Professional Documents

Culture Documents

Tank Pressure & Vacuum Relief

Tank Pressure & Vacuum Relief

Uploaded by

Estuardo Javier Gan RodríguezCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tank Pressure & Vacuum Relief

Tank Pressure & Vacuum Relief

Uploaded by

Estuardo Javier Gan RodríguezCopyright:

Available Formats

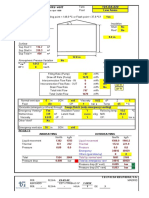

Art Montemayor

November 24, 2001

Rev: 1(05/10/02)

Eden Yuturi Oil Recovery

Attachment 1

Tank Padding Calculation Sheet

Data Entry

Stored Material

Flash Point

Boiling Point

Latent Heat vap.

Mol. Wt.

Crude Oil

Tank

T - 400

350 (Estim.)

MAWP

in WC

55.36

F

Btu/lb

360 (Estim.)

144.0 (Hexane)

274.0

Max Vacuum

Diameter

Max fill

oz/in

ft

ft

0.50

50.0

30.0

o

o

Inflows

Tag

Service

Line No.

P &ID #

P-160/-170

P-165/-175

Transfer to Storage

Transfer to Storage

10"-PL-138-A

10"-PL-055-A

-111

-112A1

or :

or :

or :

Outflows (See Note 1)

Tag

P-440

P-450

Max Head

Value

25

25

Flow, GPM

Units

PSIG

PSIG

Note 1

1,200

1,200

Total Inflows, gpm

Sonic Flow in Pipe

Pipe Flow at Maximum dP

25

psi

Other (Attach Method)

Use for Relief (gpm)

Normal Maximum (gpm)

2,400

2,400

1,500

Capacity

gpm

gpm

gpm

Total

2,500

2,500

5,000

Notes:

1) Pumps are at zero head flowrate (Max. gpm), and Control Valves have the max. trim size (Max. Cv)

Page 1 of 9

Electronic FileName: 341405428.xls

WorkSheet: Data Entry

Art Montemayor

November 24, 2001

Rev: 1(05/13/02)

Eden Yuturi Oil Recovery

Tank Pressure & Vacuum Protection

Design Sheet

Stored Material

Flash Point

Boiling Point

Latent Heat Vap.

Molecular Wt.

Crude Oil

F

o

F

Btu/lb

o

Tank

350 (Estim.)

360 (Estim.)

144 (Hexane)

274

Inflows, SCFH

Normal Operation

Relief Scenario

12,861

20,578

Outflows, SCFH

40,104

Breathing, Note 1

Out

In

SCFH

SCFH

Vent Valve set at

Required

selected

Fail Open

4

in WC

SCFH

NA

SCFH

NA

SCFH

0

Pressure Relief Cases

Inflow

SCFH

Fire

SCFH

Outflow

SCFH

T - 400

in WC

55.4

2

oz/in

0.5

ft

50.0

ft

30.0

gal

440,620

ft2

4,712.4

Fire

Therm. Conductivity

Required Capacity

BTU/hr-ft2

SCFH

4,582

801,761

Blow Through

From Upstream

From Hose

Relief, Hose +unload

SCFH

SCFH

SCFH

547,330

6,295

10,491

Blanket Gas Valve set at 2" WC

Required

SCFH

Selected

SCFH

Valve Fail Open

SCFH

MAWP

Max Vacuum

Diameter

Max fill Height

Max fill Volume

Wetted Area

Consider this when using emission vapor control system

Normal max inflow + out breathing + Blowoff (normal unloading)

With vent system Pressure Drop of 9 in WC

Consider this only if the tank vents to a vacuum source or header

50,595 sum of outflows + in Breathing + fail open vent valve

75,893 Fisher Model ___ Regulator with ___" trim.

0 This flowrate assumes the valve's Cv determines the capacity

102,766 Relief Inflow + Out Breathing + Blanket Gas Valve + Relief Blowoff

877,654 Fire + Blanket Gas valve

50,595 sum of outflows + in Breathing + fail-open vent valve + Steam Failure

Conservation Vent

Pressure side set at

5 in WC, Rated at

20

in WC

Required

SCFH

0 zero (if have Vent Valve and Emergency vent) or worst case

Selected Size

SCFH

44,000 each from catalog; total number

1

Total

2

2

Vacuum Side set at 0.5 oz/in Vacuum, rated at

2 1/2

oz/in

Required

SCFH

50,595 Outflow Case

Selected Capacity SCFH

15,000 each from catalog; total number

1

Total

Emergency Relief, Note 2

Set at

10

in WC, Rated at

20

in WC

Required

SCFH

833,654 zero (if Con vent has capacity) or Worst case - Con Vent

Selected Size

SCFH

680,000 each from catalog; total number

1

Total

Selected Equipment:

Blanket Gas Regulator

Tag

PCV 400B

Manufacturer

Fisher

Model

1190

Size, in

2

44,000

15,000

680,000

Cv

2400

Conservation Vent

PVSV 400

Emergency Vent

Notes:

1) For Tanks larger than 840,000 gal (20,000 Bbls), refer to API-2000 for breathing requirements.

Page 2 of 9

Electronic FileName: 341405428.xls

WorkSheet: Design Basis

Art Montemayor

Eden Yuturi Oil Recovery

November 24, 2001

Rev: 1(05/13/02)

2) Fire hatch is not required if: cone roof tank has a weak roof seam, or Conservation Vent has capacity.

Page 3 of 9

Electronic FileName: 341405428.xls

WorkSheet: Design Basis

Art Montemayor

November 24, 2001

Rev: 1(5/13/02)

Eden Yutui Oil Recovery

Storage Tank: T - 400

Fluid: Crude Oil

Safety Scenario Relief Rates, CFH

Vacuum Scenario

Pressure Scenario

(Note 1)

Liquid

Steam-Out

Inflow

Fire Case

Outflow

Other

Overflow

(Note 1)

Case Contributions:

1 Liquid movement in

2 Liquid movement out

3 Out Breathing (Vapor out)

4 In Breathing (Vapor In)

5 Fire Exposure

6 Pressure Transfer Blow-through

7 Blanket Gas Failure - Blocked

8 Blanket Gas Failure - Open

9 Steam Coil Rupture

10 Vent System Failure - Blocked

11 Chemical Reaction

12 Flashing Feed

13 Steam-Out

20,578

20,578

N.A.

40,104

N.A.

N.A.

N.A.

N.A.

N.A.

N.A.

N.A.

N.A.

N.A.

N.A.

N.A.

N.A.

N.A.

N.A.

N.A.

N.A.

N.A.

N.A.

N.A.

N.A.

18,993,000

40,104

6,295

10,491

801,761

547,330

75,893

1,646,139 1,646,139

N.A.

N.A.

N.A.

N.A.

N.A.

N.A.

N.A.

N.A.

N.A.

N.A.

801,761

N.A.

Total Volumetric Flow: 2,296,234 2,498,495

841,866 18,993,000

Controlling Pressure Case Design Capacity = 3,747,743 Scfh (Includes 50% contingency)

Controlling Vacuum Case Design Capacity = 1,052,332 Scfh (Includes 25% contingency)

Air density =

Blanket gas density =

Blanket gas Molecular Weight =

0.0807 lb/ft3

0.33425 lb/ft3

25.237

at

at

32 oF

109 oF

and

and

14.696 psia

79.7 psia

Blanket gas density =

0.083877 lb/ft3

at

109 oF

and

20 psia

Blanket gas specific gravity =

1.0394 lb/ft3

at

109 oF

and

20 psia

Note 1: The steam-out case is calculated in another Workbook; relief protection is recommended

Page 4 of 9

Electronic FileName: 341405428.xls

WorkSheet: Case Summaries

Art Montemayor

November 24, 2001

Rev: 1(05/13/02)

Eden Yuturi Oil Recovery

Tank Padding Calculation Sheet

Design Sheet

Conservation Vent

Pressure side set at

5

in WC, Rated at

20

in WC

Required

SCFH

#REF! zero (if have Vent Valve and Emergency vent) or worst case

Selected Size

SCFH

44,000 each from catalog; total number

1

Total

2

2

Vacuum Side set at 0.5 oz/in Vacuum, rated at

2 1/2

oz/in

Required

SCFH

#REF! Outflow Case

Selected Capacity SCFH

15,000 each from catalog; total number

1

Total

Emergency Relief, Note 2

Set at

10

in WC, Rated at

20

in WC

Required

SCFH

#REF! zero (if Con vent has capacity) or Worst case - Con Vent

Selected Size

SCFH

680,000 each from catalog; total number

1

Total

Tag

Manufacturer

Model

Size, in

Selected Equipment:

Blanket Gas Regulator

PCV 400B

Fisher

1190

2

Nitrogen Valve

Conservation Vent

PVSV 400

Emergency Vent

Notes:

1) For Tanks larger than 840,000 gal (20,000 Bbls), refer to API-2000 for breathing requirements.

2) Fire hatch is not required if: cone roof tank has a weak roof seam, or Conservation Vent has capacity.

Page 5 of 9

44,000

15,000

680,000

Cv

2400

Electronic FileName: 341405428.xls

WorkSheet: Requisition Info

Art Montemayor

May 14, 2002

Rev: 0

Storage Tank Pressure Relief

Determination of Inflows and Outflows for Storage Tanks

for use when calculating Normal and Emergency Venting Requirements

No.

Case

Inflow / Outflow

Calculate Inflow or Outflow by

1. Liquid Movement in and Breathing Out

Inflow

Determine the Maximum flow, at zero head, for each pump that can be lined up to the tank. For sources

that are not pump driven, calculate the maximum flow for the flow limiting element. For Control valves,

use the largest trim for the valve body and add the capacity of any bypass valves. The total inflow is the

sum from all of these sources. The total inflow can be reduced if engineering judgment indicates that it is

unlikely that all of the sources will be feeding into the tank simultaneously. The total inflow can also be

reduced if the pressure drop in the line(s) between the inlet manifold(s) and tank exceeds the available

pressure drop. The available pressure drop is the highest pressure sources dead head pressure.

2. Liquid Movement Out and Breathing In

Outflow

3. Exposure to Pool Fire with subsequent

tank contents' vaporization

Inflow

Do not consider inflow for fire case since there is ample time to shutoff the inflow before the fire case fully

develops. (see also API-2000 3.4.3.1.4) Do consider the failure of the nitrogen padding regulator if

applicable since they typically fail open and the heat from a fire could cause it to fail.

4. Pressure Transfer Blow-through

Inflow

Like Case 1

5. Inert Gas Pad/Purge Regulator Failure

Inflow

Like Case 1

6. Failure or loss of Control Heat Transfer

Devices

Either or both

Use Case 1 if the failure can cause the tank to vent. Use Case 2 if the failure can create a vacuum in the

tank.

7. Failure of Internal Heating/Cooling Coils

Either or both

Use Case 1 if the failure can cause the tank to vent. Use Case 2 if the failure can create a vacuum in the

tank.

8. Failure of Vent Treatment System

9. Failure of Utilities (Air, Steam, Cooling

Water, N2, etc.)

Outflow

Either or both

Determine the Maximum flow, at zero head, for each pump that can take suction from the tank. The

Outflow is the sum of all of these; even installed spare(s).

Like case 2

Use Case 1 if the failure can cause the tank to vent. Use Case 2 if the failure can create a vacuum in the

tank.

10 Chemical Reaction

.

Inflow

Like Case 1

11. Liquid Overfill

Inflow

Like Case 1

12 Flashing Liquid

.

Inflow

When introducing flashing liquids, always include the flashed vapor in the total relief capacity.

Page 6 of 9

FileName: 341405428.xls

WorkSheet: Inflow-Outflow

Storage Tank Pressure Relief

Over-Pressurization Scenario Contributions

Art Montemayor

Case

1

2

3

4

5

6

7

8

9

10

11

12

13

Liquid Movement in and Breathing Out

Liquid Movement Out and Breathing In

Fire Exposure

Pressure Transfer Blow Through

Blanket Gas Regulator Failure

Failure or Loss of Control - Heat Transfer Devices

Failure of Internal Heating / Cooling Coils

Failure of Vent Treatment System

Failure of Utilities (Steam, Nitrogen, air, CWS)

Chemical Reaction

Liquid Overfill

Flashing Liquid Feed

Steam Out (Note 4)

November 22, 2001

Rev: 1(05/05/2002)

10

11

12

Yes

No

No

No

No

No

No

No

No

No

No

Yes

No

Yes

No

No

No

No

No

No

No

No

No

No

No

No

Yes

No

Yes

Yes

Yes

Note 1

Yes

Yes

No

No

Yes

No

No

Yes

No

No

No

No

No

No

No

Yes

Yes

No

No

No

Yes

No

No

No

No

No

No

Yes

Note 2

Note 2

No

No

No

Yes

No

No

No

Note 3

No

Yes

Note 2

Note 2

No

No

No

No

Yes

No

No

Note 3

No

Yes

No

Yes

No

No

No

No

No

Yes

No

No

No

Yes

Note 2

Note 2

No

No

No

No

No

No

Yes

Note 3

No

Yes

Yes

No

No

No

No

No

No

No

No

Yes

No

Yes

Yes

No

No

No

No

No

No

No

No

No

Yes

Yes

Yes

No

No

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Notes:

1) Vent valve fails closed.

2) Either or both could be applicable depending on system.

3) If this case can cause a reaction

4) Steam Out is a special case that is handled and calculated independently in another spreadsheet; a properly sized nozzle is usually specified to be left open for this case.

Page 7 of 9

Electronic FileName: 341405428.xls

WorkSheet: OverPressure Scenarios

Art Montemayor

November 24, 2001

Rev: 0

Eden Yuturi Oil Recovery

Attachment 2

Tank Padding Summary Sheet

Input Form

Stored Material

Flash Point

Boiling Point

Latent Heat vap

Mol. Wt.

Tank

F

F

btu/lb

o

TMAWP

in WC

Max Vacuum

Diameter

Max fill

oz/in2

ft

ft

Inflows

Tag

Service

Line

P&ID #

Max Head

Value

Flow, GPM

Units

Total

or Sonic Flow in Pipe

or Pipe Flow at Maximum DP

or Other (Attach Method)

Note 1

0

0

psi

0

USE 9999999999

Outflows, Note 1

Tag

gpm

gpm

gpm

Total

Notes:

1) Pumps at zero head flowrate, CVs at max trim size

Page 8 of 9

Electronic FileName: 341405428.xls

WorkSheet: Input Form

Art Montemayor

November 24, 2001

Rev: 0

Eden Yuturi Oil Recovery

bbl

100

20,000

scfh

100

20,000

gal

4,200

840,000

100

20,000

60

12,000

4,200

840,000

gpm

gpm/1000

12

2.968

2,493

2.968

7

1,496

ft2

Btu/hr

Btu/hr-ft2

2,800 14,089,283

5,032

1,000

9,949,623

9,950

1.781

1.781

Page 9 of 9

Electronic FileName: 341405428.xls

WorkSheet: Volumetric Conversions

You might also like

- Tank Venting According API 2000Document34 pagesTank Venting According API 2000Youssef Lagrini50% (2)

- Pressure Drop CalculationDocument30 pagesPressure Drop CalculationEbby Onyekwe100% (1)

- Coil Heat CalculationDocument2 pagesCoil Heat CalculationTarmana Antt100% (1)

- Hydraulic Calculations For Water Storage TankDocument1 pageHydraulic Calculations For Water Storage Tankbrock67% (3)

- Restriction Orifice SizingDocument5 pagesRestriction Orifice SizingjoeNo ratings yet

- Pump Sizing CalculationDocument24 pagesPump Sizing CalculationEbby Onyekwe100% (1)

- API2000 Tank Venting CalcsDocument5 pagesAPI2000 Tank Venting Calcsapminshull88% (8)

- Introduction of Automatic Generation Control (Agc) : Chapter-1Document24 pagesIntroduction of Automatic Generation Control (Agc) : Chapter-1Shivank Shukla100% (1)

- Venteo API 2000 (Amine)Document8 pagesVenteo API 2000 (Amine)Produccion VegetalNo ratings yet

- Ammonia Water Steam StrippingDocument17 pagesAmmonia Water Steam Strippingkomalrana2007100% (3)

- CPF-010 Process Line Sizing Attachment - 0Document38 pagesCPF-010 Process Line Sizing Attachment - 0goodspeed_ph100% (1)

- Engineering Design Calculation - Dennis Kirk Single Stage Centrifugal Pump Calculation (Clean Water Use) System CurveDocument1 pageEngineering Design Calculation - Dennis Kirk Single Stage Centrifugal Pump Calculation (Clean Water Use) System Curvebuntimehta007No ratings yet

- CPF-010 Utility Line Sizing Attachment - 0Document31 pagesCPF-010 Utility Line Sizing Attachment - 0goodspeed_phNo ratings yet

- T.R. Padmanabhan-Programming With Python-Springer (2016)Document345 pagesT.R. Padmanabhan-Programming With Python-Springer (2016)nmngoyal1100% (1)

- Pipe Heat Loss CalculationDocument10 pagesPipe Heat Loss Calculationingemarquintero67% (3)

- Venting-CalculationsDocument3 pagesVenting-CalculationsKartik PatelNo ratings yet

- Valve SizingDocument38 pagesValve SizingEmmanuel JohnsonNo ratings yet

- Tank SizingDocument1 pageTank SizingSaeid Rahimi MofradNo ratings yet

- Observation ChecklistDocument2 pagesObservation ChecklistShielah Marie Requiz100% (1)

- Best Practice GuidelinesDocument24 pagesBest Practice GuidelinesE.ANANDAN100% (1)

- Strainer Pre. Drop and Sizing CalcDocument6 pagesStrainer Pre. Drop and Sizing CalcChandrakant SalunkheNo ratings yet

- Hot Crude Oil StorageDocument13 pagesHot Crude Oil Storagesachinumarye100% (1)

- PSV Sizing For Fire SpreadsheetDocument2 pagesPSV Sizing For Fire SpreadsheetKrisTian EdogawaNo ratings yet

- Heating Coil Sizing For Fuel Oil TankDocument2 pagesHeating Coil Sizing For Fuel Oil TankAhmed Mujtaba93% (14)

- Storage Tank Design Calculation - Api 650: Close Floating RoofDocument32 pagesStorage Tank Design Calculation - Api 650: Close Floating RoofhgagNo ratings yet

- Calculation of Height of The Siphon SystemDocument2 pagesCalculation of Height of The Siphon SystemPhyu Mar Thein Kyaw100% (1)

- Control Valve Sizing - LiquidDocument4 pagesControl Valve Sizing - Liquidbrazili2010100% (1)

- EIND 3184 15 Liquid Flash Vessel SizingDocument20 pagesEIND 3184 15 Liquid Flash Vessel SizingzamijakaNo ratings yet

- Pump Head CalculationDocument11 pagesPump Head CalculationZoebairNo ratings yet

- Control Valve SizingDocument3 pagesControl Valve SizingN. S. PanditNo ratings yet

- Pipe Sizing Criteria Schedule 40 Steel S-40 Steel: 198962529.xls - Ms - OfficeDocument34 pagesPipe Sizing Criteria Schedule 40 Steel S-40 Steel: 198962529.xls - Ms - Officeangel darioNo ratings yet

- PVRV Sizing Calculations - Crude Oil Stroage Tank (007486-T-01)Document2 pagesPVRV Sizing Calculations - Crude Oil Stroage Tank (007486-T-01)karthipetro100% (7)

- Safety Valve CalcDocument12 pagesSafety Valve CalcArjun CharanNo ratings yet

- Familiarization TasksDocument82 pagesFamiliarization TasksAlbert John Alipala100% (1)

- PSV Blocked Fire Relief Valve CasesDocument21 pagesPSV Blocked Fire Relief Valve CasesTun Naing WinNo ratings yet

- Strainer SizingDocument20 pagesStrainer Sizingaliscribd46No ratings yet

- NSPHa CalculationDocument3 pagesNSPHa CalculationYakubuNo ratings yet

- InsulationDocument6 pagesInsulationBrinto VargheseNo ratings yet

- API2000Document39 pagesAPI2000Sudhanshu Shekhar50% (2)

- HydraQuacker Double Acting Hydraulic Drilling Jar.Document93 pagesHydraQuacker Double Acting Hydraulic Drilling Jar.Muhammad Zikry Alfindy HazNo ratings yet

- Pressure Safety Valve Sizing Calculation Rev.01 APUDocument10 pagesPressure Safety Valve Sizing Calculation Rev.01 APUAlvin SmithNo ratings yet

- Storage Tank PressControl Rev1Document46 pagesStorage Tank PressControl Rev1sachinumarye100% (2)

- Tank Heat CalculationDocument7 pagesTank Heat CalculationElton Situmeang100% (3)

- Separator SizingDocument9 pagesSeparator SizingTolstoy LeoNo ratings yet

- Storage Tank Heat Loss Calcs - Rev.1 31.12.2010Document16 pagesStorage Tank Heat Loss Calcs - Rev.1 31.12.2010Jade GeronimoNo ratings yet

- Tank Venting Rate EstimationDocument3 pagesTank Venting Rate EstimationOmar KallufNo ratings yet

- Design Calculations - Insulation Thickness REV-1Document4 pagesDesign Calculations - Insulation Thickness REV-1delMAK100% (1)

- Api 620 - 2002Document12 pagesApi 620 - 2002ductaiutc100% (1)

- Sizing StrainerDocument8 pagesSizing Strainerchadvillela0% (1)

- Tank Pressure & Vacuum ProtectionDocument4 pagesTank Pressure & Vacuum ProtectionrodrigoperezsimoneNo ratings yet

- Liquid Line SizingDocument12 pagesLiquid Line Sizinglolofm25No ratings yet

- Seperator Sizing v3Document5 pagesSeperator Sizing v3camasa2011No ratings yet

- Scorbot Er 5Document2 pagesScorbot Er 5Adry AqilNo ratings yet

- JDBC Netbeans MysqlDocument18 pagesJDBC Netbeans Mysqlgrprasad1957No ratings yet

- Inlet Flow For Out Breathing: Total Pump in m3/hr 20Document9 pagesInlet Flow For Out Breathing: Total Pump in m3/hr 20sonaldivNo ratings yet

- Spreadsheet - Gas Blanketed Tanks - Outbreathing Process Calculations & Control Valve Sizing - Rev2Document33 pagesSpreadsheet - Gas Blanketed Tanks - Outbreathing Process Calculations & Control Valve Sizing - Rev2MaheshNo ratings yet

- Atm Sto Tanks Venting Req API2000 2009 Rev1Document2 pagesAtm Sto Tanks Venting Req API2000 2009 Rev1fzhou100% (4)

- Steam - Pipe Pressure Drop - From MyChemEDocument11 pagesSteam - Pipe Pressure Drop - From MyChemEkomalrana2007No ratings yet

- Chiller Product Report Design Conditions PDFDocument2 pagesChiller Product Report Design Conditions PDFSiddharth JainNo ratings yet

- Tank Pressure & Vacuum ReliefDocument12 pagesTank Pressure & Vacuum ReliefsachinumaryeNo ratings yet

- PSV SizingDocument6 pagesPSV SizingBui Khoi Nguyen100% (1)

- DorksDocument62 pagesDorksMarcos MexNo ratings yet

- Pipe Size CalcDocument19 pagesPipe Size Calcnitin_bir100% (1)

- Very Good Presentation - ATEX IchemEDocument109 pagesVery Good Presentation - ATEX IchemEkomalrana2007100% (8)

- Safety Valve Blowback Calculation (Optimization2)Document18 pagesSafety Valve Blowback Calculation (Optimization2)Durjoy ChakrabortyNo ratings yet

- Ambient Crude Oil StorageDocument1 pageAmbient Crude Oil Storageanto3harrish3fdoNo ratings yet

- Storage Tank Padding DesignDocument6 pagesStorage Tank Padding DesignHelena MartinsNo ratings yet

- Water-Cooled Series R (TM) RTHD Product Report PDFDocument2 pagesWater-Cooled Series R (TM) RTHD Product Report PDFMajho CanilangNo ratings yet

- Re Boiler RRRDocument1 pageRe Boiler RRRBhavesh BansalNo ratings yet

- RTWD Series R (TM) 70-250 Ton Water-Cooled Chiller Dimension DrawingsDocument2 pagesRTWD Series R (TM) 70-250 Ton Water-Cooled Chiller Dimension DrawingsJhon LewisNo ratings yet

- Evergreen Chiller Performance Outputs: Tag Name: Selection1 - Sel01Document1 pageEvergreen Chiller Performance Outputs: Tag Name: Selection1 - Sel01picuNo ratings yet

- Carrier China Operation: Customer DateDocument1 pageCarrier China Operation: Customer DatepicuNo ratings yet

- Flowrate 10 Line Size 40 (MM I.d.) Flowspeed 2.21 M/s (M /H)Document4 pagesFlowrate 10 Line Size 40 (MM I.d.) Flowspeed 2.21 M/s (M /H)komalrana2007No ratings yet

- Dog House Megaways - Căutare GoogleDocument1 pageDog House Megaways - Căutare GoogleClaudiu GoronNo ratings yet

- HRM Practices at TelenorDocument17 pagesHRM Practices at TelenorAbdul RehmanNo ratings yet

- Unicos URK 700 PDFDocument3 pagesUnicos URK 700 PDFRyan AgustikaNo ratings yet

- Microsilica Grade 920 ConstructionDocument1 pageMicrosilica Grade 920 ConstructionAnkur Barsainya0% (1)

- Cisco PI Hardware Appliance Installation GuideeDocument20 pagesCisco PI Hardware Appliance Installation GuideeMauricio Cifuentes BNo ratings yet

- Anirudh Kapoor: DemographicsDocument2 pagesAnirudh Kapoor: DemographicsShambhawi SinhaNo ratings yet

- How To Add A Username To A V7 BIRT Report PDFDocument5 pagesHow To Add A Username To A V7 BIRT Report PDFJanderson AlmeidaNo ratings yet

- 1.5T AcDocument32 pages1.5T AcTarun SurejaNo ratings yet

- Study and Implementation of Project LEB 20203: Portable Solar GeneratorDocument25 pagesStudy and Implementation of Project LEB 20203: Portable Solar GeneratorFarizal JaafarNo ratings yet

- Programacion HTML5 CC3 and JSDocument654 pagesProgramacion HTML5 CC3 and JSErick FloresNo ratings yet

- Sheet 2Document3 pagesSheet 2Amr OkashaNo ratings yet

- Compilation of Openfoam in Redhat Linux: Tar XVF Openfoam-2.1.0.TgzDocument4 pagesCompilation of Openfoam in Redhat Linux: Tar XVF Openfoam-2.1.0.TgzAwadh KapoorNo ratings yet

- CMD1Document6 pagesCMD1Prabha Shankar ManuNo ratings yet

- The Kile Handbook: Jonathan Pechta Federico Zenith Holger Danielsson Thomas Braun Michel Ludwig Felix MauchDocument75 pagesThe Kile Handbook: Jonathan Pechta Federico Zenith Holger Danielsson Thomas Braun Michel Ludwig Felix MauchAmjad ShahNo ratings yet

- PWD Project ReportDocument20 pagesPWD Project ReportSandeep PatelNo ratings yet

- Attendance ManagementDocument45 pagesAttendance ManagementSanjay GodboleNo ratings yet

- Projections Examples of Different Projections Coordinate Systems DatumsDocument53 pagesProjections Examples of Different Projections Coordinate Systems DatumsRajNo ratings yet

- Sample Content ArticleDocument16 pagesSample Content ArticleKyo AmiNo ratings yet

- Microsoft Corporation v. Funmobile, Et. Al." Case Number 09-2-21247-3Document20 pagesMicrosoft Corporation v. Funmobile, Et. Al." Case Number 09-2-21247-3JoshLowensohn100% (2)

- SunCalc GuideDocument8 pagesSunCalc GuideGRSmithNo ratings yet

- Atomic Improv IntroductionDocument2 pagesAtomic Improv Introduction曹鹏No ratings yet

- Assignment 1 FinalDocument13 pagesAssignment 1 Finalaljr_2801No ratings yet