

shall not exceed 0.10".

(iii)

The gross settlement of the pile at twice the working load shall not exceed

1.5"

Cawangan Jalan, Ibu Pejabat JKR, K.L

Page 41

Pile Design Report

FOR INTERNAL USE ONLY

d) Group Effect

Negligible because of small group (2 or 3 pile per group) & large spacing 2.5 .

4.

Structural Capacity of Piles

Since piles are not fully reinforced, the structural capacity of the piles will be solely depend

on the concrete section of the piles* In this case, the pile is reinforced for the top 40ft.

only for the dispersion of the possible slight bending moment elperienced at the pile top.

The piles will be designed as short columns. According to CP 2004, the structural carrying

capacity of Cast-in-situ concrete pile, that is, the safe working load per pile, W

W - 1/4 (Acc.Uw)

5.

Where Acc

Uw

=

=

=

Gross cross section of the area of concrete

Specified cube crushing strength at 28 days.

3000 psi.

For d

d

d

=

=

=

18, max. structural load =

24, max. structural load =

30, max structural load =

80 Ton.

150 Ton

230 Ton.

Check Pile Capacity

Use 18" bored piles x85 ft max. Meyerhofs formula (modified) is applicable for bored

piles in residual soil

Qu

Qs + Qp

=

=

fs As.+ Op Ap

N As + N. Ap

50

where N =

average SPT along pile shaft

average SPT near pile base (4 above pile base & 2 below pile base).

As

pile shaft area (ft2)

As

pile base area (ft2)

Cawangan Jalan, Ibu Pejabat JKR, K.L

Page 42

Pile Design Report

FOR INTERNAL USE ONLY

Based on DB12

18" x 75'

= 0.32 TSF

16

fs = N

50

50

qp = 50 TSB

Qs

=

=

fs As

0.32 x (1.5' x 3.1416 x 75) = 113 Ton

Qp

50 x (1/4 x 1.52 x 3.1416) = 88 Ton

Qa

=

Qs/20 + Qp/3.0

=

56.5 + 29.3

=

85.8 Ton

say 80 Ton

Based on DB 10

18" x 55ft

N

20

fs

= 0.4 TSF

=

=

80

qp

= 80 TSF

0-4 x (1o5 x 301416 x 55)

Qp

80 x (1/4 x 1o5 x 1o5 x 3o1416) = 141 Ton

Qa

Qs/2.0 + Op/3.0 = 52 + 47

=104 Ton

= 99 Ton

say 80 Ton.

Based on DB 13

18 x 80ft.

N

23

fs

= 0.46 TSF

35

qp

= 35 TSF

Qs

0.46 x (1.5 x 3.1416 x 80)

Qp

35 x (1/4 x 3o1416 x 1o5 x 145) =62 Ton

Qa

Qs / 2.0 + Qp / 3.0

Cawangan Jalan, Ibu Pejabat JKR, K.L

=173 Ton

=173/2 + 62/3.0

= 86 + 31

= 117 Ton

> 80 Ton.

Page 43

FOR INTERNAL USE ONLY

Pile Design Report

6.

Founding Level

Founding level should be determined by observing the soil type from the boring. Suitable

founding soil should be weathered granite bedrock or oompacted/cemented clayey silt with

gravels, or up to a max depth of eft'. In case of dou7gt, SPT should be carried in the bored

base.

7.

Recommendation

Use 18 bored pile Vrith max capacity 80 Ton per pile. Site engineer should use the DB

results to determine the founding level. Para 6 above can be used as a guide. 4 Nos load

tests should be carried out to verify the capacity.

Cawangan Jalan, Ibu Pejabat JKR, K.L