JOHOKU MANUFACTURING PVT LTD

ISO No. [Link]

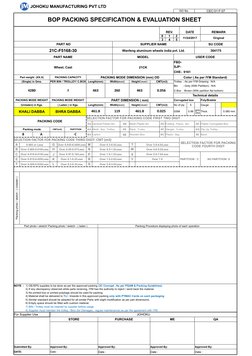

BOP PACKING SPECIFICATION & EVALUATION SHEET

REV. DATE REMARK

0 1 2 11/24/2017 Original

3 4 5

PART NO SUPPLIER NAME SU CODE

21C-F5168-30 Wanfeng aluminum wheels india pvt. Ltd. 304175

PART NAME MODEL USER CODE

FBD-

Wheel, Cast 21CK SJP-

CHE- 9161

Part weight (XX.X) PACKING CAPACITY PACKING MODE DIMENSION (mm) OD Color ( As per IYM Standard)

(Single) in Gms. PER BIN / TROLLEY/ [Link] Length(mm) Width( ) Height CMT(m3) Trolley : As per IYM Drawing : N/A

Bin : Grey (With Partition) : N/A

4280 2 463 260 463 0.056 [Link] : Brown (With partition flat bottom)

Technical details

PACKING MODE WEIGHT PACKING MODE WEIGHT PART DIMENSION ( mm) Corrugated box Poly/Bubble

(Unladen) in Kgs. ( Laden ) in Kgs. Length(mm) Width() Height CMT(m3) No of ply 5 Gauge

grm

KHALI DABBA BHRA DABBA 461.8 119 461.8 0.025 GSM 0.98

/m3

Thick. 0.080 mm

SELECTION FACTOR FOR PACKING CODE FIRST TWO DIGIT

PACKING CODE

A General Plastic Bin B Mesh Plastic Bin C FoldingPlasticBin E Plastic Corrugated Box

Packing mode CMT(m3) PARTITION A MeshBoxTrolley E RackTrolley F HangerTrolley G Flip Up Trolley

8 A C A Carton 8B Wooden Box C PlasticBag 8E Band

SELECTION FACTOR FOR PACKING CODE THIRD DIGIT- CMT (m3)

SELECTION FACTOR FOR PACKING

A 0.005 or Less G Over 0.035-0.050/Less M Over 0.3-0.5/Less T Over 3.0-4.0/Less

CODE FOURTH DIGIT

B Over 0.005-0.010/Less H Over 0.05-0.07/Less N Over 0.5-1.0/Less W Over 4.0-5.0/Less

C Over 0.010-0.015/Less J Over 0.07-0.10/Less P Over 1.0-1.5/Less X Over 5.0-7.0/Less

E Over 0.015-0.025/Less K Over 0.1-0.2/Less R Over 1.5-2.0/Less Y Over 7.0 PARTITION : C NO PARTITION: S

F Over 0.025-0.035/Less L Over 0.2-0.3/Less S Over 2.0-3.0/Less

Packing photo / sketch - ( Unladen )

Part photo / sketch/ Packing photo / sketch - ( laden ) Packing Procedure displaying photo of each operation

NOTE : 1) OE/SPG supplies to be done as per the approved packing (3C Concept , As per PQAM & Packing Guidelines)

2) If any discrepancy observed while parts receiving, IYM has the authority to reject / send back the material.

3) No printed box or printed polybags should be used for packing.

4) Material shall be delivered to TLI / lineside in this approved packing only with PYMAC Cards on each packaging

5) Similar standard should be adopted for all similar Parts with slight modification as per part dimensions.

6) Empty space should be filled with cushion material.

7) BIN / Trolley must be cleaned by supplier before usage

8) Supplier must maintain the trolley / Bins (for Damages , regular maintenance) as per the agreement with IYM.

For Supplier Use JOHOKU

STORE PURCHASE ME QA

Submitted By: Approved By: Approved By: Approved By: Approved By:

DATE: Date : Date : Date : Date :